Manuals, Instruction Books Parts Lists and Reproduction

Catalogs are available for most Clausing lathes

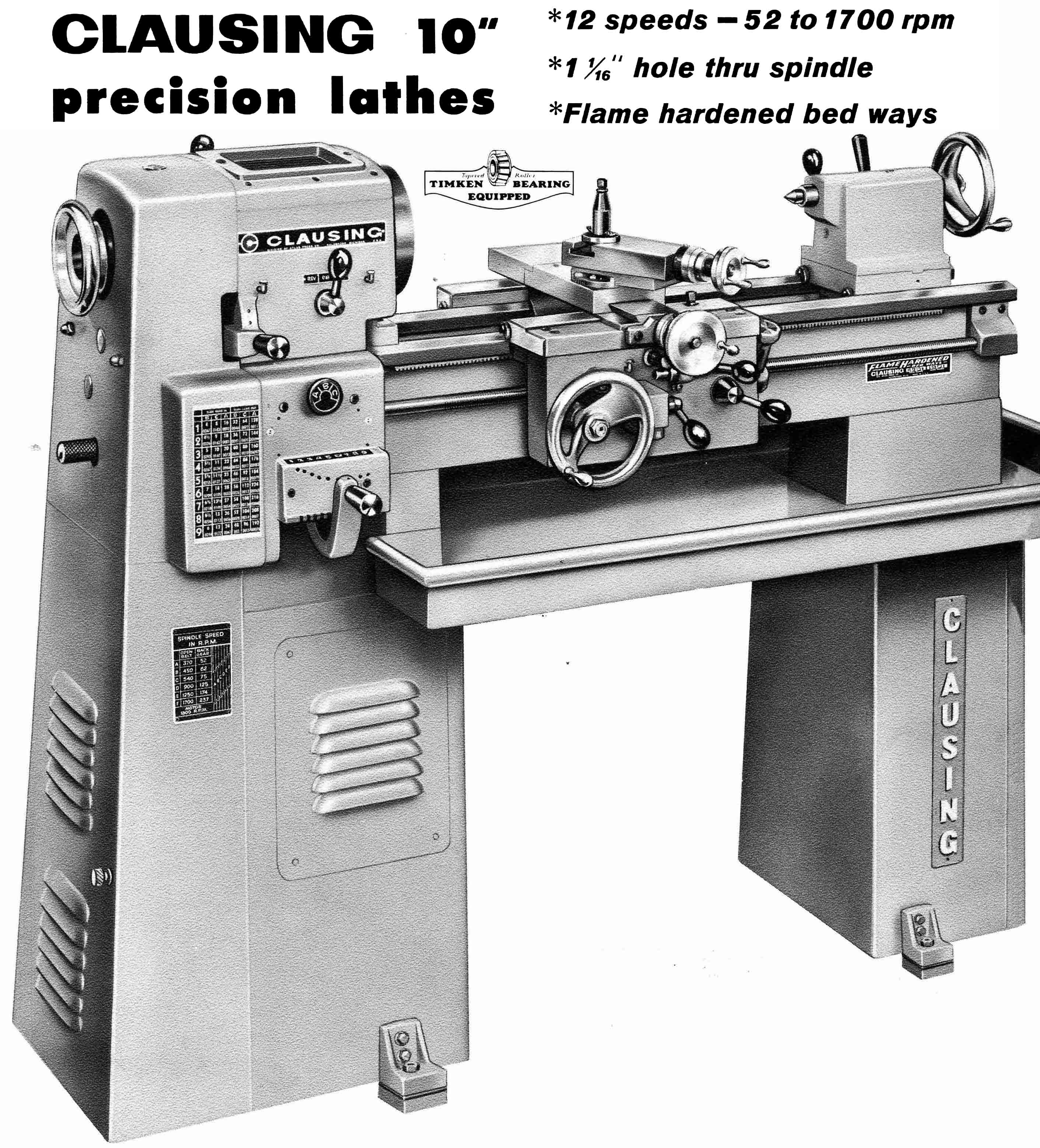

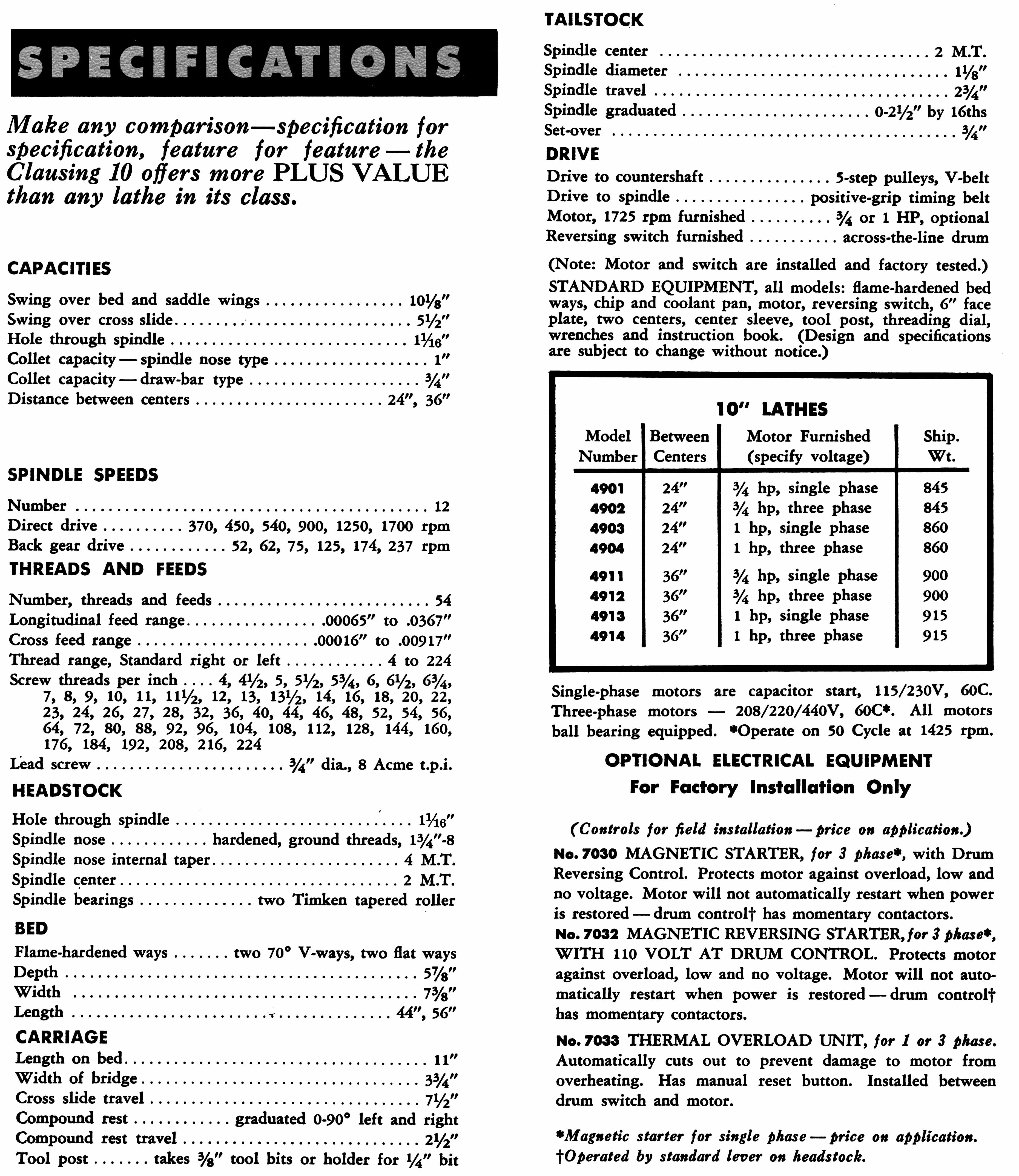

