|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

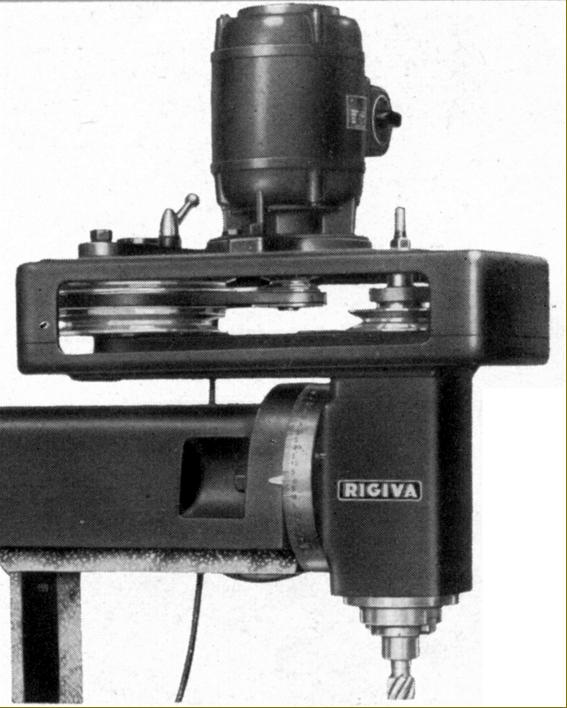

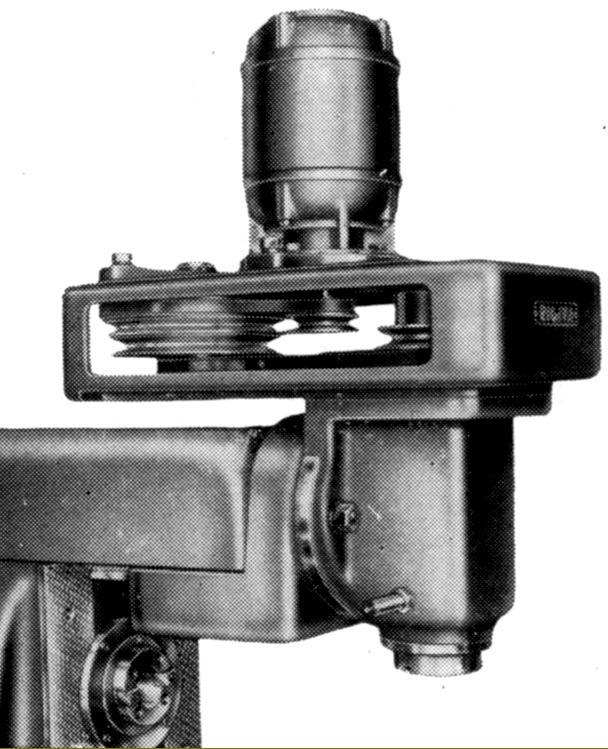

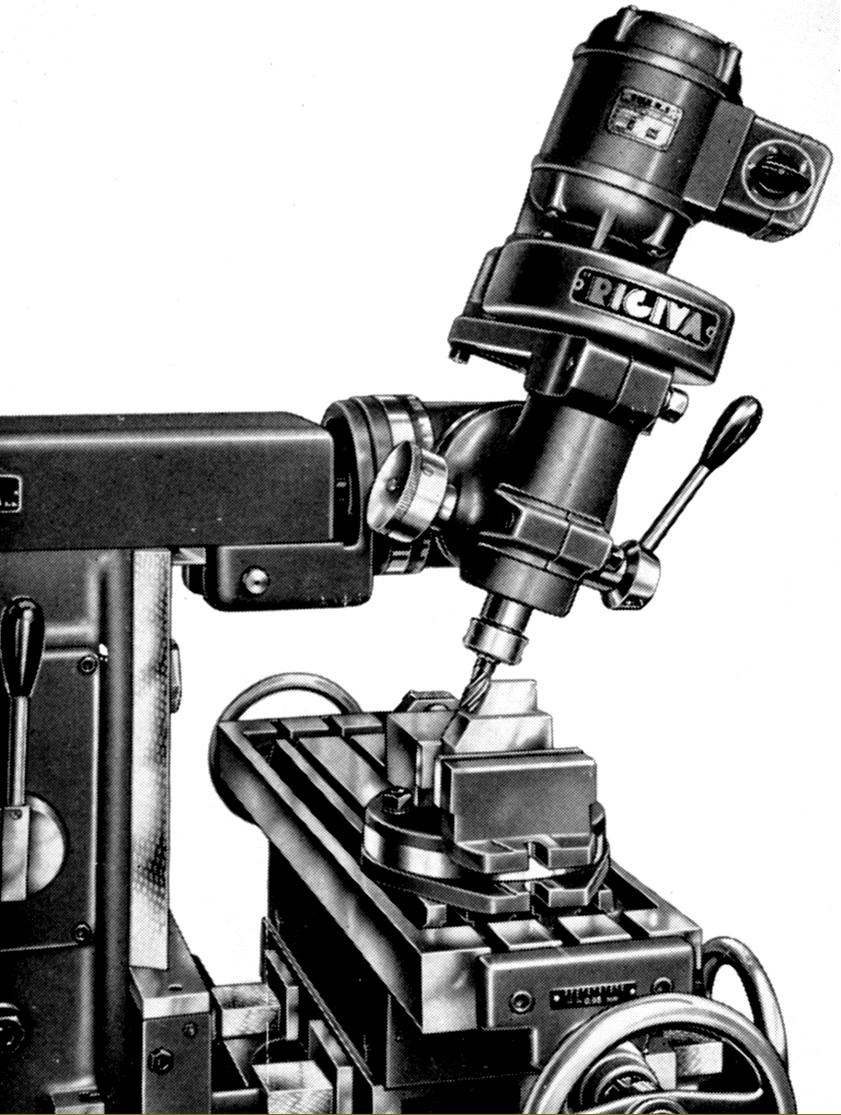

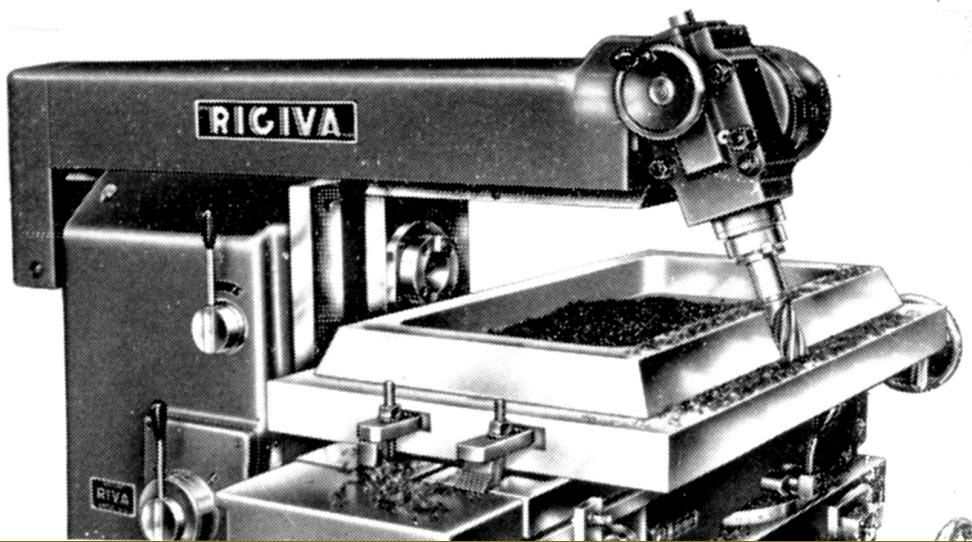

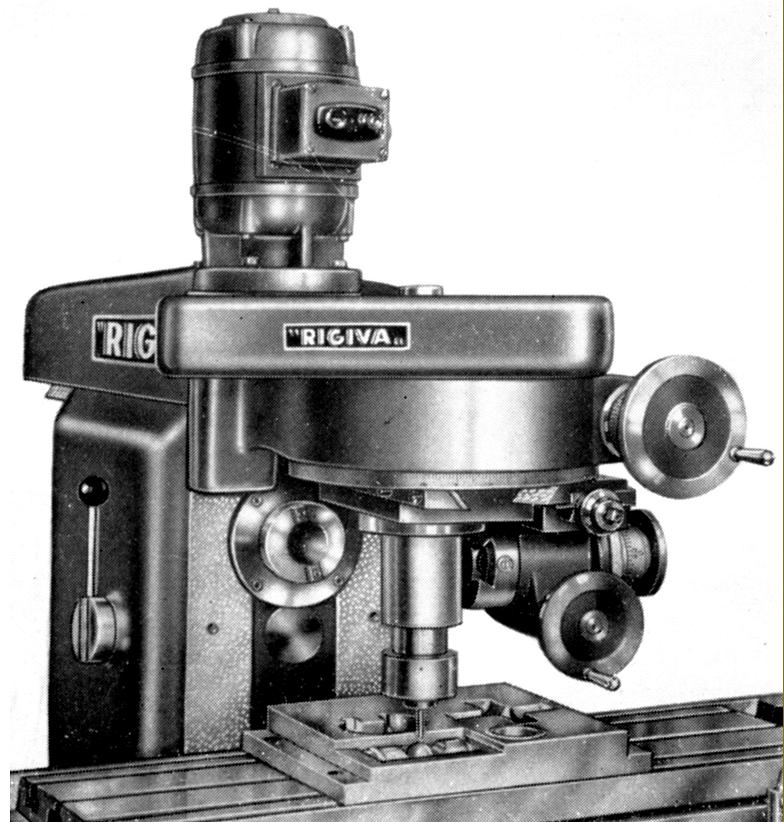

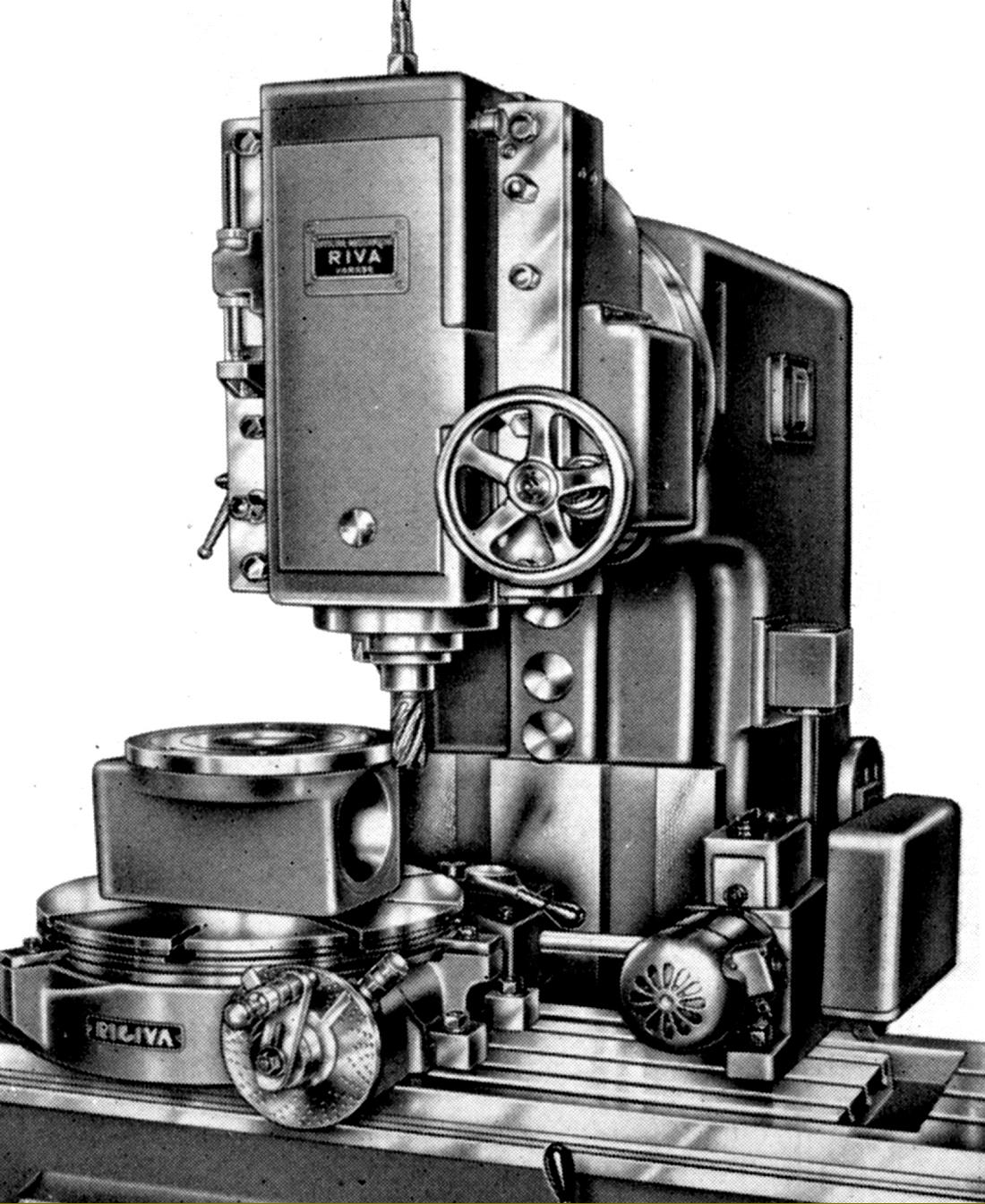

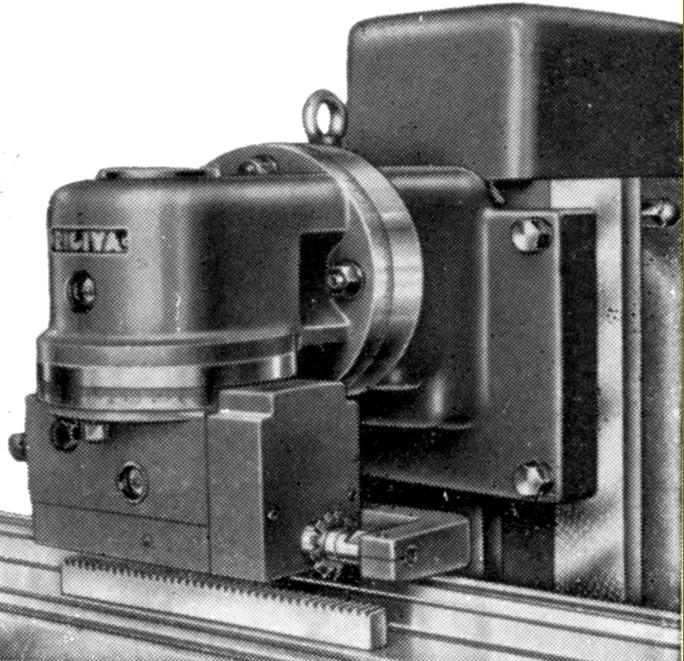

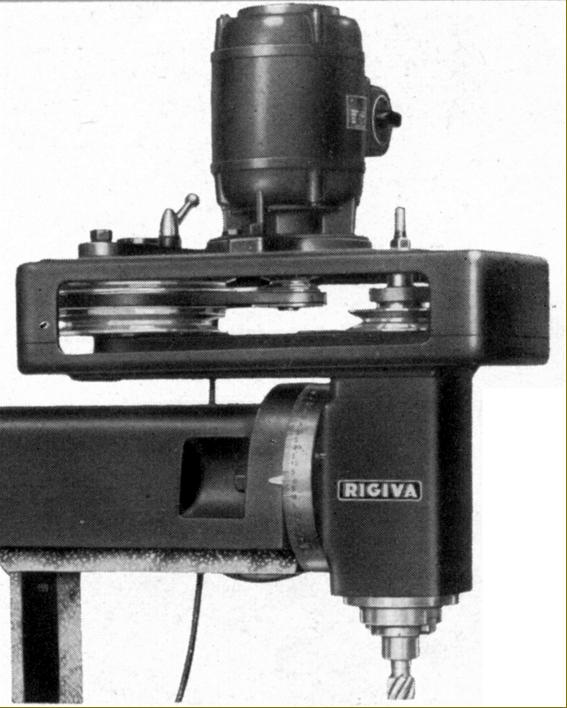

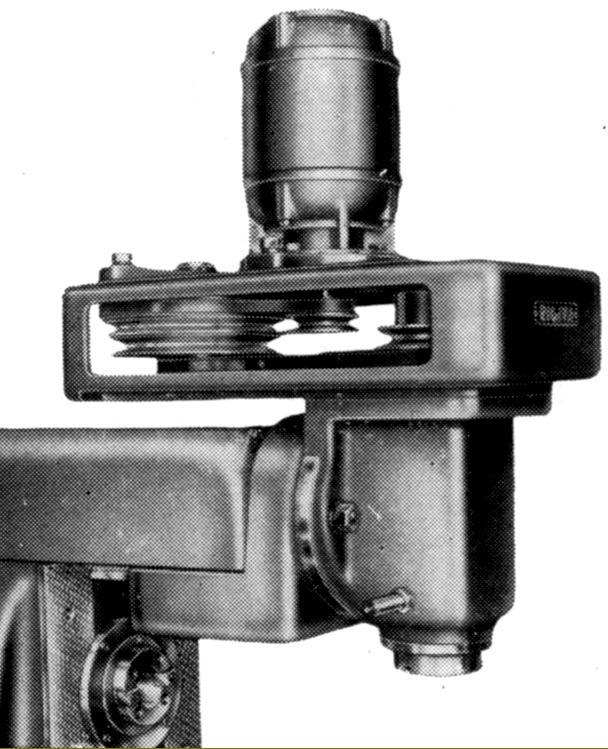

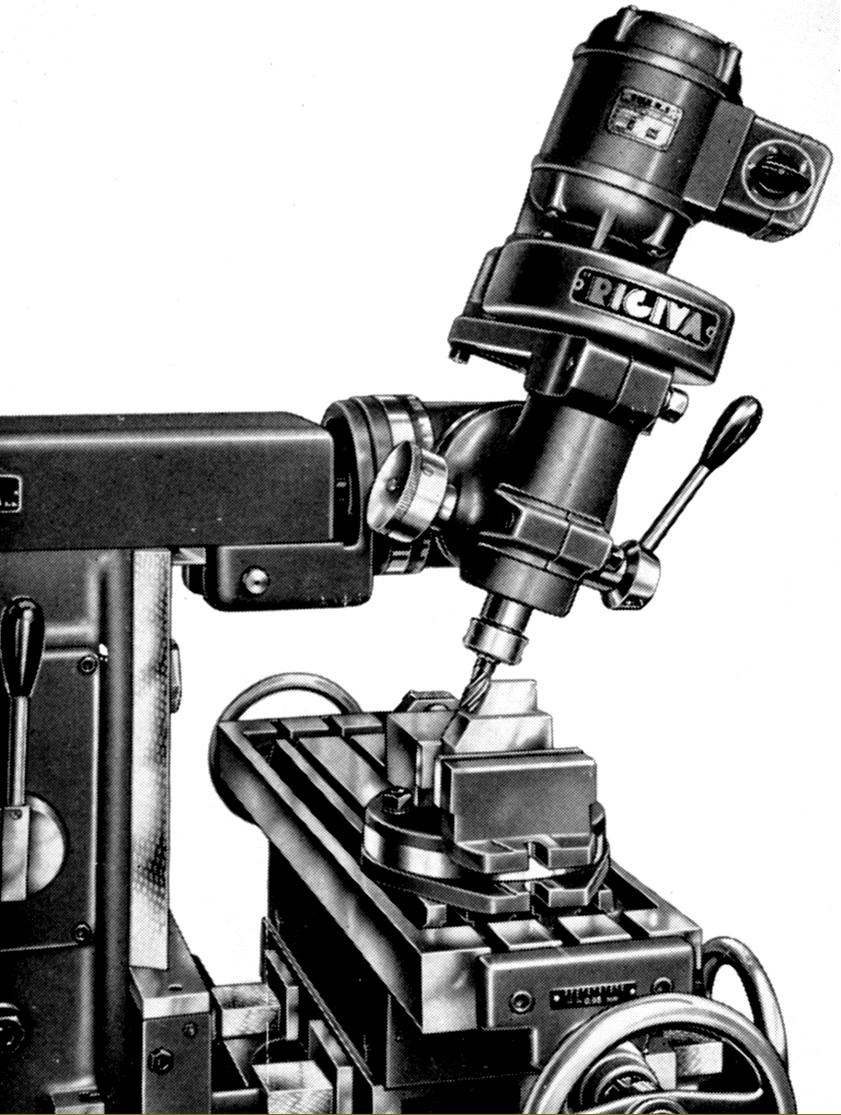

