|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overhead Countershaft Drive on Unit Bench

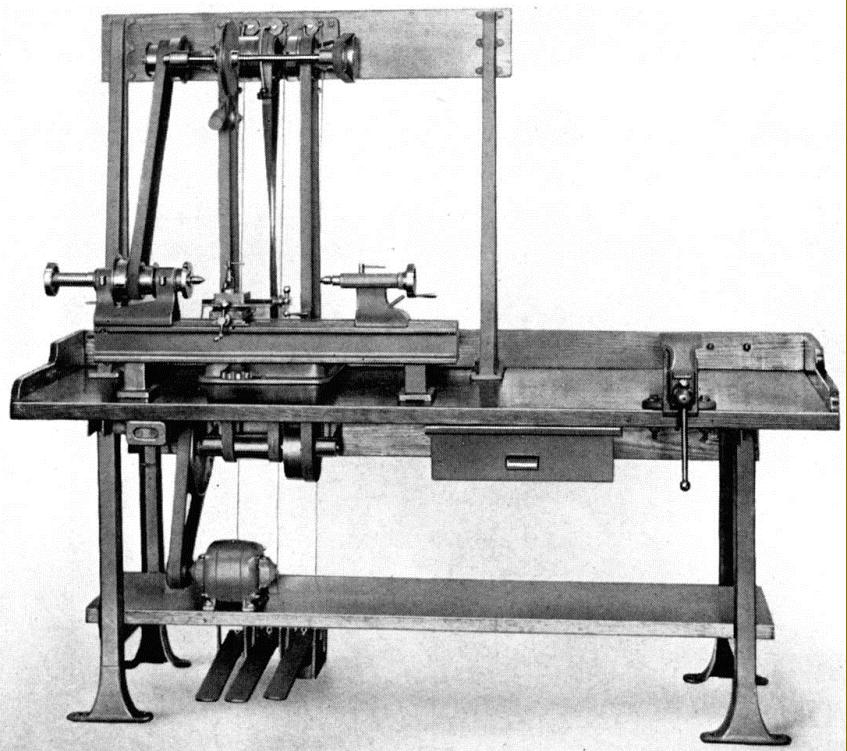

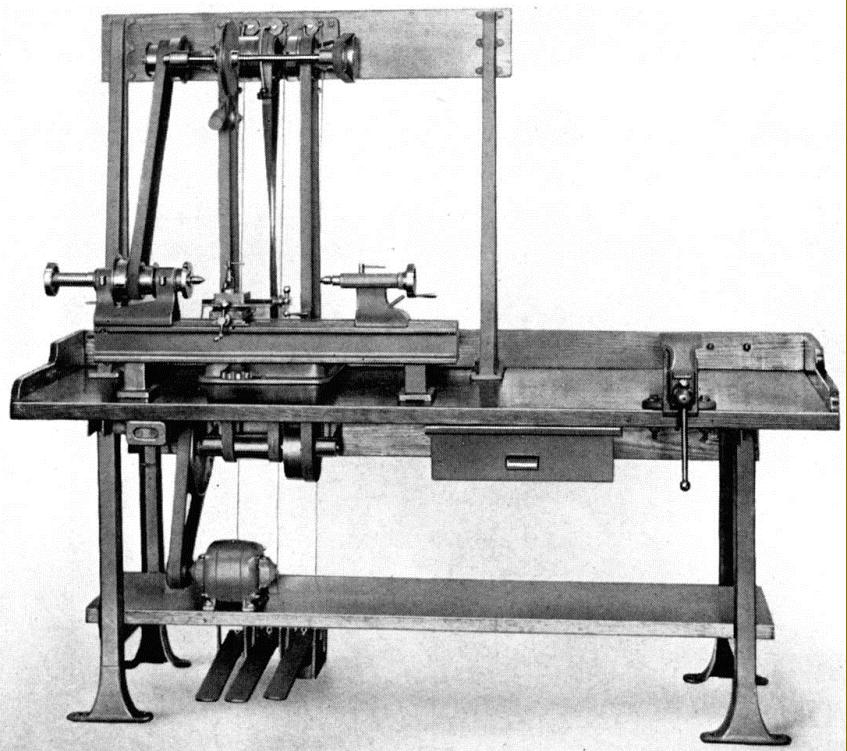

A complete 505 and 507 drive system with workbench space, pedal-selected speed change and an auxiliary high-speed grinding and milling drive. Although Rivett supplied the complete countershaft drive unit, a pair of cast-iron countershaft supports (39.5-inches) high, a pair of pressed-steel legs (maximum distance apart was a recommended 8-feet), foot treadles, an all-welded 18" x 16" steel drawer assembly, a cast-iron belt guard (just visible in the picture above below the bottom line of the bed) and other mechanical parts they did not offer any of the woodwork, this had to be obtained locally and made up in-house. A particularly well-thought-out system, with as many as 24 speeds, the