Manuals are available for Induma Millers

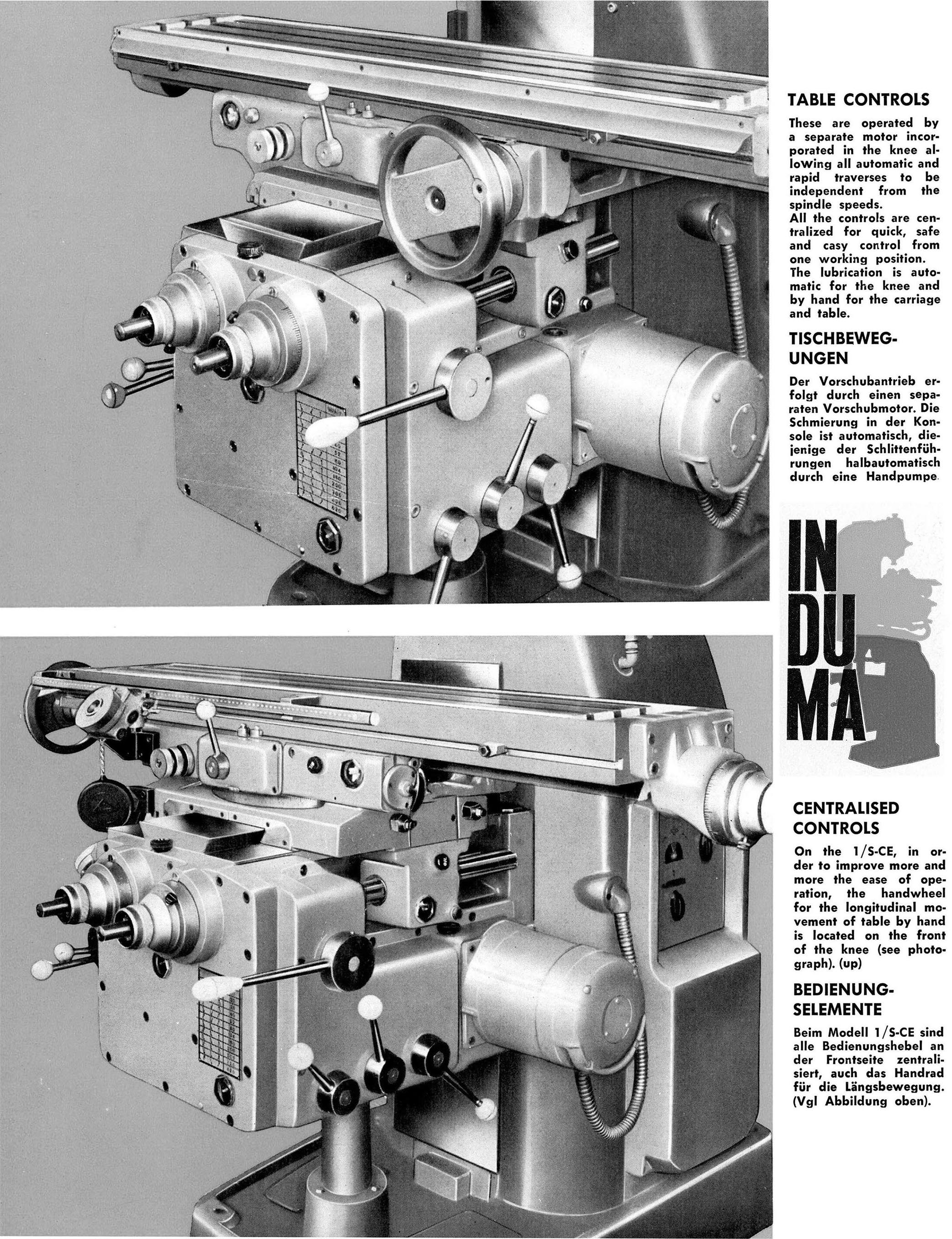

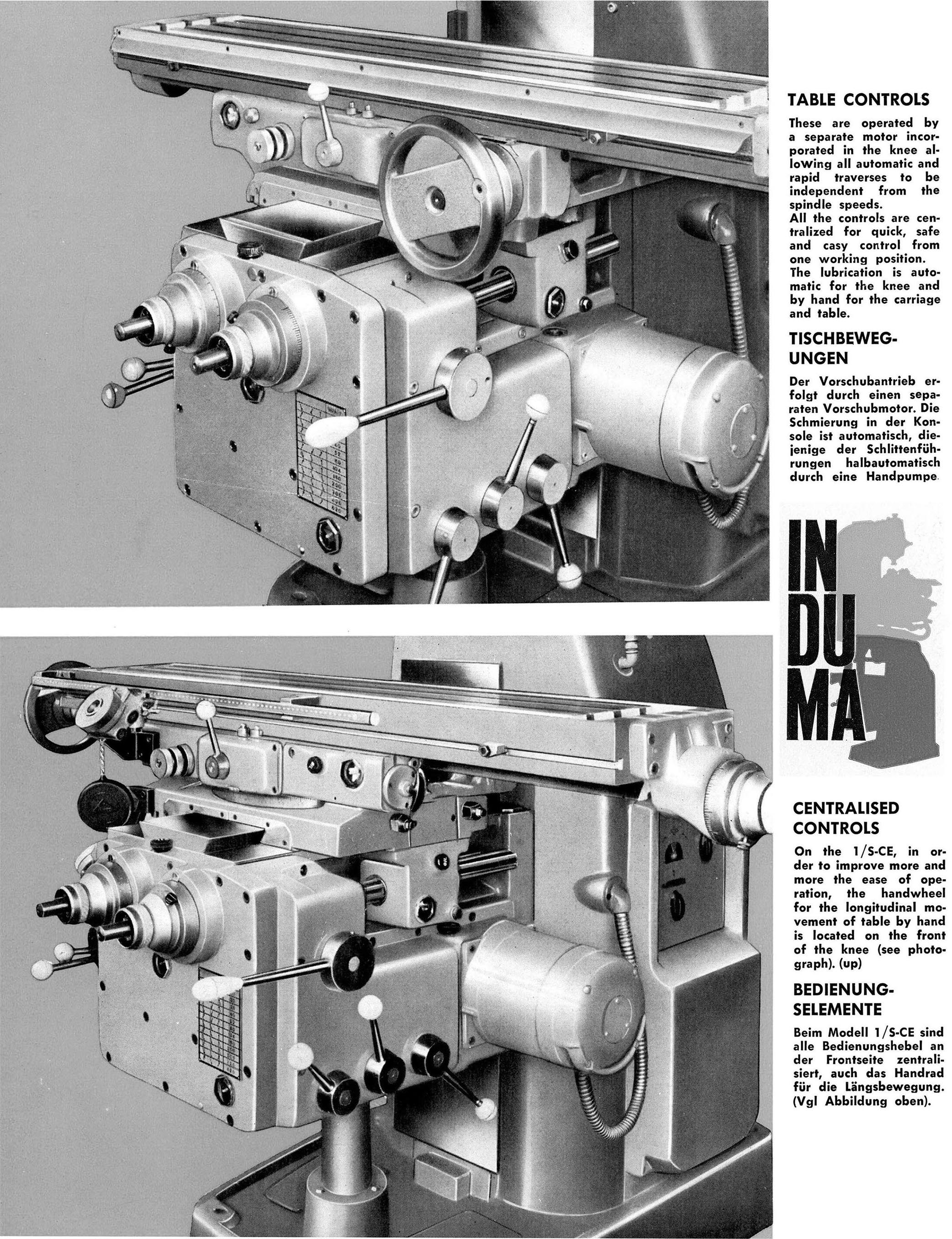

Built alongside the standard Induma 1/S, the 1/S-CE was a ram-head type miller similar to the ordinary machine but, with a more massive column, designed to take heavier jobs and fitted with a longer 50" x 10" (1270 x 254 mm) table. The latter was normally provided with three T-slots, but was also available with a plain surface and could be arranged, at extra cost, as a "universal" type able to be rotated through 45° each side of central. Also changed was the previously very simple knee, this being replaced by an entirely different, very much more complex one with a built-in gearbox and a side-mounted motor that gave power longitudinal, traverse and vertical feeds together with rapids in all directions. Twelve rates of power feed were provided, these ranging from 0.56" to 24.4" (13 to 620 mm) per minute longitudinally and across and from 0.22" to 10.3" (6.5 to 310 mm) vertically. Rapids were set at 63" (600 mm) longitudinally and across and 26.75" (800 mm) vertically with control being by the usual, press-to-operated, spring-loaded return levers.