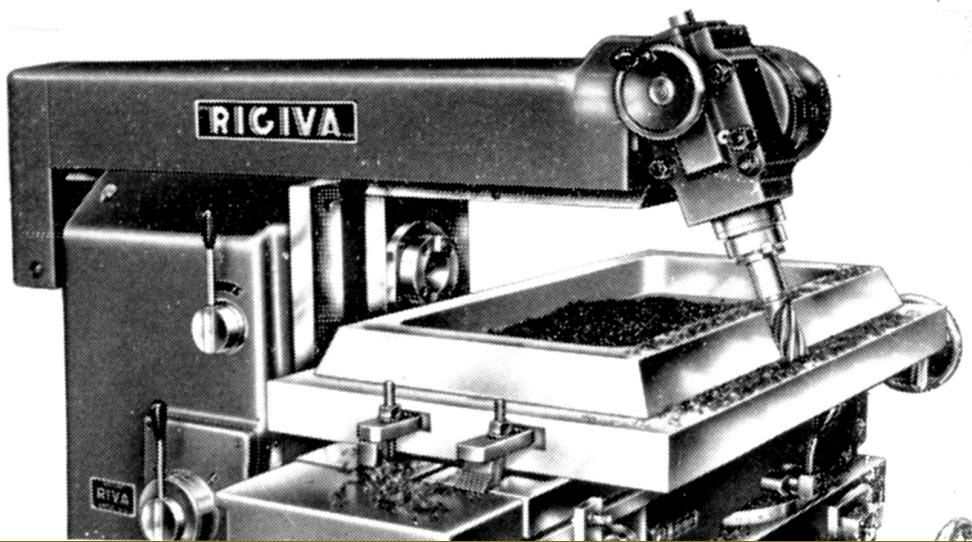

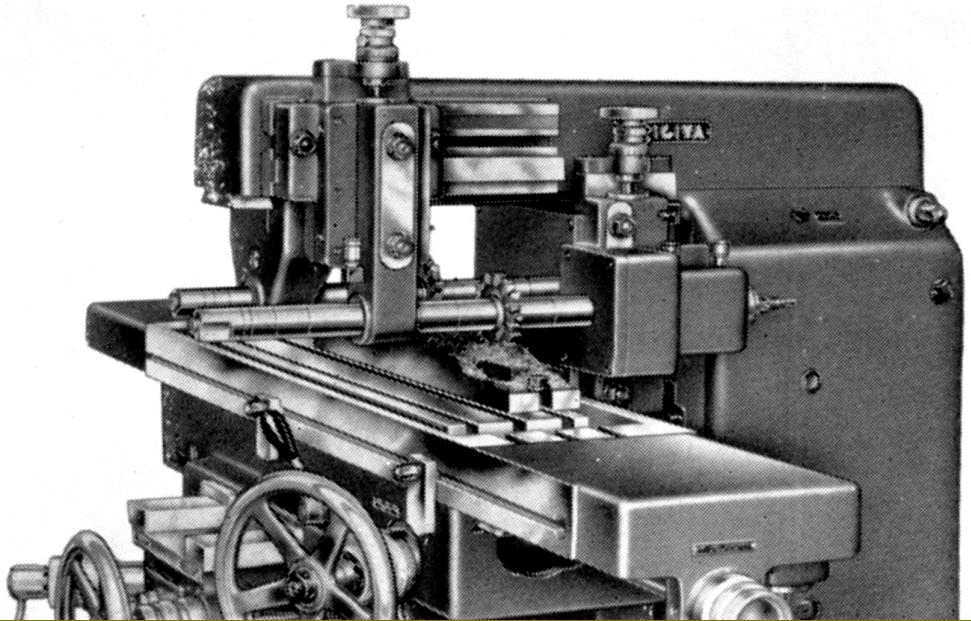

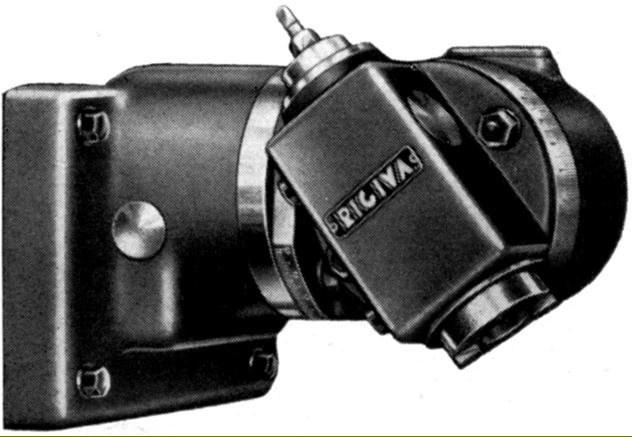

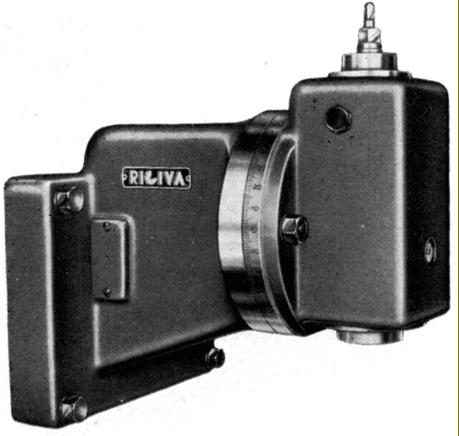

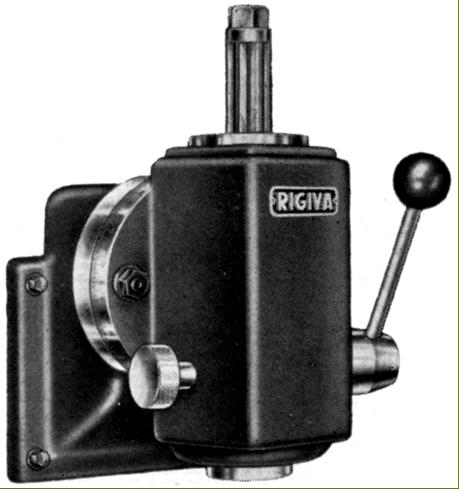

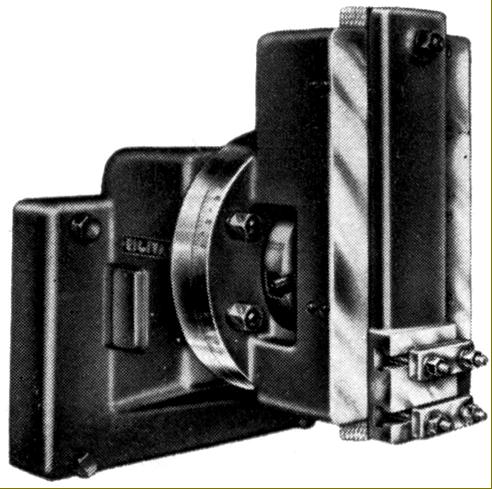

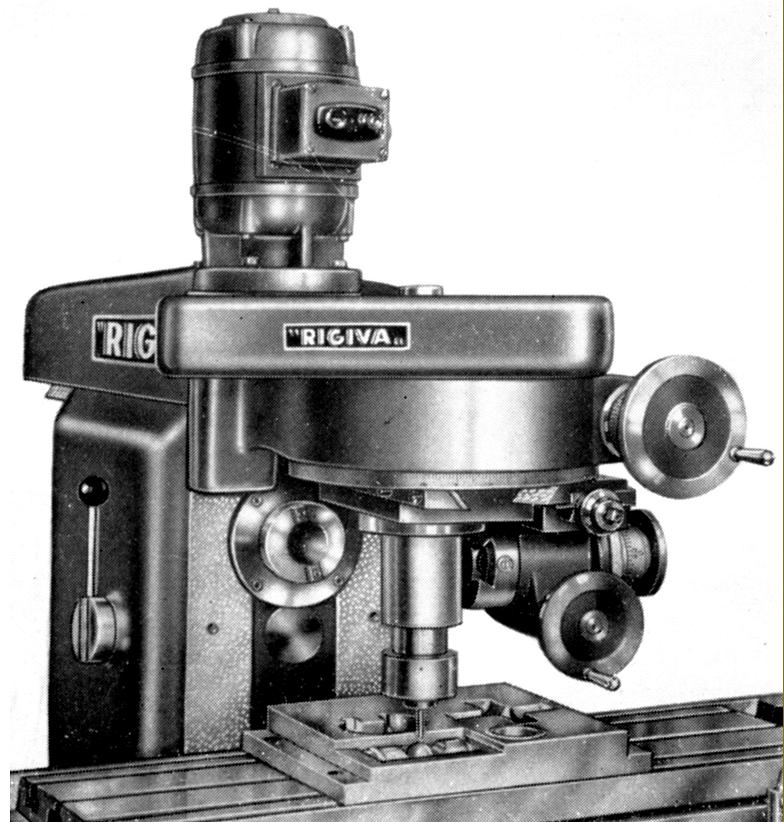

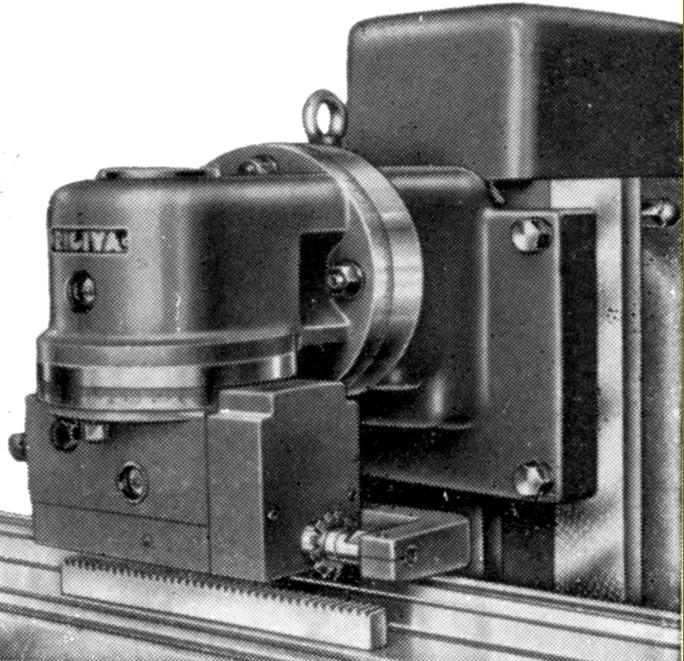

This High-speed Milling Head was used, unaltered, on a wide range of Riva millers. It changed a little in design over the years and was available with a number of mounting options including a bolt-straight-to the-face type, with a supporting right-angle casting or with a double-swivel mount. The 2-speed, 1/0.75 hp motor carried a 2-step pulley that drove rearwards by V-belt to jockey pulley that had 2-speed drive forwards by V-belt to the lathe spindle. 8 speeds were provided of 150, 220, 300, 440, 700, 1000, 1400 and 2000 r.p.m.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