all-ball-bearing countershaft was carried on neat, cast-iron uprights attached to the bench with spindle speeds selected by either hand levers or foot pedals. The system could also be fitted with a built-in drive to power toolpost-mounted accessories. With a working space to the right of the lathe, the assembly was intended for use

In laboratories or toolrooms where space was needed for tools, small parts and sub-assembles to be laid out and a trail fit of components made. However, despite all these conveniences, by the 1940s this type of drive arrangement was beginning to look distinctly old-fashioned.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

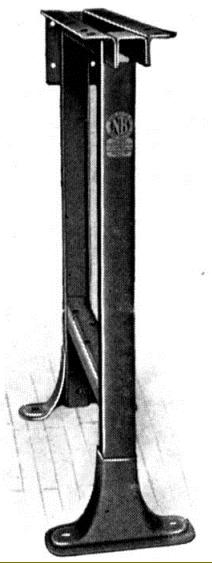

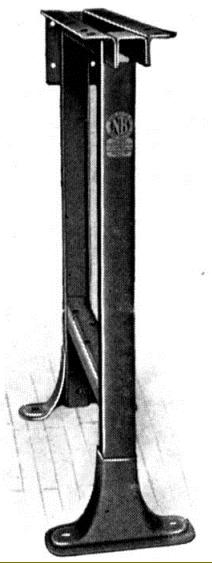

Oil Pan Mounting Stand with Overhead Drive A type 507 on the stand intended for heavier industrial use on the shop floor