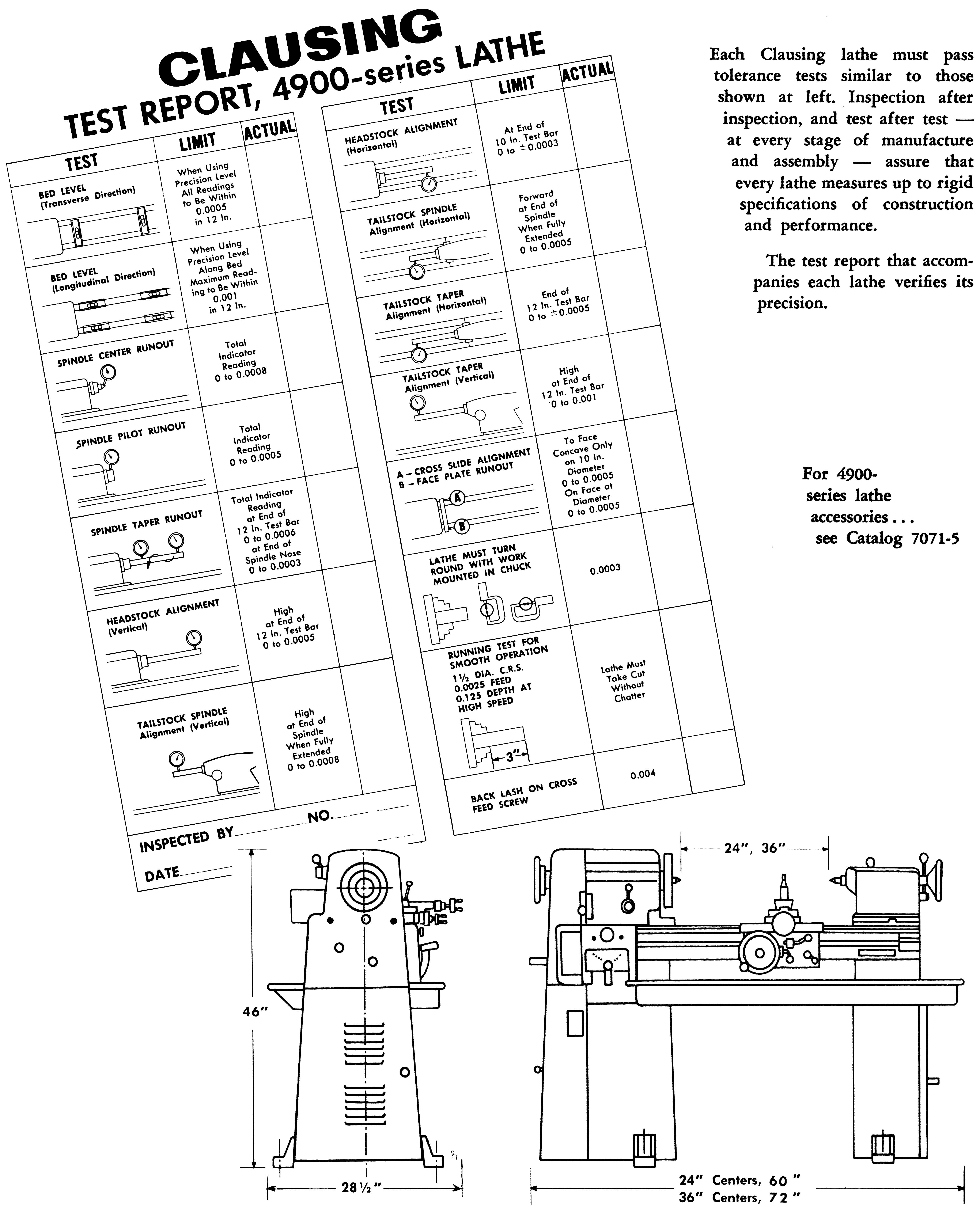

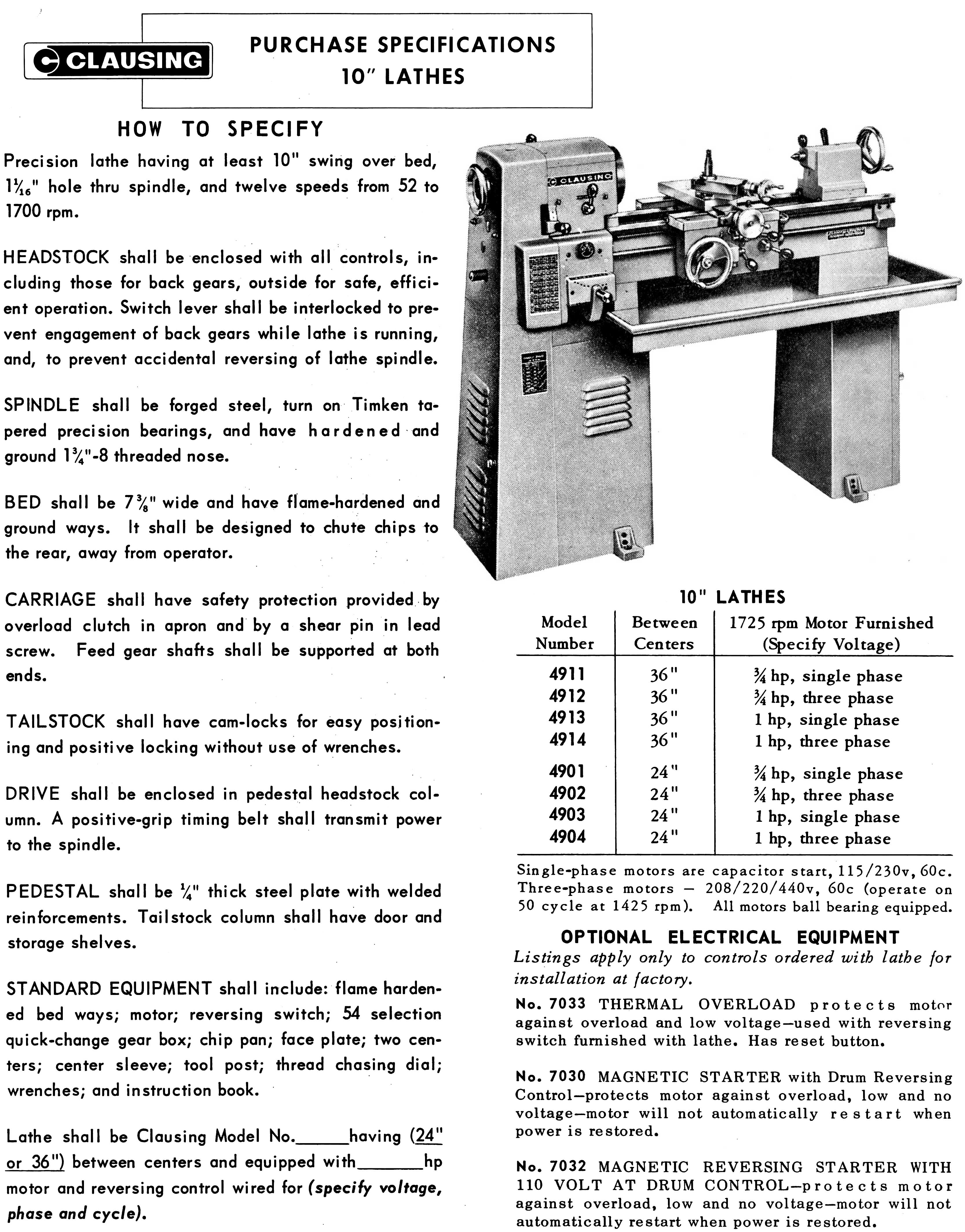

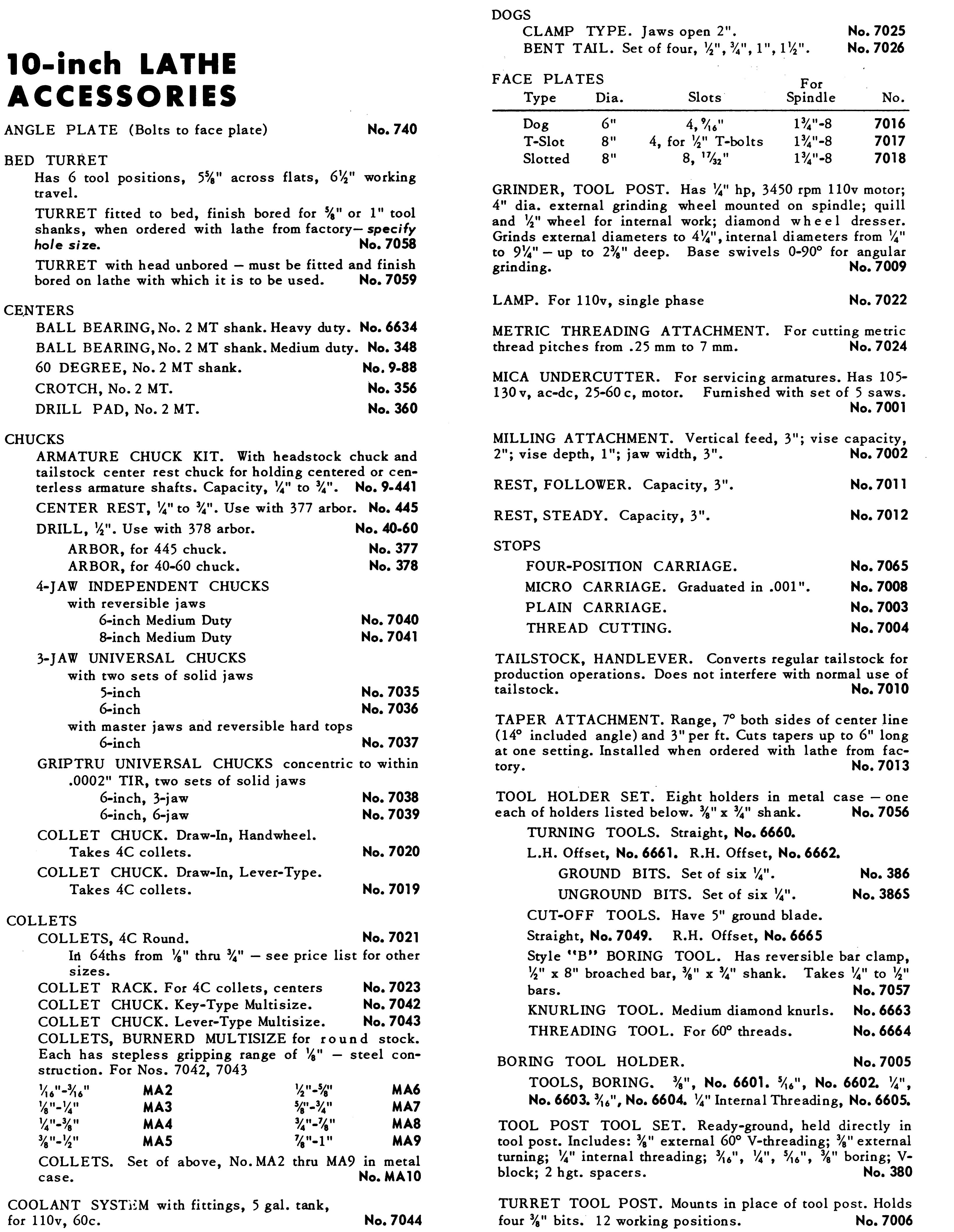

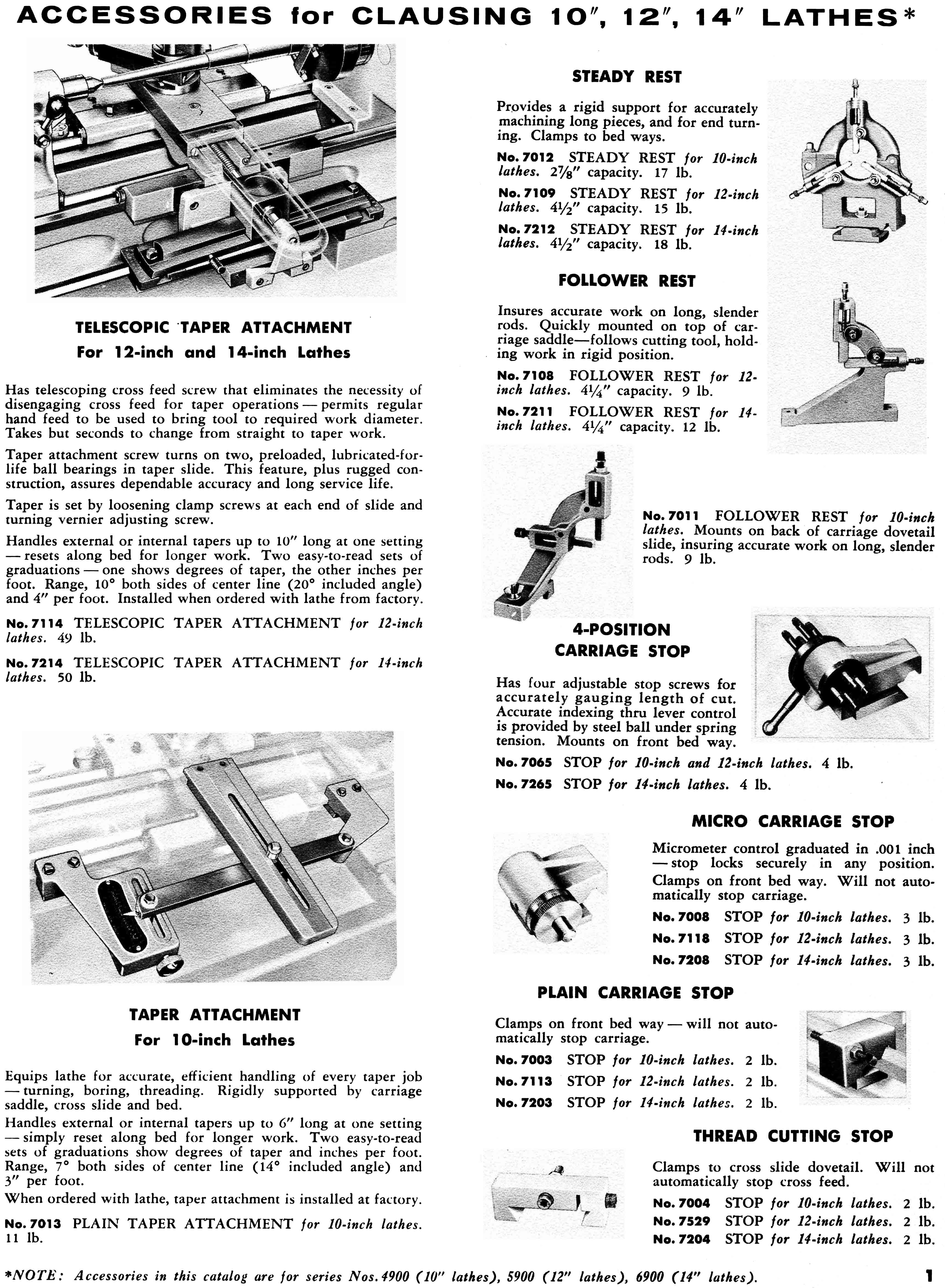

By the late 1960s Clausing lathes had become rather squarer in appearance, a styling and design change clearly seen in the baby of the 1968 Clausing 4900 Series machine and its bigger brothers the 12-inch and 14-inch models--all illustrated and described in the following pages. While the 5900 and 6900 models were intended for serious work in professional machine and repair shops, the 10-inch was aimed at the educational, training and wealthy amateur market and was, as a consequence, kept mechanically simple - yet still of high quality. It was based on a robust, flame-hardened, ground-finished bed whose deep walls were well braced between elliptically shaped, rearward-draining, swarf-clearance holes.