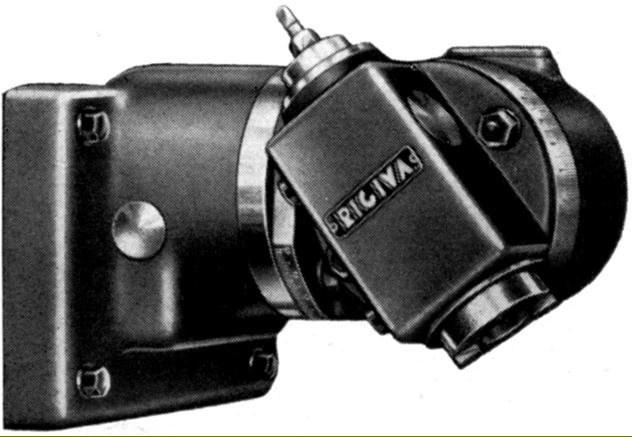

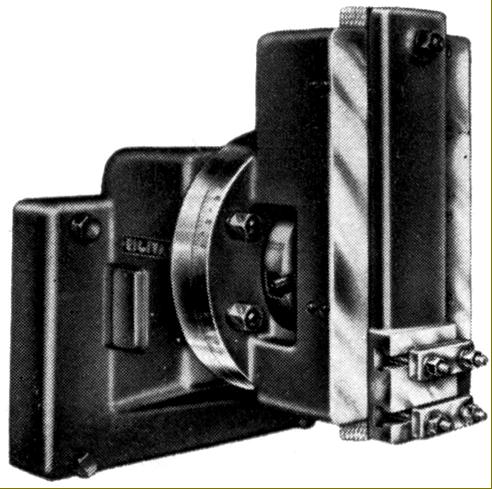

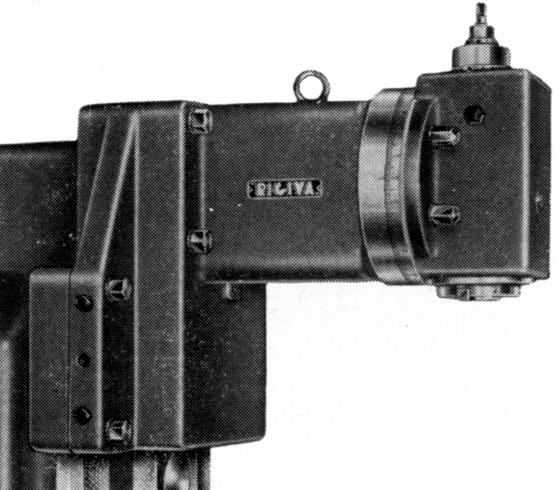

High-speed Head with a reinforced, single-swivel mounting

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

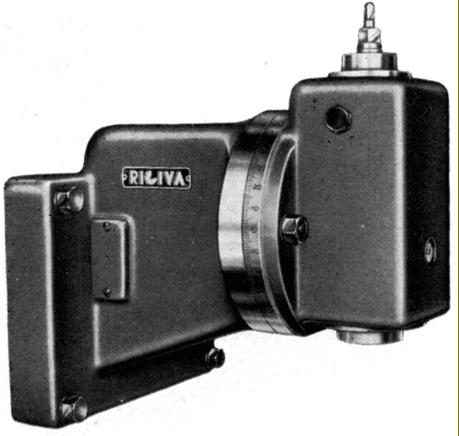

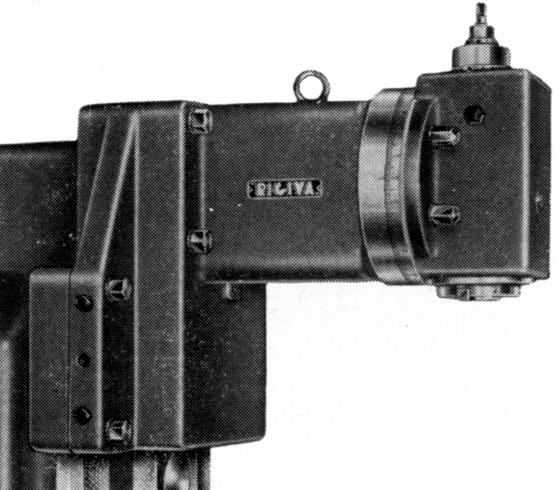

High-speed Head with double-swivel mount

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

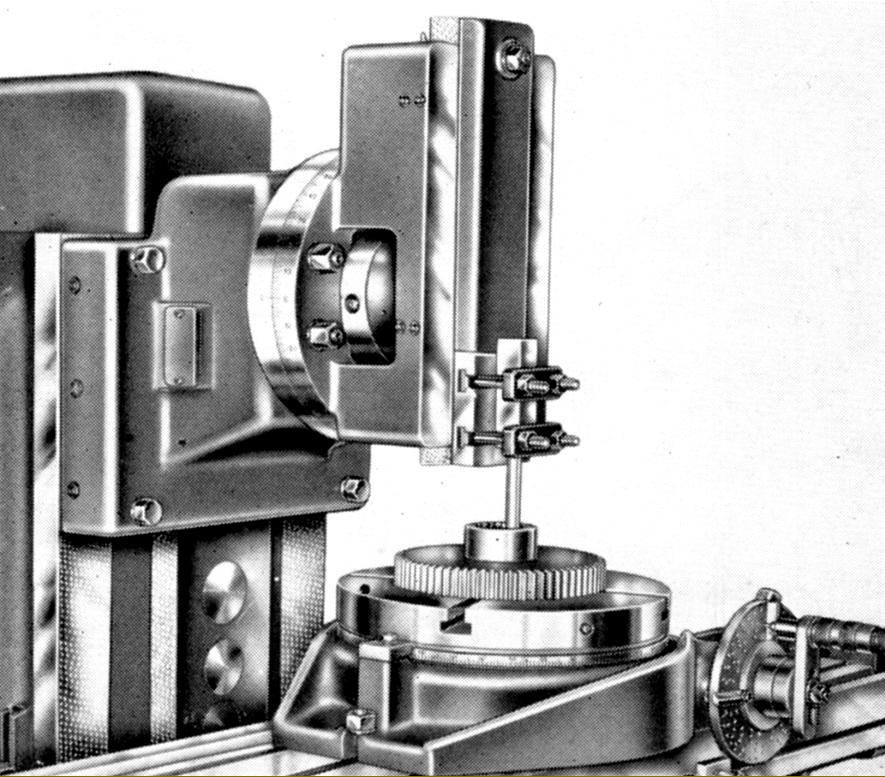

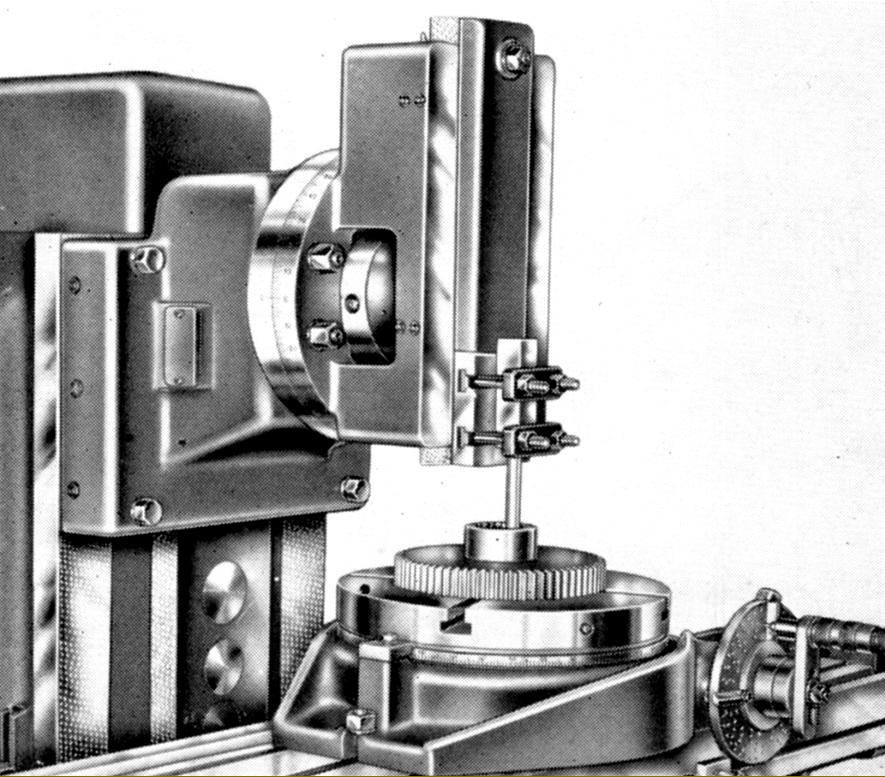

The High-speed Head on a double-swivel mount set-up to machine an awkward job

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Another view of the high-speed head on a double-swivel mount

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

An unusual swivel-mounted vertical head, with a fine-feed by handwheel. The drive passed down the inside of the overarm having been picked up from an extension to the rear of the horizontal spindle.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For production work a double arbor attachment was available. A special overarm was machined on an outside face with a T-slot and rectangular guide-way onto which was mounted a bracket to take the end of the second arbor. The assembly could be adjusted vertically over a small distance to allow an accurate setting of the second cutter.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

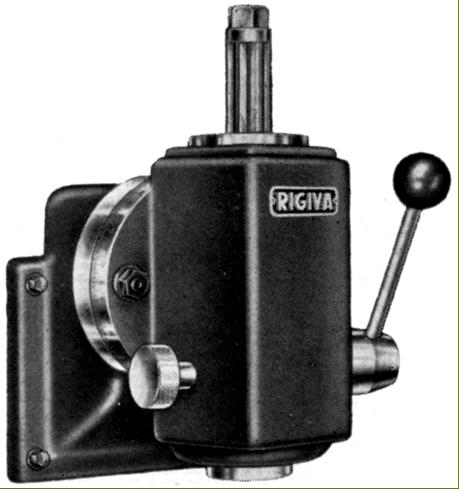

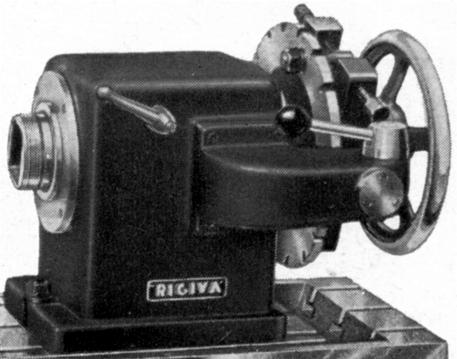

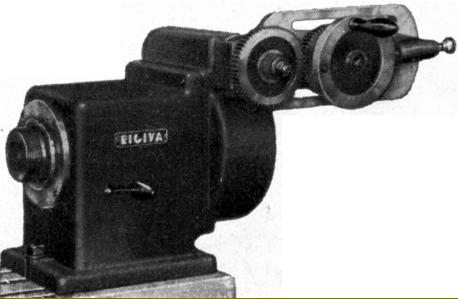

Double-swivel Vertical head Type T.U.4 with a No. 3 Morse taper and speeds from 70 to 1500 r.p.m.

|

|

|

|

|

|

|

Swivel-end Vertical Head Type T.V.2 with a No. 3 Morse taper and speeds from 70 to 1500 r.p.m.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vertical head Type T.M.2 with a No. 3 Morse taper and a quill movement of 50 mm

|

|

|

|

|

|

|

|

Inclinable Slotting Head Type M.2

with a stroke adjustable between 0 and 70 mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Slotting head in use putting a key way into the bore of a gear

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A special Raised Vertical Head designed to give a greater clearance beneath the cutter

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S.G. "cherrying head" - intended for the production of geometrically shaped dies and other awkward jobs. It was also fitted to two dedicated machines, the heavier Type S.G.A. and lighter S.G.M. Speeds from 450 to 3600 r.p.m. were available.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

