|

Home Machine Tool Archive Machine-tools Sale & Wanted Geared-head Master & Triumph Lathes A data pack is available for the early Master and early Triumph Master & Triumph 1930s to Early 1950s Master-1940s/1950s Photo Essay By the early 1930s the Colchester Master (6" x 38") and Triumph (7-inch centre height) lathes were being produced in both flat-belt and geared head forms, as shown below; the Mascot, a name later associated with a heavy 81/2" centre height machine, was also being made, but as a 6-inch lathe. |

|

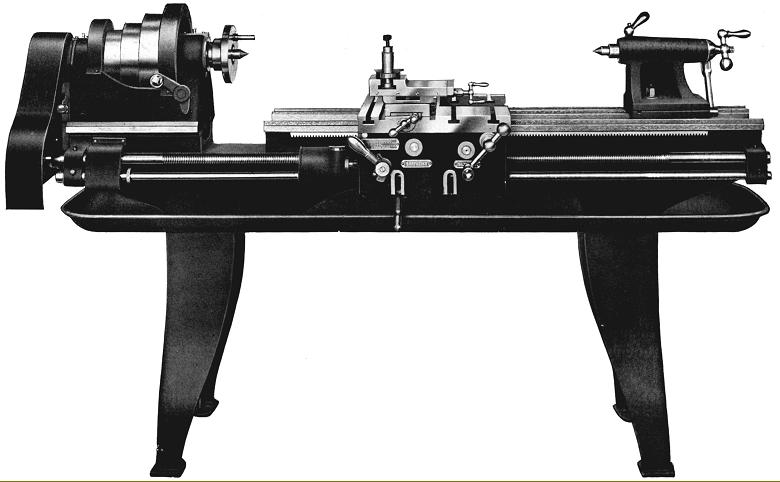

Typical Triumph from the late 1950s mounted on the makers cabinet stand. In the USA the lathe was sold as the Clausing 15-inch |

|

Above and below - the Colchester Master as made circa 1930 to 1939 in flat-belt drive and geared-headstock forms. The latter was equipped with a spindle clutch (a useful fitting later dropped by Colchester for their lathes of the 1940s and 1950s), pressed-steel changewheel guards, external tumble-reverse drive to the leadscrew, a simple two-speed gearbox connecting the powershaft and leadscrew (under covers at the headstock end of the leadscrew) and steel-tipped handles to the cast-iron spindle-speed selection levers. The motor was bolted to the back of the headstock-end leg and drove to the spindle by either a flat or twin V-belts. The 7.5-inch centre height Triumph looked virtually identical, but was of a slightly heavier build. Note the electric isolator box bolted to the front of the headstock-end plinth, a fitting later developed to include full push-button and reverse-switch control. |

|

Mid 1940s to early 1950s geared-head Master on cast iron standards. Early versions of this lathe pre-dated the availability of a full screwcutting gearbox and employed a 2-speed (disengageable) drive to the leadscrew and power shaft. The changewheel guards were made in both in cast iron and cast aluminium (instead of pressed steel), and the reverse drive to the leadscrew and power shaft by an enclosed gear mechanism within the headstock with control by a lever in the bottom left-hand corner of the headstock's front face. The spindle-speed selection levers were tipped with inverted-cone plastic knobs, the spindle clutch was dropped and replaced by a spindle brake - the operating lever for which is the tall lever pivoting bottom right on the face of the headstock. Electrical controls were neatly integrated into a single plate let into the front face of the headstock-end cabinet leg - foreshadowing the even neater demountable system introduced with the full cabinet introduced in the mid 1950s. |

|

|

||

|

|

||

|

|

|

The spindle-speed selector levers (on top of the headstock) had their spring-loaded indents at the end of the long cast-iron levers; later machines (with rod levers) had them built into the pivot hub and, with less leverage available to keep them in place, were more prone to accidental disengagement. |

||

|

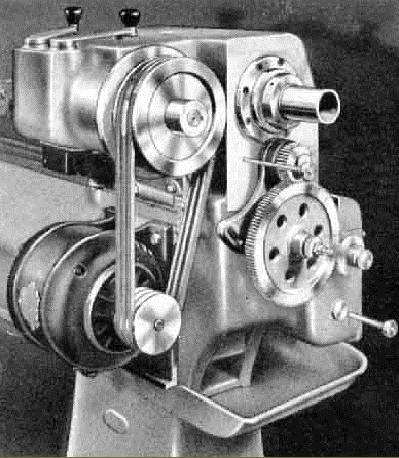

This unusual and compact drive system is fitted to an early Colchester Triumph. A motor, carrying a fabric universal joint on its shaft (as commonly employed on pre-WW2 cars) drives a standard worm-reduction right-angle gearbox. The gearbox output shaft - carrying a 3-step cone pulley - is supported in brackets with the one closest to the lathe being inside the headstock-end leg. As the leg is cast with a hole for the shaft to pass though, this assembly is almost certainly an original Colchester system.. |