|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

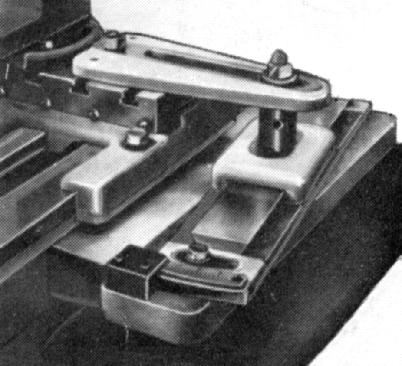

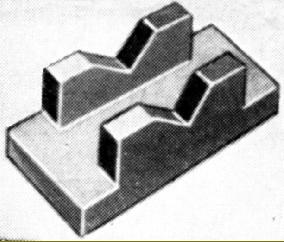

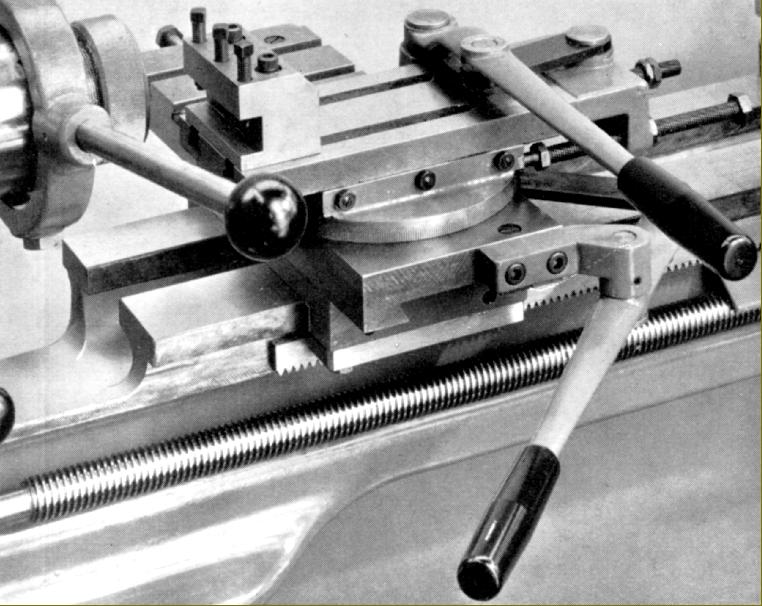

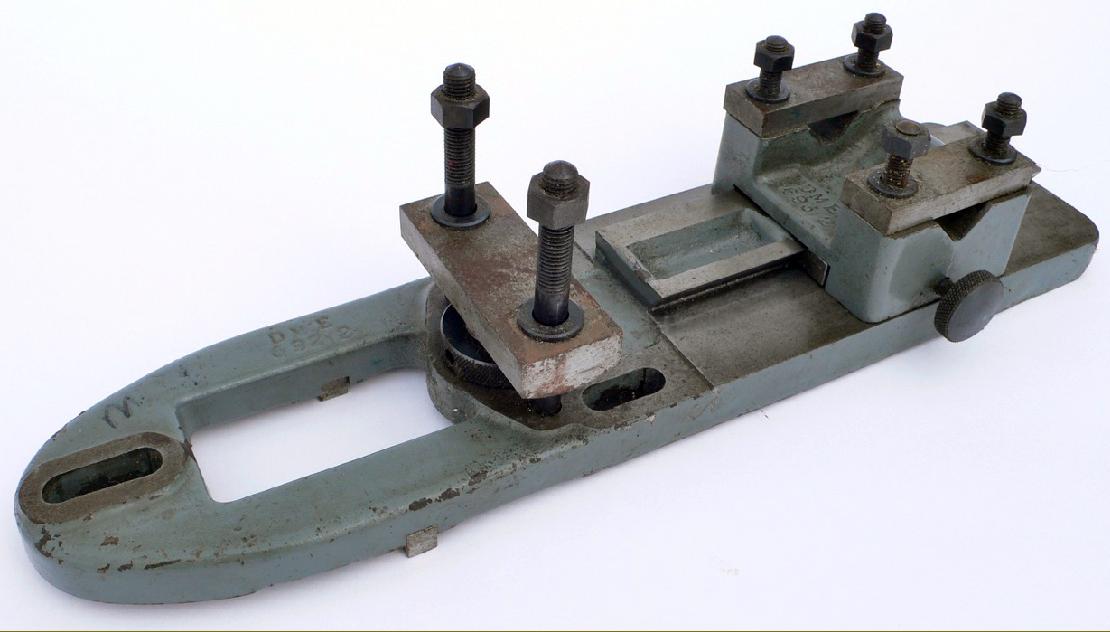

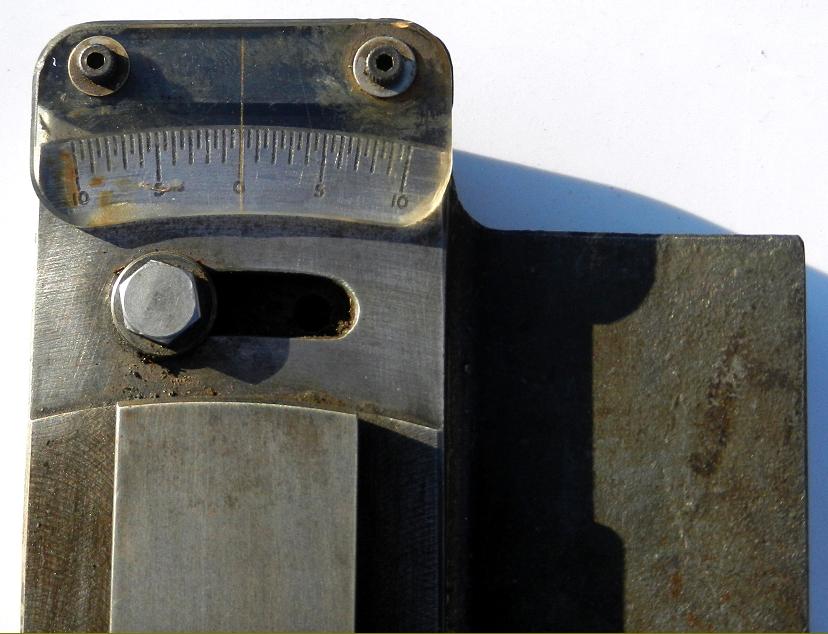

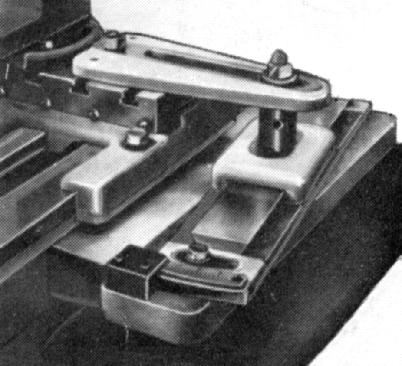

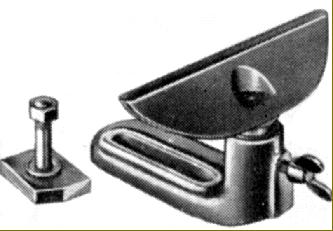

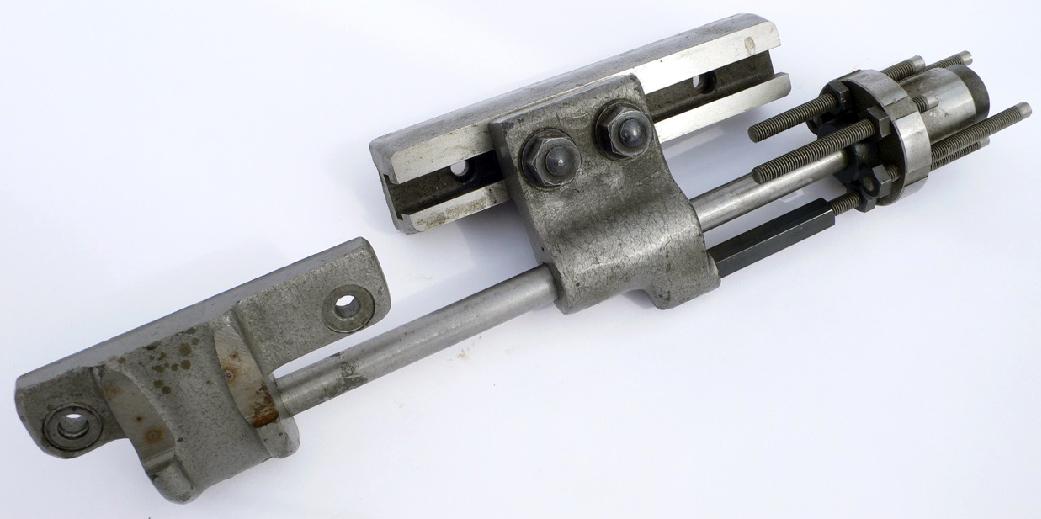

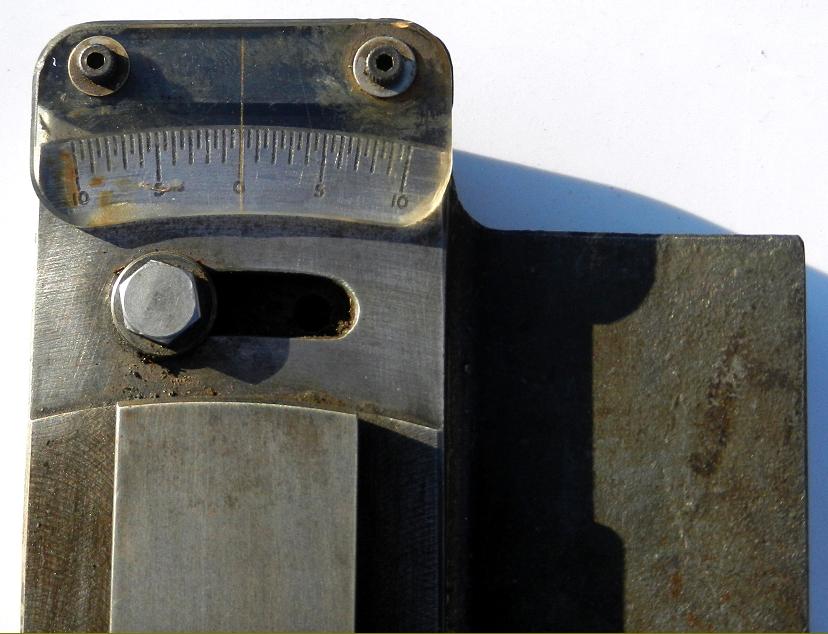

Swivelling milling slide

A widely used and popular accessory- and easily adapted to fit a number of other small lathes. This slide was made in two forms: the early as shown with a single bolt per axis and a later improved model with two bolts per axis. In addition, in later years, Myford offered larger versions of both the plain ands swivelling slides.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

