|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Powered Super-fine Feed Drive to Carriage.

This very rare factory-fitted device was designed to allow very fine, smooth tool feeds to used when turning and boring, for example, with diamond-tipped tools. At a spindle speed as high as 2500 rpm a carriage-feed rate of 0.00029" to 0.016" could be obtained.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indexing Attachment for 10" lathe headstock. With this device in place the spindle could be accurately indexed to assist in fluting, splining, graduating, cross drilling and similar operations. The attachment included eight index wheels having 45, 56, 64, 72, 80, 84 and 100 divisions.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

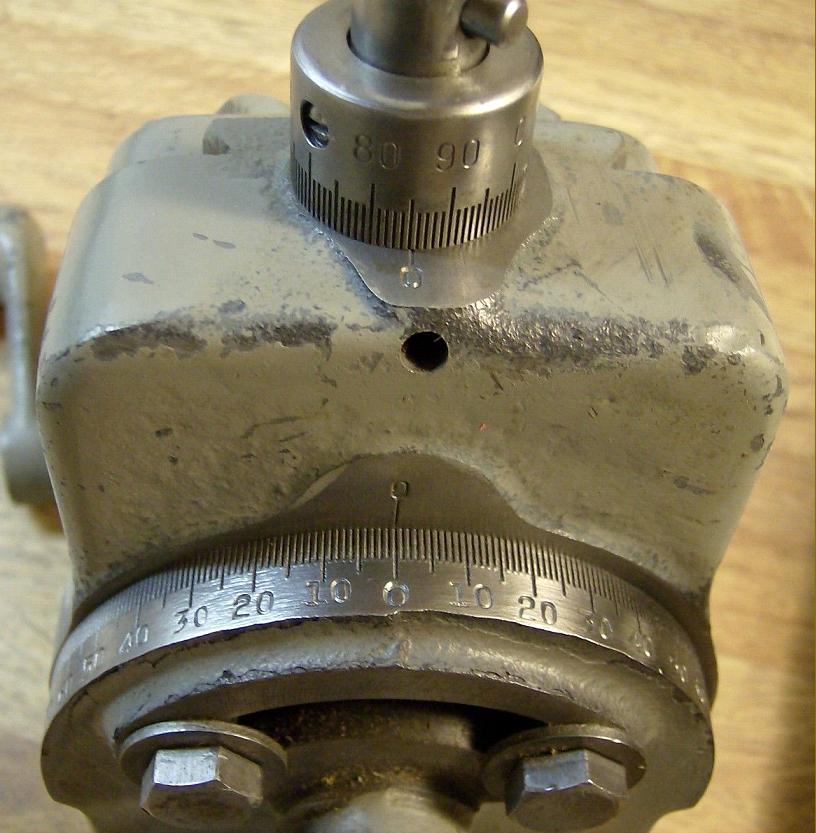

Direct-reading Micrometer Collar

These large-diameter collars replaced the far-too-small originals and indicated the amount of material removed from the work diameter directly, in thousandths of an inch. Each graduation marked a moment of the tool of one-half thousand of an inch.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cross-slide Threading Stop

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bed-mounted multi-stop

Ideal for assisting in small-scale repetition manufacture.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bed-mounted Micrometer Stop

One of the most genuinely useful lathe accessories it is possible to own.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 in 1 Toolholder

This fully-hardened holder was available in a range of sizes and came with a set of basic turning tools and a built-in, self-aligning knurl. The tool height could be set by an adjusting screw which passed down through the main body of the toolholder.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Collet Draw Bar, spindle-thread protector, spindle adapter and collet