The table's longitudinal travel by hand was 32.3" (760 mm) but with power feed engaged this reduced to 31.5" (800 mm) Cross feed by hand was 9.75" (250 mm) and using power 9" 230 mm - vertically travel was 17.375" (440 mm). The maximum clearance between the spindle nose and the table was 18.5" (470 mm) though a realistic gap, with a typical collet chuck fitted, was 14.5" (368 mm). The throat was 26.75" (680 mm).

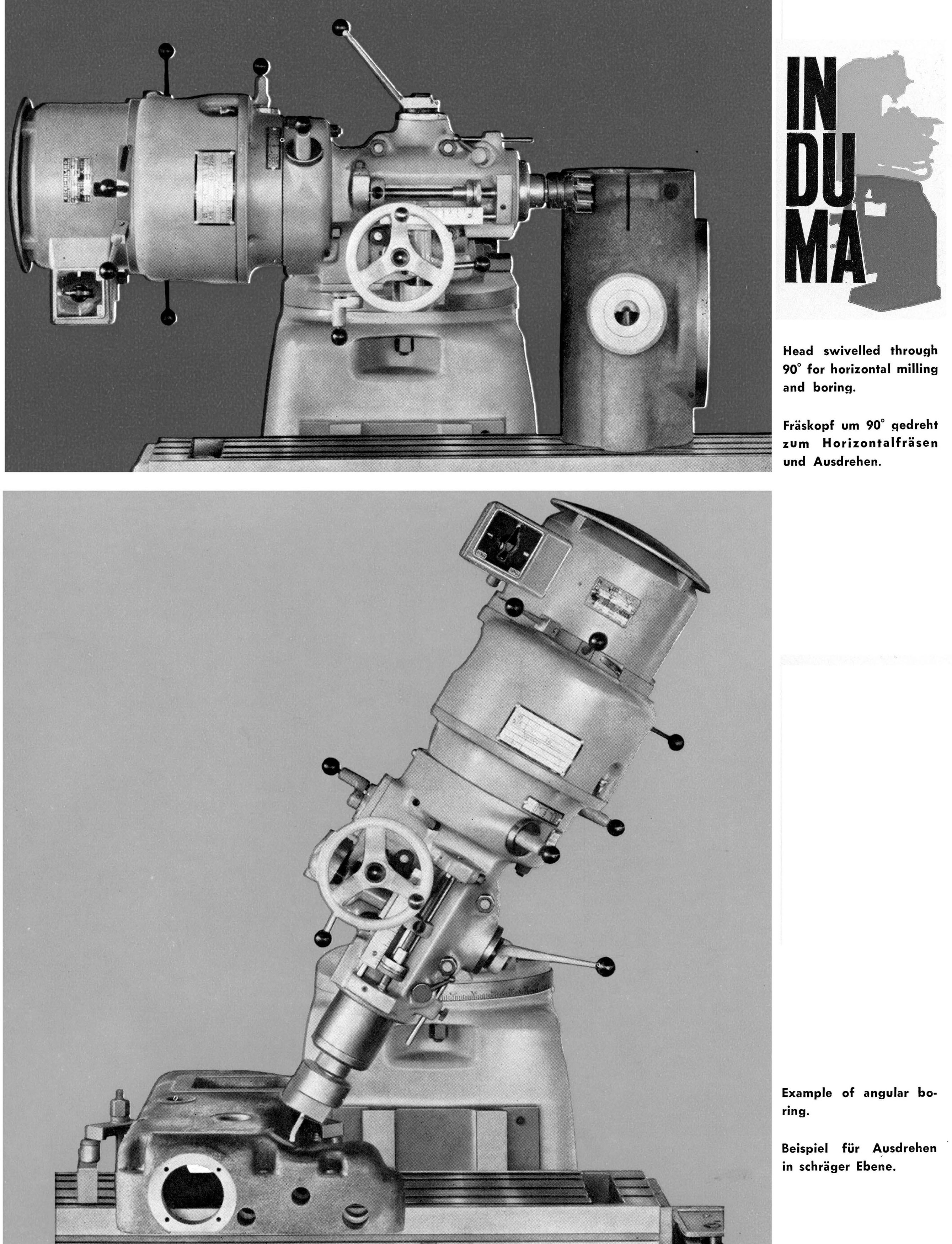

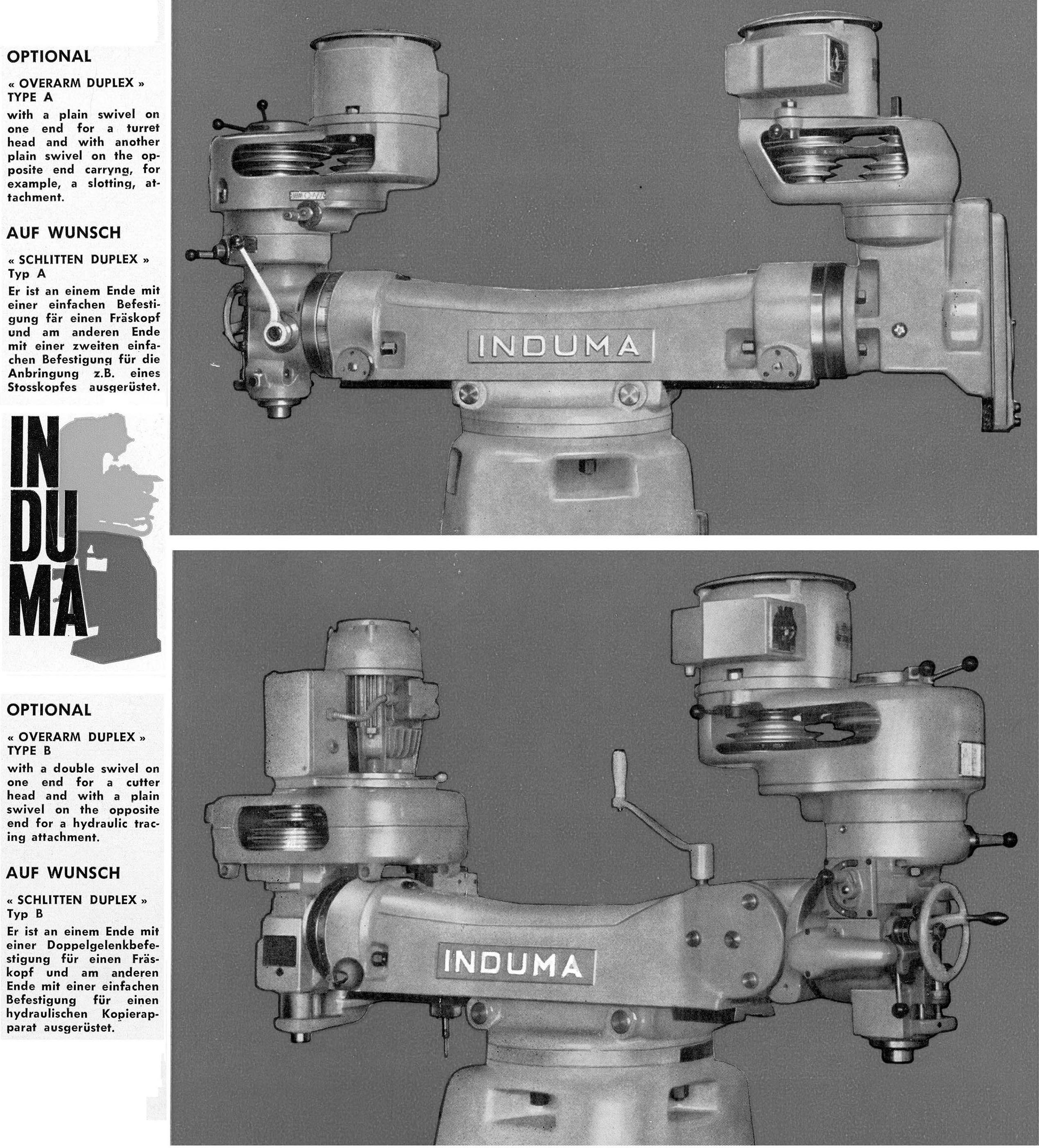

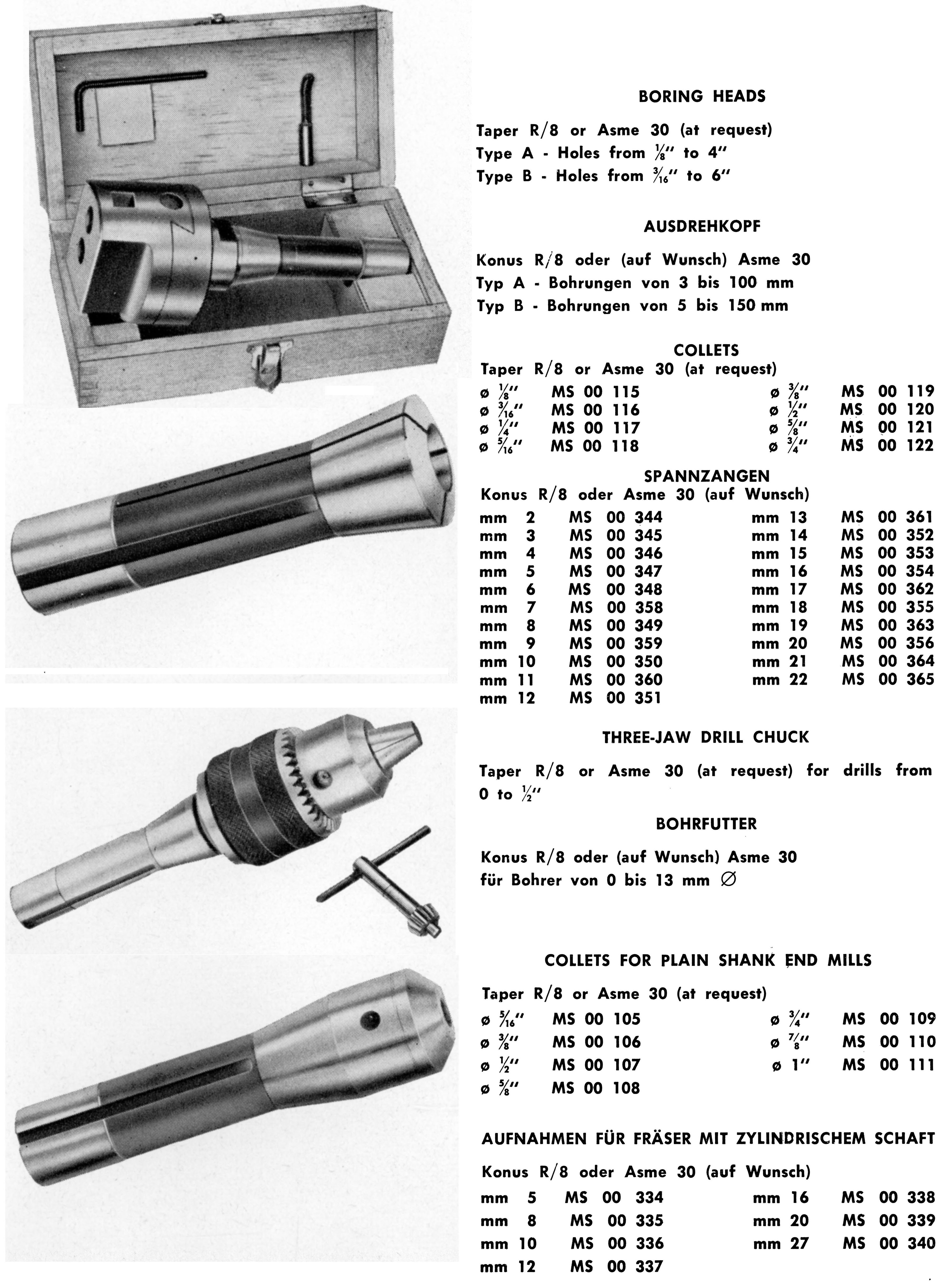

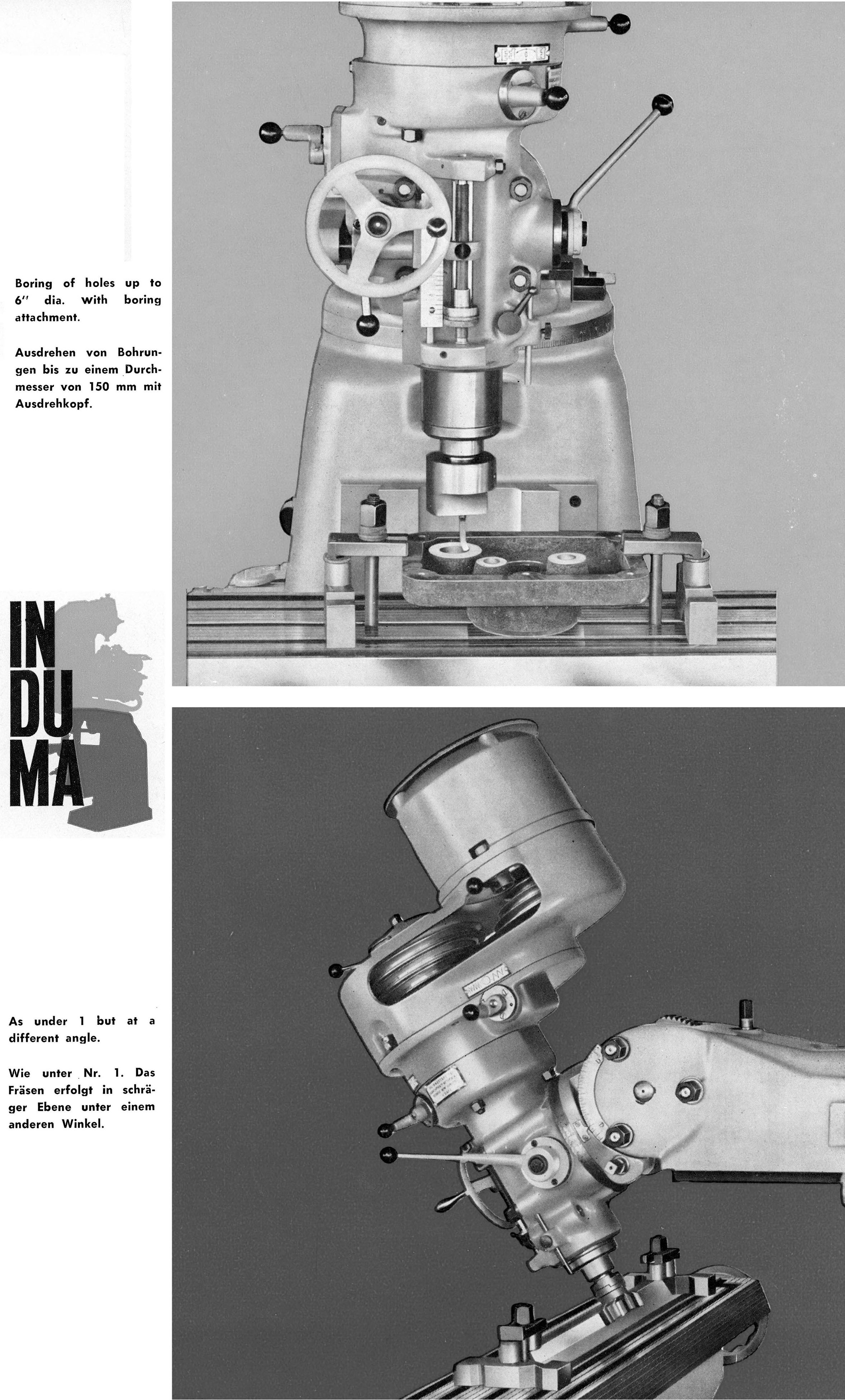

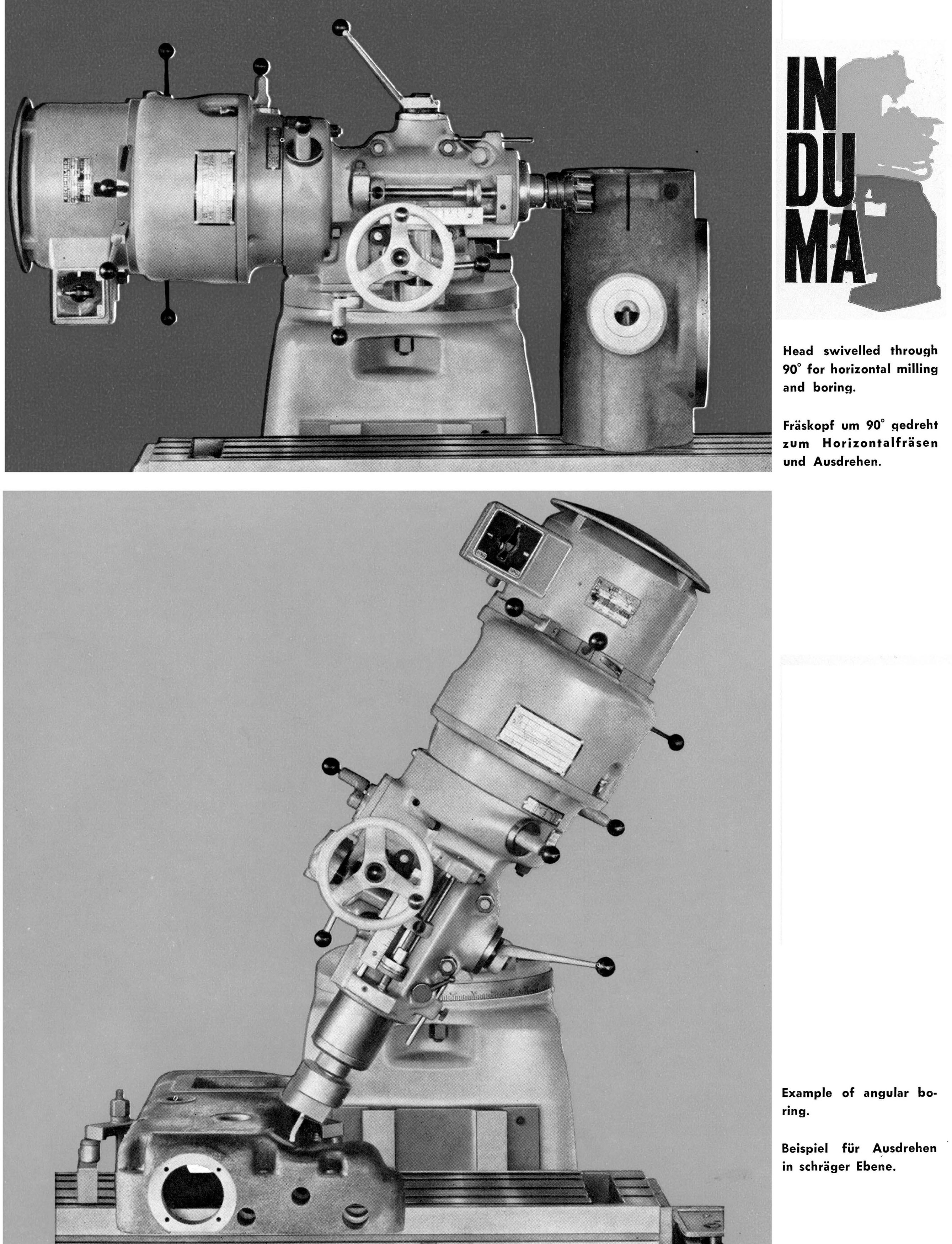

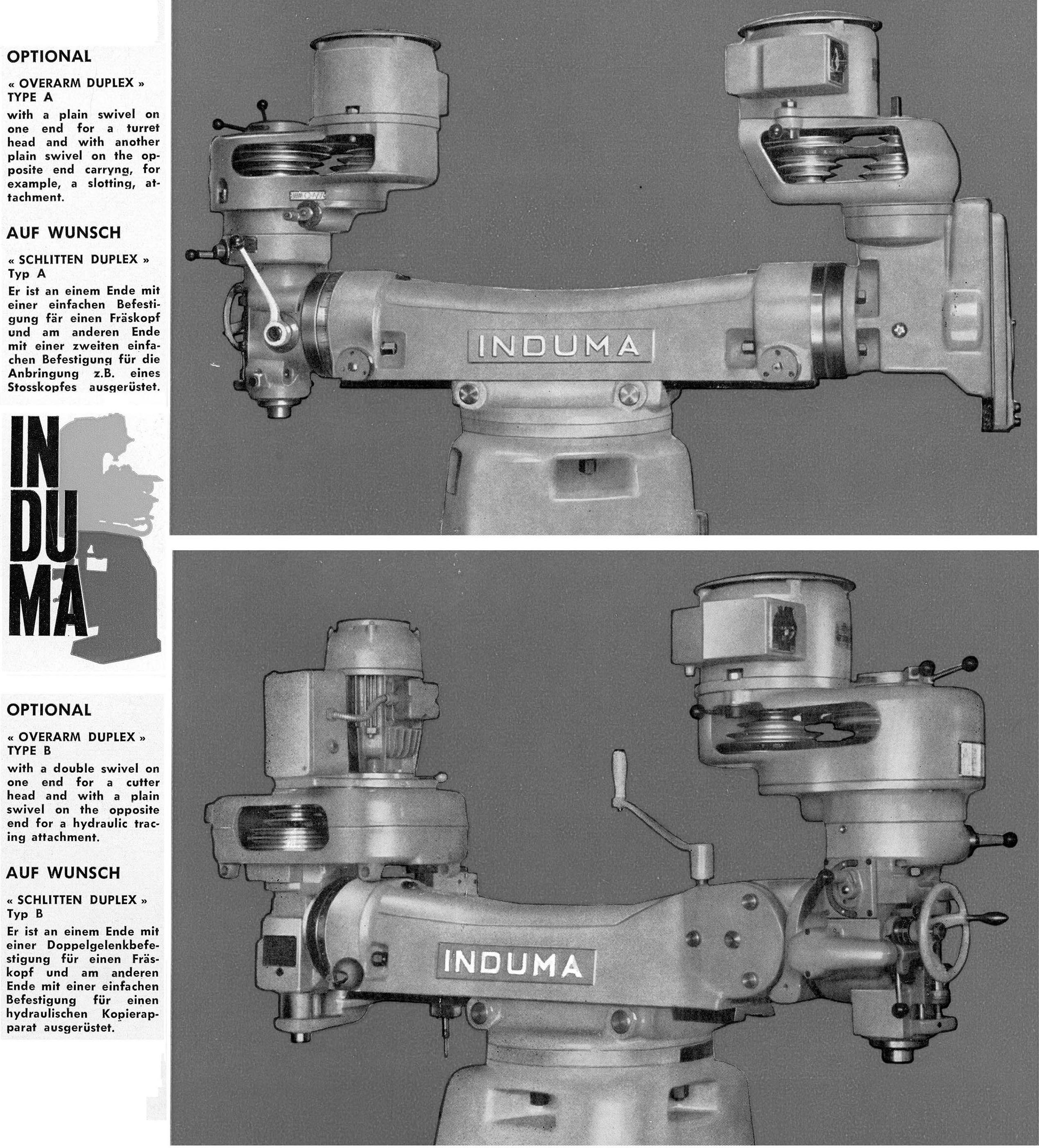

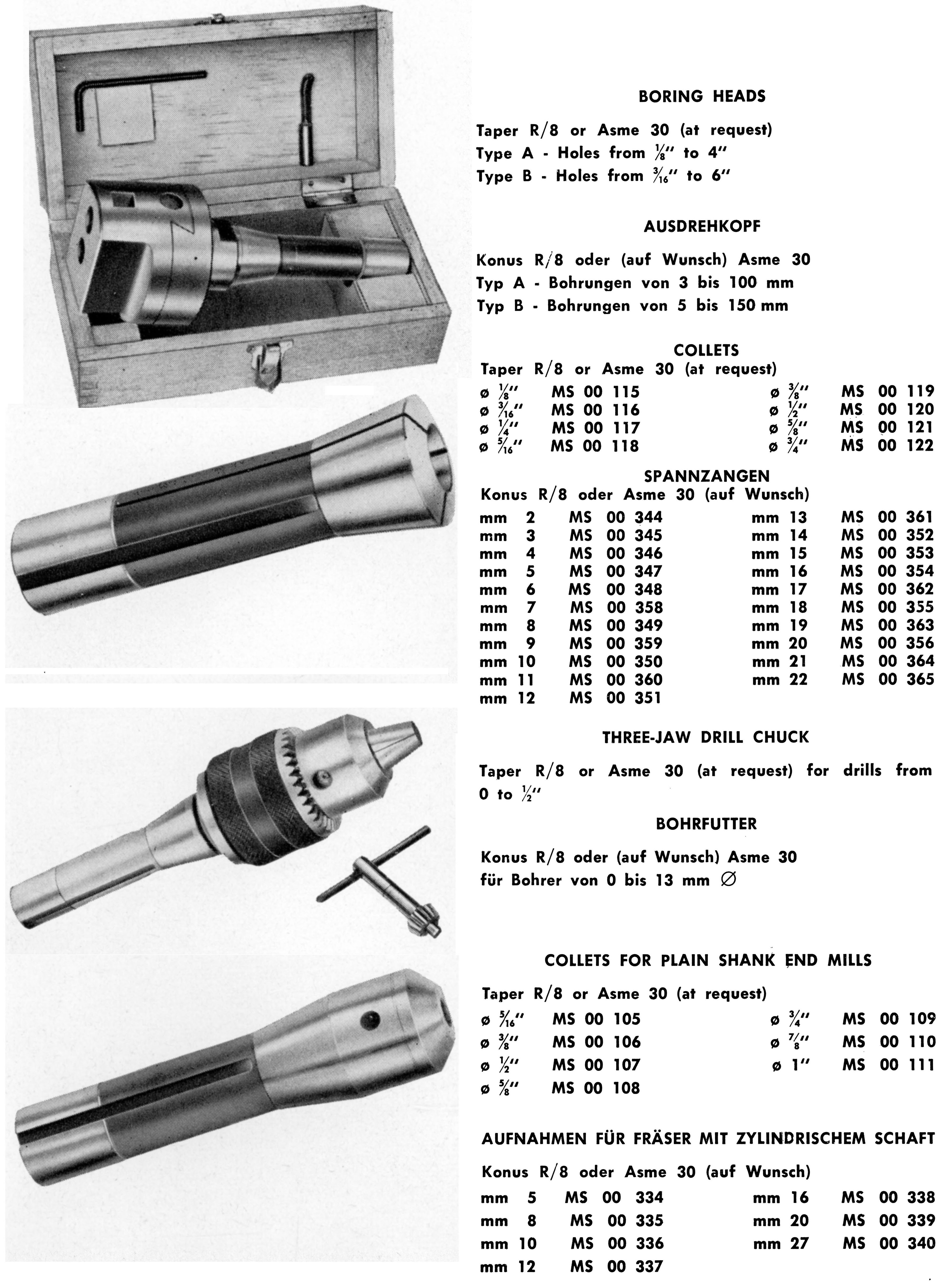

Like all of its type, the entire head unit on the 1/S-CE could be rotated on the column and the ram - of which several versions were available - advanced forwards and backwards. The ram Type A Simplex had a single mount at the front that allowed the head to swivel; the Type A Duplex had a swivel at both ends, one to carry the vertical head and the other to mount a slotting ram; the Type B Simplex had a single end that allowed the head to both swivel and nod while the Type B Duplex had a swivelling and nodding fitting at one end and carried the slotting head at the other. To engage either the milling head or slotting attachment into action was, of course, a simple matter of rotating the whole head on the column. The swivel action allowed the head to be inclined to the left or right through 90°, while the head could be nodded forwards or backwards through 40° each side of upright.