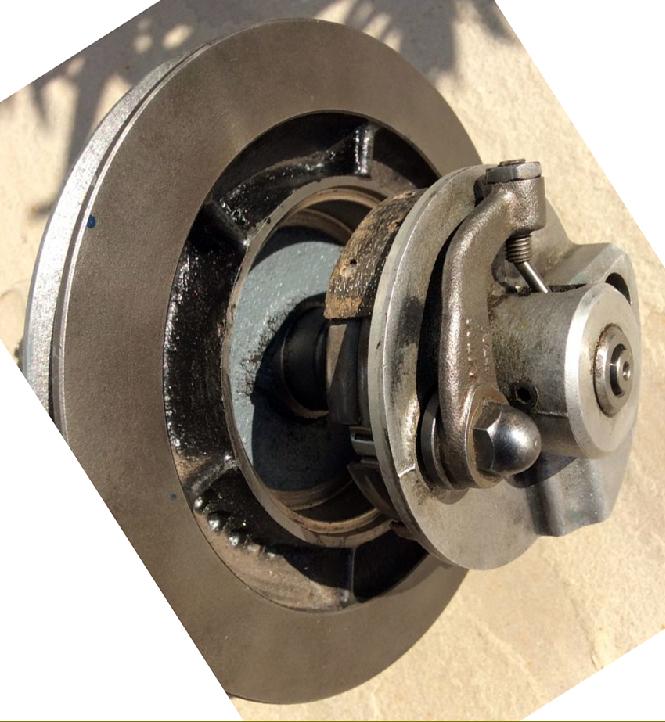

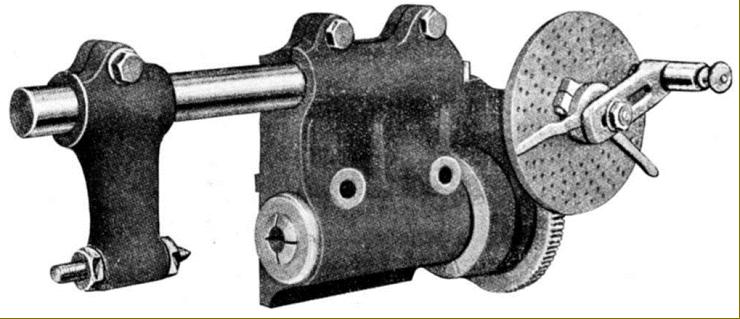

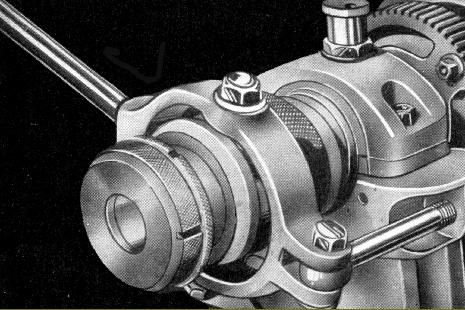

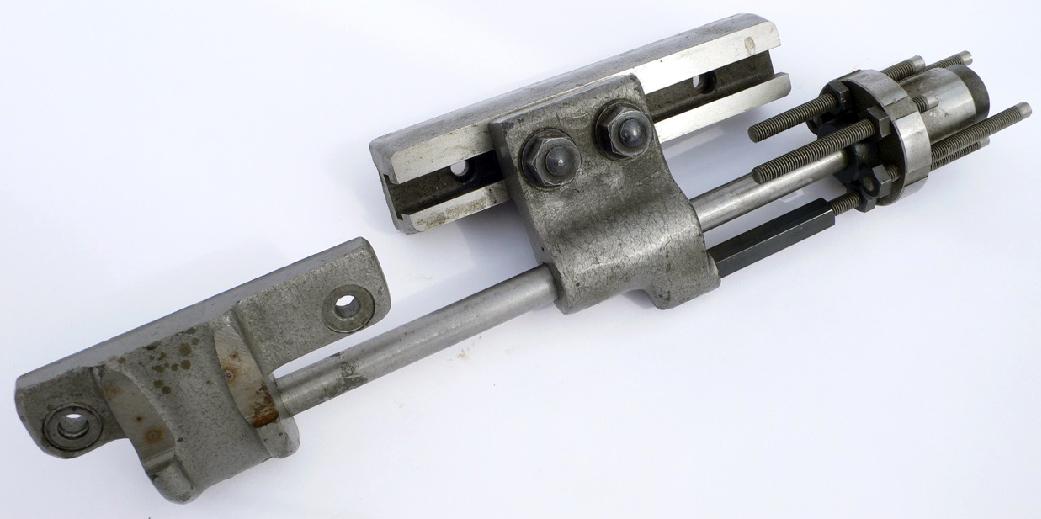

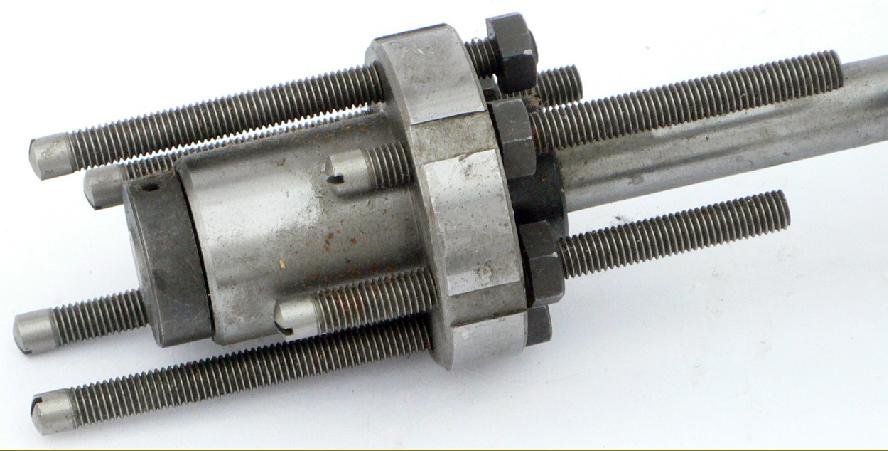

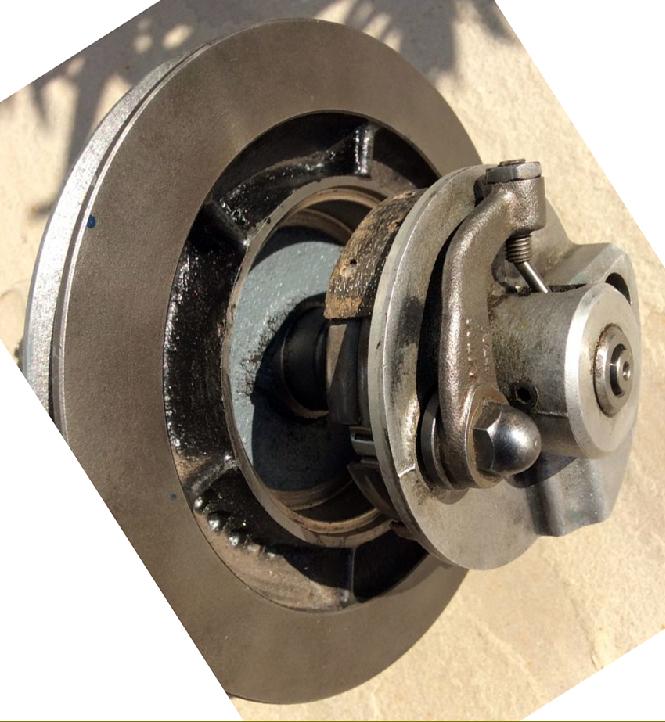

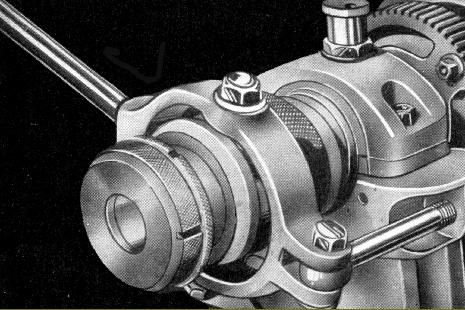

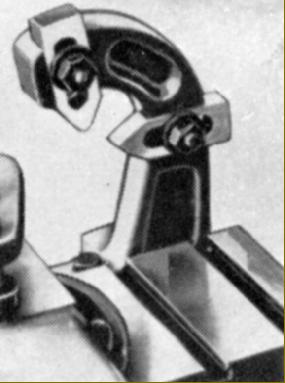

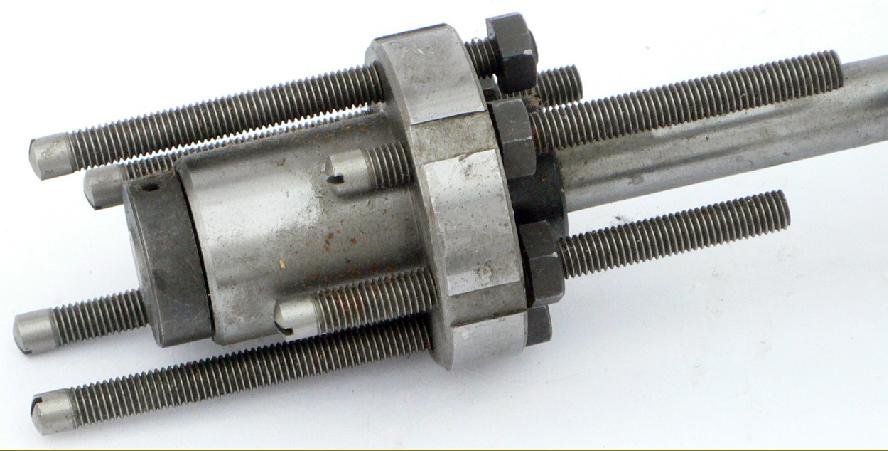

Clutch unit for an ML7. Unfortunately, this very useful accessory is no longer sold by the factory - but occasionally second hand units become