|

Although the long threaded rod along the bed was originally termed a master thread, or leading screw, it is now generally referred to as the leadscrew. Any leadscrew needs to be very accurately made (they are often produced by specialist manufacturers, not the machine-tool builders themselves) with an Acme, square or other thread form optimised for the task - but never with a standard Whitworth or Metric form - as unfortunately found on many cheaper lathes from the Far East. The leadscrew will reproduce its exact pitch (hence the need for accuracy) on the material to be threaded - providing it can be driven directly in some way from the headstock spindle - usually by ordinary straight-cut gears but occasionally by bevel gears, epicyclic drives or even, in a few cases, using toothed belts. Of course, with the advent of computer control, the relative movements of spindle and carriage are easily manipulated electronically - hence, it's now possible to generate threads with no need for any mechanical connection between spindle and carriage).

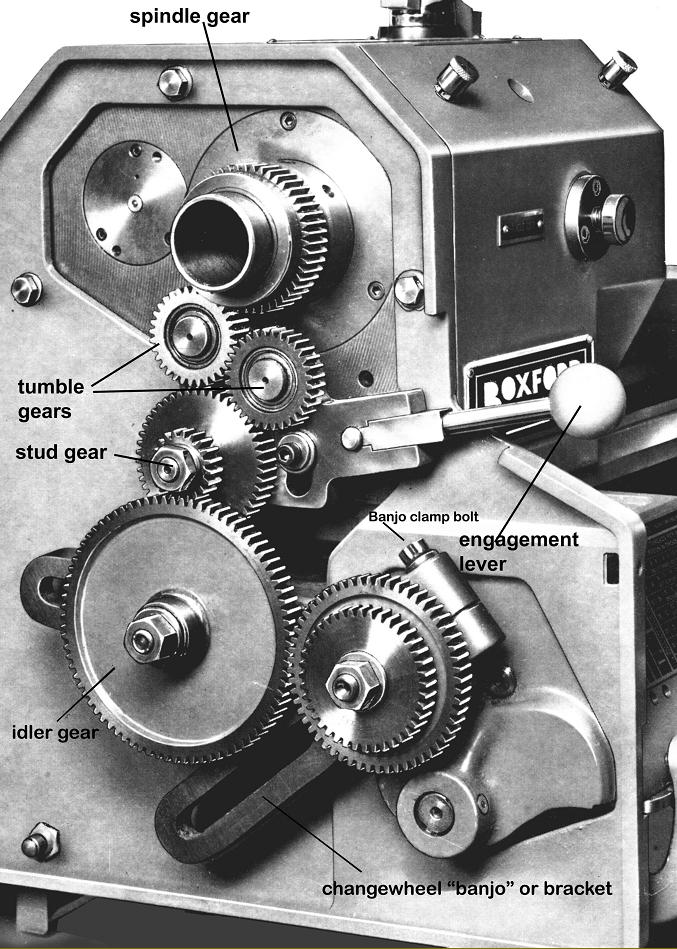

A side benefit of screwcutting was the realisation that an automatic, and hence steady, feed along the bed produced a much-improved surface finish, especially if the feed was slow and the tool was correctly shaped. Thus, for everyday use, the changewheels are normally arranged to provide a very fine feed to the carriage; to set them for screwcutting means removing most or all of them and building up a fresh train following the instructions on a "screwcutting chart" (normally attached to the machine). At the end of the threading job, the screwcutting train is removed and the fine-feed gears replaced. This time-wasting work can be largely avoided if a screwcutting gearbox is fitted - hence their popularity in industry. However, not even a full "quick-change" screwcutting gearbox can generate every pitch of thread, and it is sometimes necessary to substitute changewheels in order to extend the range of the box - or generate metric threads from an English gearbox, or vice versa. Despite the attractions of a screwcutting gearbox for amateur use (quick and simple gear selection), as the saving of time is not usually as consideration (except for the indolent) a lathe fitted with changewheels provides a much more adaptable machine.

If the lathe's changewheel chart is missing, all is not lost; the book, Screwcutting in the Lathe, will help to calculate a fresh set. Further help, including instructions for using changewheel calculators and the necessary program downloads, can be found here.

As already explained, driving the cutting tools via a direct mechanical connection to the headstock also allowed, in ordinary work, a much smoother, more consistent finish and, at the same time, greatly reduced the fatigue suffered by the operator. This form of powered motion was originally called self-acting or self-act - and both terms were once widely used to distinguish between plain-turning and screwcutting lathes.

