|

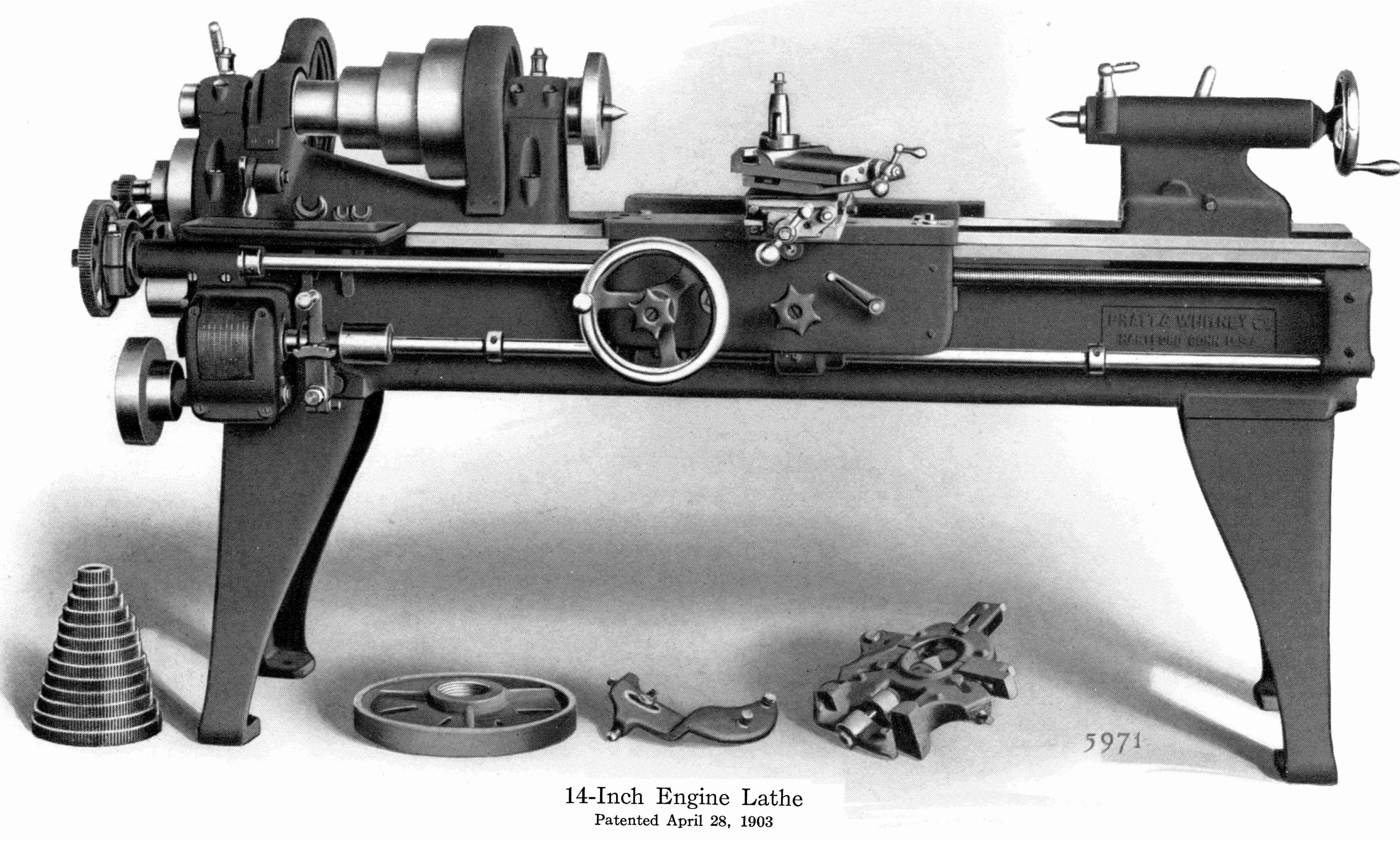

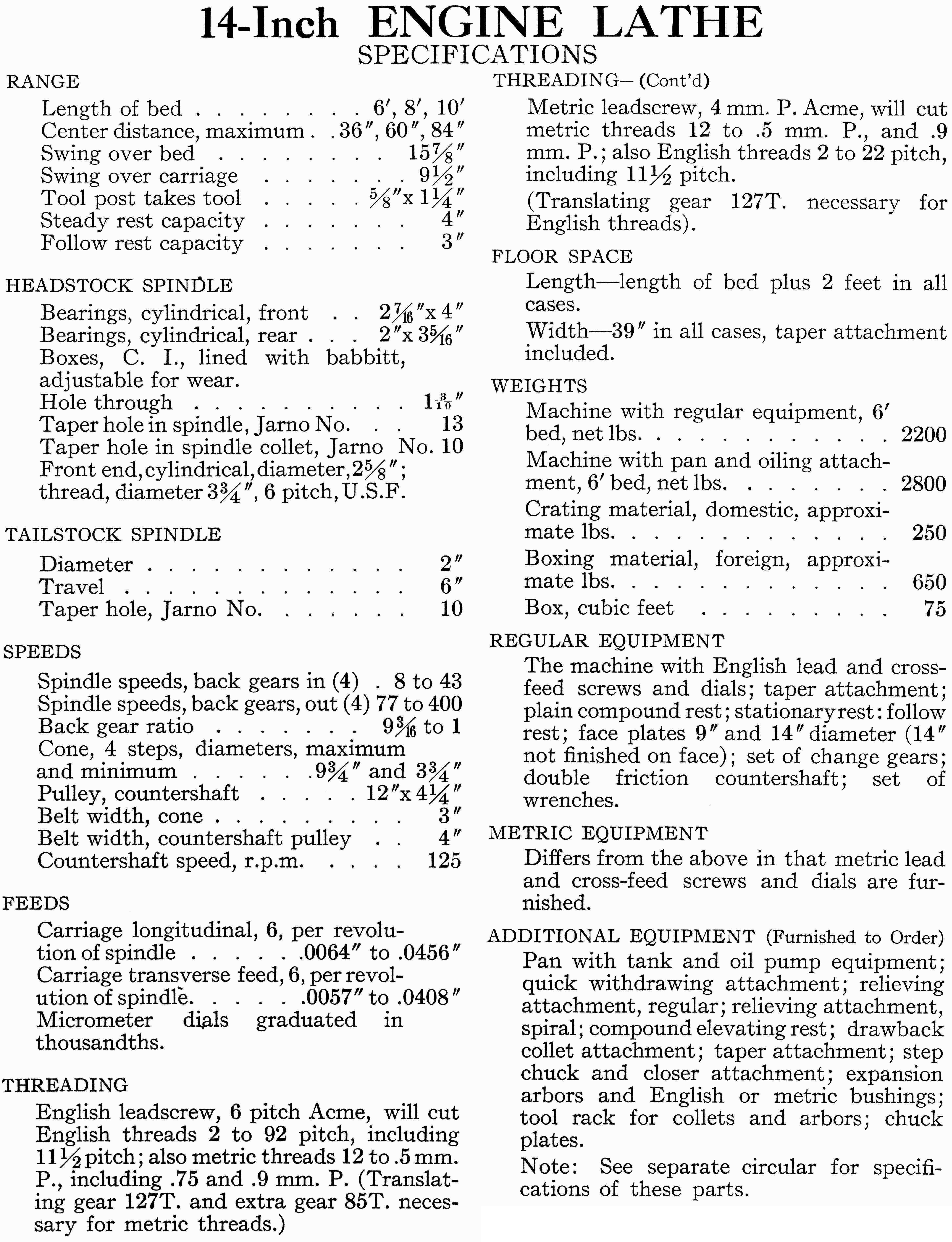