available and are well worth acquiring. The unit economised by utilising the brake shoes from the front wheel of a Nottingham-made Raleigh moped, the "Gadabout". The picture below shows some details of the rather "unusual" engagement mechanism. The hardened pin, that flicks back and forth to open and close the clutch, is rounded at both ends to register into its holders - and 29 mm long and 3 mm in diameter.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Graduated handle for leadscrew end

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Taper-turning attachment (photographs below)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

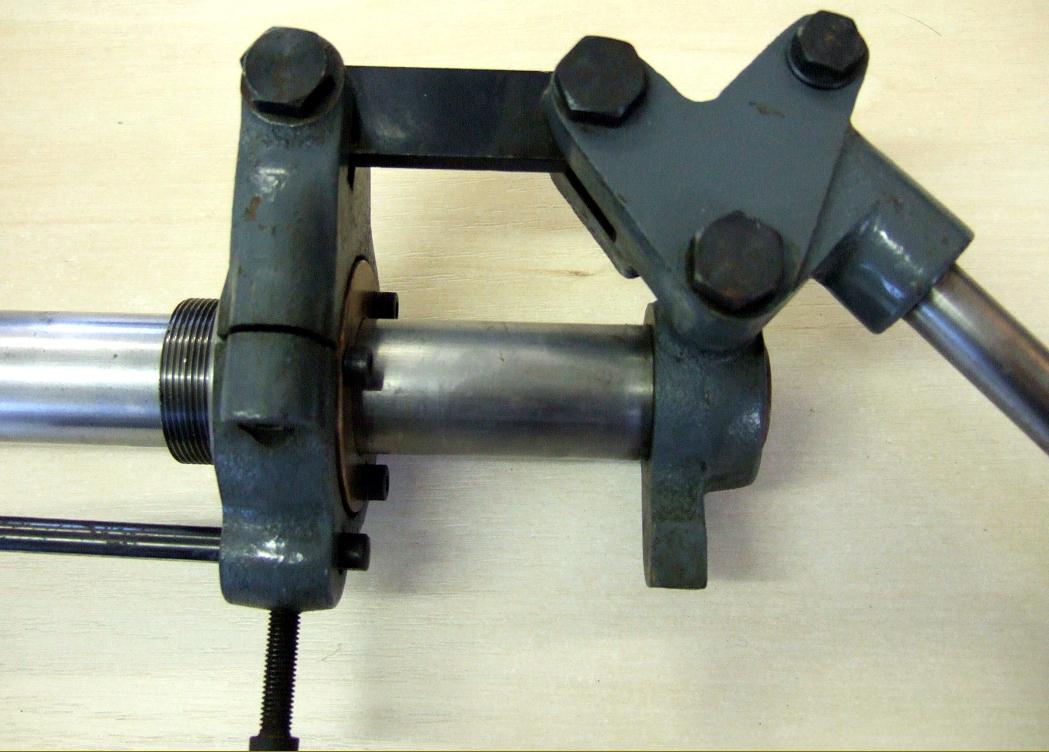

Lever action tailstock

Myford-made versions are available for both the ML7 and Super 7 - but not the ML10 lathe.

This is a very useful accessory and transforms the feel of the tailstock, especially when performing delicate operations with small drills. A highly recommended addition to any lathe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