|

|

|

|

|

|

|

|

|

|

|

|

|

|

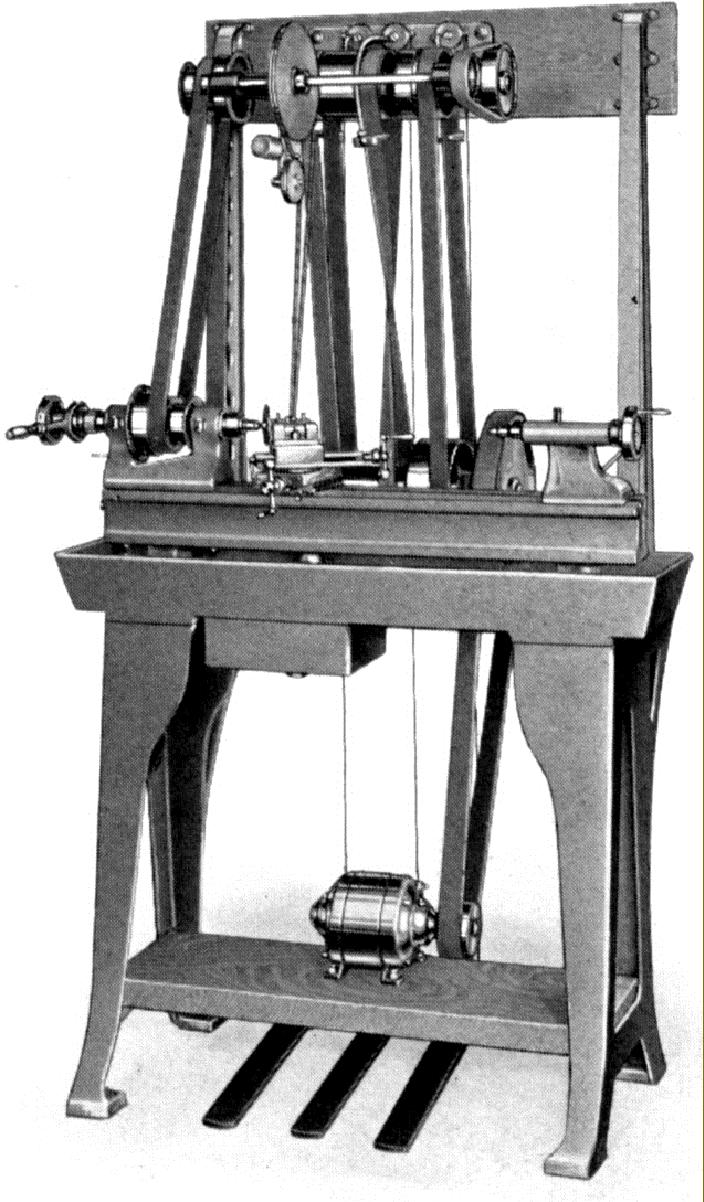

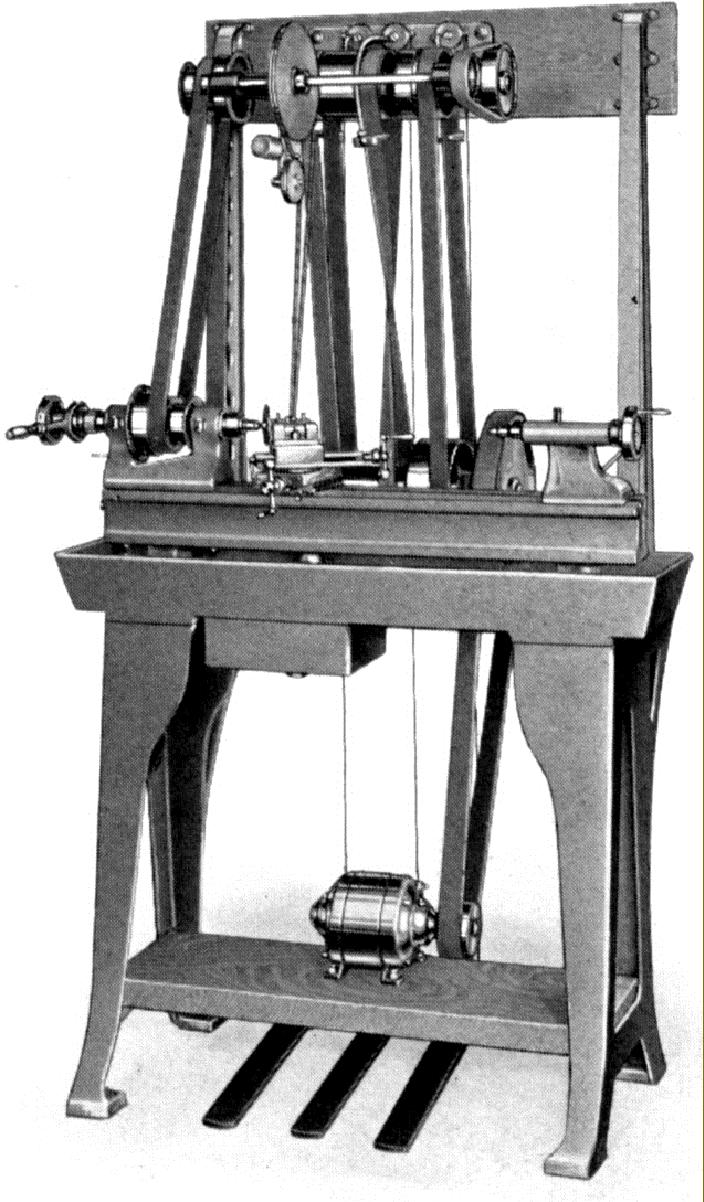

Rivett 507 Junior arranged as a hand turret lathe on an all-cast-iron stand and tray, lever-action collet closer and a coolant pump with pipework.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Section through the Rivett 507 Junior plain-bearing headstock.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

