|

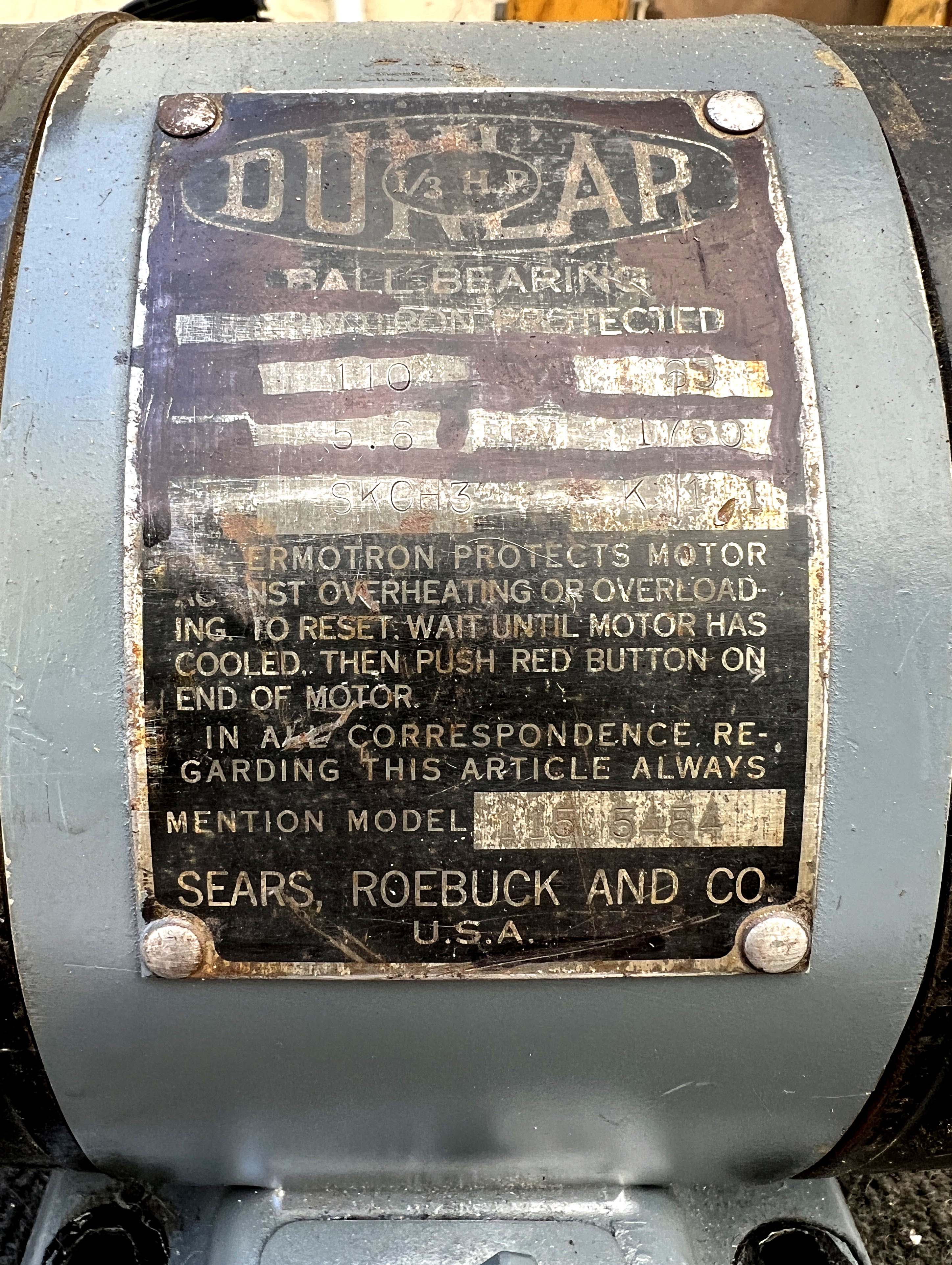

Home Machine Tool Archive Machine-tools for Sale & Wanted and "Pick-o-Matic" Screwcutting A dedicated manual was issued for the gearbox unit - copies are available - together with a complete data pack for the Atlas 10-inch and other Lathes Restored 10-D & 10F Acorn, Halifax & Sphere Copies Early 9-inch Metalmaster Lathes Atlas Factory Catalogue Covers Accessories Atlas Wood Lathes Countershafts Atlas Miller Atlas Shaper Atlas Drill Presses |