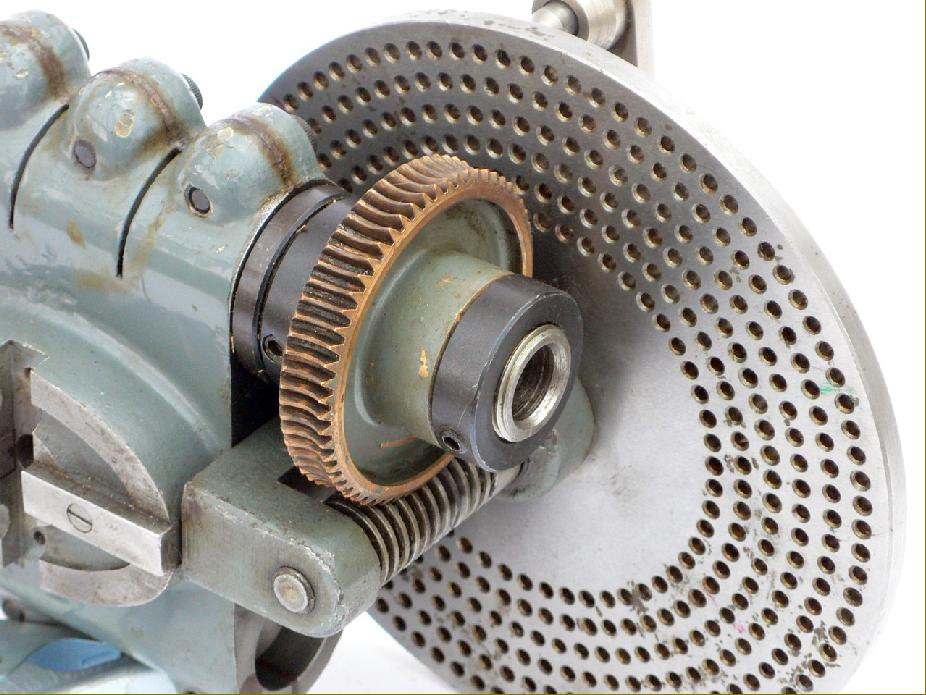

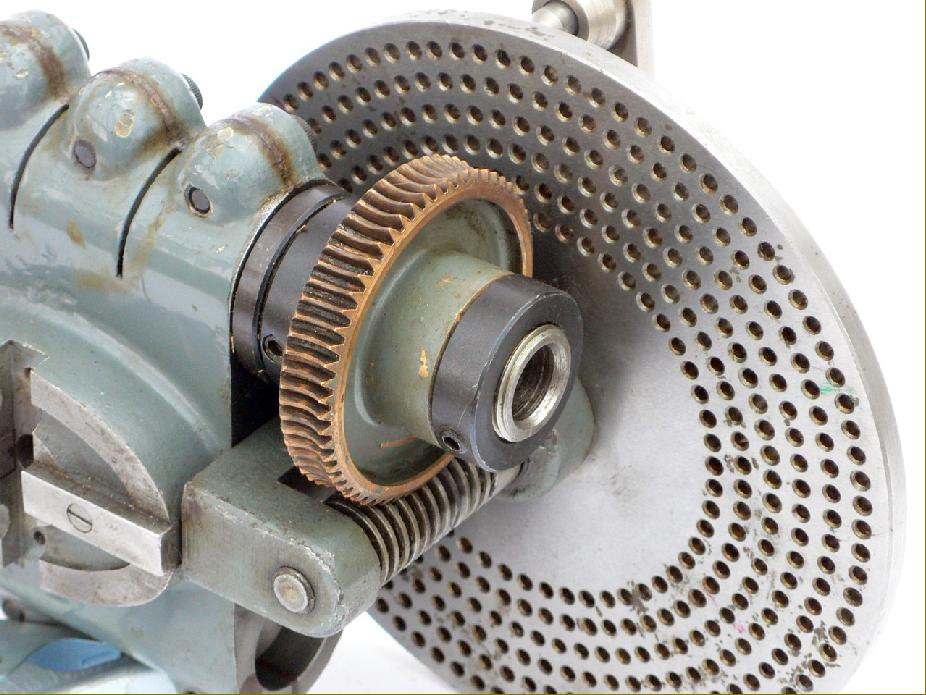

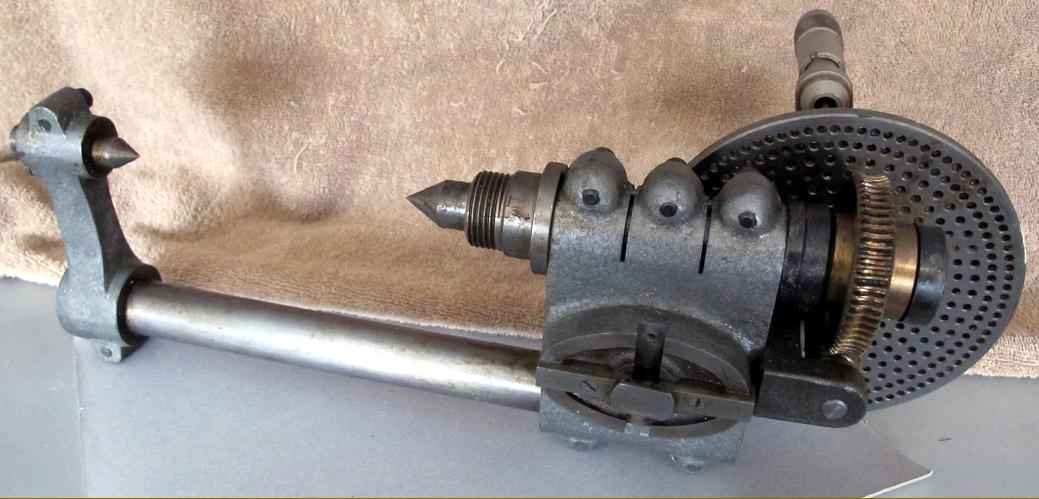

Dividing Attachment.