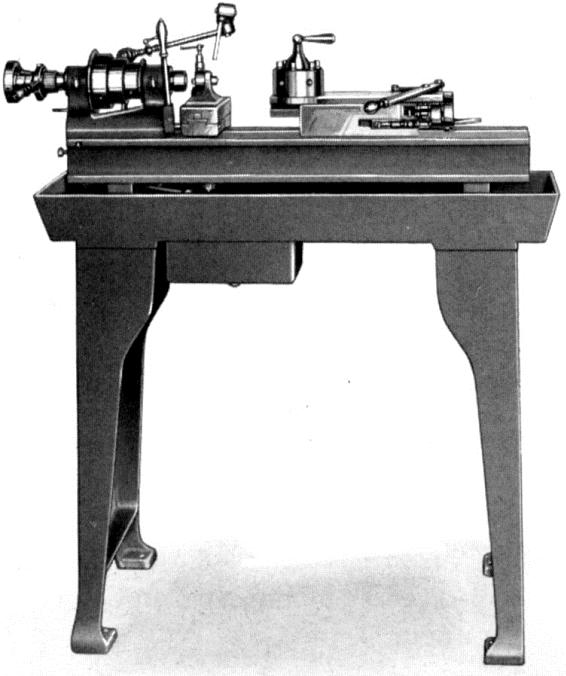

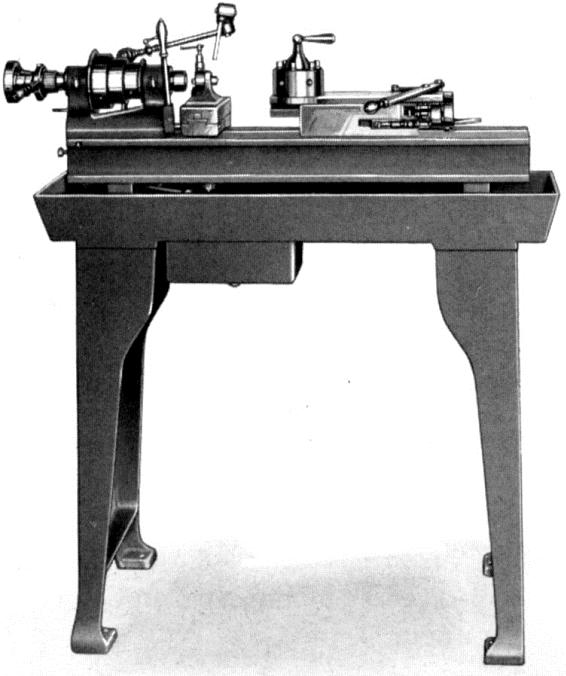

Type 507 with an ordinary rocker toolpost in a T-slotted top slide

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type 507 with the traditional Rivett quick-set eccentric-mount toolpost

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

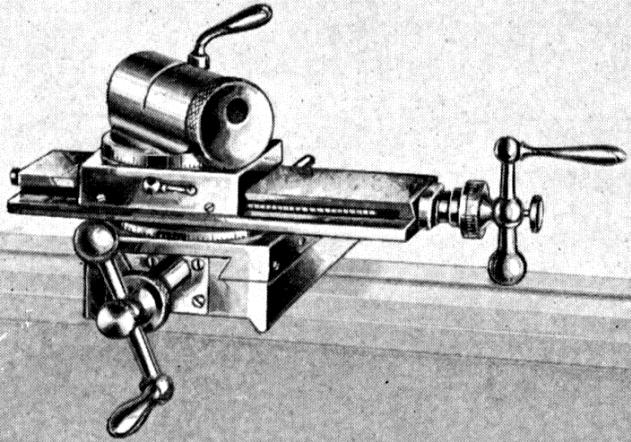

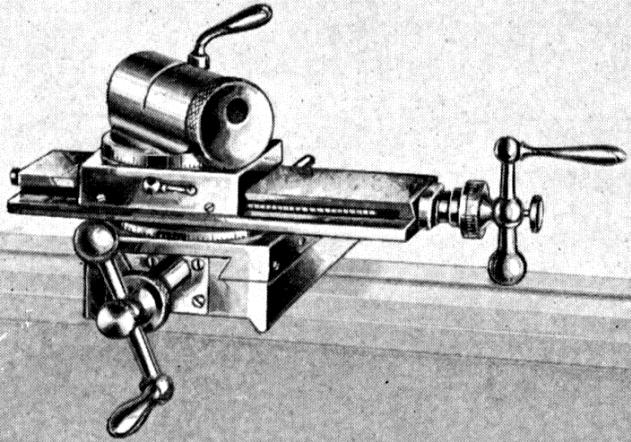

The versatile and ingenious Milling Accessory - the complete unit is illustrated in the picture below, mounted on the lathe bed, and fitted with the Indexing Attachment.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Milling Attachment being used to generate the teeth of a milling cutter.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The basic Milling Attachment being used with a simple angle plate to mill a keyway in a shaft.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Special Rivett vice employed to hold material being cut to a dovetail form.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rivett vice held on angle plate and set for milling teeth in a rack.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Indexing Attachment mounted on the ordinary compound slide and being used to drill equally spaced holes at an angle in a disc.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