|

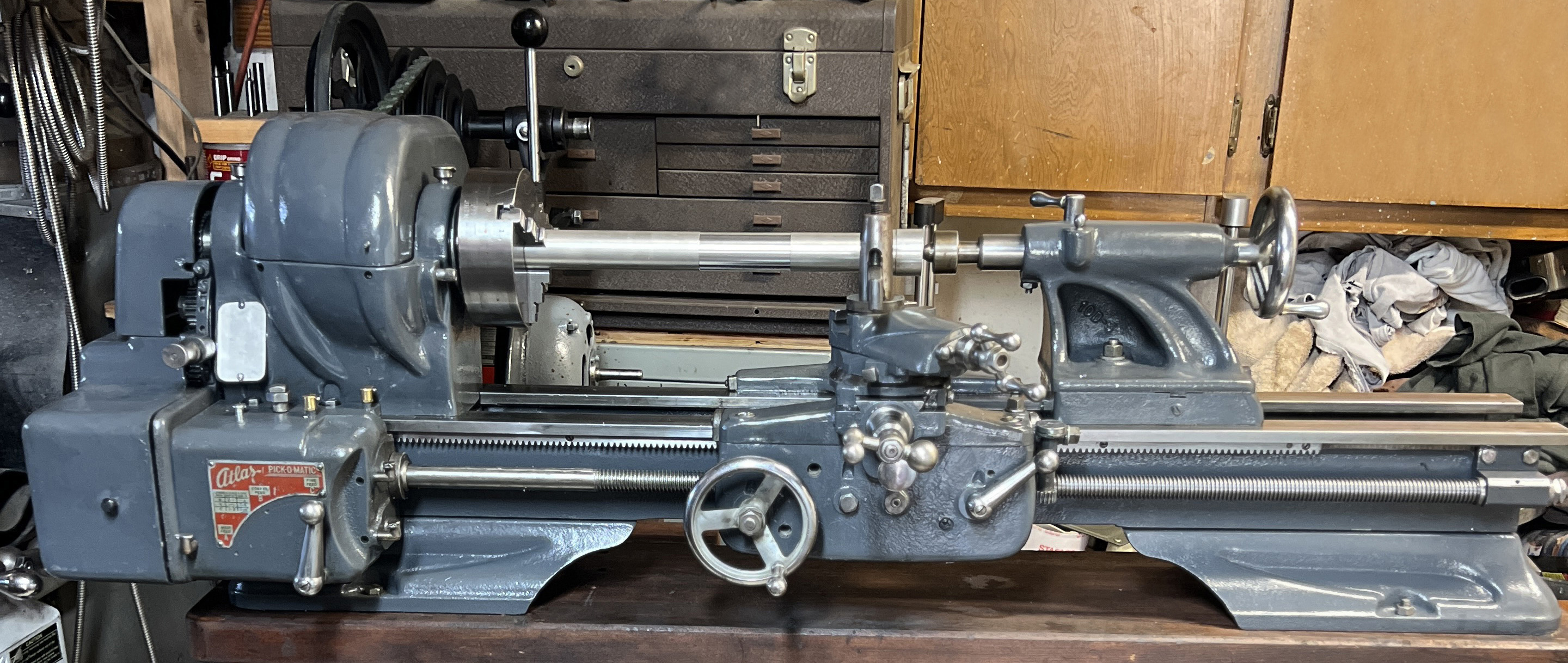

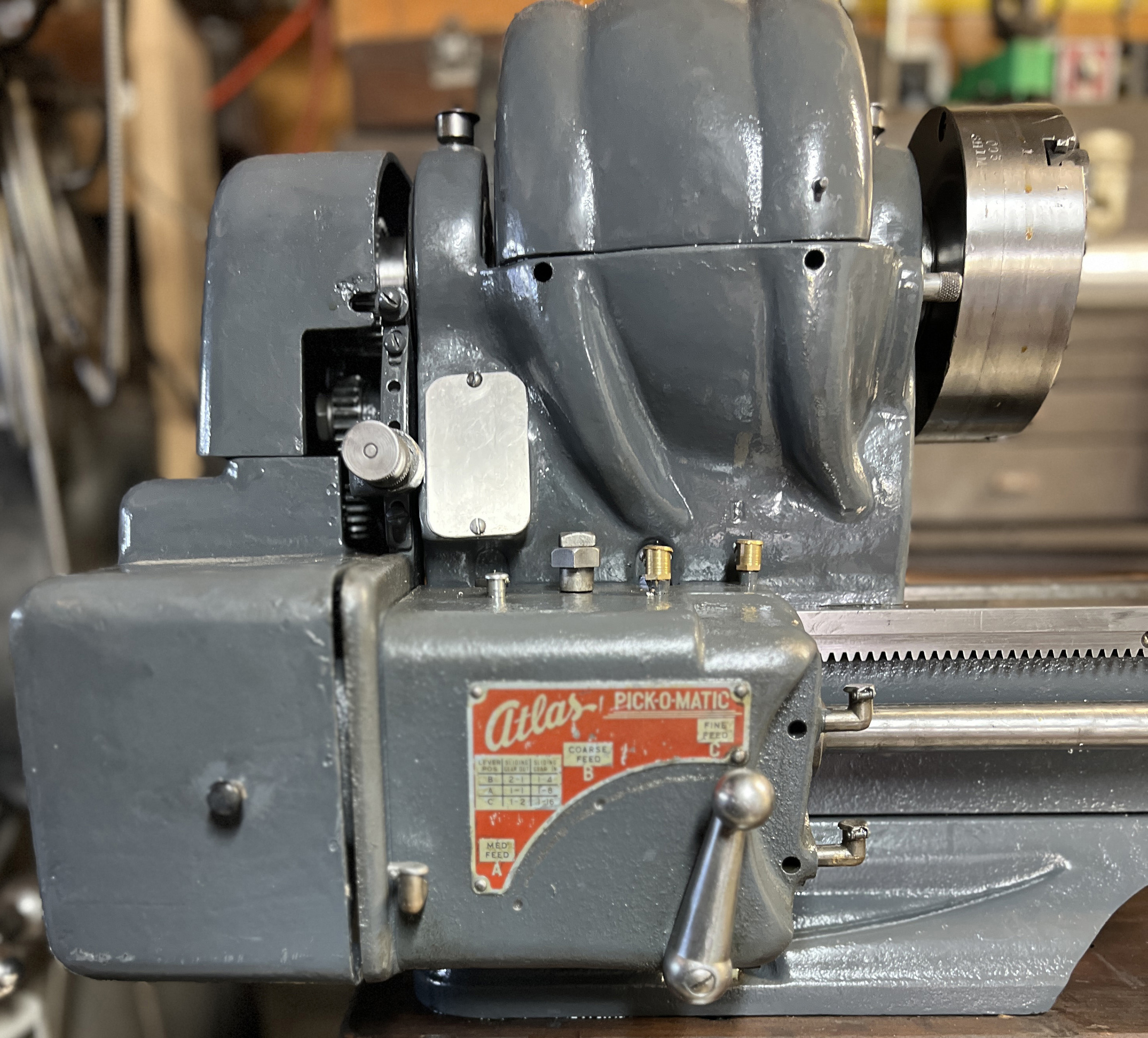

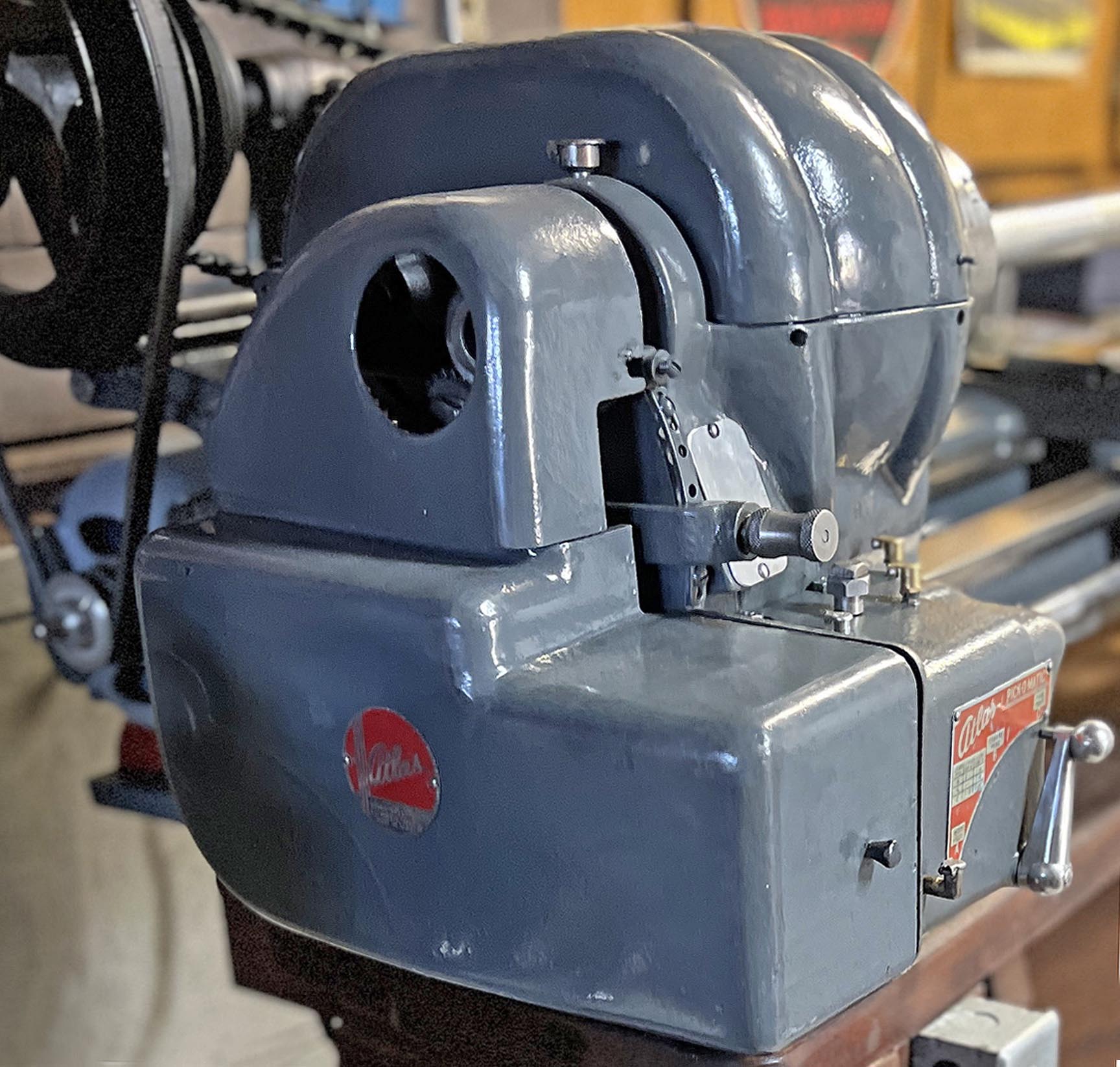

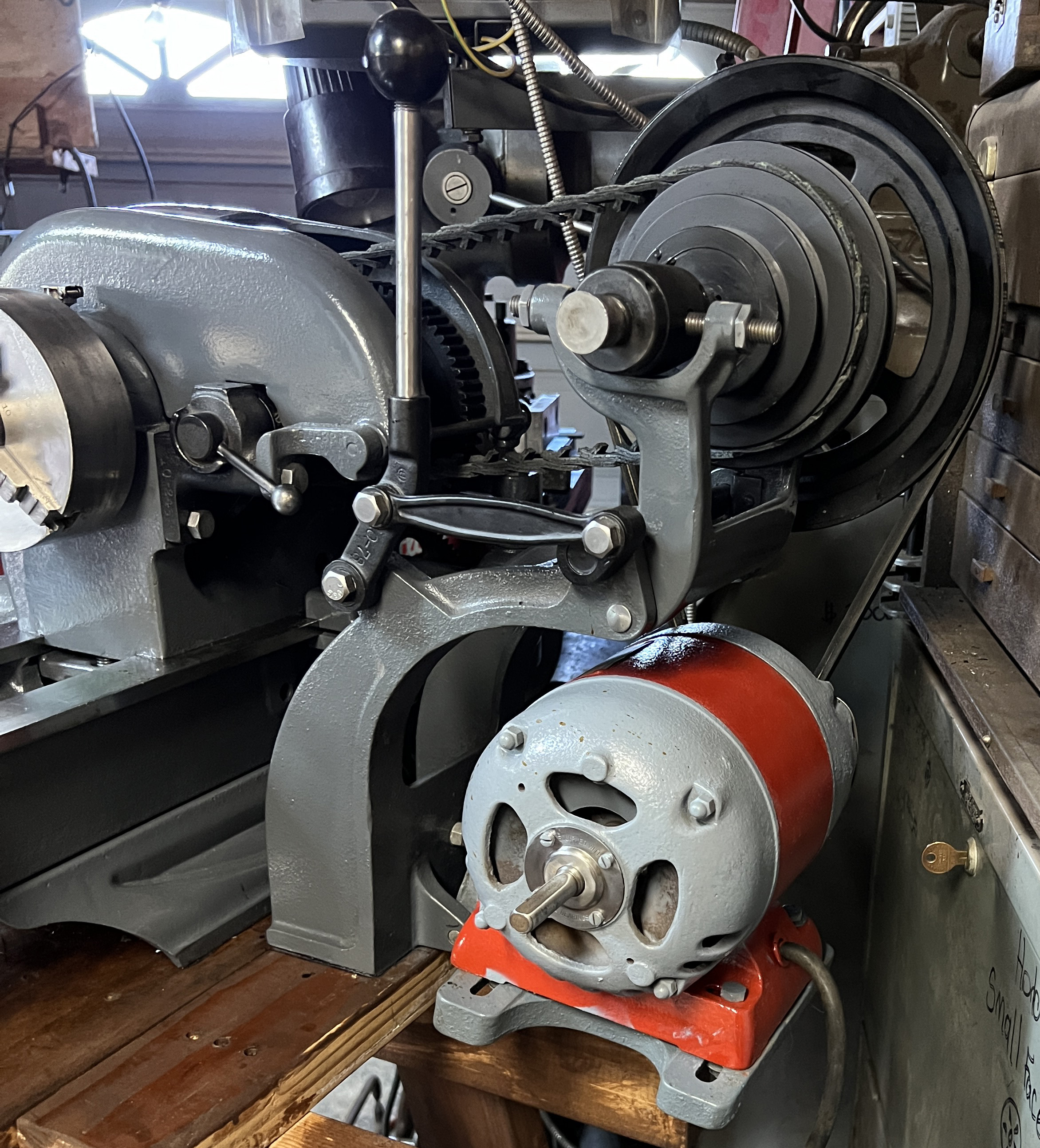

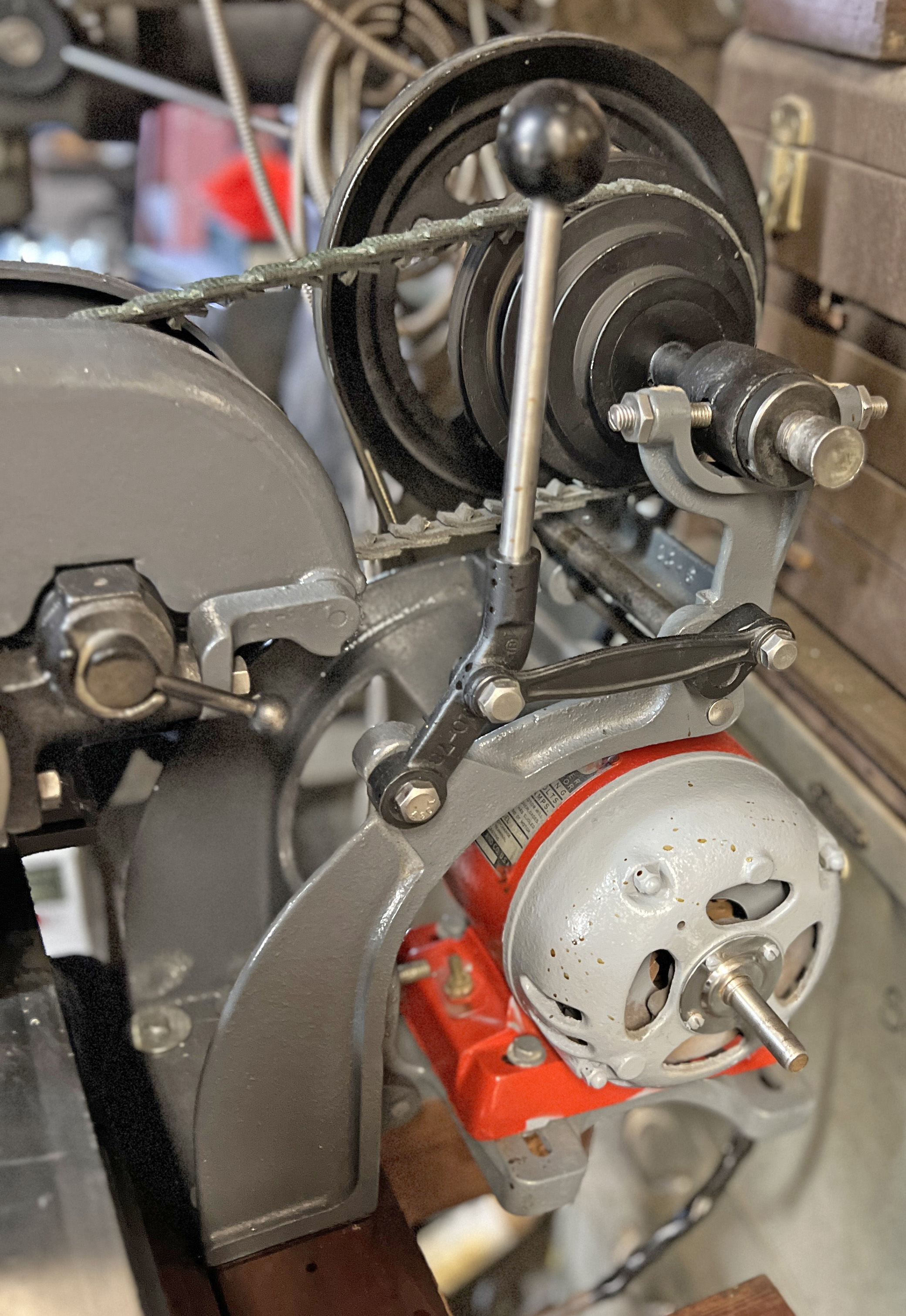

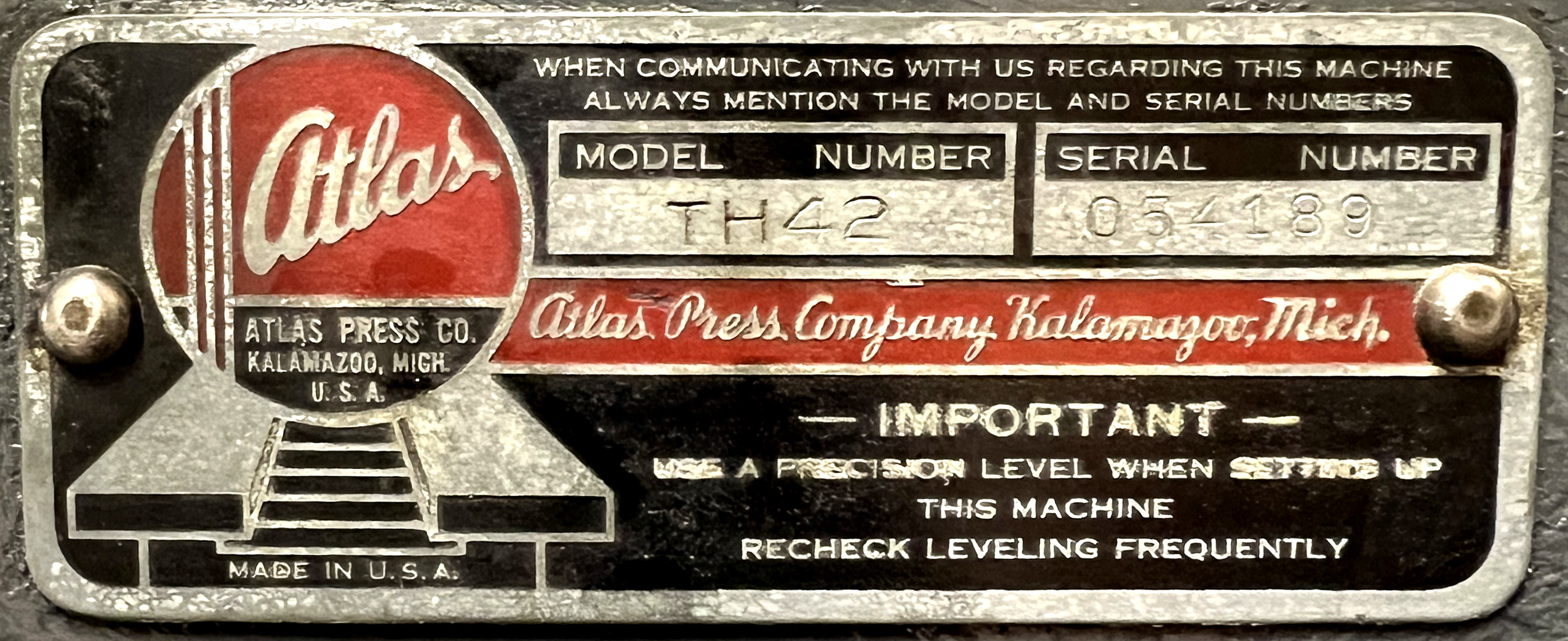

