|

Home Machine Tool Archive Machine-tools Sale & Wanted 504, 505, 507 & 606 Precision Lathes 715 Lathe 918 Lathe 1020/1030 Toolroom Lathes 1020R Toolroom Lathe Rivett Watchmaker's Lathes Rivett Factory Rivett Millers |

||

Speed Box Motor Drive on Unit Bench with Auxiliary Drive. This version provided an alternative mounting for the two-speed gearbox unit and was designed to provide greater bench space when the lathe was used for tool making and experimental machining in a laboratory or toolroom setting. The 72" x 26" x 21/4" top (that allowed ample space to lay out components for trial fits, etc.) was made of maple, shellaced and waxed. The cast-iron legs, braced with steel ties were finished in machine-tool grey.

Mounted at the back of the lathe was an auxiliary 1/4 hp 1750 rpm motor to drive an "overhead" used to run slide-rest mounted grinding and traverse-milling attachments and able to provide speeds of 6000, 8000 and 10,000 rpm. To complicate matters, various other combinations of motor drive were offered with this stand, including the Horizontal Safety Drive and the rear-mounted Motor Jackshaft Assembly - with final drive to the headstock by V-belt.

|

Overhead Countershaft Drive on Unit Bench. This was a particularly well-thought-out system with as many as 24 speeds and with the all-ball-bearing countershaft carried on neat, cast-iron uprights attached to the bench. The system included a built-in drive to power toolpost-mounted accessories and the spindle speeds could be selected by either hand levers or foot pedals. However, despite all these conveniences, by the 1940s this type of drive arrangement was beginning to look distinctly old-fashioned . |

||

|

Unit Bench with Horizontal Safety Drive. Yet anther variation on the open-bench mounting but this time with a rear-mounted countershaft fitted with an electric motor having spindles emerging from both ends. Whilst one motor shaft was utilised to drive the lathe-spindle countershaft, the other was employed to power the counterweighted "overhead". This stand was fitted with cast-iron legs, but if the customer wished to save weight, the option was available to replace these with ones fabricated from pressed steel; at the same time the threaded steel tie rods at the back of the stand were changed for ones made from flat steel strip. |

||

|

|

||

|

|

|

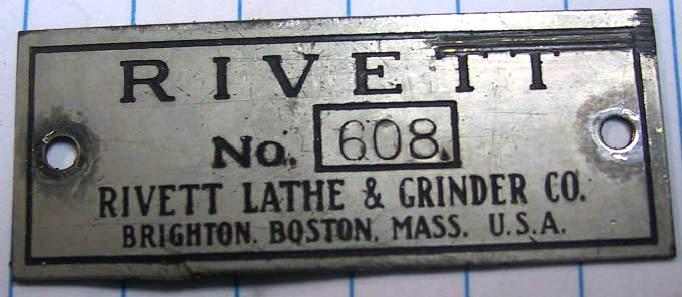

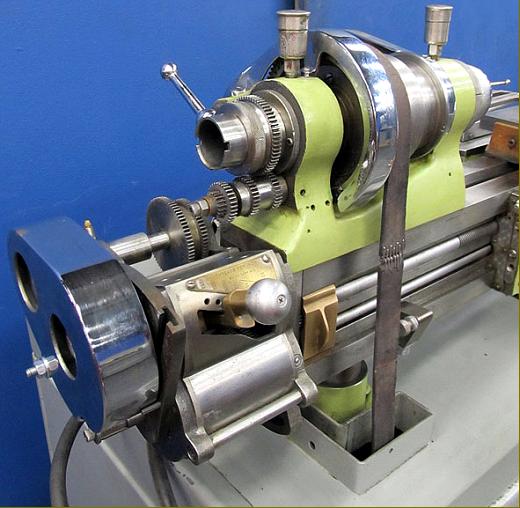

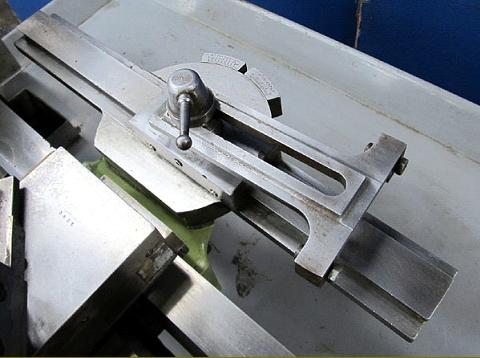

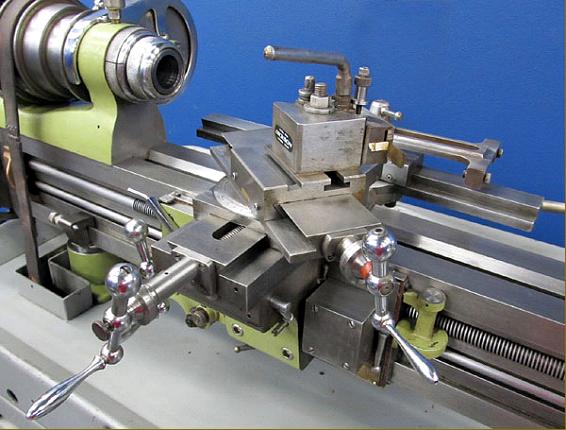

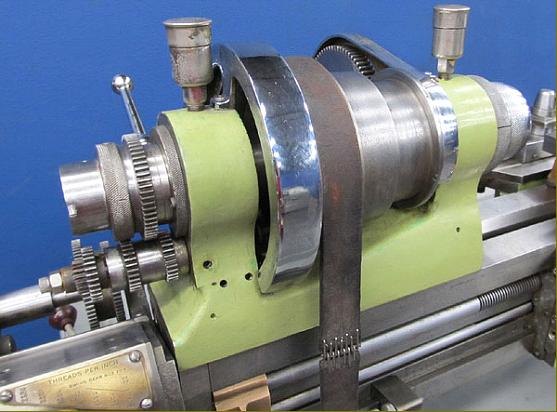

Rivett 608 with a 5C collet headstock on the maker's metal cabinet stand. Stamped: Model 608/PB/5C Serial 636 6/24/1941. |

|

504, 505, 507 & 606 Precision Lathes 715 Lathe 918 Lathe 1020/1030 Toolroom Lathes 1020R Toolroom Lathe Rivett Watchmaker's Lathes Rivett Factory Rivett Millers Home Machine Tool Archive Machine-tools Sale & Wanted |

||