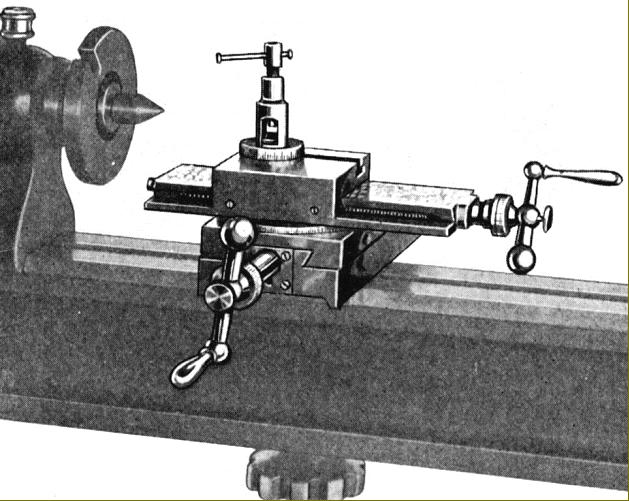

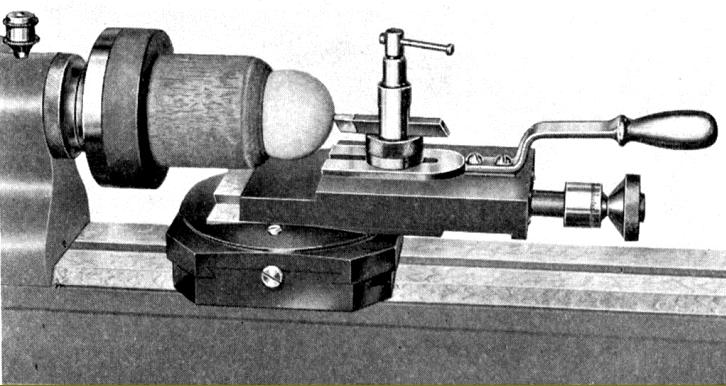

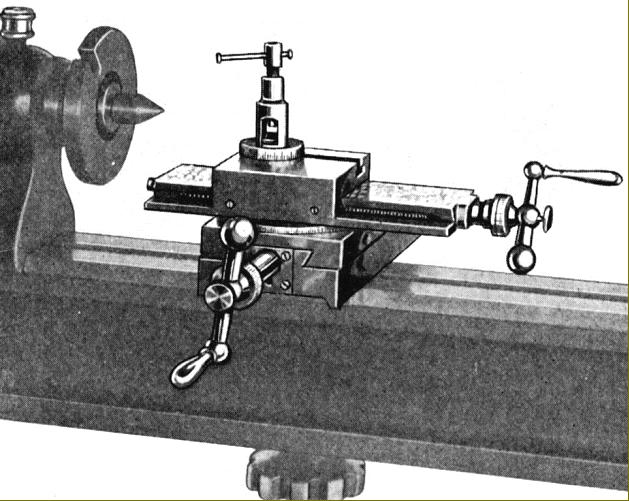

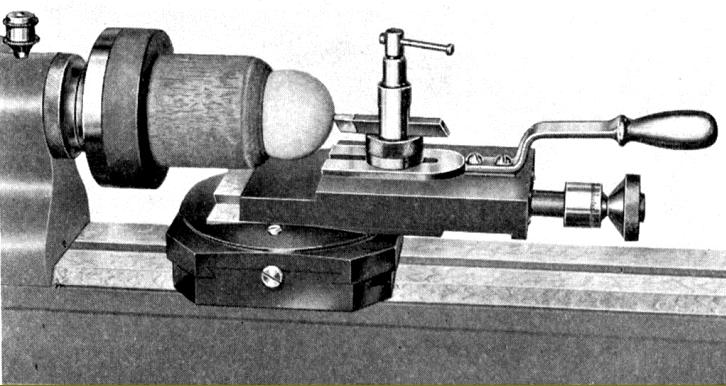

Ball-turning attachment

|

|

|

|

|

|

|

|

|

|

|

|

|

|