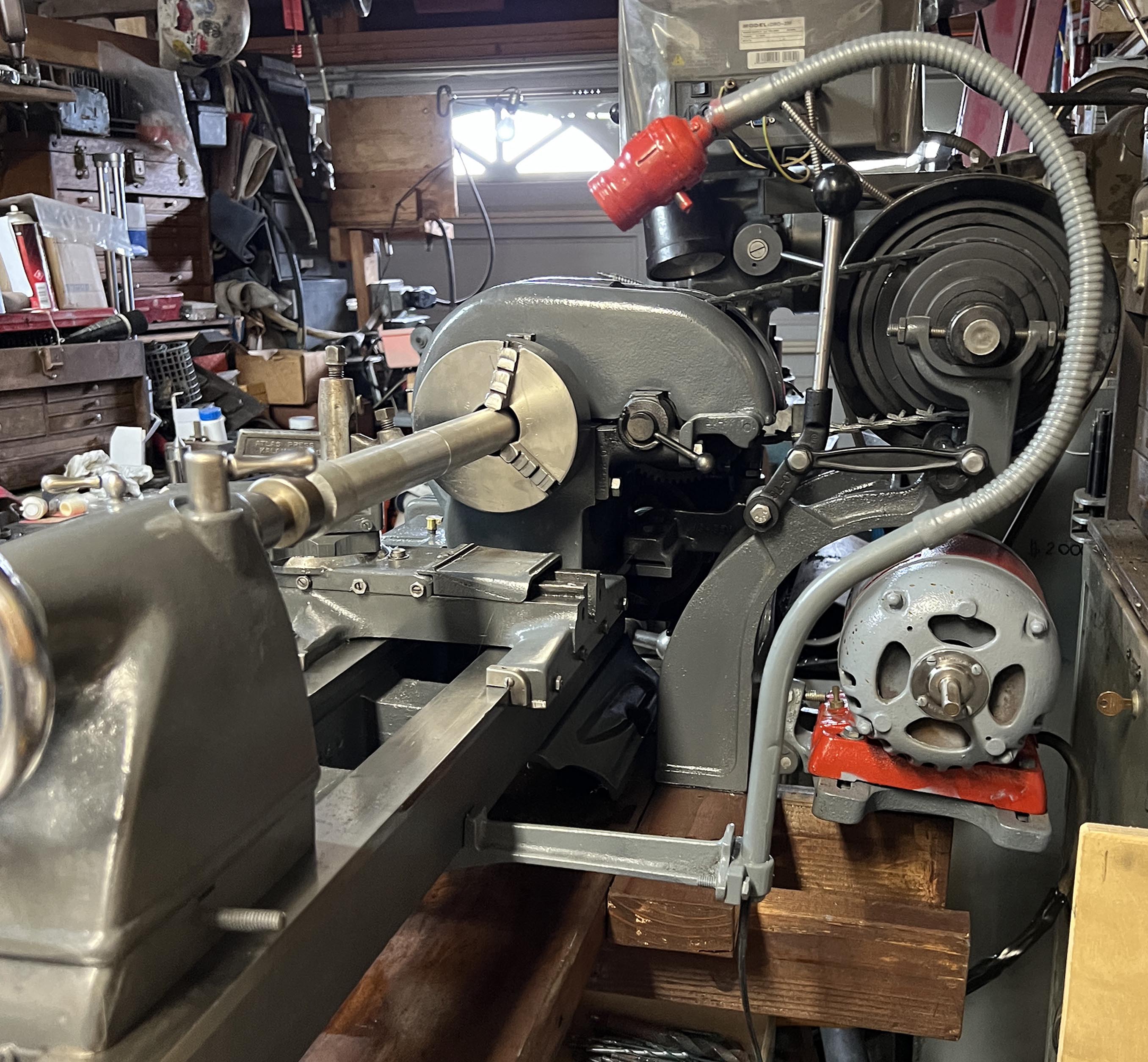

It took a little over 10 years for a screwcutting and feeds' gearbox to become available as an option for the Atlas lathe but, when it was introduced, in 1947, it was also offered as complete conversion kit to for retro fitting to earlier lathes - both those with 3/4" and 5/8" diameter leadscrews. An unusual Pick-o-Matic semi-gearbox was also available, where gears, clustered into sets , were supplied pre-assembled to speed up the thread-cutting process (this unit is shown and explained lower down the page). Just before the introduction of the official gearbox, another was offered by the Western Aircraft Tool Co., a version they described as the "New-All" unit. |