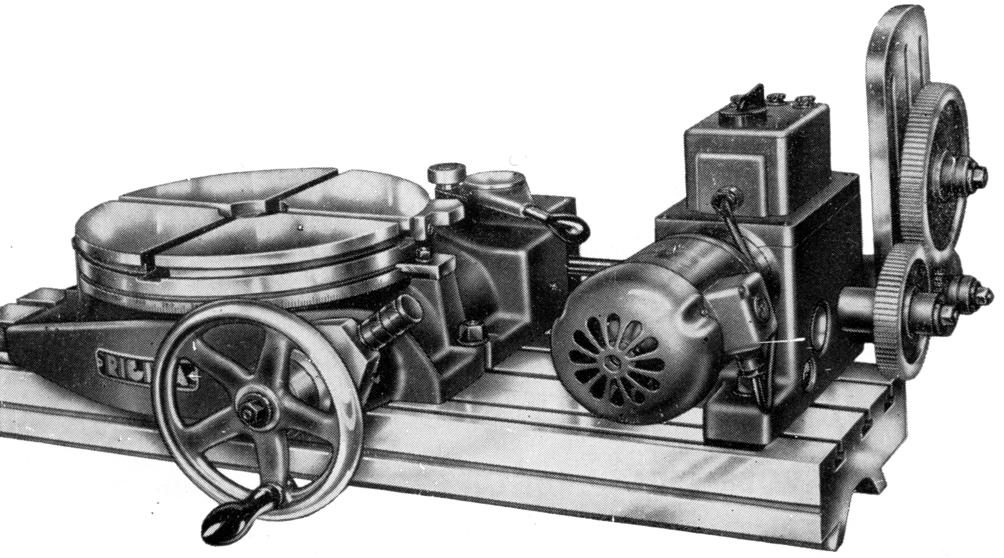

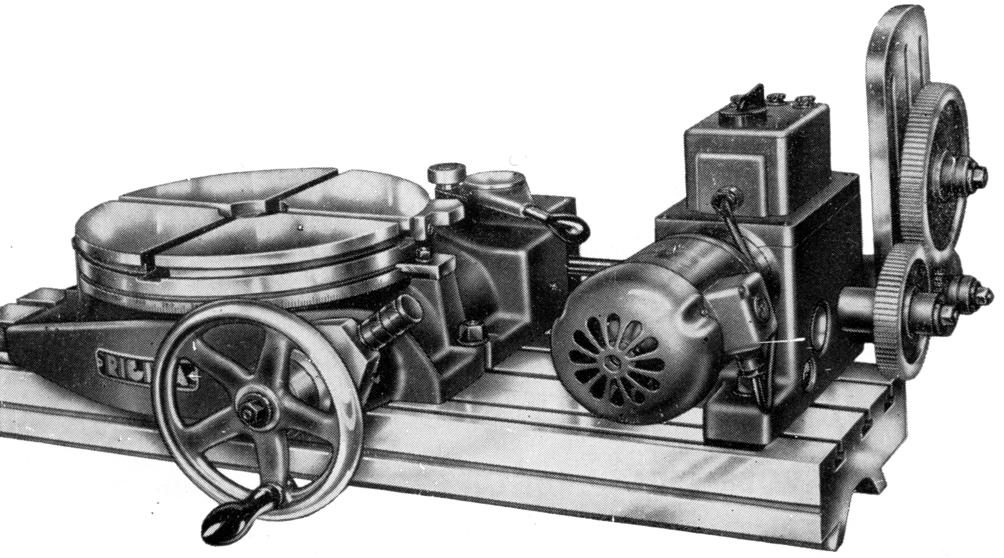

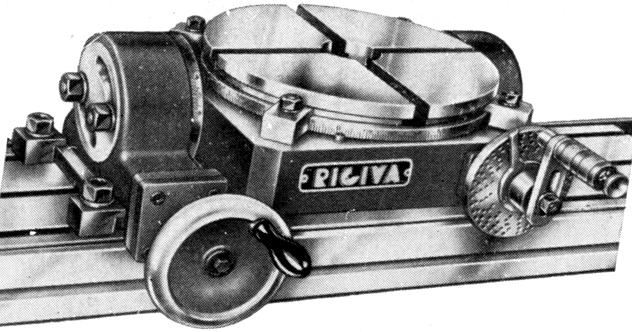

Automatic Motorised Rotary Table Type T.G.A. This unit was produced with a table diameter of 350 and 500 mm. Speeds were set by external, interchangeable gears with a manual stop/start by lever. In addition an automatic mechanical stop was provided at the end of the stroke in each direction

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

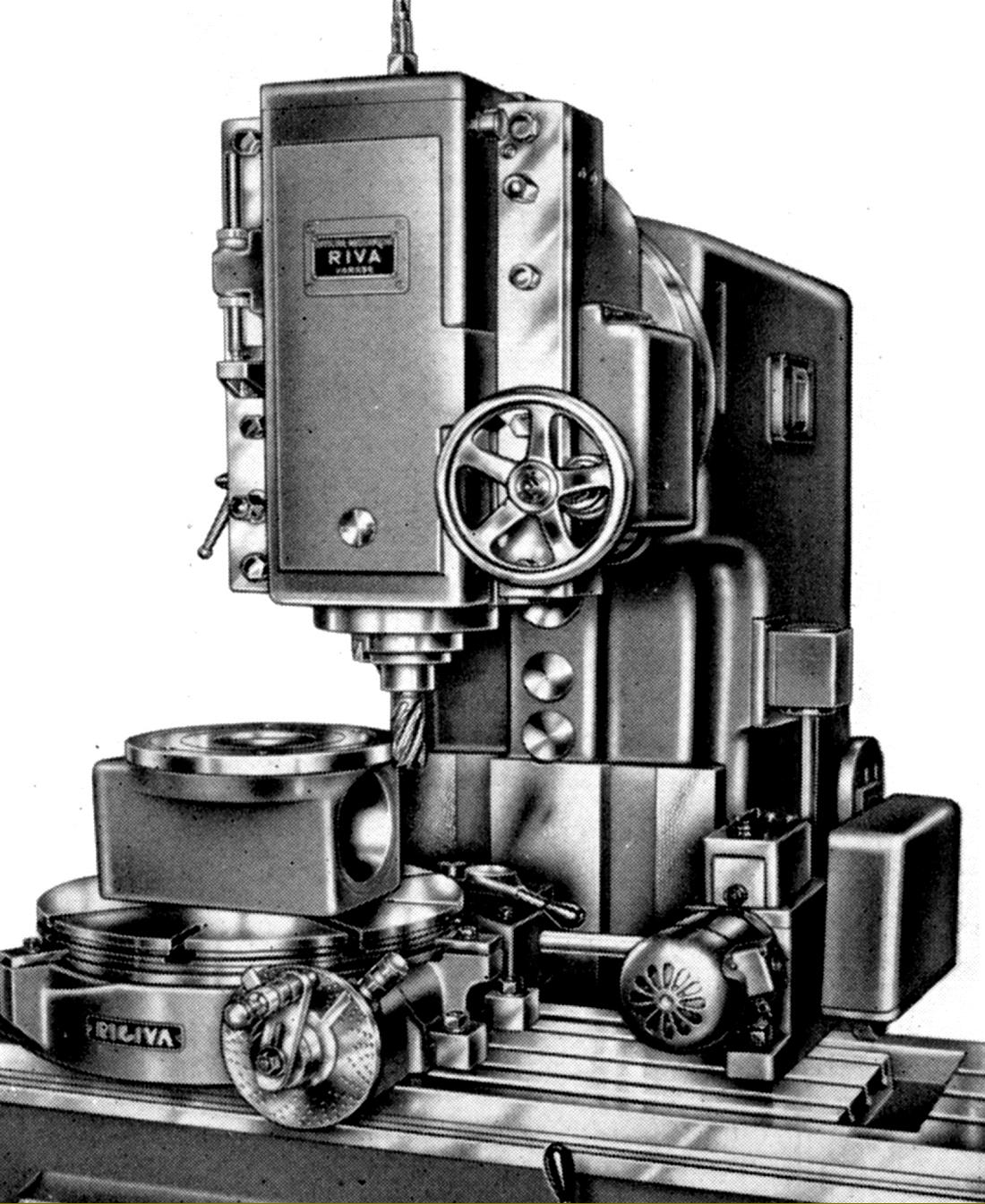

Automatic Motorised Rotary Table Type T.G.A. in use milling the periphery of a casting

