|

Home Machine Tool Archive Machine-tools for Sale & Wanted Books Accessories Sheldon 1940s 10-inch Lathes Early 8, 9 & 10-inch Lathes Handbooks, Manuals & Parts Lists are available for most Sheldon Lathes |

|

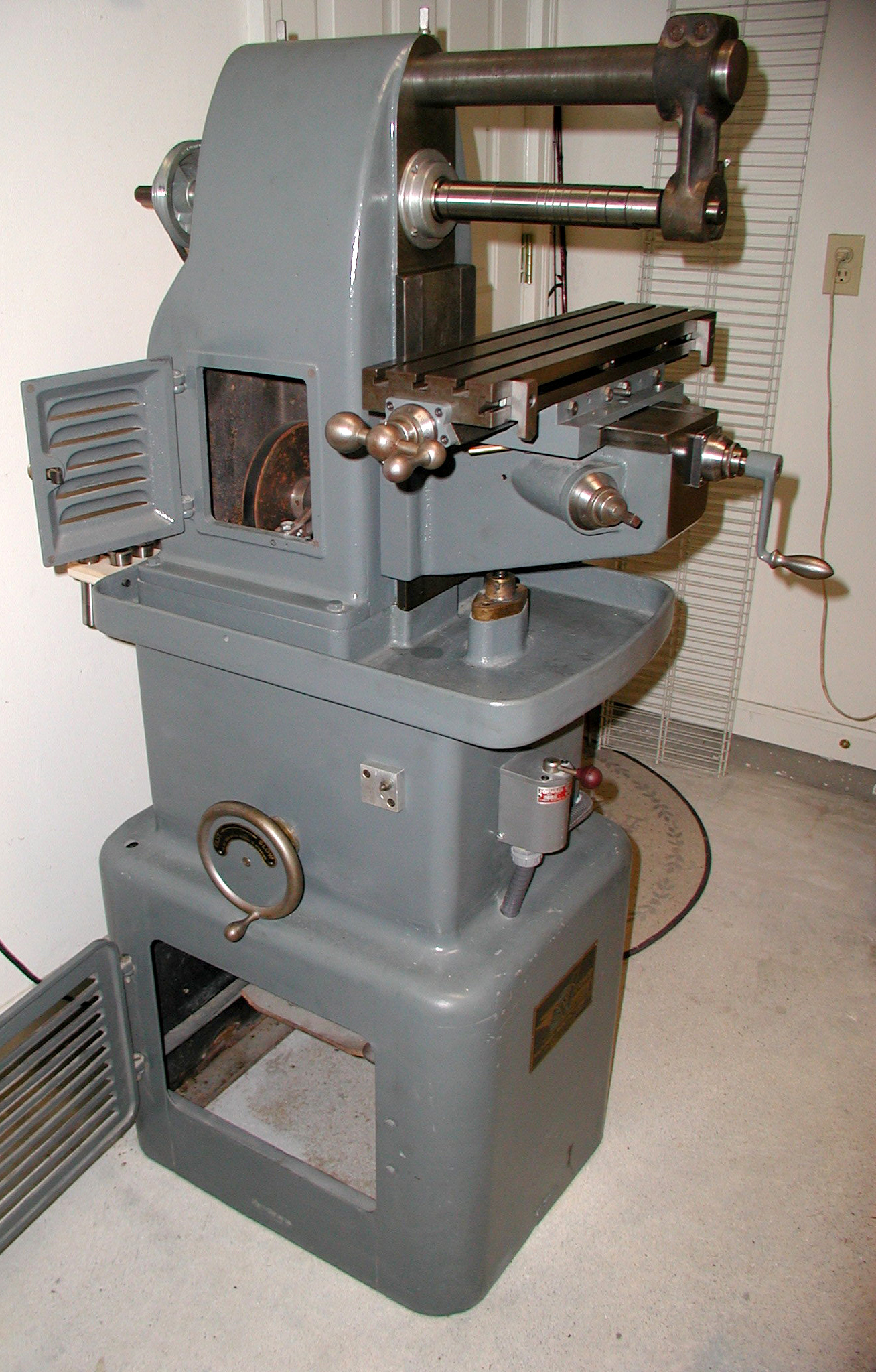

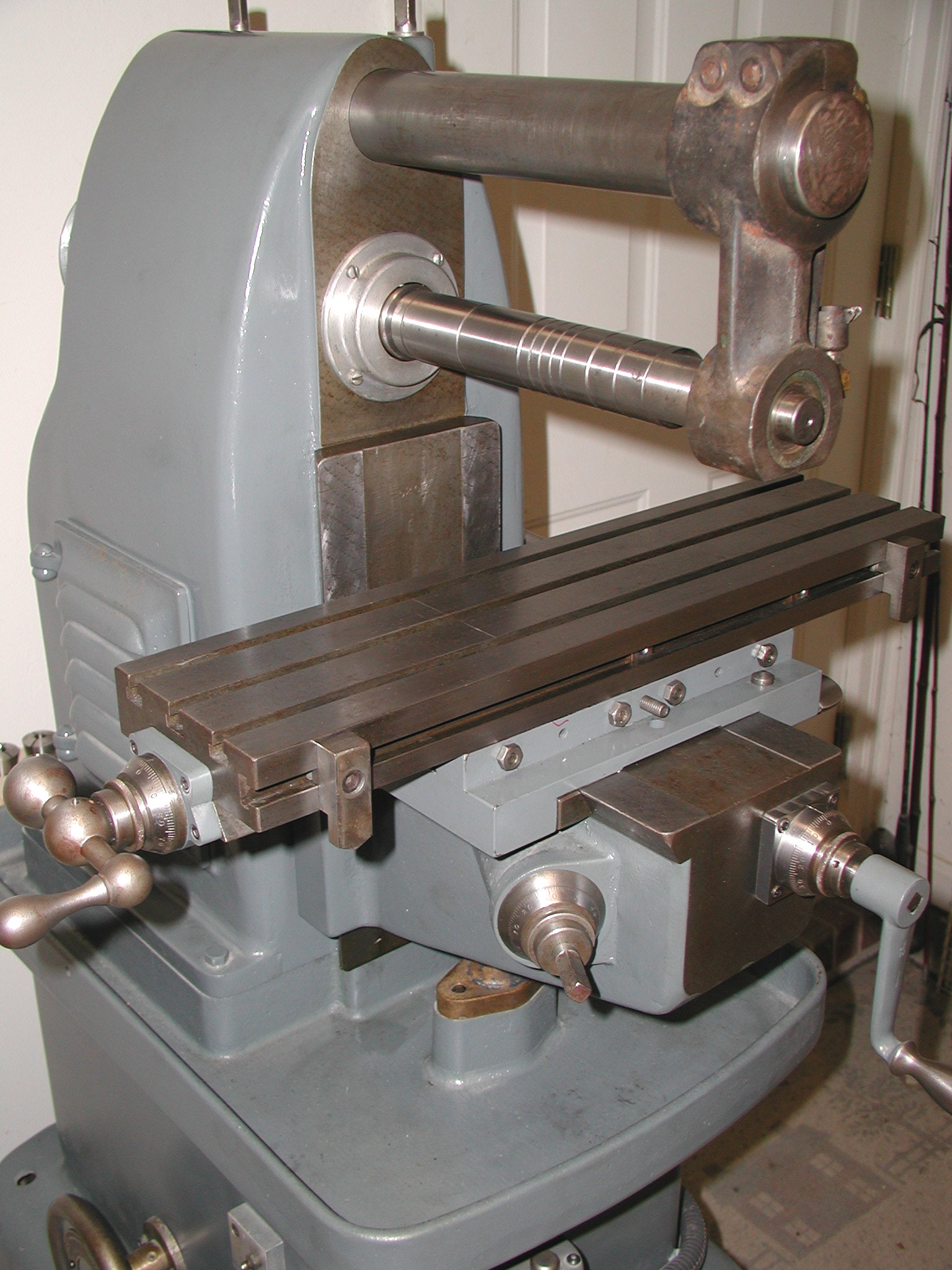

Manufactured by Vernon Machinery Manufacturing Company of 1915 East 515T Street, Vernon, Los Angeles, California (and originally sold under that company's "Vernon" label) Sheldon marketed both vertical and horizontal milling machines. The vertical miller (details can be found on the Vernon pages) was really a miniature jig borer along the lines of the well-known Linley, while the horizontal model, shown on this page, was of utterly conventional design and construction but with the advantages of variable-speed drive and an epicyclic backgear built into the V-belt drive pulley to give a range of especially slow speeds. |

|

|

||

|

Later versions of the miller, though mechanically almost identical to the earlier, were fitted to stands of a cleaner design with much larger chip and coolant trays. The table was made 2 inches longer and given three instead of two T slots - and the drive system modified to give usefully higher speeds. |

||

|

Completely enclosed within the cast-iron cabinet base, the drive system consisted of a 1 hp single (or 3-phase) motor that drove a robustly constructed, double-acting expanding-and-contracting (wide V-belt) variable-speed drive unit with ordinary twin V belts providing the final stage to the spindle. The tachometer drive components are shown in the top right-hand corner of the illustration. |

|

Described by Sheldon as a "backgear" - but in reality an epicyclic arrangement - the low speed drive for the miller was built into the V-belt drive pulley. |

||

|

Simple, non-quill feed swivelling vertical head that socketed into the hole normally occupied by the round overarm. It was driven from the horizontal spindle. |

|

Self-contained, swivelling, quill-feed vertical head carried on the end of the round overarm. This head was made by Rusnok and listed as their Model 70. |