|

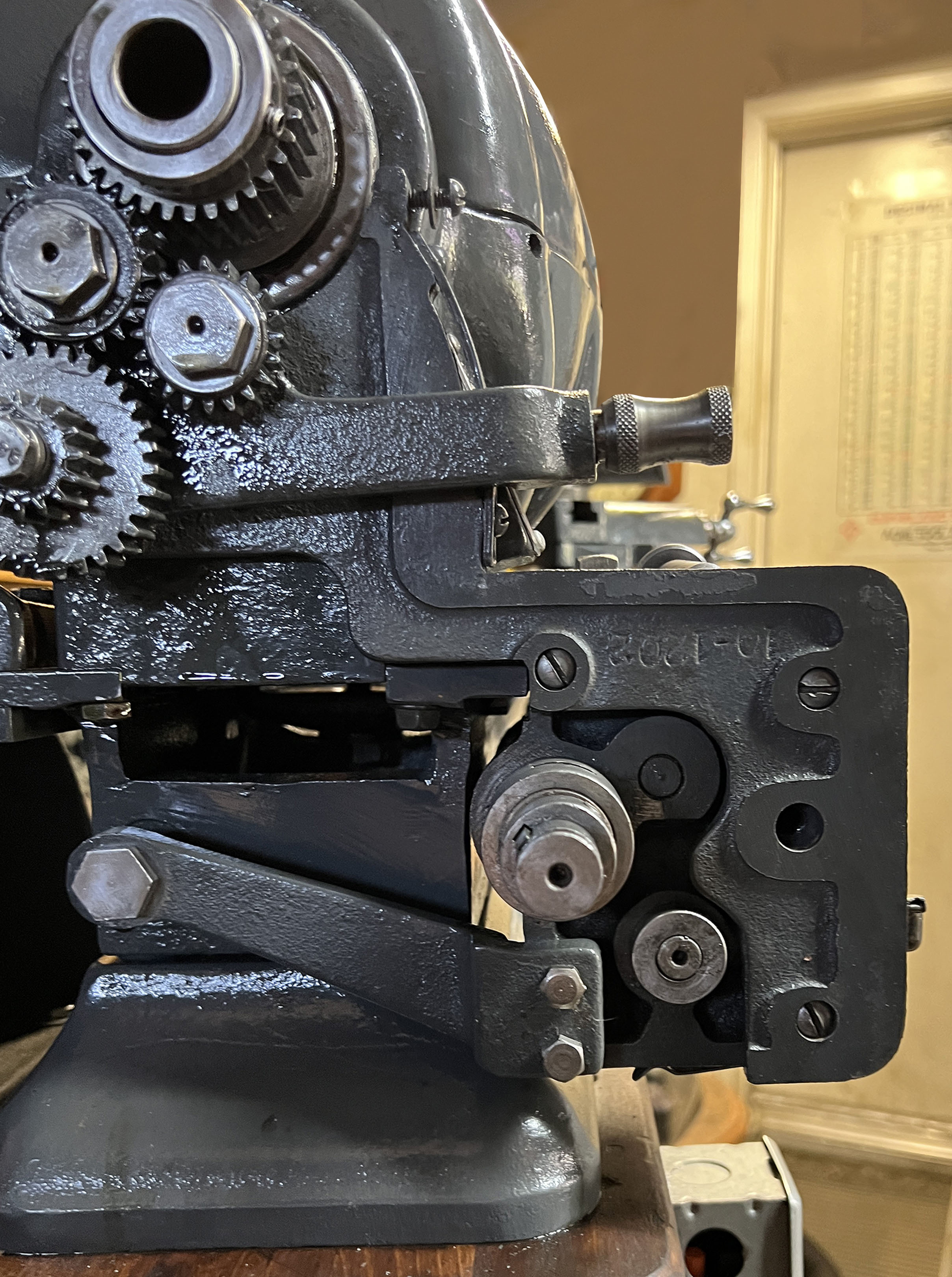

Screwcutting gearbox kit for the earlier Atlas 10" lathe. The assembly was complete in every detail and included the complete tumble-reverse quadrant plate and arm - the original bed-mounted, leadscrew-reversing gearbox being made redundant when the installation was fitted. A cast-iron cover was also supplied together with a comprehensive instruction and screwcutting-chart book. |