With a design inspired by the pre-WW2 "gear-cutting" attachment sold by Tom Senior, and although and expensive addition to the amateur's tool chest, this versatile unit holds it value very well and is in constant demand. It not only transforms the lathe into a gear-cutting machine but enables it to mill square, hexagon and other forms and, if employed with the supporting overarm, allows it to cut single or multiple keyways in shafts, etc. The usefulness of this attachment is limited only by the imagination of the user.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dividing attachment shown fitted to the earlier type of single- bolt-per-axis swivelling vertical slide.

The attachment fits the ML7, Super 7 and ML10 lathes

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

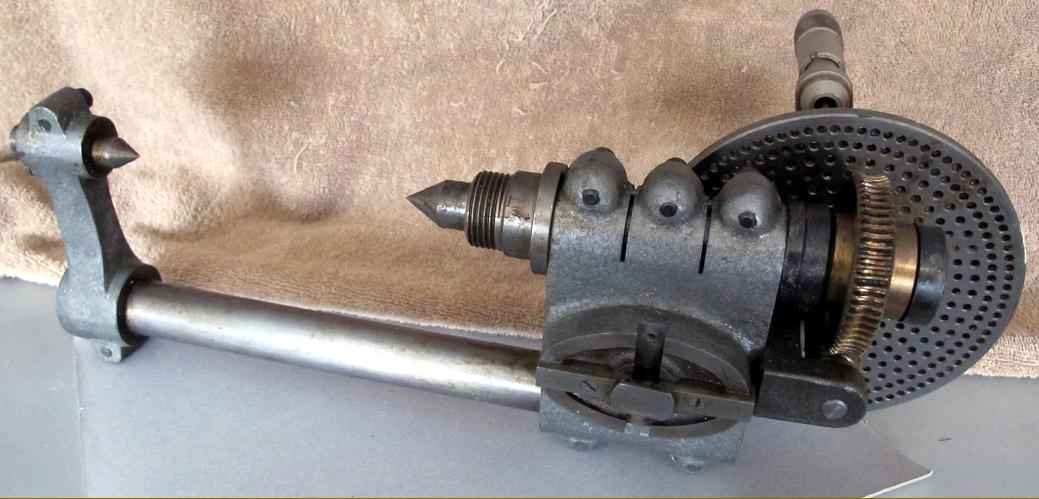

The inspiration for the Myford dividing head: the pre-WW2 "gear-cutting" attachment sold by Tom Senior,

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wood and hand-turning rest

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

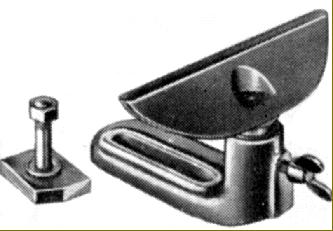

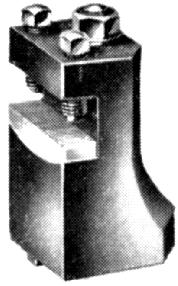

Small machine vice for mounting on the cross slide or vertical slide.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Quick-release, lever-operated collet chuck.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fixed steady for ML7 and Super 7

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

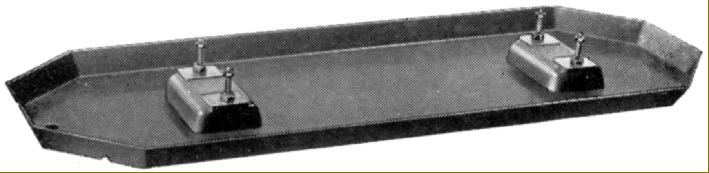

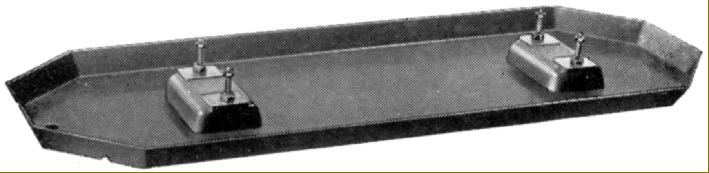

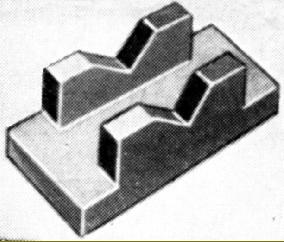

2-inch deep chip tray with cast-iron levelling blocks

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The ordinary Myford stand fitted with a deep chip tray and levelling blocks. The stand is 37" long, 33.5" high and the floor mounting bolts pitched about 15.5" apart front to back. The chip tray is 42" long, 15.25" wide and 1.5" deep. The raiser blocks are 6" long, 4" wide and 0.875" high. The blocks are drilled and tapped and fitted with large diameter, hollow, internally threaded bolts into which the lathe holding down studs are screwed. The lathe feet fit on top of these hollow bolts. Once the blocks are secured to the stand the hollow bolts can be screwed in or out to level the lathe bed. A finishing touch, typical of Myfords attention to detail, was the provision of cork mats on the shelves ...