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

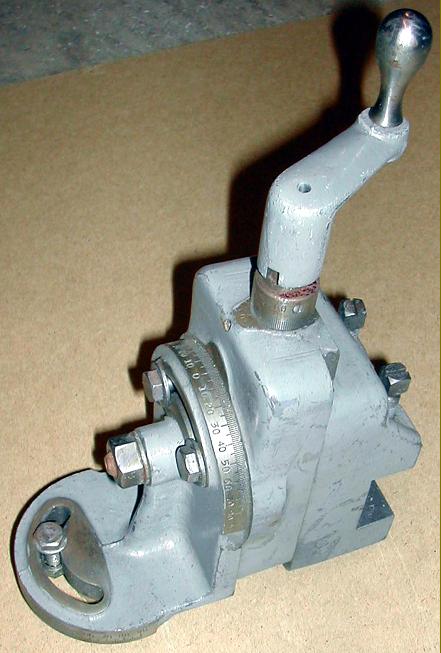

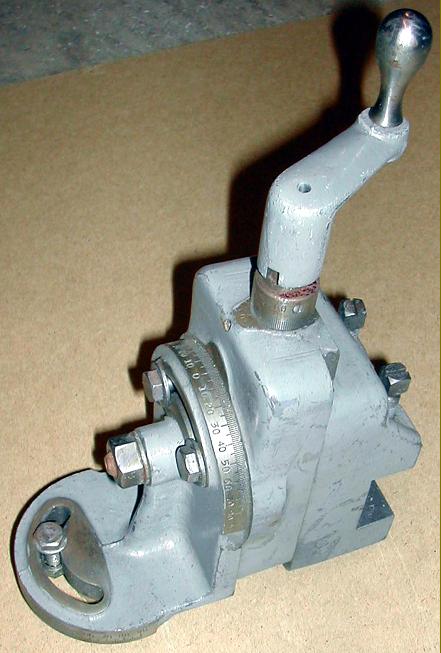

Lever-action Collet Assembly. Available across the range of South Bend lathes this is a comparatively rare fitting on the smaller machines. The mounting details varied over the years, and according to the size of lathe, but the basic principle of operation remained the same. Of the South Bend clones makers, only Smart and Brown offered a similar accessory.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Collet Splash Guard

Designed to stop coolant and chips being flung into the operator's face as he attended closely to work held in a collet.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

360 degree graduations on the cross slide

A post-WW2 offering to overcome the disadvantage of having the graduations inscribed only on the top slide.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Swivelling Machine Handles.

These were only available as a set when ordered with a new lathe and replaced those fitted to the apron, cross-feed and tailstock.

A very rarely-encountered fitting.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