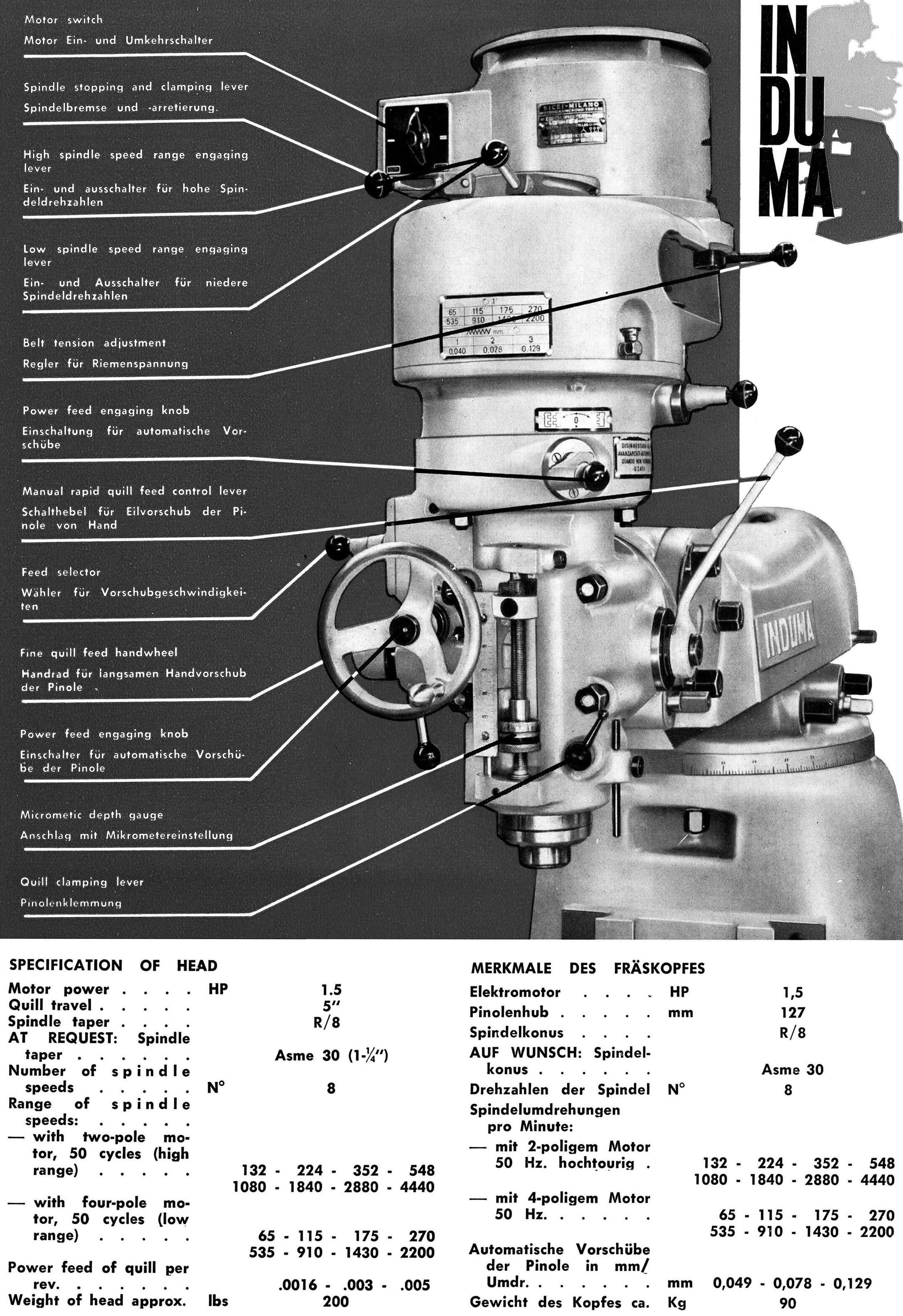

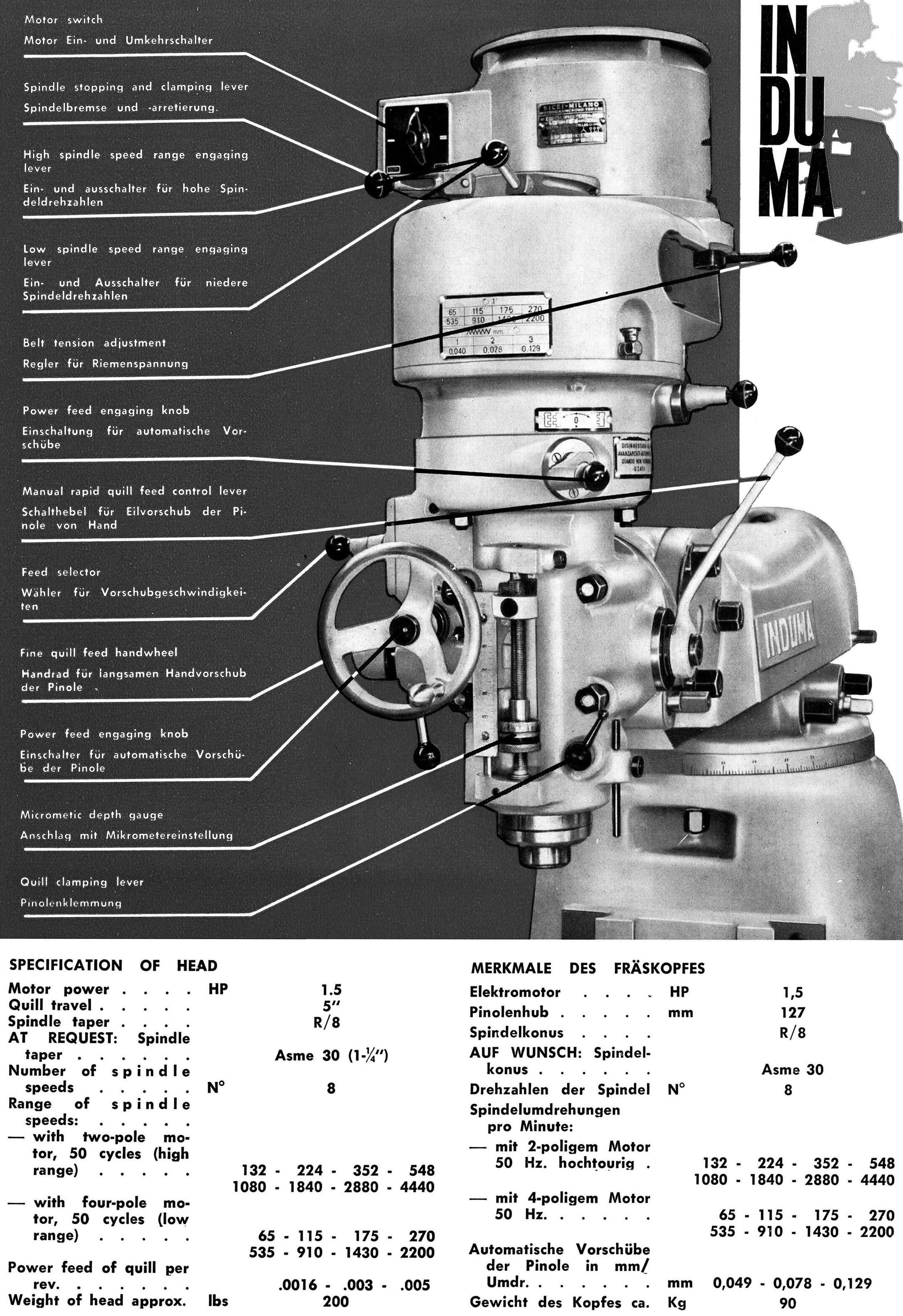

Driven at first by a 1.5 h.p. 3-phase motor - later models are found with a 2 h.p. unit - drive to the spindle was through a single V-belt running over 4-step pulleys. A choice of 4-pole 1400 and 2-pole 2800 r.p.m. motors was offered. The 4-pole motor gave eight spindle speeds that (on a 50-cycle supply) ran from 65 through 115, 175, 270, 535, 910, 1430 to 2200 r.p.m. The two-pole motor, on a 50-cycle supply, produced eight from 132 to 4440 r.p.m. The four lower speeds were driven through a separate belt and engaged by a lever on the top housing; in this range the spindle ran in the opposite direction to the high-speed range, making use of the motor reversing switch essential.

One option not listed but almost certainly available (as it was on the 1?s and 1S-43 versions) was a variable-speed head that, when fitted with a 50-cycle 2 h.p. motor, gave speeds from 60 to 4000 r.p.m. and on a 60-cycle supply from 70 to 400 r.p.m.