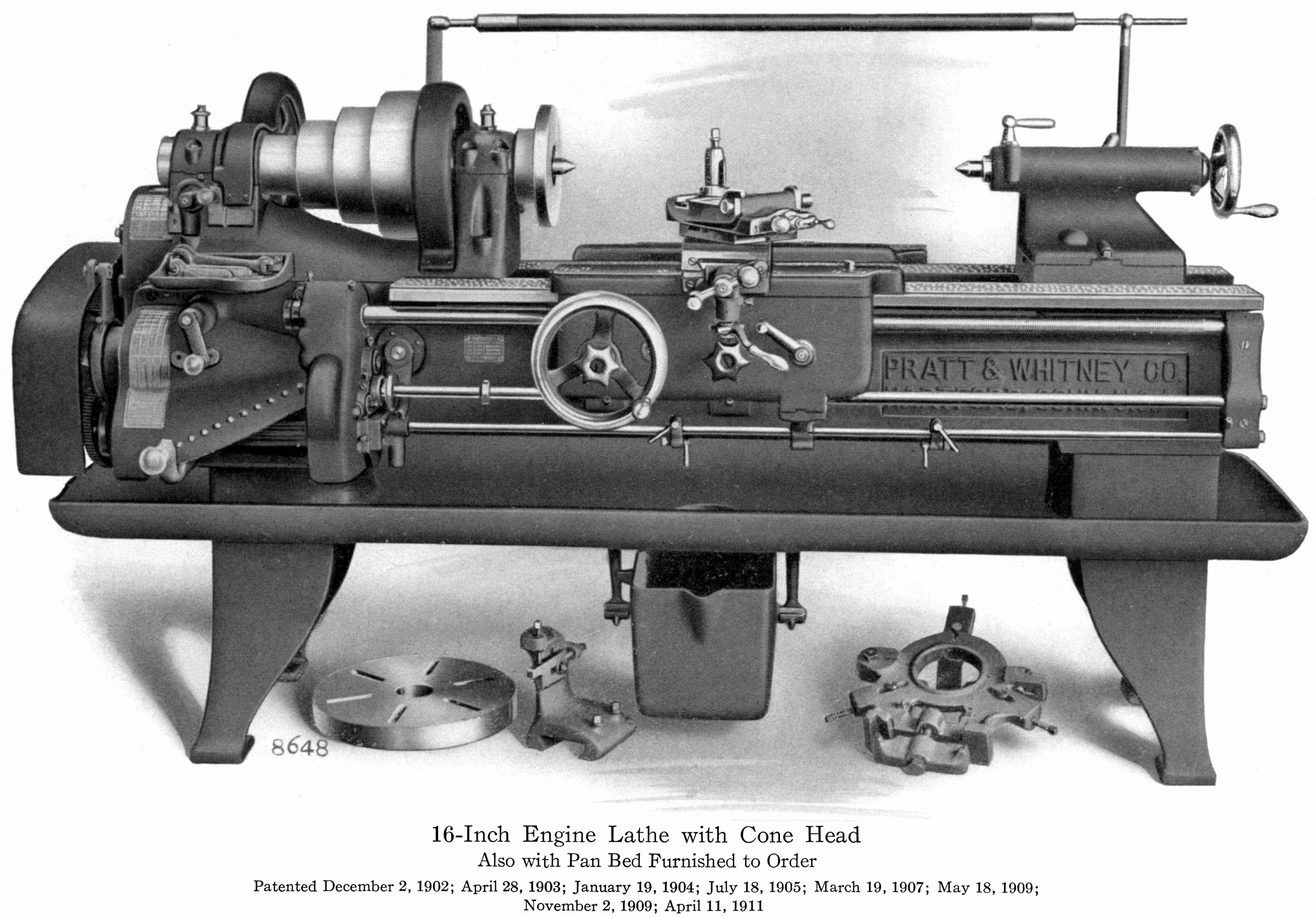

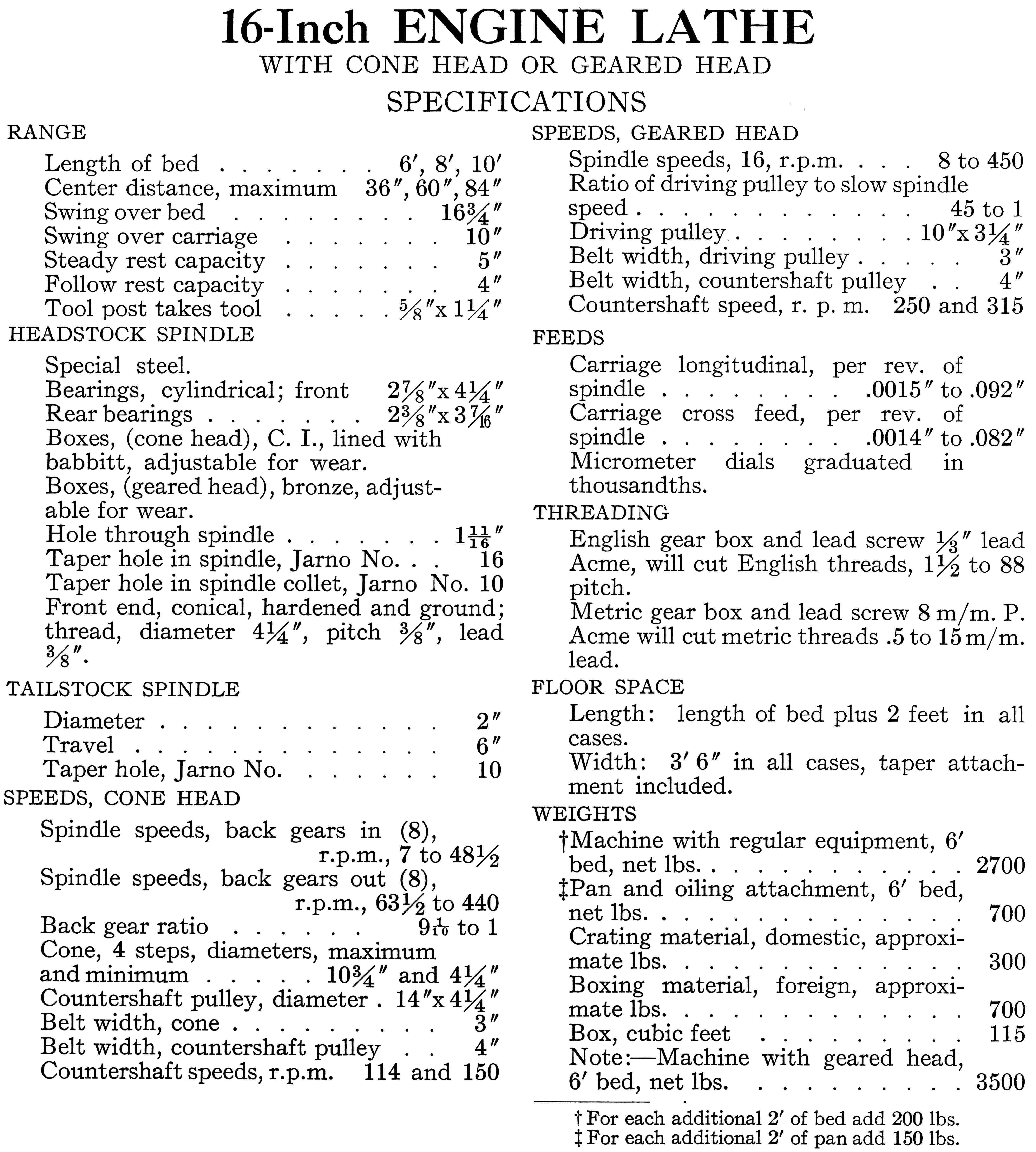

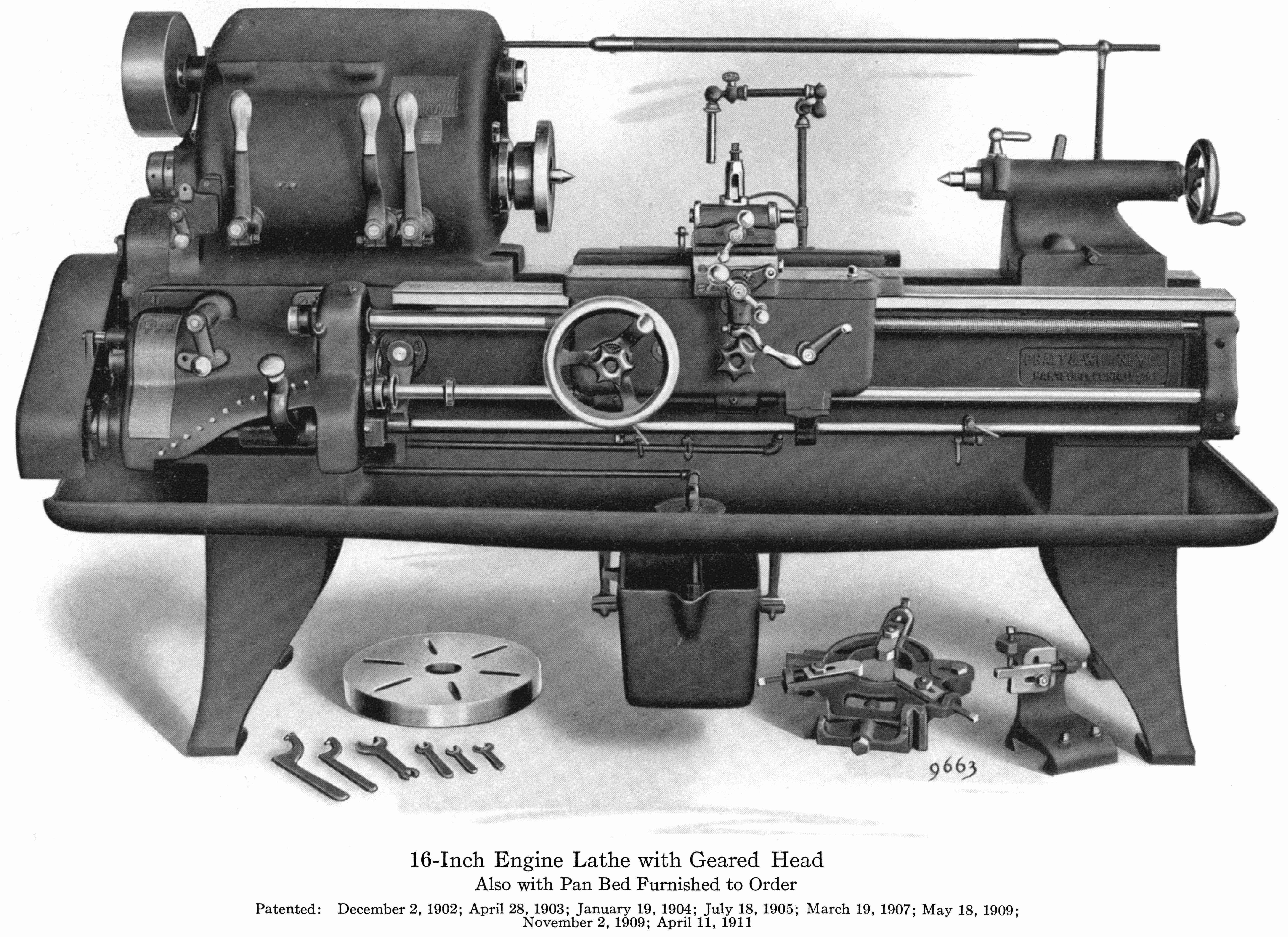

In the 1917 edition of the hard-back Pratt & Whitney all-models "Precision Machine Tools" catalog there were just four models of backgeared and screwcutting "engine" lathe shown: cone-head 10-Inch, 14-Inch, and a 16-Inch available with a choice of a cone-head or geared-headstock.