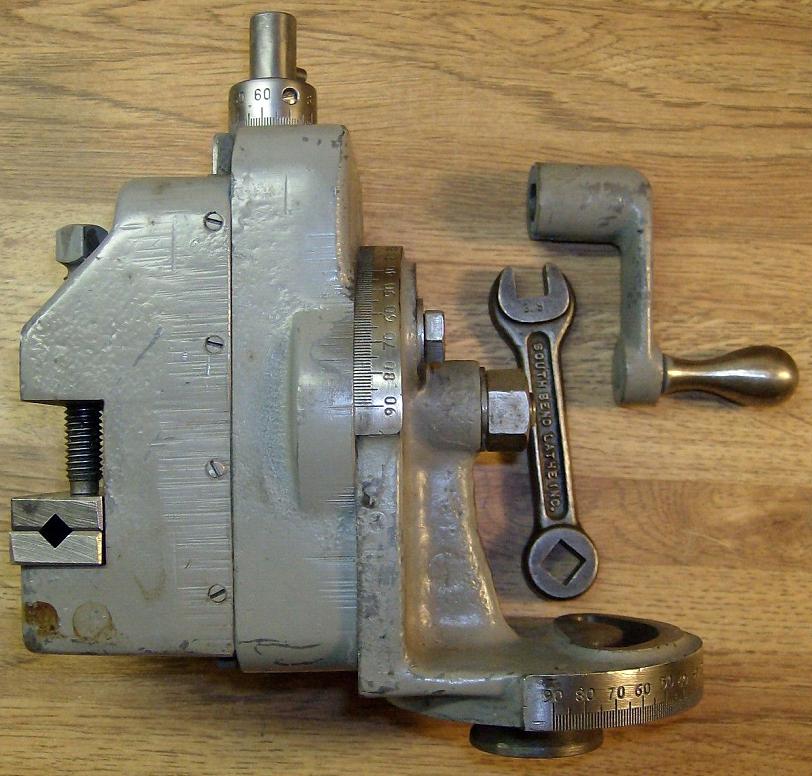

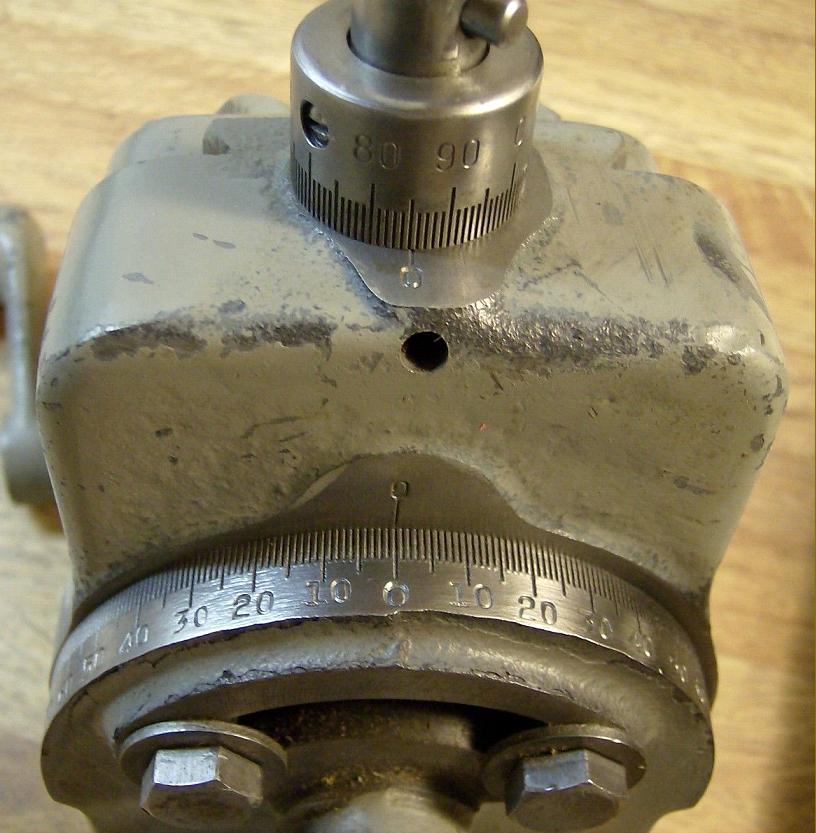

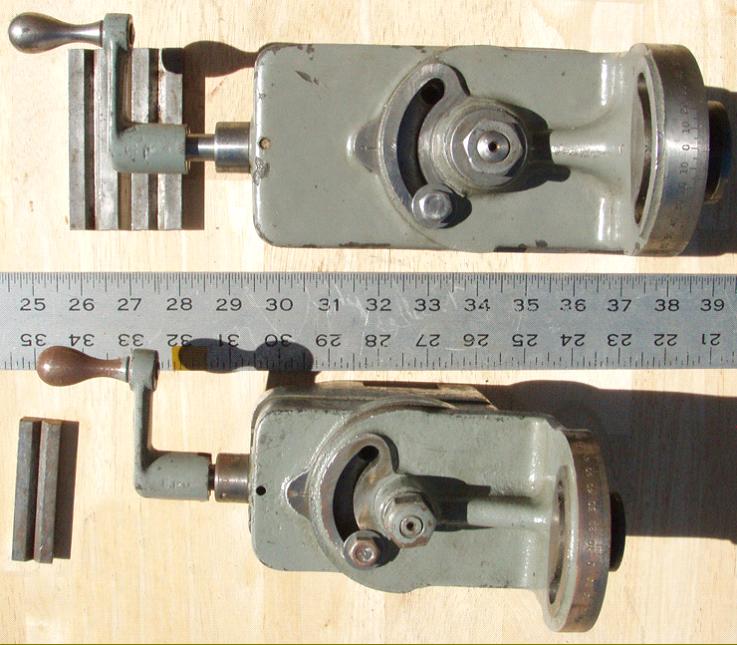