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

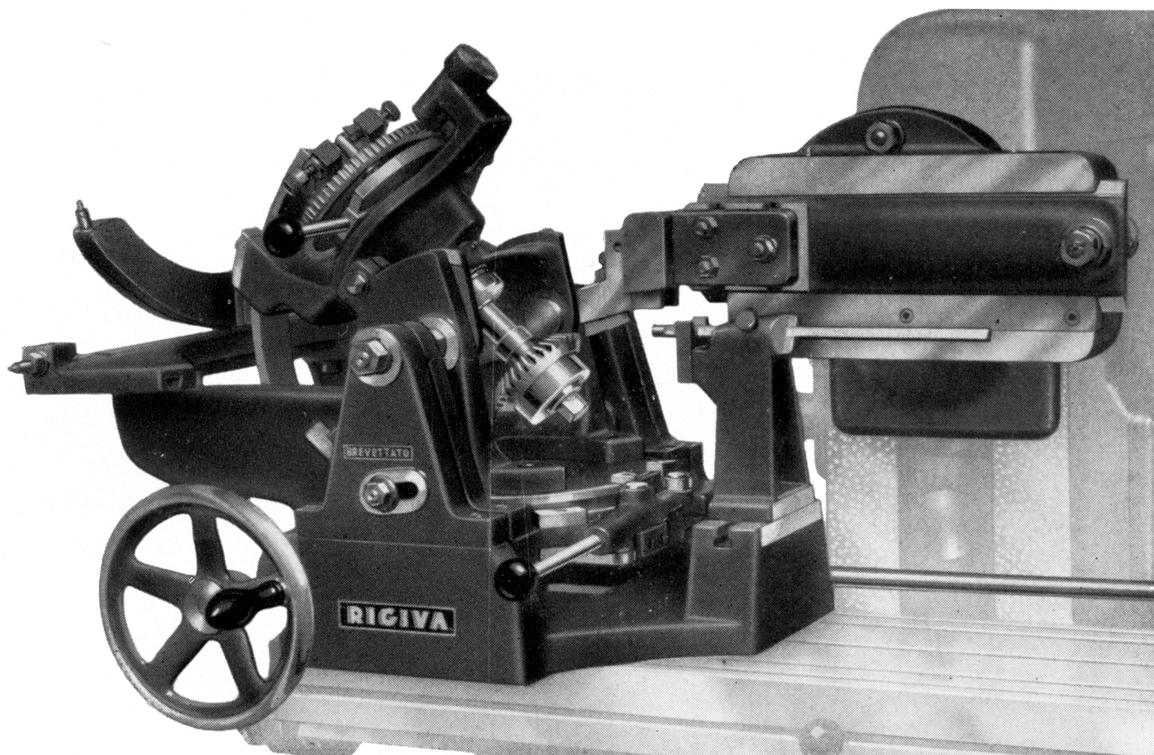

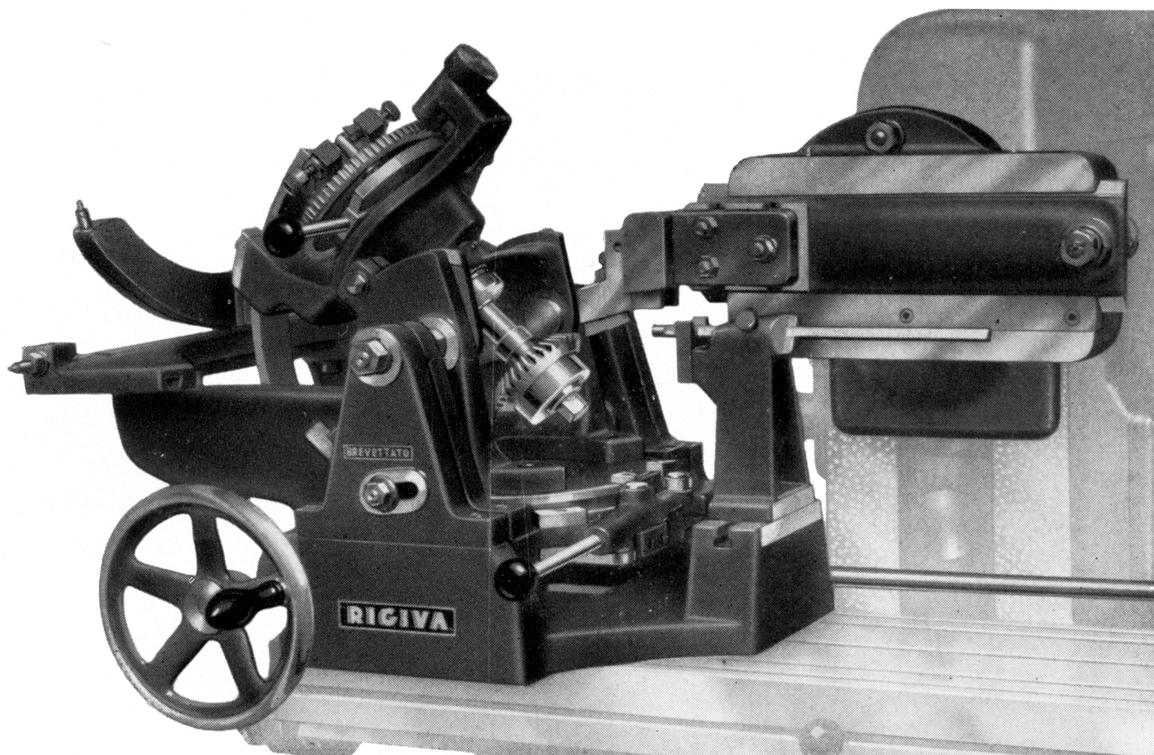

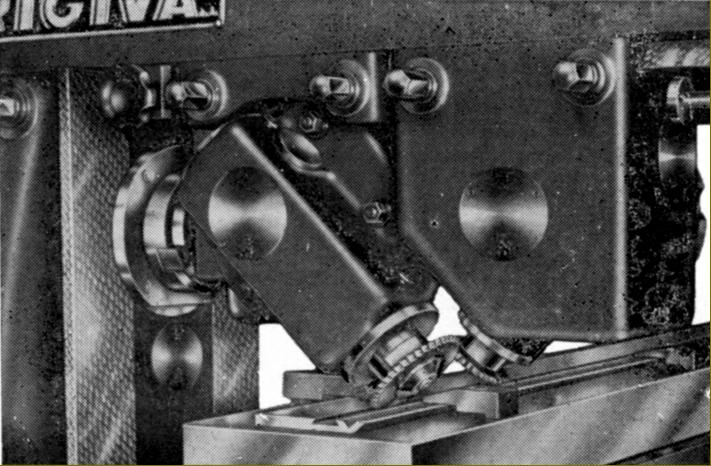

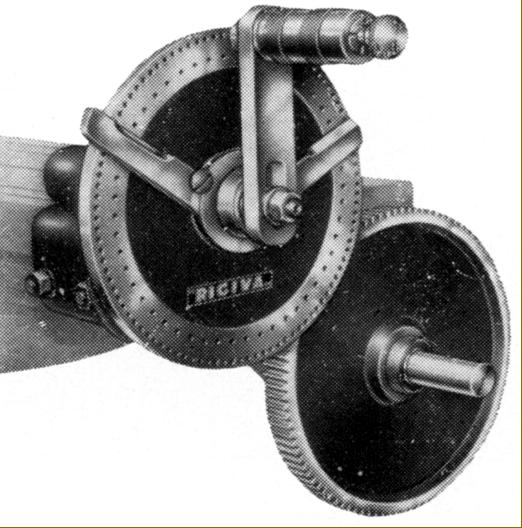

Type C Bevel Gear Machining Attachment. Used in combination with the standard slotting attachment (see mounted, horizontally, at the right) the largest diameter of gear that could be handled was 180 mm with a maximum of a No. 4 Module. The generation of the involute was obtained by rolling the arched sector (top left) while a single cutter, used with a planing motion, finished each side of the tooth in turn.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

By using one of the Type T.V. vertical heads turned through 90° and a special attachment horizontal boring became possible

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

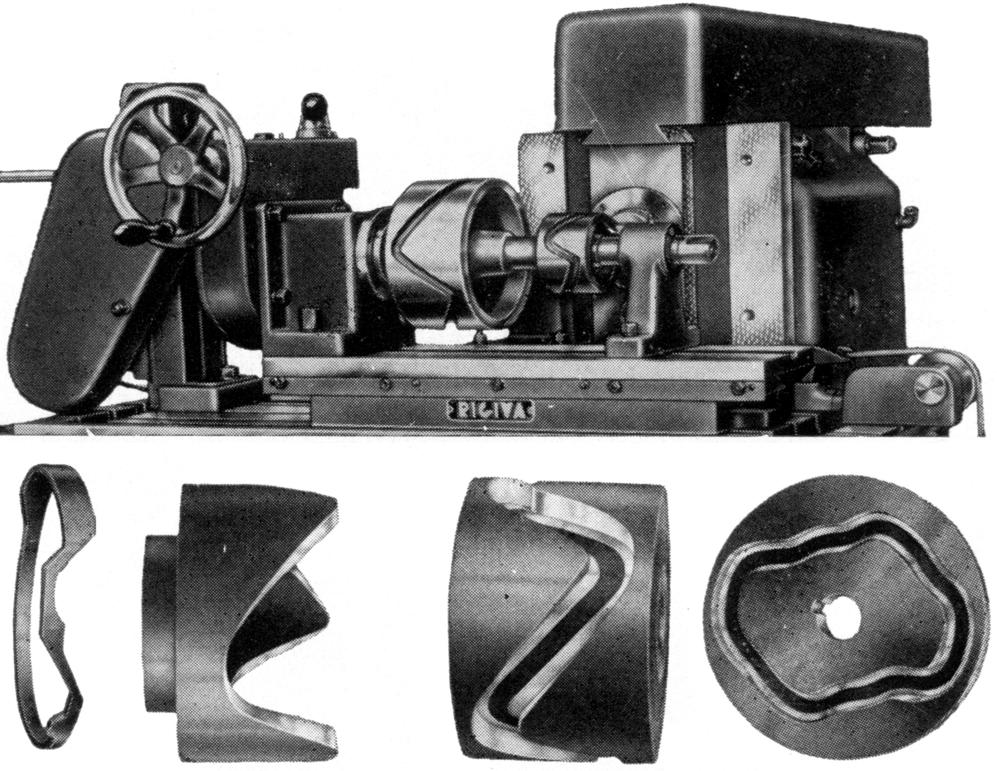

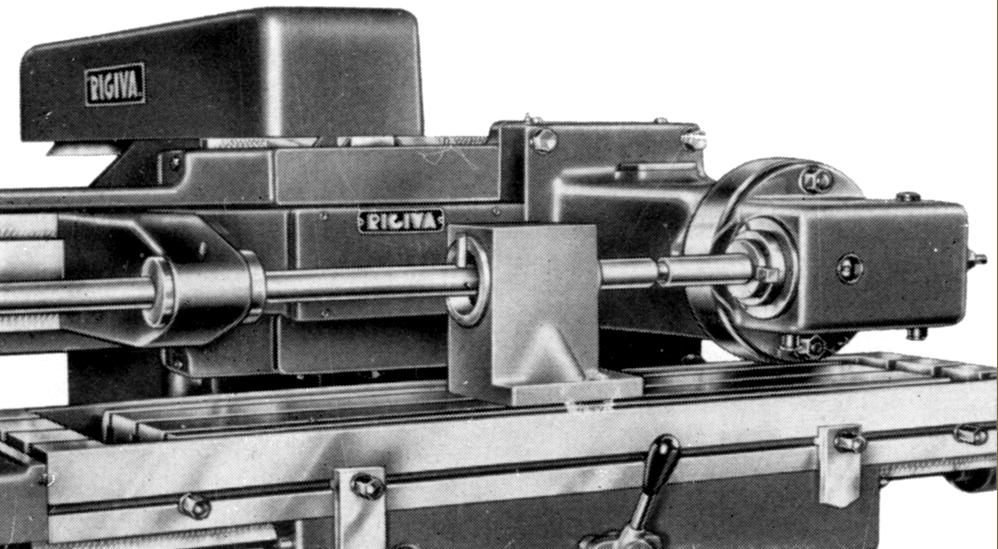

C.S.M. Motor-driven Drum and Plate Cam Milling Attachment. Three models were listed: the C.S.M. 150, C.S.M. 260 and C.S.M. 300 able to make drum cams up to 150, 260 and 300 mm respectively

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

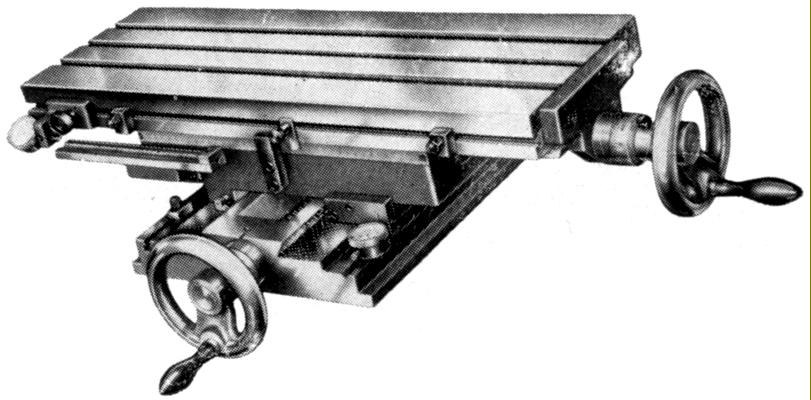

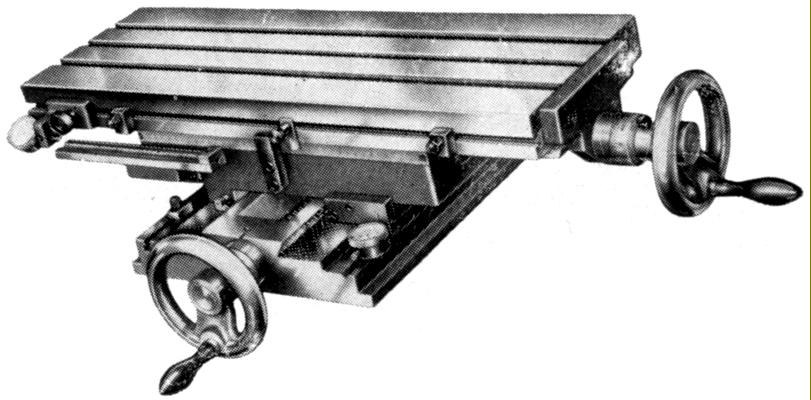

Two sizes of Compound Table were offered: 300 x 150 mm and 500 x 150 mm. The former was 130 mm high and the latter 140 mm. The works also offered to construct table to a customer's particular requirements.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

