|

Home Machine Tool Archive Machine-tools for Sale & Wanted Flexispeed - Wizard, Meteor - Simat 101 Lathes and Countershafts Flexispeed Meteor Simat Home Page Flexispeed Meteor Simat Page 3 Flexispeed Milling Machine Flexispeed Meteor 11 Flexispeed Shaper including handbooks and drawings, is available |

||

|

Flexispeed Meteor 11--few survive with the headstock badge intact. More pictures of this original example here. The same lathe, but less the automatic carriage traverse and with a single swivelling toolslide, it was known as the "Meteor 1". |

|

Simat 101 |

||

|

|

||

|

|

|

|

|

|

|

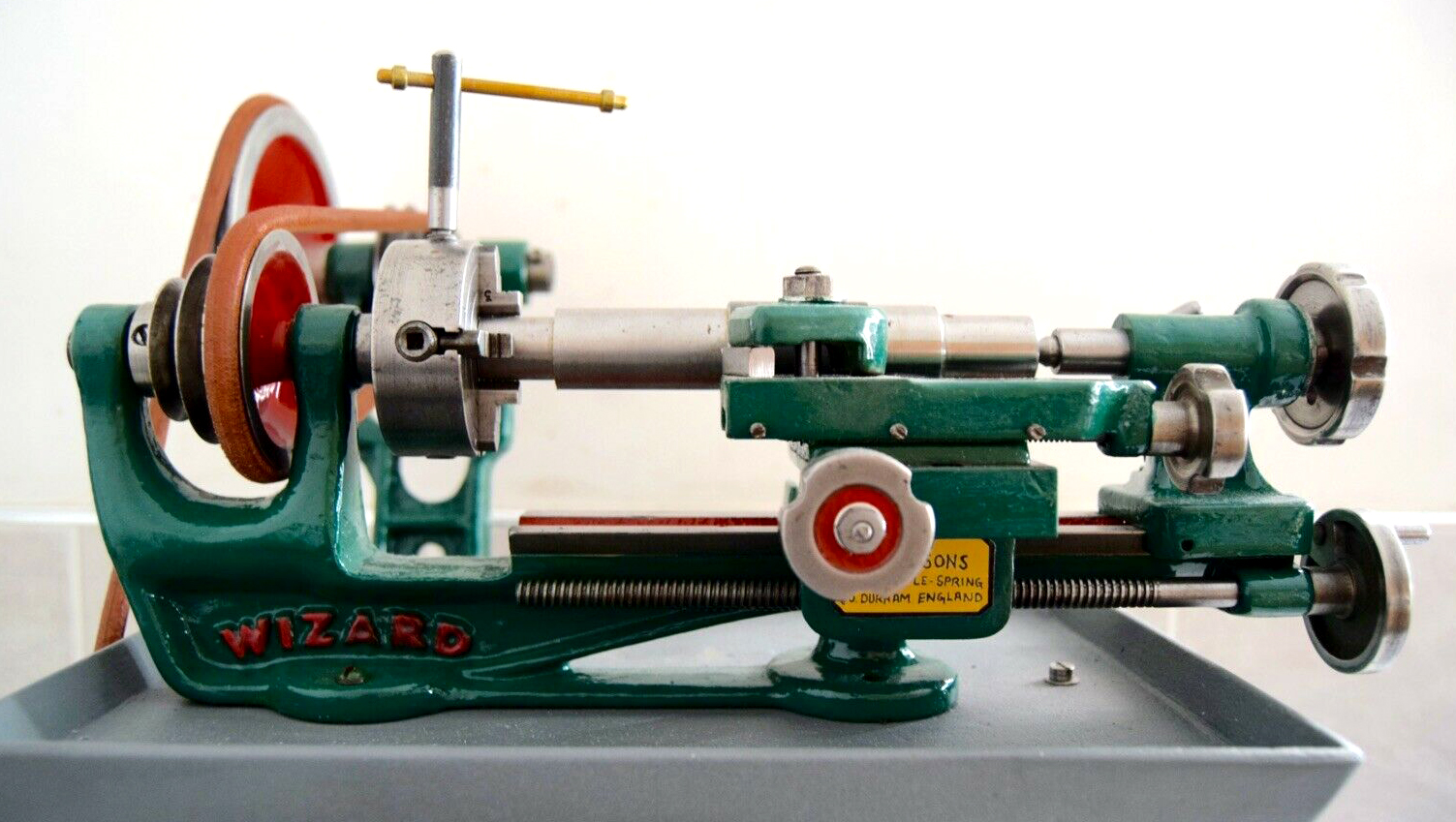

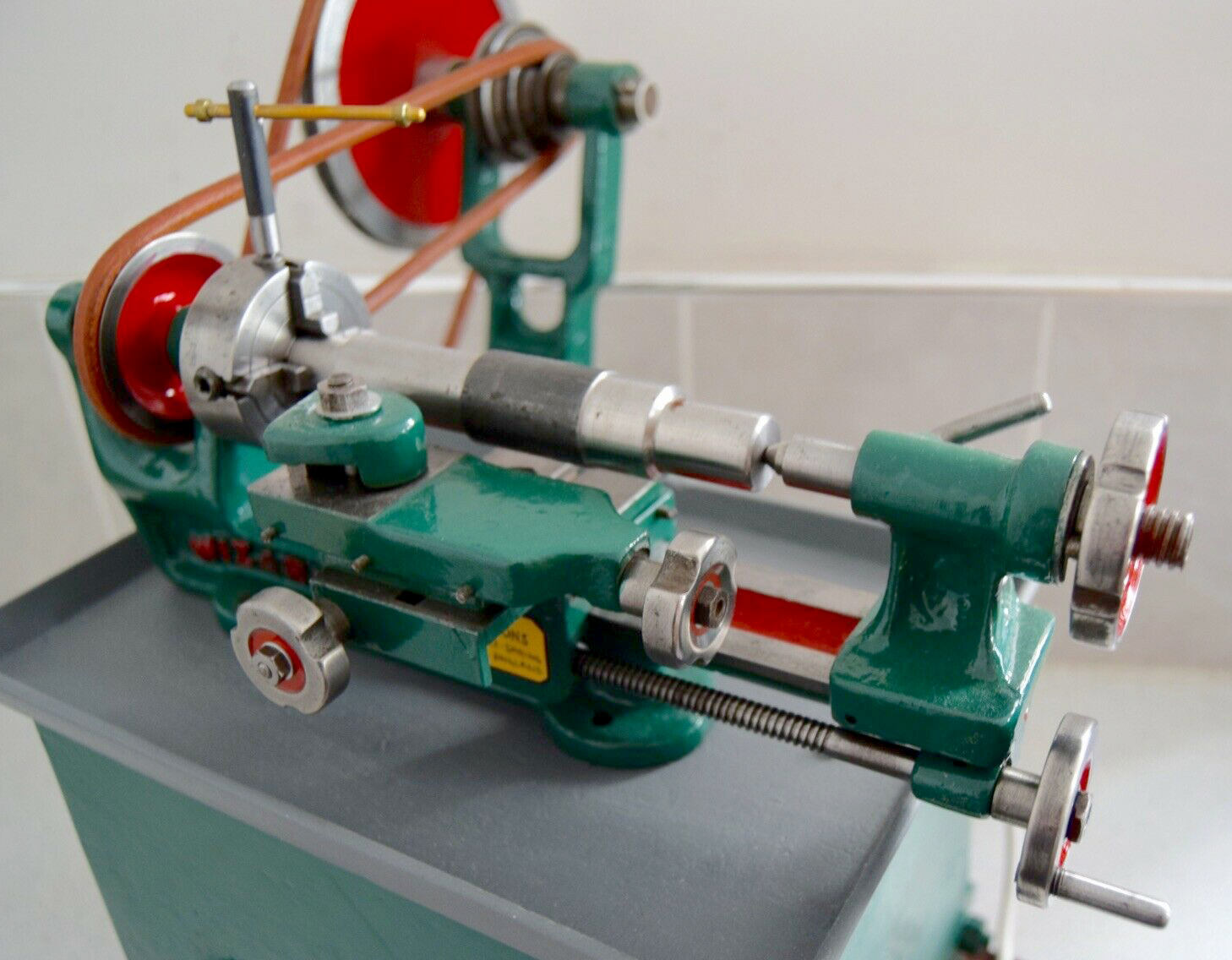

Although carrying a "Wizard" lathe, this is clearly a miniature and very rare Flexispeed cast-iron cabinet stand. As the picture below shows, it carries a standard Flexispeed countershaft unit, hinged from the back face and driven by a motor contained neatly within the housing. |

|

Another example of the "Flexispeed-Wizard" this time a typical bulled-up-beyond-belief example from eBay where the "restorer" has tried to make a silk purse out of a sow's ear. However, as a display piece it is rather fetching - and set off by the lovely vintage oil can with its hand-made soldered joints and thumb-operated pump in brass. |

|

After the fitting of backgear and auto feed the next stage was to equip the lathe with screwcutting and a dog clutch on the leadscrew. The screwcutting attachment was, in relative terms, very expensive - with its 10 changewheels it added 48% to the basic (1965) price of £31 : 9 : 6d. The lathe was supplied with covers over gears and belt drive - removed for the photograph. |

|

|

||

|

|

|

A very prominent maker's badge cast into the belt-guard. Unlike some manufacturers of small machine tools - who appeared to have been shy about badging their machines - Flexispeed were keen to remind the owner who made the lathe and from where it came. |

||

|

Flexispeed Milling Machine Flexispeed Meteor 11 Flexispeed Shaper including handbooks and drawings, is available |

||