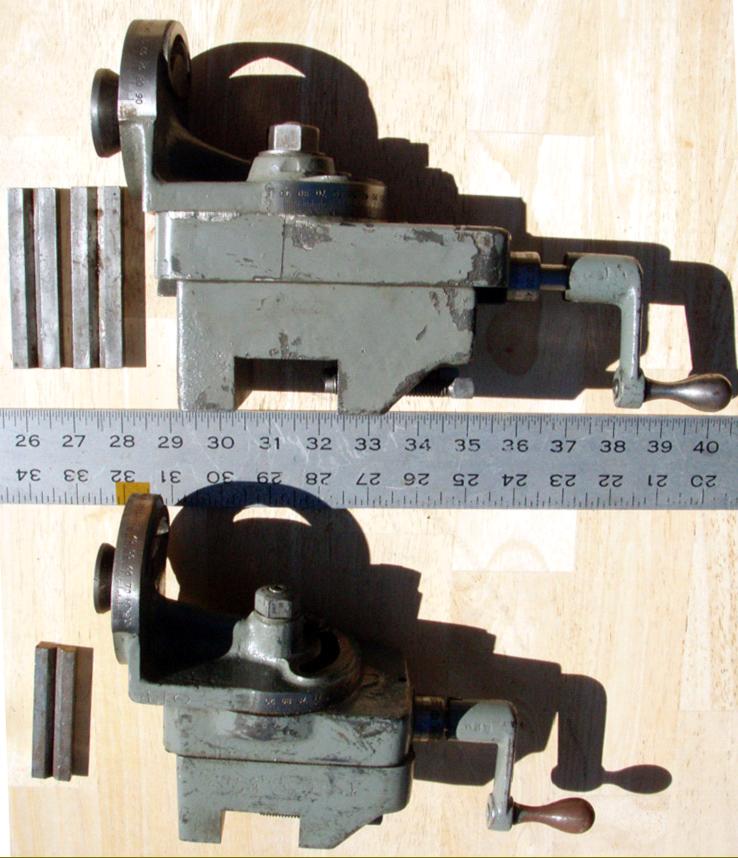

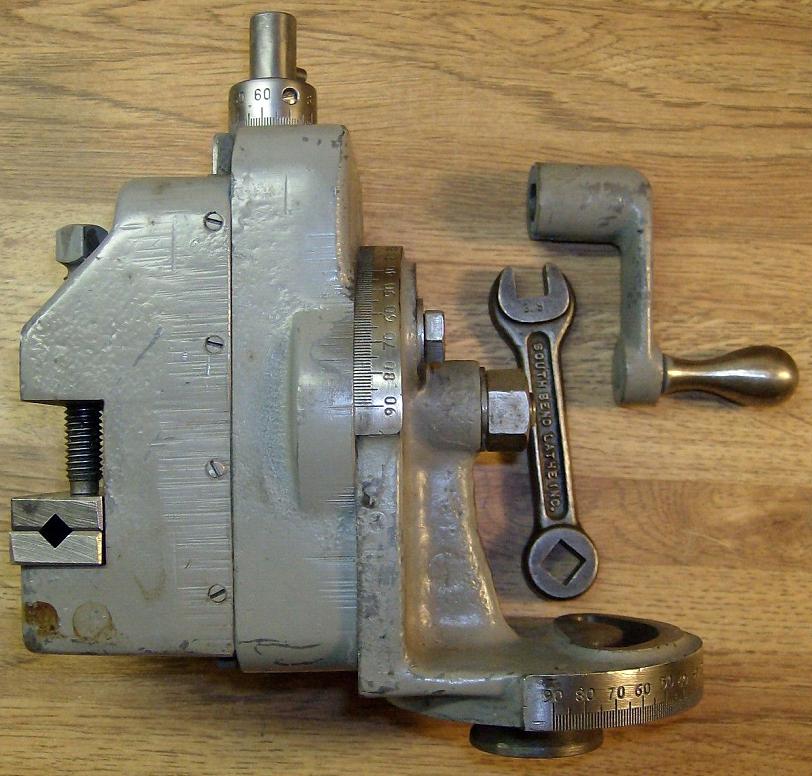

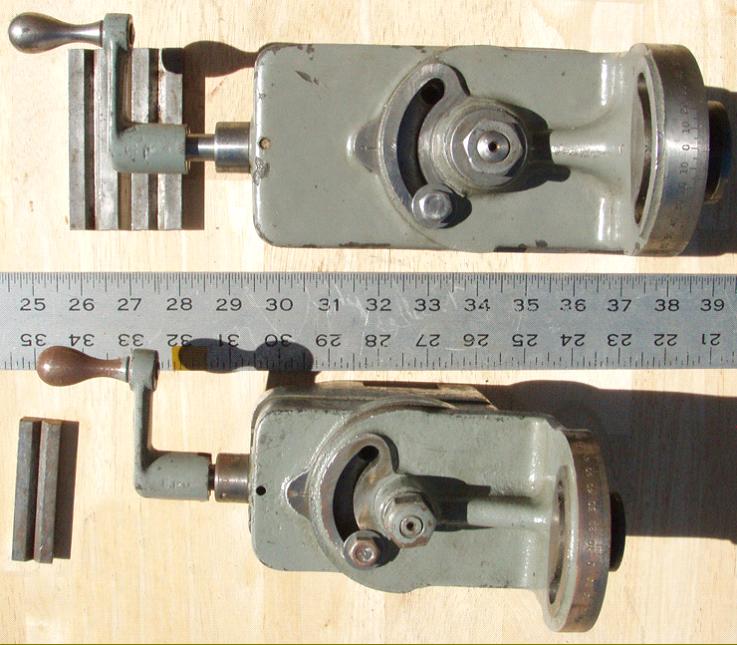

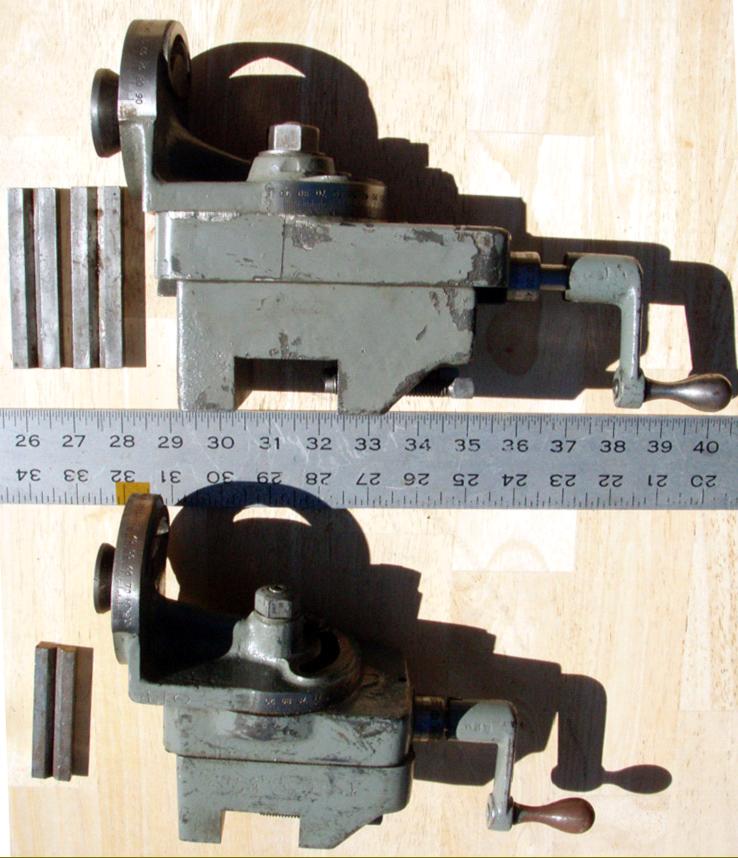

Two sizes of the South Bend milling slide with its integral vice

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|