|

|

||

|

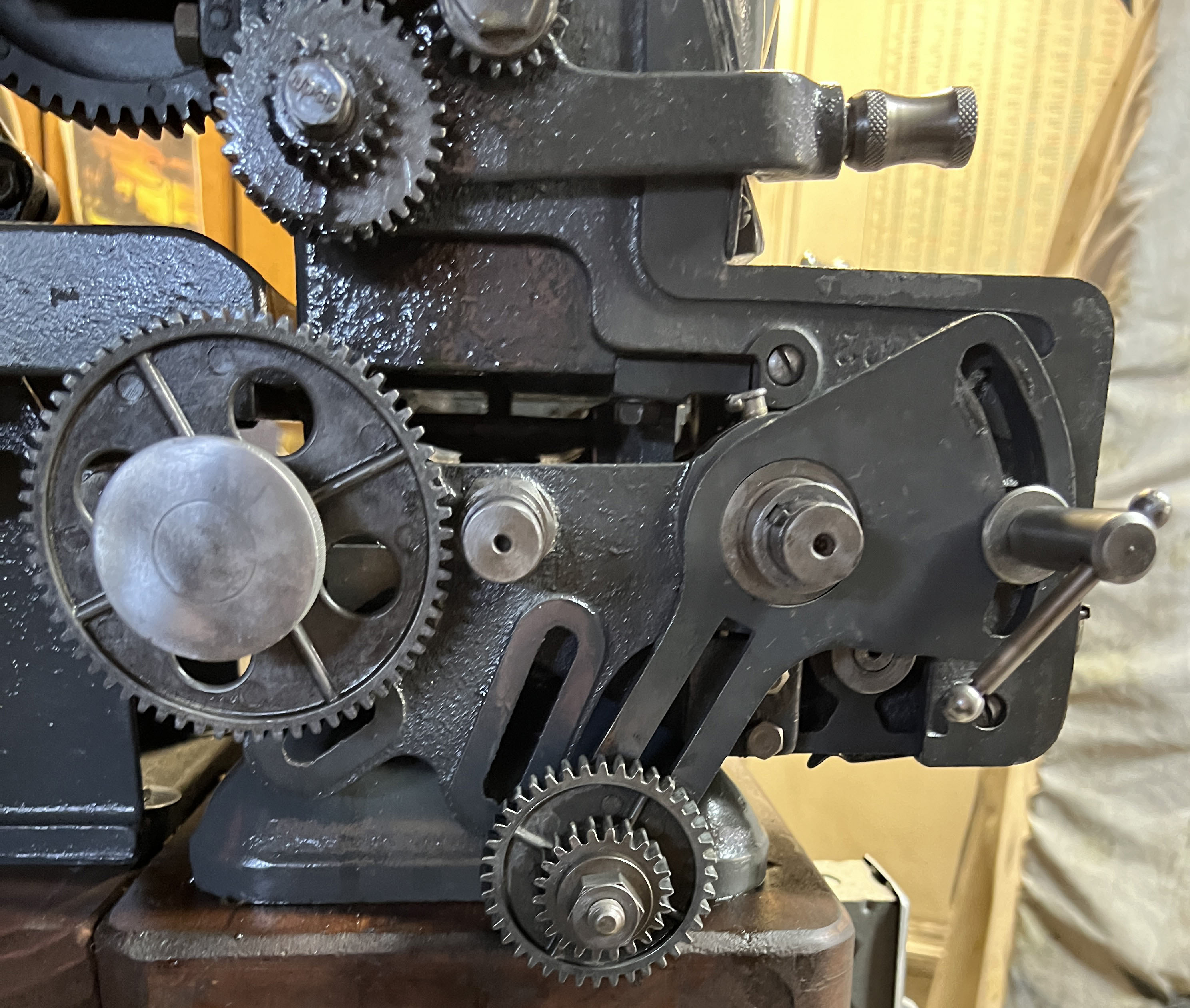

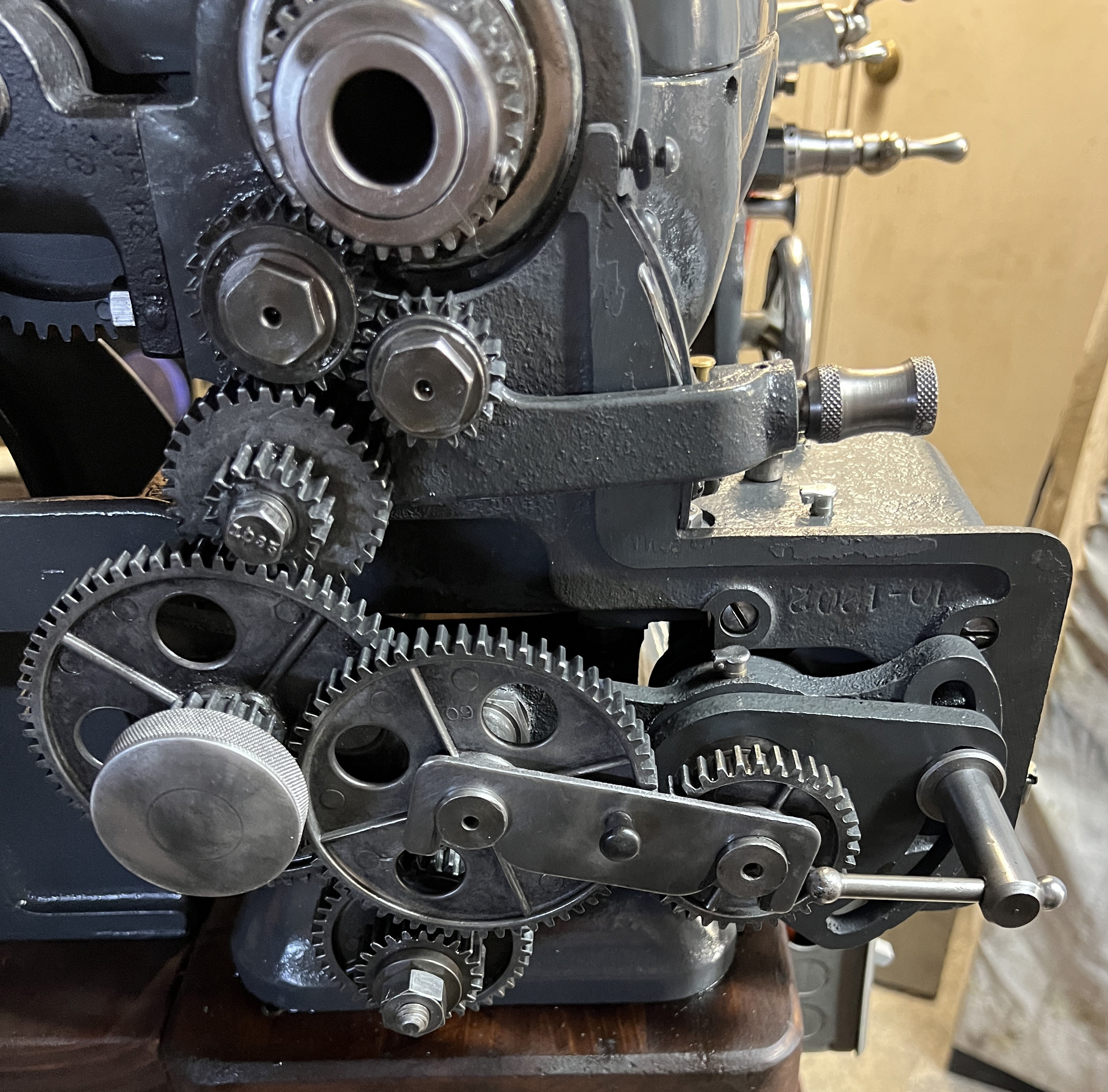

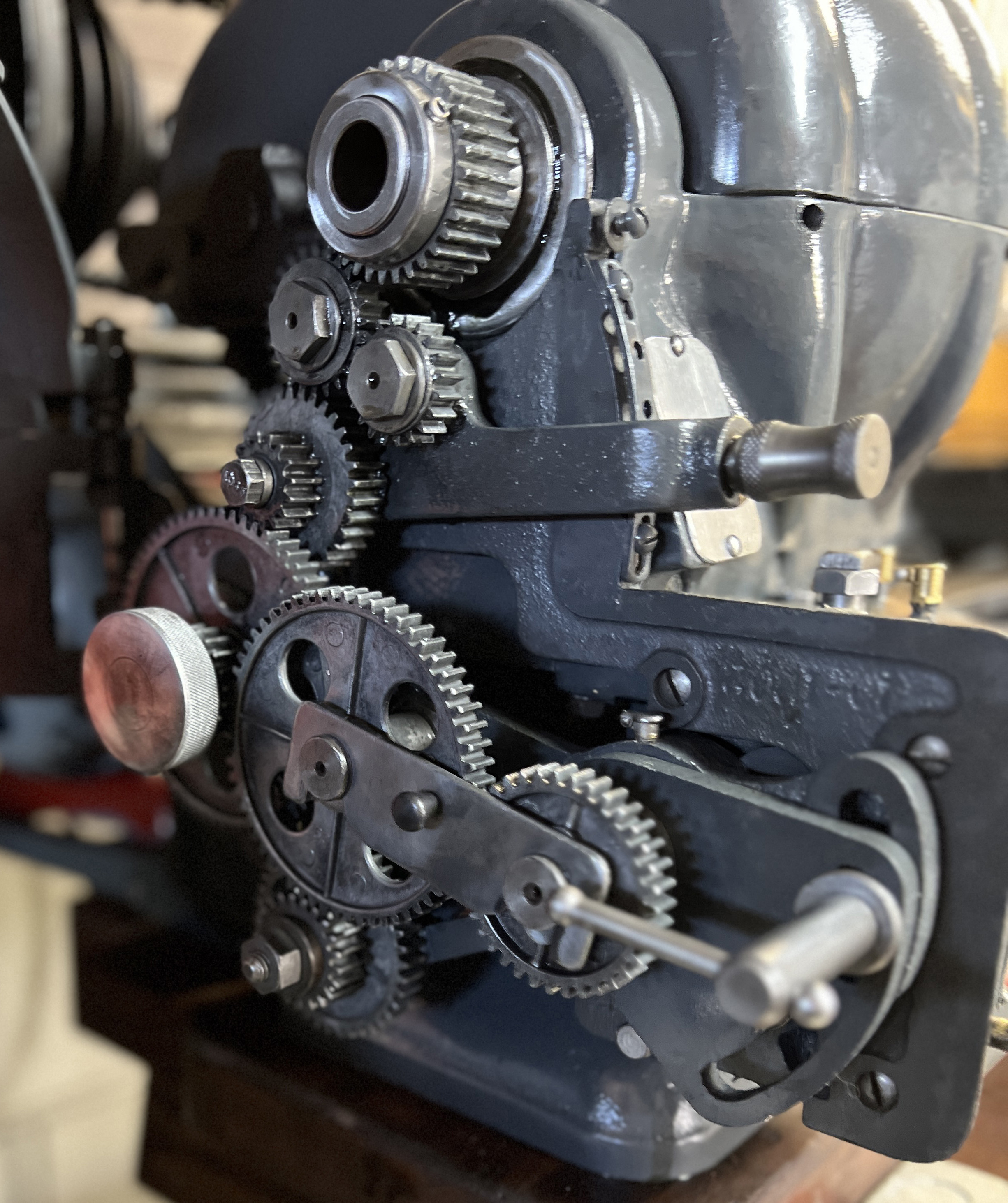

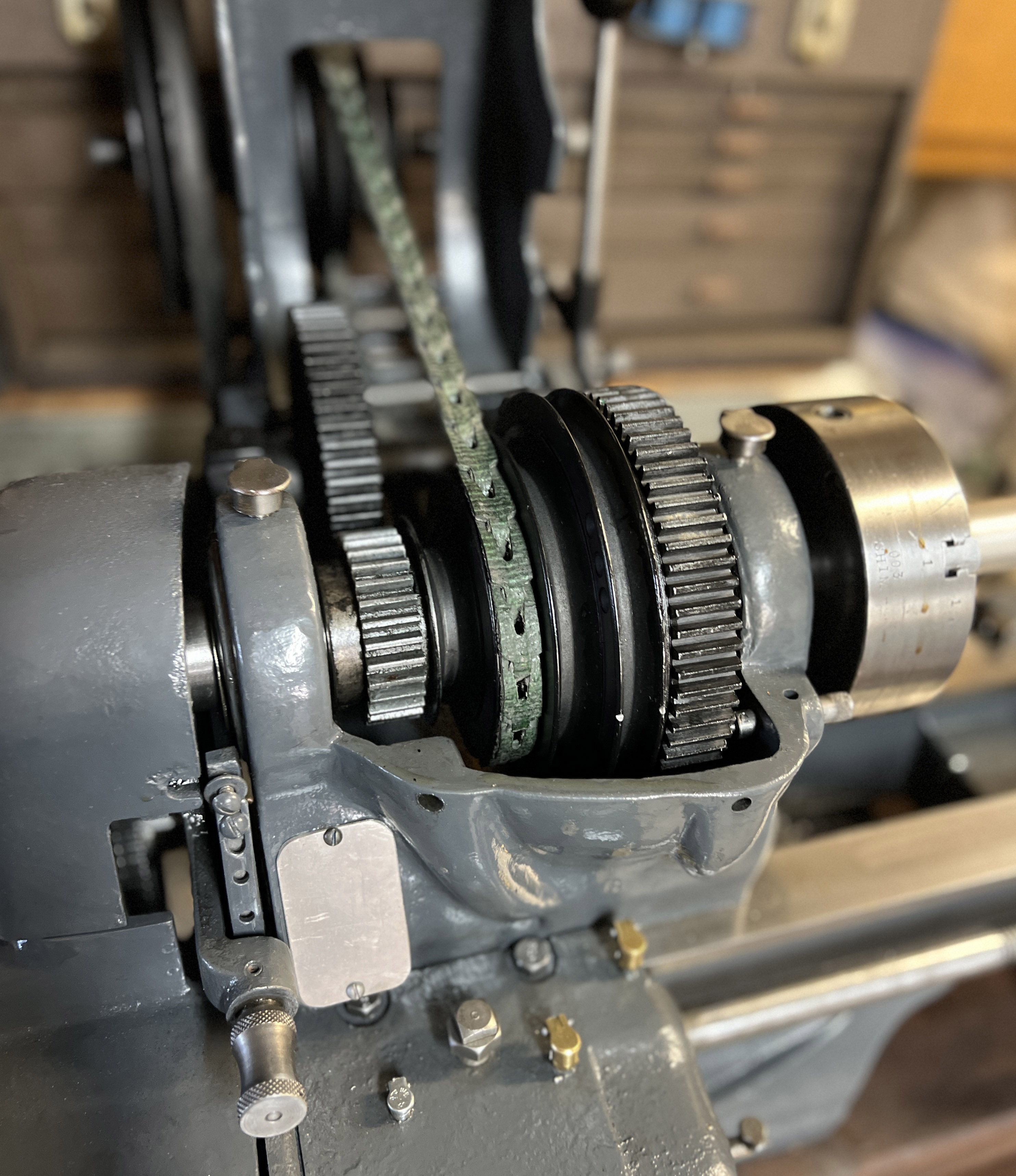

Designed in 1944, the unfortunately-named "Pick-O-Matic" screwcutting set was conceived as a half-way house to a full screwcutting gearbox. The mechanism used changewheels grouped into "Gearsettes" of which six were available: three were used for threading (to give a range of pitches from 5 to 64 t.p.i.) and three for fine carriage feeds (along the bed) from 0.0024" to 0064" per revolution of the spindle. For each setting of the changewheels 6 different feeds or threads could be selected; three were obtained from the "translation" gearbox fitted to the end of the leadscrew, whilst moving a two-position sliding gear arrangement fitted to a stud on the quadrant arm - a mechanism reminiscent of that used on a traditional Norton-type screwcutting gearbox - put them into high or low ratio. The gears were arranged into sized pairs and, consequently, could be attached to their mounting studs without the need to adjust the latter's spacing; a slotted steel yoke held the gears in place. |

|

|

||

|

|

||

|

|

||

|

|

||

|

with a complete data pack for the Atlas 10-inch and other Lathes Restored 10-D & 10F Acorn, Halifax & Sphere Copies Early 9-inch Metalmaster Lathes Atlas Factory Catalogue Covers Accessories Atlas Wood Lathes Countershafts Atlas Miller Atlas Shaper Atlas Drill Presses and "Pick-o-Matic" Screwcutting Home Machine Tool Archive Machine-tools for Sale & Wanted |