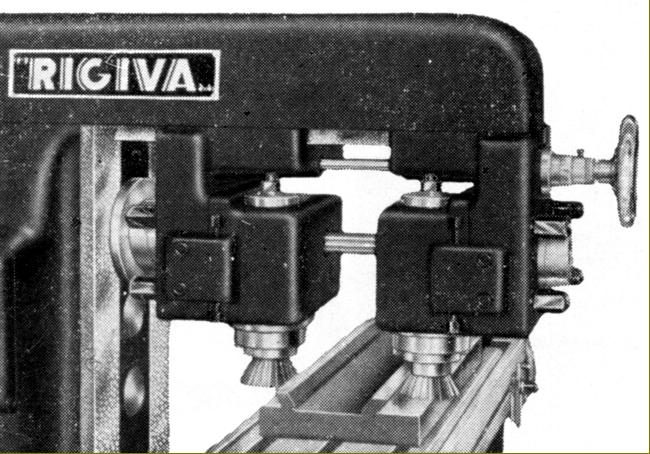

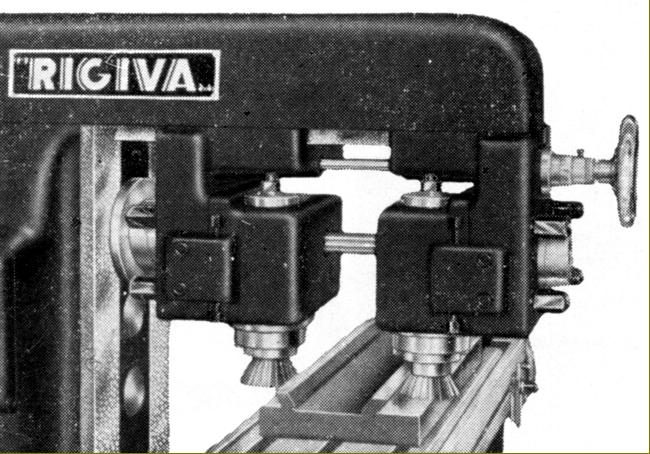

Coupled Vertical Heads. Driven from the horizontal spindle, this unit allowed two cutters to be employed simultaneously

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

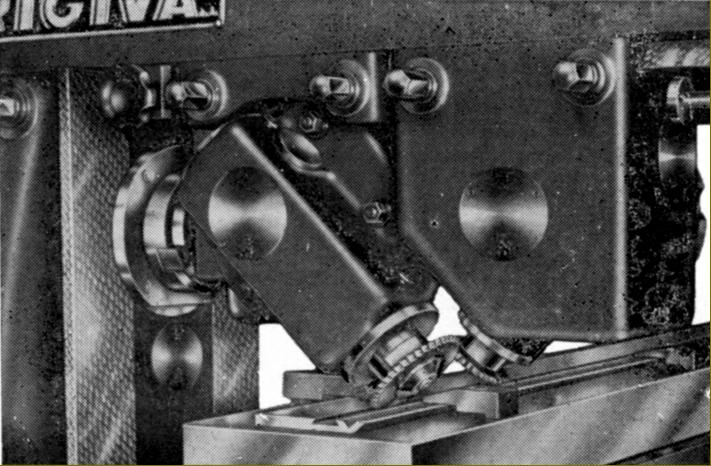

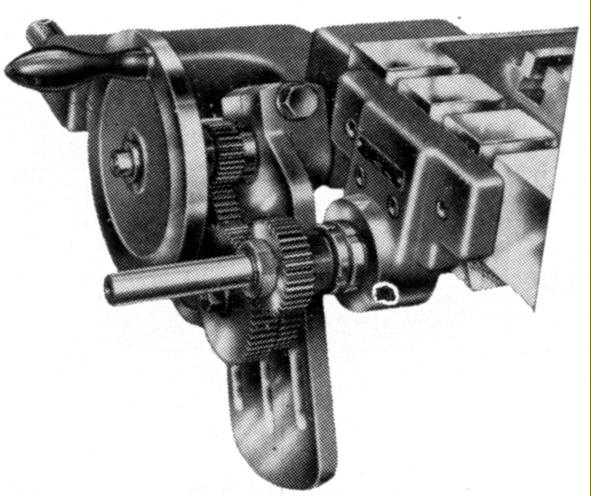

Coupled Vertical Inclinable Heads. A complex and expensive assembly, this was designed to mill angular surfaces - for example the V-ways on the underside of a lathe cross slide--the minimum cutter separation was just 10 mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type D.O. Diving Head with indexing by a train of gears. Two centre heights were available: 130 and 200 mm.

|

|

|

|

|

|

|

|

|

|

|

|

The D.O was also available fitted with simple and quick indexing by a notched plate, of which a number were available from stock or made to special order.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inclinable Rotary table Type T.C.1.300. Designed for use by toolmakers and diesinkers this 300 mm diameter table, with a 1 : 120 gear ration, could be rotated through 90-°

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

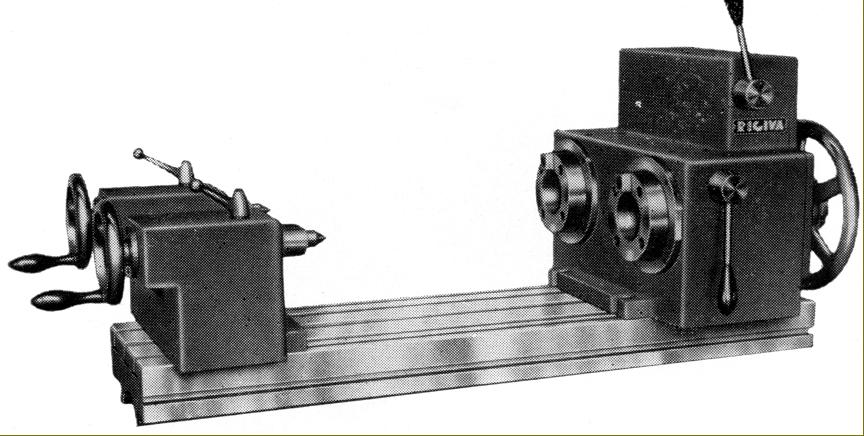

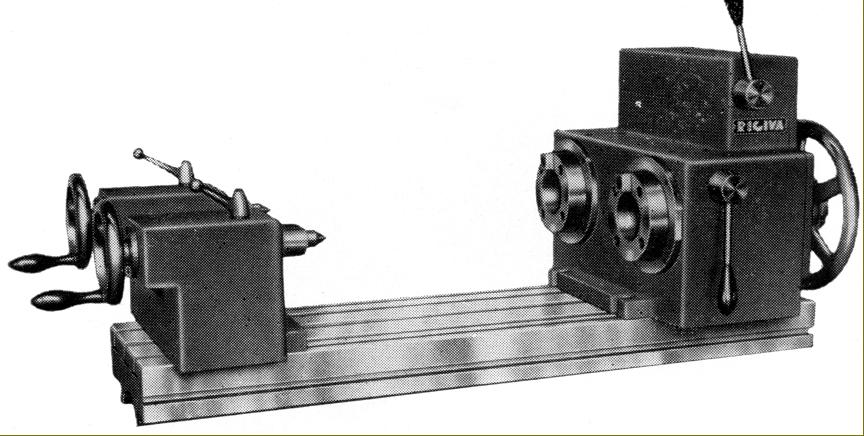

Two-spindle 150 mm centre height dividing head able to admit 250 mm between centres. Indexing was by notched plates

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

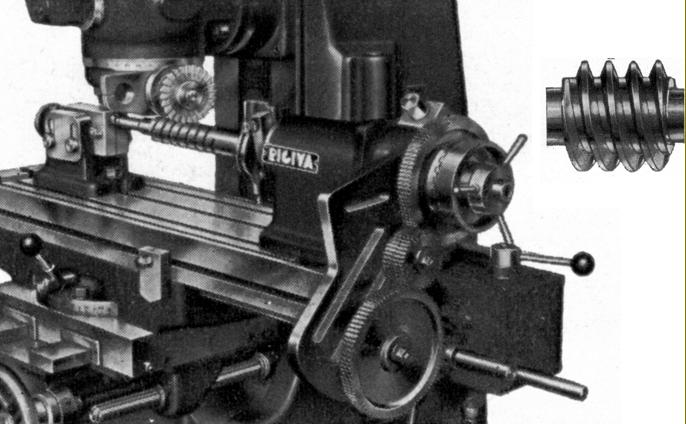

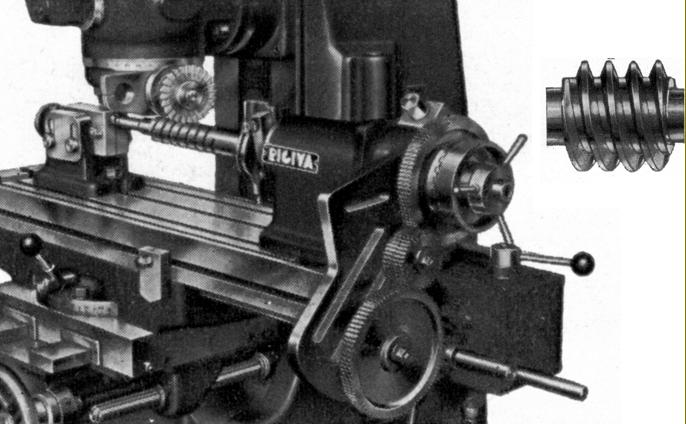

For manufacturing short lead spirals and worms Riva offered three Models: S.110, S.130 and S.150 with centre heights equalling the model number. The unit was suitable for milling spirals with a modulus pitch of less than 60 mm.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