When the carriage is connected to the leadscrew, some form of "nut" is used: either a solid, permanently engaged nut or a single or double "clasp nut" that the operator can engage and disengage at will. However, once the "clasp nuts" have been opened, and the carriage moved back to allow another cut to be taken, the problem arises of how to re-engage the nuts at the correct point--a problem solved by a simple but ingenious device, the "Dial Thread Indicator". The DTI consists of a gear engaged with the leadscrew, mounted on a shaft with a dial plate at the other end, engraved with lines so that the operator, by following charts (which vary with the pitch of the thread being cut), can safely engage the nuts and continue threading accurately. Unfortunately, an interesting difficulty arises when cutting metric pitch threads on an English lathe - or vice versa - the leadscrew nuts must not be disengaged, and the lathe has to be "electrically reversed" back to a start point each time a new cut is taken.

Different Threads:

The first question that springs to the mind of the novice is: "Will my lathe be able to cut different types of thread?" (Whitworth, British Standard Fine, American National Coarse, British Standard Brass, American National Fine, British Standard Brass, Unified National Coarse, Unified National Fine, British Association, British Cycle Standard, Metric, etc.) The answer is, yes. Providing the lathe has the changewheels necessary to gear the spindle to the headstock so that the tool moves the right distance whilst the spindle revolves once, it can be done. The 'form' or "shape" of the thread (which, simply put, is what makes the essential difference between the "types" of thread, not their pitch) is entirely in the 'shape' of the tool (or tools) used to cut it. The tool can be ground to replicate any thread angle at will; if you wished, for example, you could even invent your own; first, however, check this link or this one: they list and explain many of the threads forms both current and obsolete. Of course, not all is quite so simple, and at the end of this introductory article is a simple explanation of one of the confusing differences between metric and Inch threads.

A History Lesson:

it up at the back--a test follows: the two engineers most closely associated with the development of mechanically-developed screw threads (although they did not invent the process) were both active in the 1800s: Henry Maudsley (1771 - 1831) "Machine Builder" of London, England (the "engineer's engineer") and one of his apprentices, Joseph Whitworth (1803 - 1887) Toolmaker of Manchester, England known for his plain-speaking not to say blunt ways (and probably the epitome of Shaw's dictum that "all progress depends on the unreasonable man."). Maudslay was the first engineer able to make and exploit a very accurate screw thread. His masterpiece was a screw 5 feet long and 2 inches in diameter (1525 mm by 51 mm) with 50 turns per inch (50 per 25 mm), on which ran a nut 12 inches (305 mm) long with 600 threads. The apparatus was designed to average out pitch errors over short distances and was a vital element in engraving the scale markings on astronomical and other very accurate measuring devices. Maudslay went on to manufacture a range of screwcutting lathes (using the principle of a "master thread" or "leading screw") examples of which can be seen in the London Science Museum and the Henry Ford Museum in Dearborn, Michigan, USA. Astoundingly, so accurate were Maudslay's threads (and so precise his measuring equipment). that he was able to observe the expansion effect of sunlight warming one half of a leadscrew. Whitworth was a prolific inventor, toolmaker and designer (and millionaire businessman) who brought a disciplined approach to engineering. His design and development skills ranged across almost the whole field of mechanics, but following the publication in 1841 of his "On a Universal System of Screw Threads", he is best remembered for his success in standardising what was, at the time, a chaotic system of hand-fitted, non-interchangeable fastenings. Having collected a large sample of nuts and bolts from a variety of workshops and examined their properties, he proposed a system whereby the ratio between the depth of the thread and its pitch was maintained over a range of sizes - and that the angle of the thread be 55 degrees. The system was employed in his own workshops by 1858 and was quickly taken up by other engineers as its benefits of simplicity and interchangeability - to say nothing of its recommendation by the greatest living British engineer of the day - became obvious.

Forming Threads by Hand:

It is possible to generate threads on a revolving cylindrical surface without using mechanical assistance by employing a "chaser". These look rather like wood-turning chisels with a "thread form" cut into their end or side faces and are made from hard steel - tool steel for the finest-quality ones - and vary in width and thickness according to their thread pitch and job they have to do.

The full-sized type are normally fitted to stout wooden handles to give the necessary purchase (which can be considerable) and are expensive. However, there is a cheaper alternative, the chasers that come from automatically-releasing die holders; these units are used on capstan lathes and hold four small identical sections of tool steel formed with a very accurate thread along one edge. If these are removed and mounted in a suitable metal holder they can be used exactly like their full-size cousins. Unfortunately, using either type is difficult and beginners are well advised to avoid them completely - although they can have a role to play in "cleaning up" a mechanically-cut thread and imparting a radius or other shape to the crest and root of the thread, a process not possible with the single-point thread generation method described above. In use the chaser is rested against a suitable support - with some lubricant between the two - and fed into the workpiece on centre height with a steady sliding motion.

Continued below:

|

|