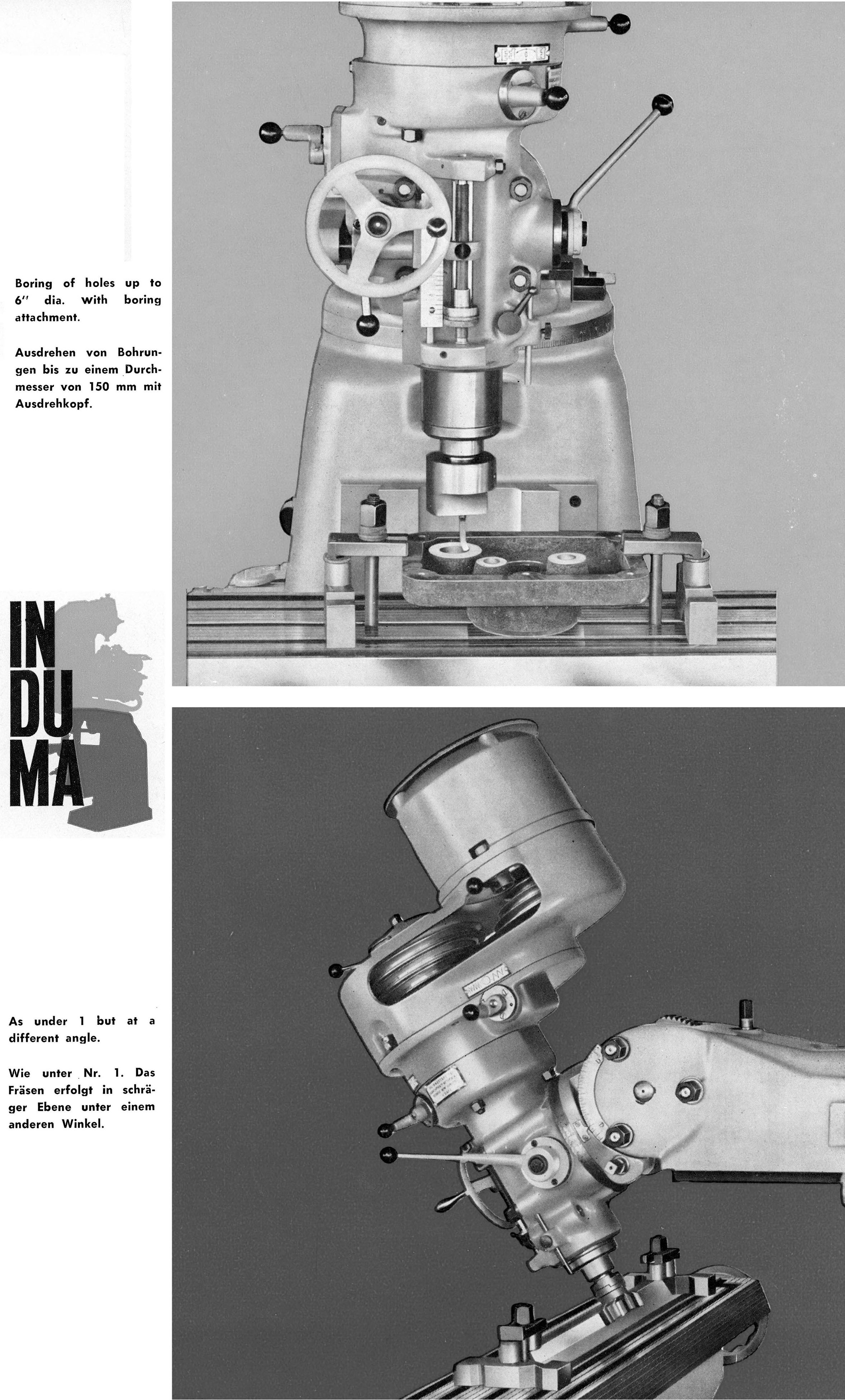

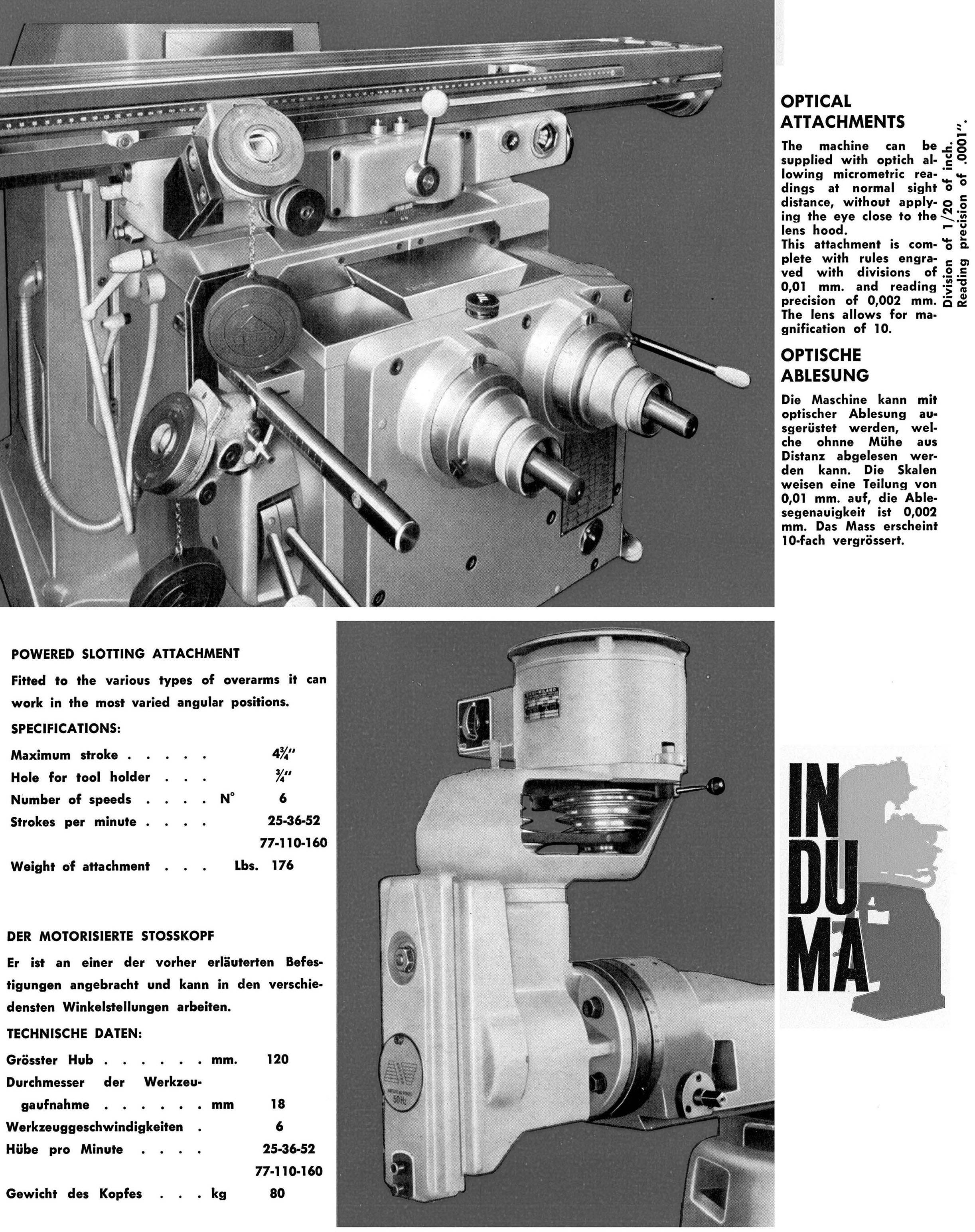

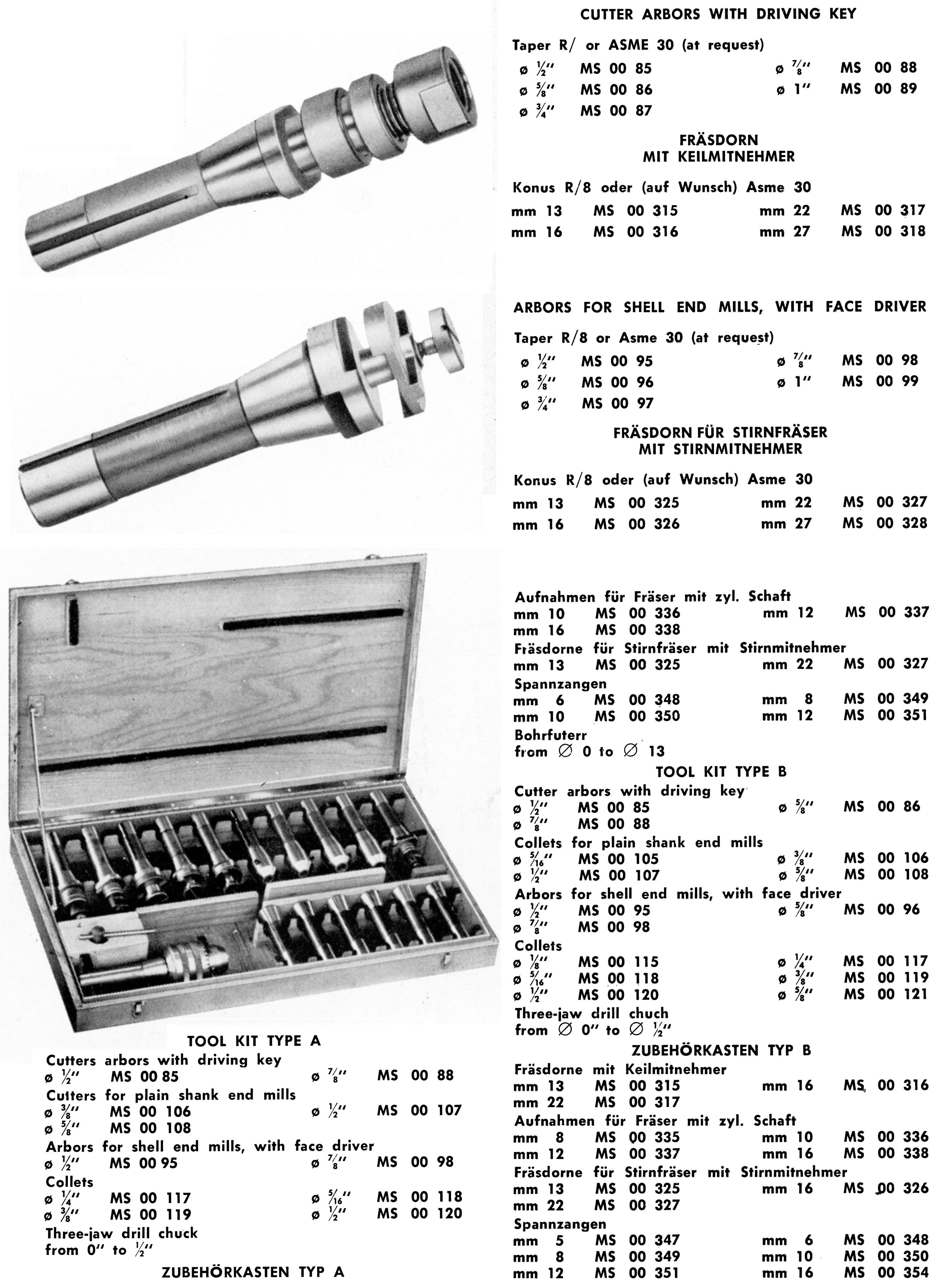

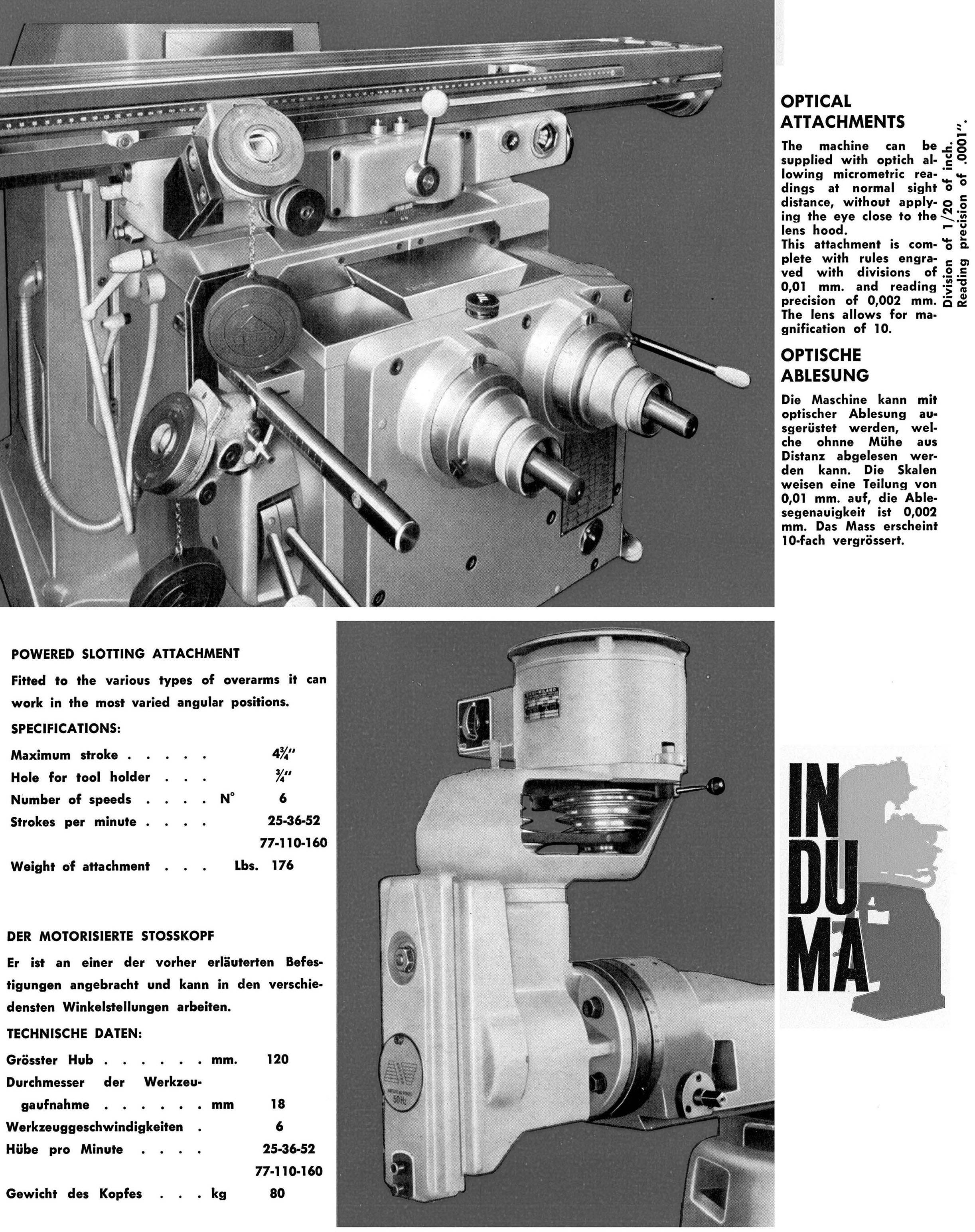

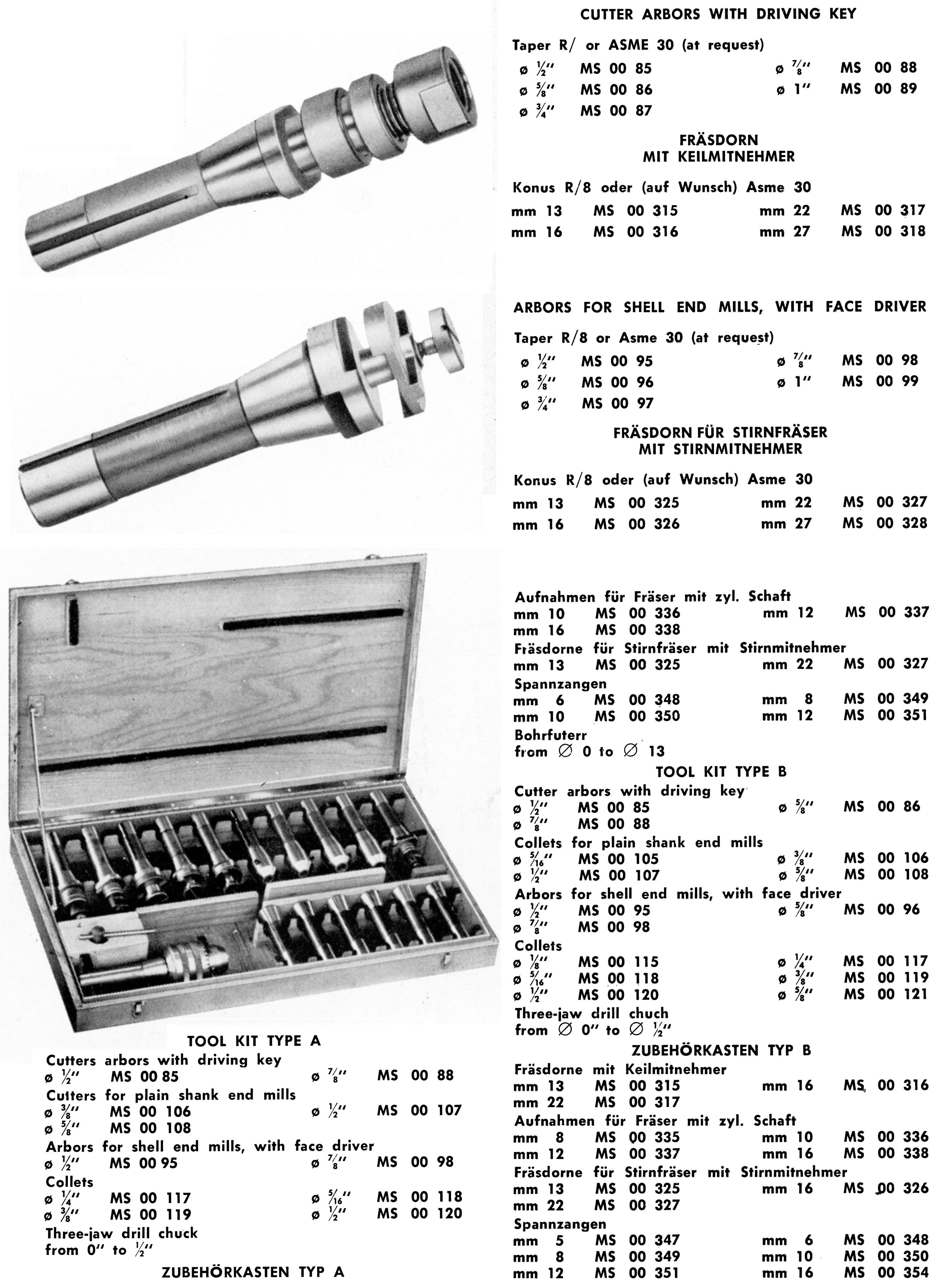

The spindle was fitted, as standard, with a Bridgeport-type R8 nose and held in a quill that had 5 inches of travel. Quill feed could be by a quick-action lever for drilling, by a fine-feed handwheel through worm-and-wheel gearing - or by power. With the power feed engaged, three rates of travel became available: 0.0016, 0.003 and 0.005 inches ((0.049, 0.078 and 0.129 mm) per spindle revolution.

The 1/S-CE stood 81.5" (2070 mm) high, spanned 62" (1578 mm) over the table handles and weighed approximately 2450 lbs (1000 kg). The full technical specification (in English and German) options and accessories are all shown below..