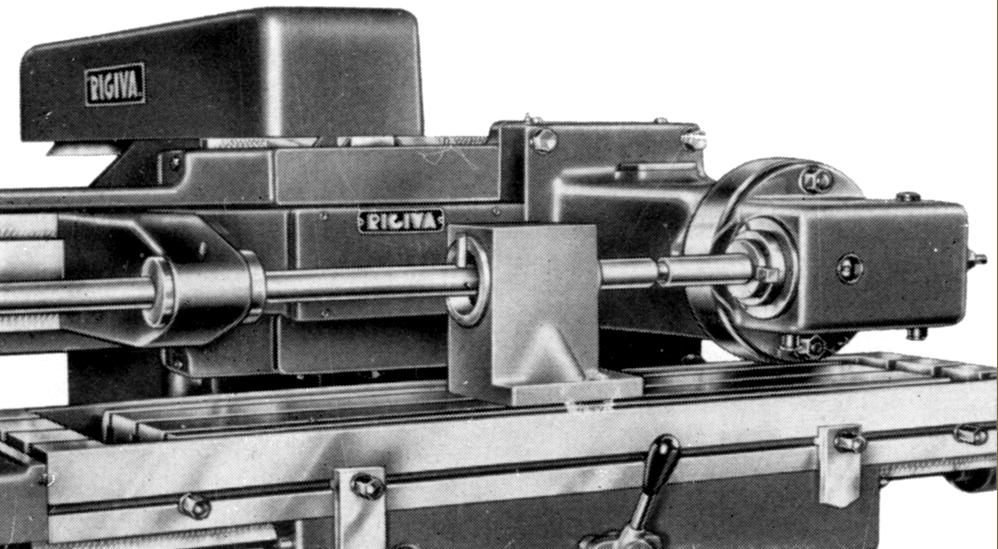

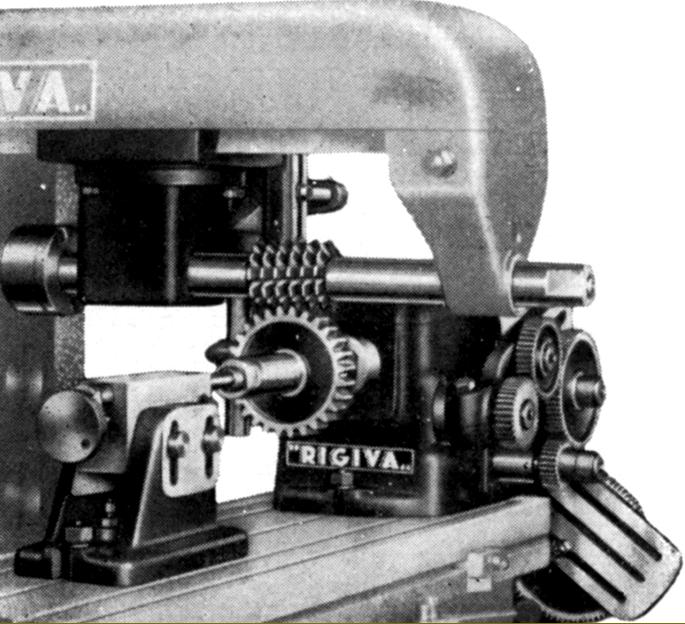

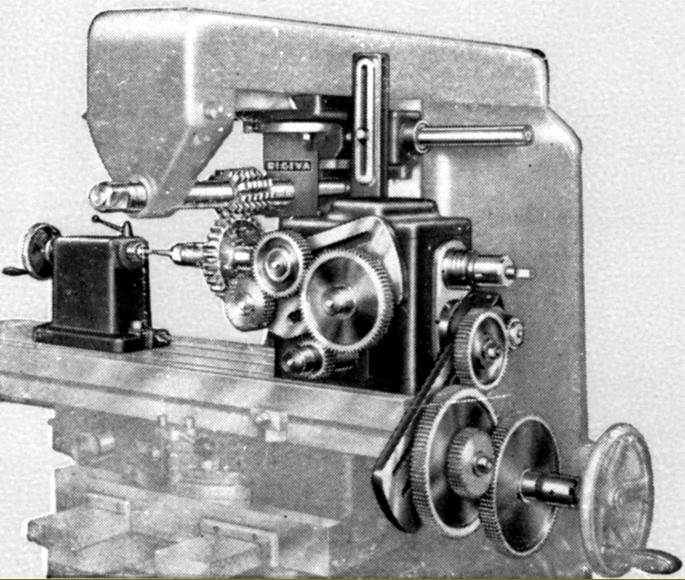

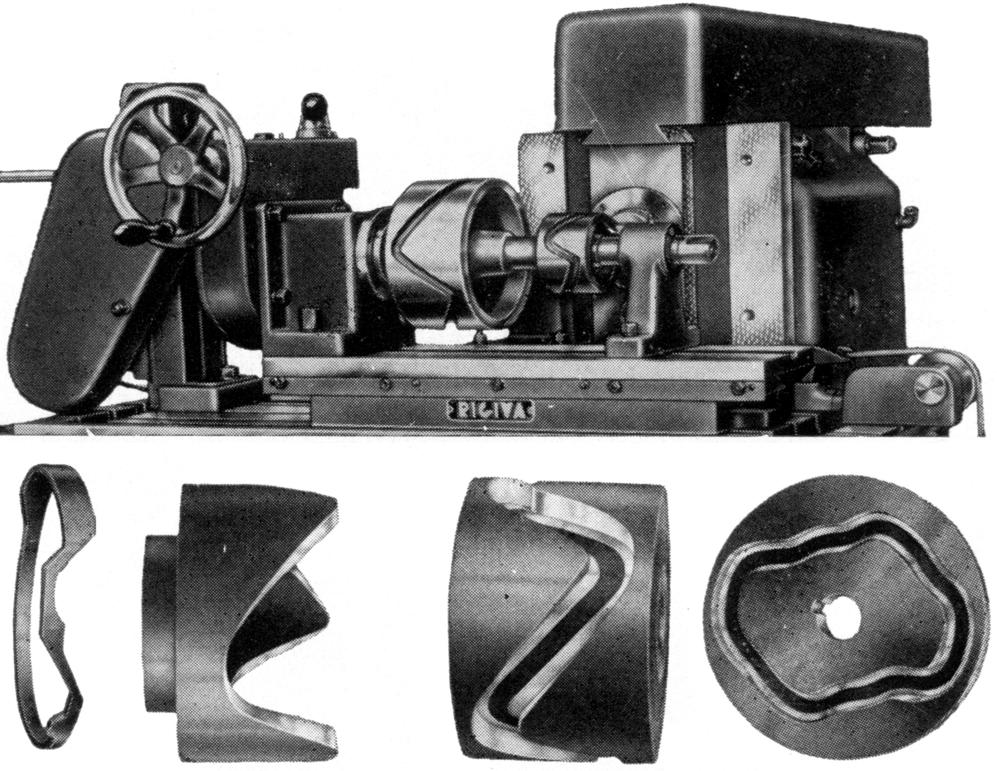

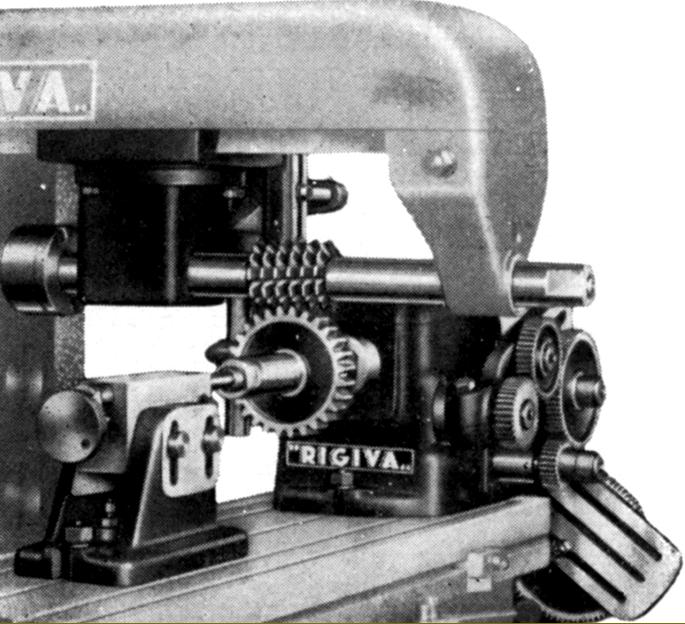

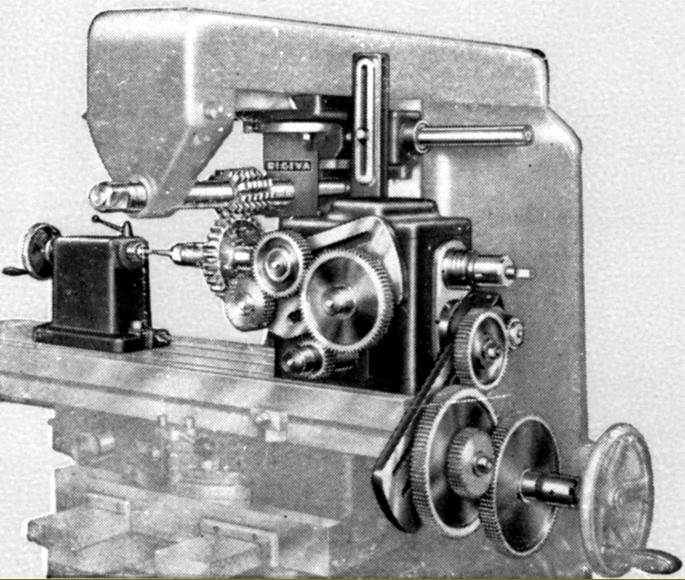

For hobbing (cutting straight and helical gears, worms and splines, etc.) Riva supplied an Automatic Dividing Attachment in three sizes: D.130, D175 and the D.175.70 - with centre heights matching the model number. The dividing unit was driven from gearing at the right-hand end of the table with the head section clamping to the V-ways underneath the overarm..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Another view of the Automatic Hobbing and Dividing Attachment

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

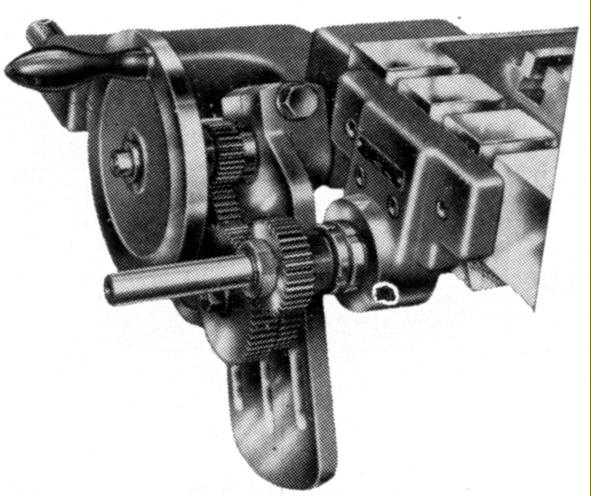

For simple hand-operated rack cutting the pitch indexing could be obtained by a series of compounded gears. Once set up o provide the spacing required, a ratchet was disengaged and the handle given a single turn to move the spacing on.

|

|

|

|

|

|

|

|

|

|

An alternative method of indexing for cutting racks was provided by a dividing plate.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A special attachment, designed exclusively for rack and worm milling, was the Fixed Vertical Head. Type C.R.2. This could handle Modular gears from 0.5 to 2.5 and DP equivalents and was available with a special holding attachment to fit on the Universal Dividing Head. It was also built in sizes to suit other Riva Millers as the C.R.6, C.R.8 and C.R. 20.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Another model of Fixed Vertical Head, the T.U.C, for rack and worm cutter was also manufactured - this design having a swivel end and being built in C.R.2, C.R.6, C.R.8 and C.R. 20 sizes

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

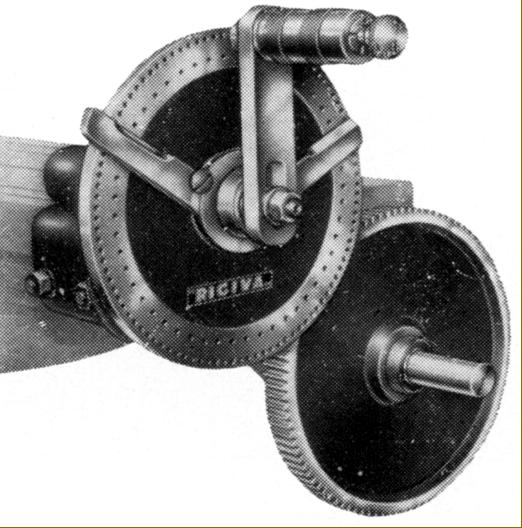

Universal Dividing and Spiral-milling Head. Built in several centre heights, it was driven from gearing at the right-hand end of the table with its spindle revolved in roller bearings. It came complete with 2 indexing plates, an adjustable intermediate rest, two centres, a catchplate, an extension arm, for differential indexing, 13 gears and a set of ready-reckoner tables for performing divisions - with 2200 already calculated for spiral pitches.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|