|

These notes should be used in conjunction with the following programs:

Evans Lewis has done wonderful work in producing a number of programs to assist with screwcutting including this one that calculates all the possible combinations of transposing changewheels to make an imperial lathe generate metric pitches, and metric lathes imperial ones

For other lathes using changewheels for screwcutting (on a lathe like this) use: NthreadsP written by Geoff Carter

For lathes with a screwcutting gearbox (on a lathe like this) use BoxfthreadP

Both the latter pair of programs have to be downloaded and unzipped - however, in Windows 10 they appear to unzip automatically without recourse to a third-party program.

When running, you'll see the following:

- a box in the centre to enter the number of teeth of the changewheels in your set (this setting can be saved)

- top left is a tick box to change to metric pitches

- an "Edit Quickbox" in BoxfthreadP is to enter, if known, the internal ratios of the screwcutting gearbox

Fill in the other boxes as required and click "Calculate"

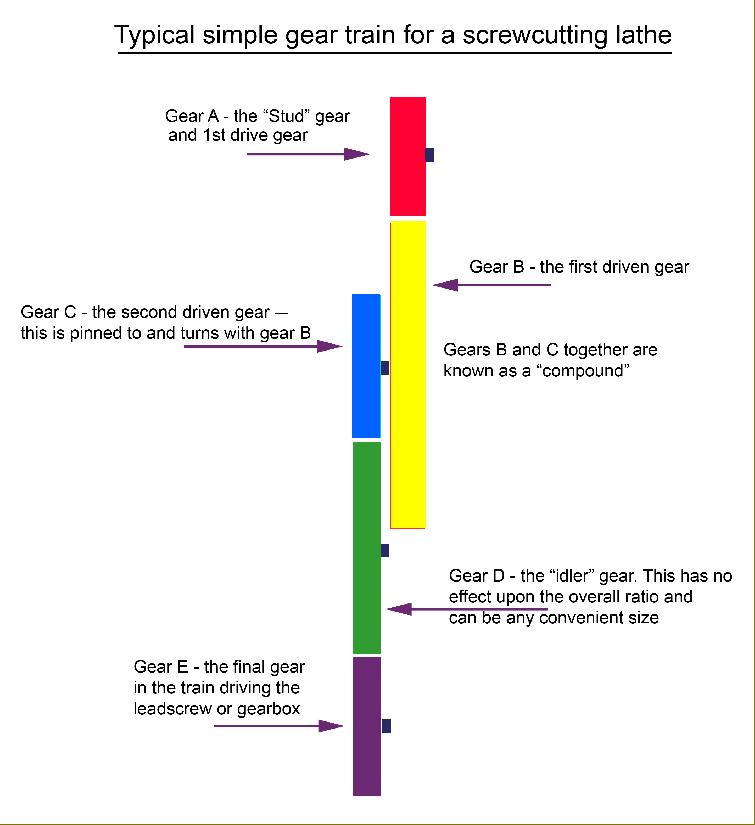

The results are displayed as a list of changewheels to use - and where they should be mounted described in terms of "Driver" and "Driven" gears. The position of the "Driver" and "Driven" gears can be determined by reference to the changewheel diagram below - which is also reproduced here: gear-train.bmp (you might want to print it out). More detailed instructions can be found further down the page - please read them

Another screwcutting calculator program - for changewheels only and ready to use - is here.

Don't just jump in and attempt to use the programs, to get the best results read and understand these notes first - and if your lathe has a screwcutting gearbox it's even more important to go though the explanations and examples steadily.

The programs have been written to help with the following situations:

1) If your screwcutting chart is absent - or to calculate a new one.

2) Should changewheels be missing the programs will attempt to calculate alternative arrangements using the gears to hand

3) To generate a pitch not on a threading chart

4) To calculate the missing changewheels necessary to make a more useful set

5) To generate metric pitches on an English lathe without using a 127 tooth gear

A book with screwcutting information most suitable for the amateur (and ideal to refresh the memory of the professional) is: "The Amateurs Lathe". This gives a complete breakdown of the process with simple-to-follow instructions that will enable even the complete beginner to cut threads successfully. Other useful publications include the inexpensive: "Screwcutting in the Lathe" and a newer, beautifully produced hard-back book that is highly recommended: "Screwcutting"

Remind me which program to use…..

NthreadsP is the program for lathes with screwcutting by changewheels. BoxftrhreadP is for lathes with a quick-change gearbox. Note: some lathes with changewheels for screwcutting have, rather handily, a two or three speed box that gives two or three sets of ratios for each train of gears. Examples include some Models of the Harrison L5 and certain early American Sheldon lathes

Background:

Calculations show that a set of 20 gears will generate, for example, 380 sets of 2-gear arrangements, 29,070 sets of 4-gear and 775,200 sets of 6-gear: a total of 804,650. By calculating all these possibilities it is possible to set up gear trains that will generate pitches with only a very minor or even zero pitch errors. It would, of course, be extremely laborious to calculate all these many arrangements by trial-and-error method with a pocket calculator - but a computer program can do it very quickly.

The Gear Train:

Typical lathes for which the NthreadsP program was written include the smaller British and American types such as Myford, South Bend, Boxford, Colchester, Drummond, Atlas, Craftsman, Sheldon, Delta, Rockwell, etc. For lathes that have either screwcutting by changewheels or a screwcutting gearbox a diagram of a typical set-up is shown below with the gears coloured - and in gear-train.bmp - together with a photograph of a similar arrangement here: changewheels.bmp. Briefly, a gear on the end of the main headstock spindle engages with a "tumble-reverse mechanism" - two gears on a pivoting arm arranged to reverse the drive. The tumble-reverse mechanism has an output gear (often referred to as the "Stud" gear) driving a train of gears, this being, sometimes, a "compound set" where one or more studs carry two gears that rotate together as they fastened to each other by a key or pin. An important point is that the stud gear is usually made removable, allowing it to be part of the screwcutting train while also providing a quick and easy means of slowing down or speeding up the minimum carriage feed rate..

To space the gear-train out and make it physically possible to build, idler gears are also sometimes included, but these, no matter how large, or small - or how many - have no effect upon the overall ratio.

The "Stud" gear "A" on the end of the primary shaft (shown red on gear-train.bmp) is the first DRIVER gear. It turns a gear "B" on the 1st stud (shown in yellow) this being a DRIVEN gear.

The adjacent gear "C" (coloured blue on the 1st. Stud) is a DRIVER gear and is fastened to and turns with gear B - the arrangement being known as "compound". Gear C, in turn, drives either an idler gear (in green) or direct to the gear (in purple) fitted on the end of the leadscrew or screwcutting gearbox input shaft.

In many cases spacing collars are needed to get the gear train in line - these can be plain distance pieces or often just spare gears.

The number of teeth on the idler gear (green) has no effect on the thread produced.

NB : Depending on the gears required to cut a given thread, it will sometimes be necessary to fit the idler gear on the first stud and a compound set of gear (two gears pinned together on one shaft) on the second.

"Simple" Gear-trains:

Frequently the train of changewheels can be simplified to just three gears: a driver (red gear on primary shaft), an idler (green gear) and the final driven gear (purple) on the leadscrew). Very occasionally the drive can be direct from output stud to leadscrew, or gearbox, with no idler gear in the train.

A note: 'Changewheels' you say. Why not 'changegears'? - the explanation is that, while laymen call gears "cogs", the rest of us use the term "gears" - but in the past a time-served, hands-on engineer would have referred to them as "wheels" - hence the "changewheels" (gears) you change to set up a particular screwcutting train. Watch and clockmakers also use the term "wheels" in place of "gears".

Continued below:

|

|