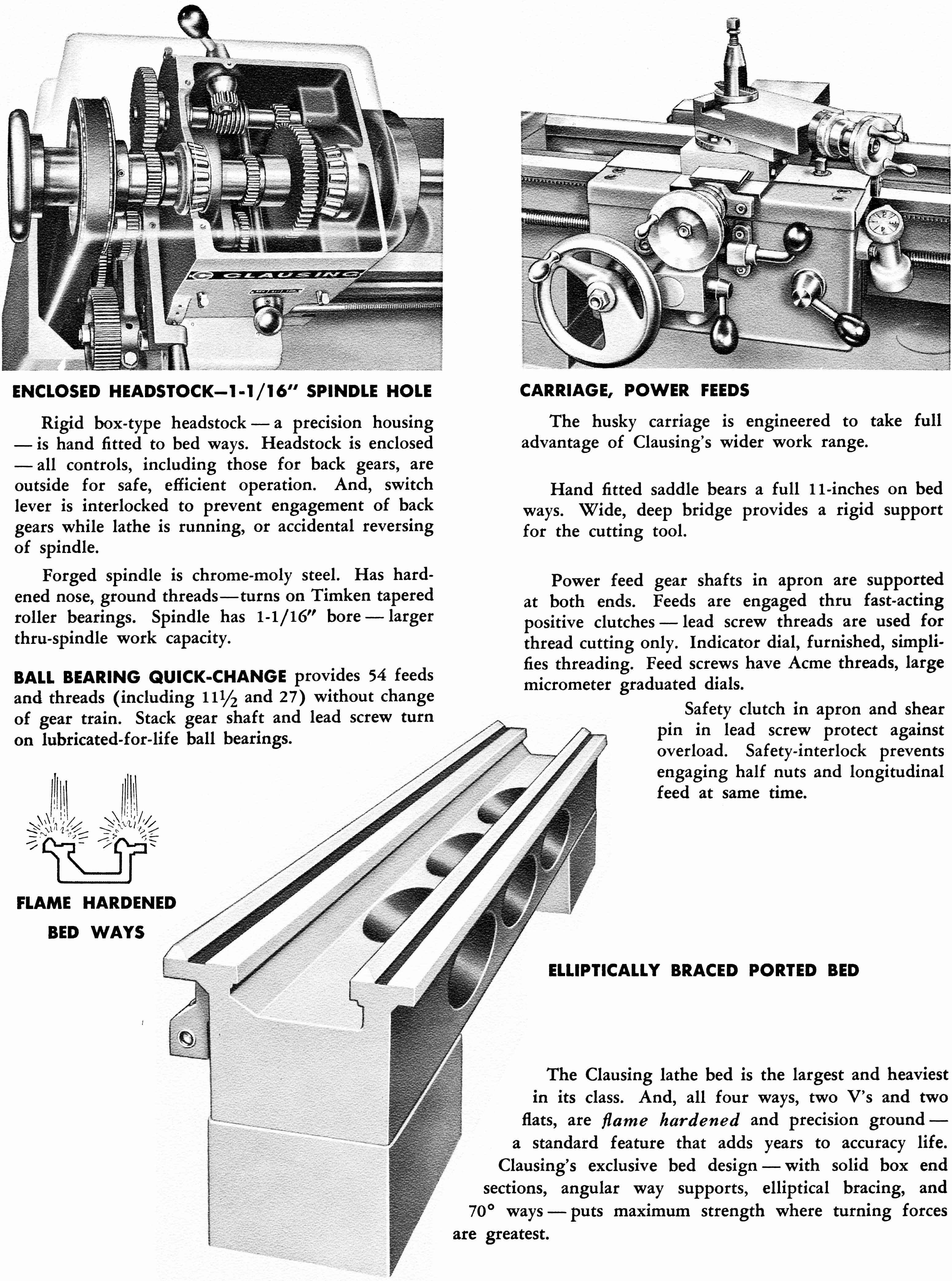

Made in a forged, chrome-steel the headstock spindle had a hardened nose, was bored 11/16", and ran on precision Timken taper-roller bearings. Two types of collet fitting were available, a simple spring-collet assembly (which used either a hand-operated or lever-type draw tube) or the beautifully-well engineered English Burnerd Multisize collet set that ranged in capacity from 1/16" to 1". Each Multsize collet spanned a 1/8" gripping range and so could be used for both English and metric-sized material.

A conventional tumble-reverse mechanism was fitted to the changewheel drive that connected to a screwcutting gearbox of the traditional Norton Quick-change pattern with a single tumbler and open base - a design as fitted, for example, to thousands of early South Bend lathes. A knob protruding from the headstock-end guard was used to select either fine feeds or screwcutting ratios.