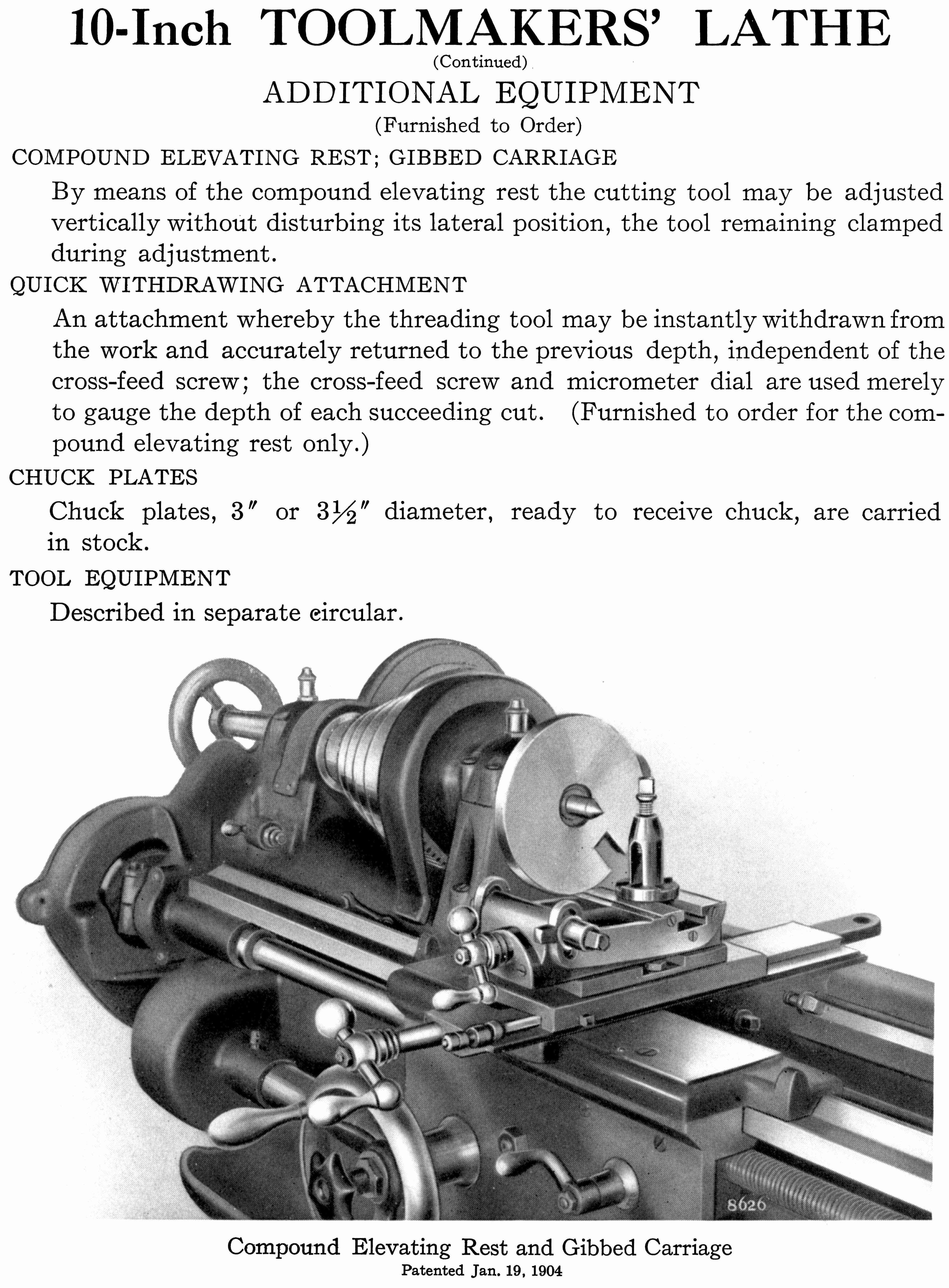

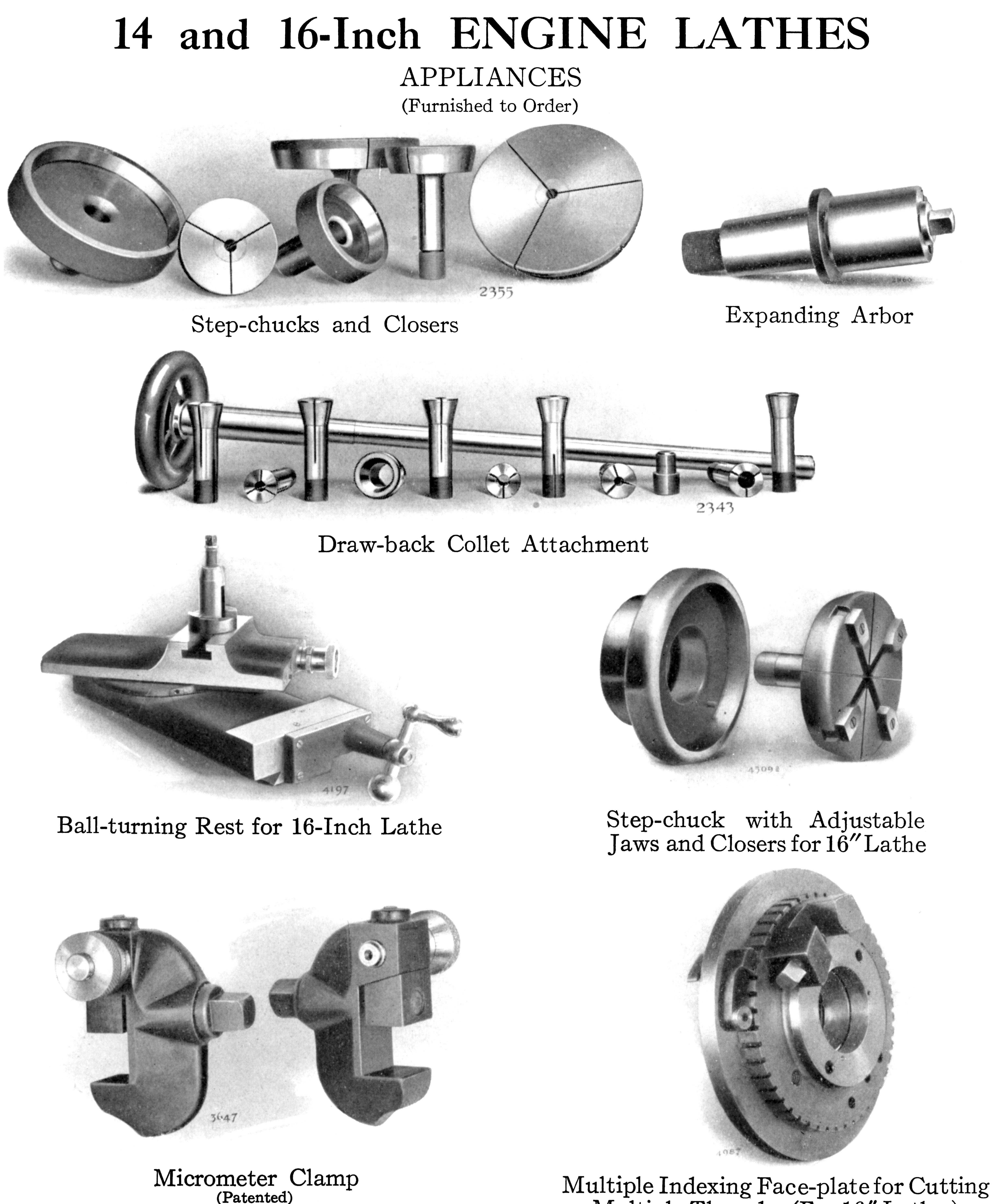

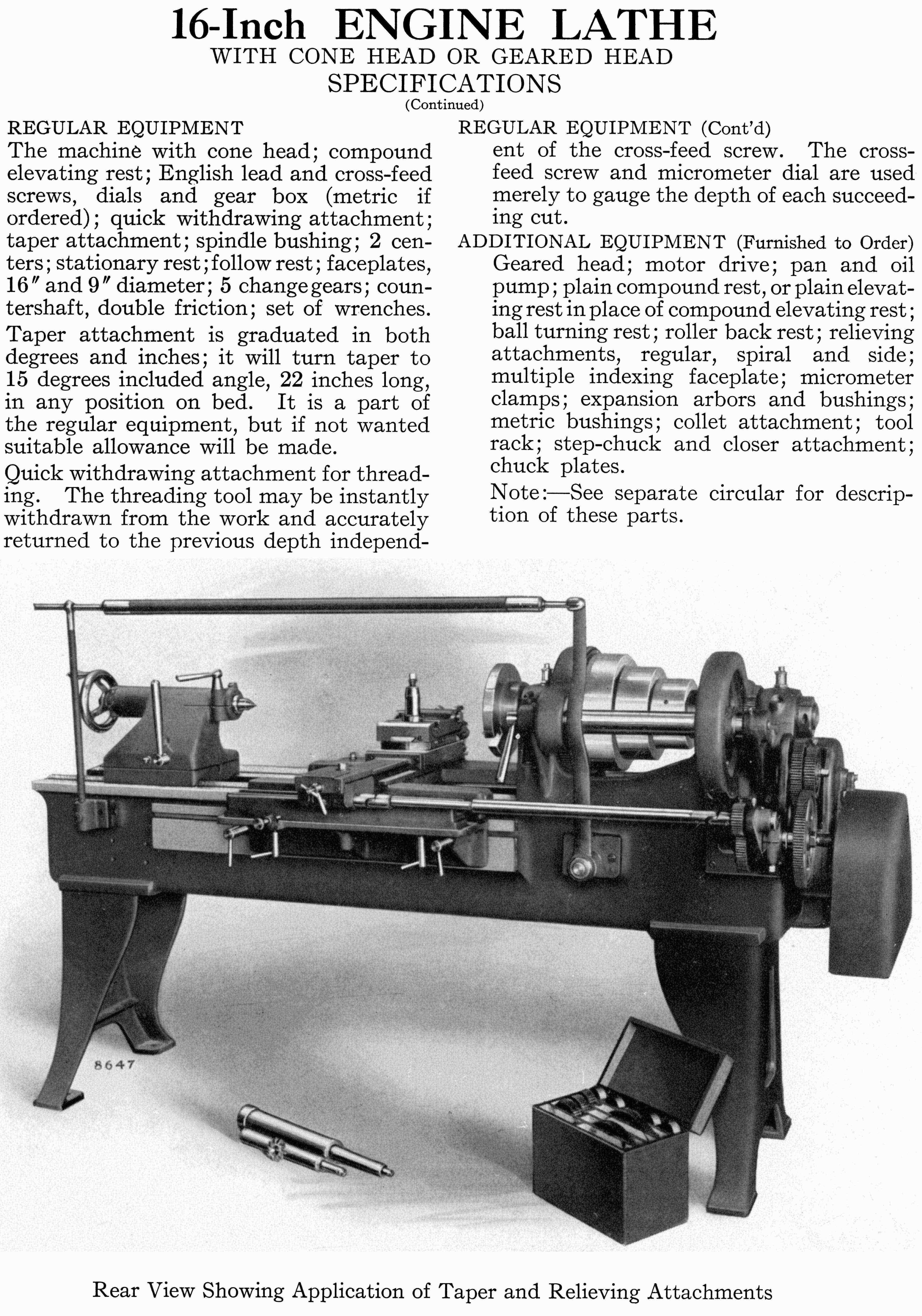

All had deep, straight, gapless beds and were of traditional Pratt & Whitney quality. Strong, well built and using high-quality materials they incorporated much of the latest in design thing from the early years of the 20th century with Patents taken out registered from 1902 to 1911.A range of accessories was offered that included fix and travelling steadies, draw-in collets, a pair of patented micrometer-adjustable carriage stops for travel both towards and away from the headstock, several sizes of standard and one a multiple-indexing faceplate for gear cutting, a top slide that could be elevated over a short range to adjust setting of the cutting tool and, for the same slide, a most useful 'quick-withdrawal' mechanism independent of the feed screw, could be used when screwcutting to pull back the tool and then return it to its original position before applying the next cut..

|

|