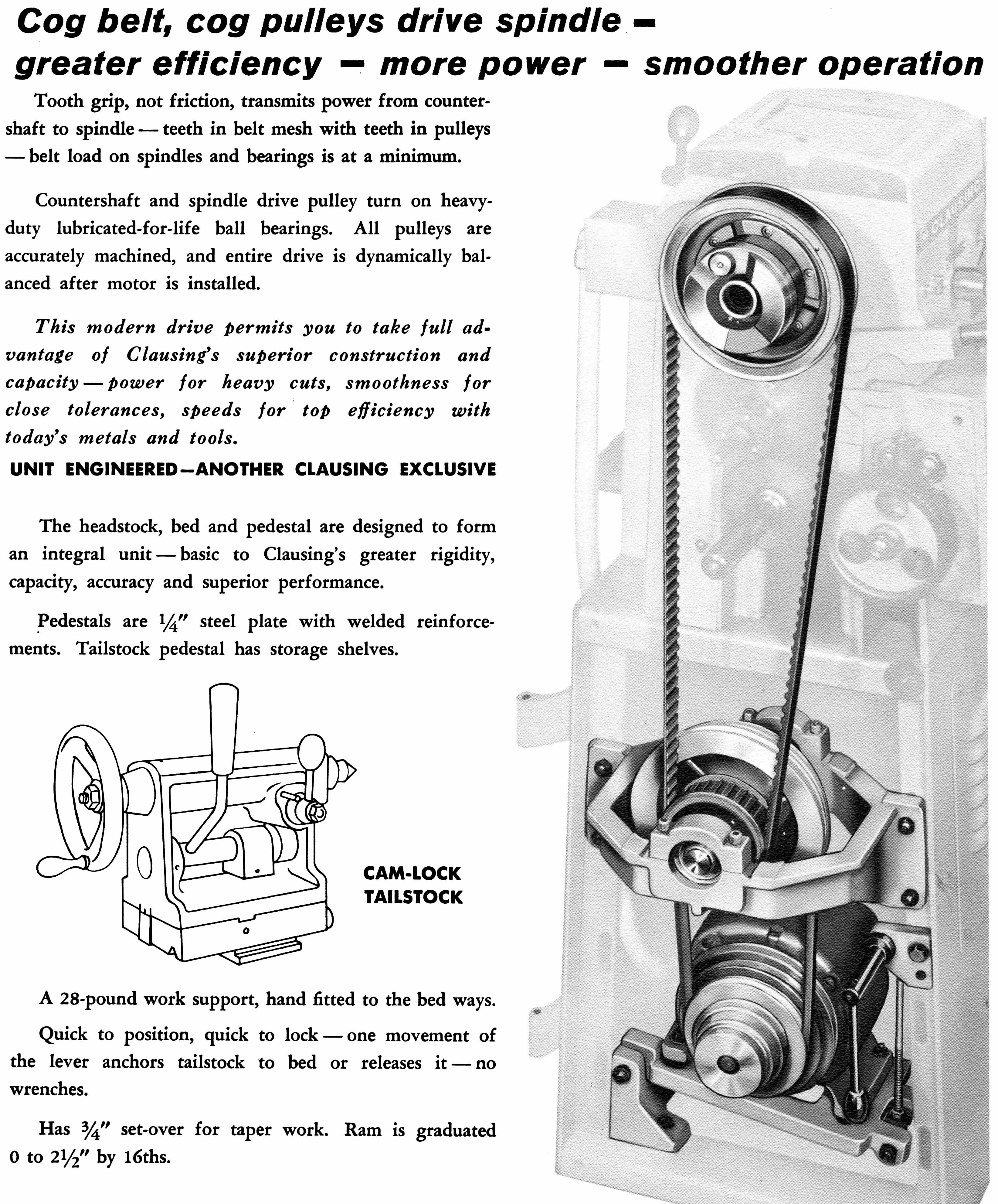

The drive system on the 4900 consisted of a motor, mounted in the base of the cabinet stand, driving upwards using a V-belt to a rigidly-mounted, Multi-V Step countershaft unit. Reflecting contemporary changes to drive technology, from there the motion was taken by a slip-free "toothed" belt to an overhung pulley on the end of the headstock spindle. To change speeds the stand door had to be opened, an over-centre lever operated and the motor to countershaft V belt repositioned on its pulleys. Twelve spindle speeds were provided: in backgear: 52, 62, 75, 125,174,237 r.p.m., and in open gear: 370, 450, 540, 900, 1250, and 1700 r.p.m.

Full details of the 4900 range are shown below..