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

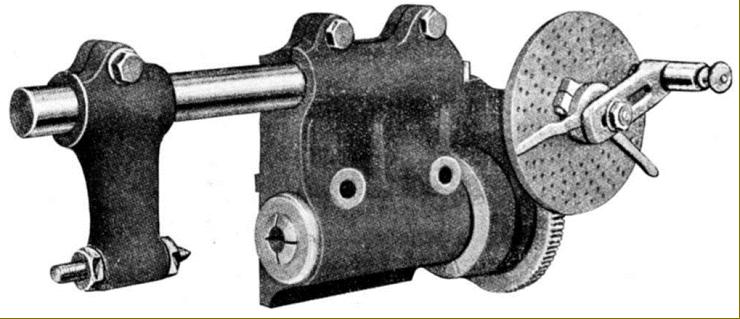

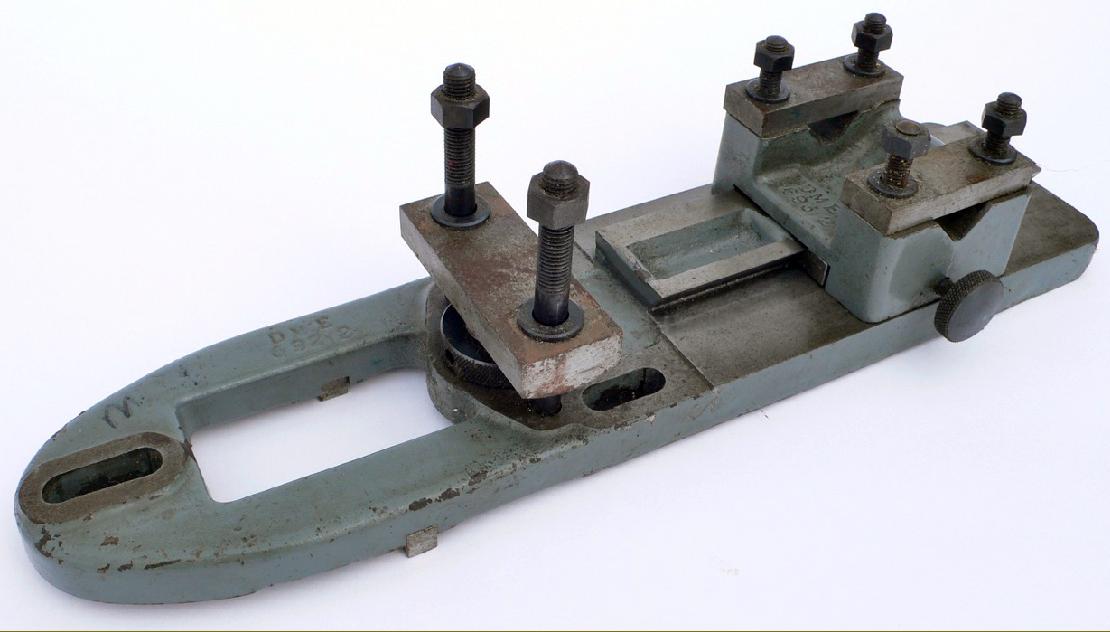

A con-rod boring jig. This is the same unit as supplied by Drummonds for their M Type lathe and adapted by Myford after they started manufacturing the latter machine in 1942.

This unit really worked, as witnessed by Britain's foremost re-metaler of vintage-car engine bearings who began his business at home with just such a lathe and attachment.

|

|

|

|

|

|

|

|

|

|

|

|

|

The Dividing Head and Swivelling Milling Slide being used together to cut a gear.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

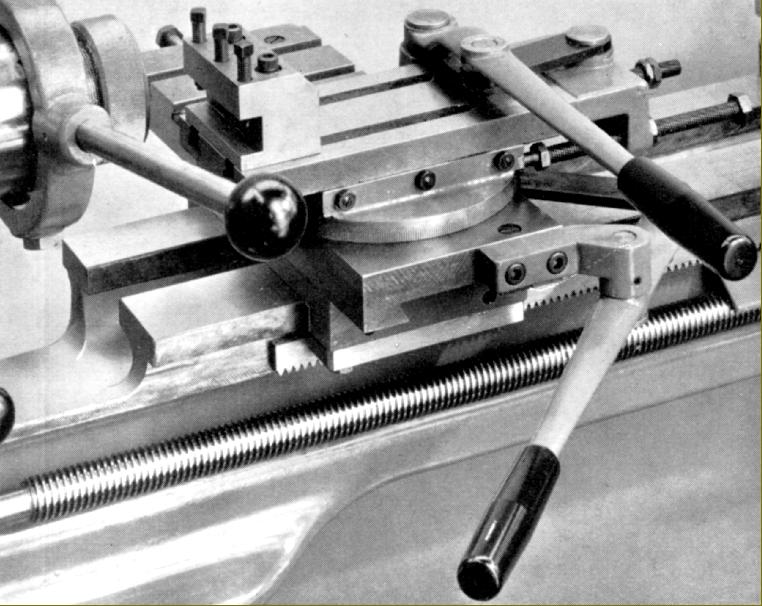

Production equipment mounted on an early Super 7.

Lever-action collet unit, cross slide mounted six-station capstan screw-feed cut-off slide with front and rear toolposts and, partially visible, a bed-mounted multi-stop.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rotating carriage Multi-stop - part of the production equipment

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

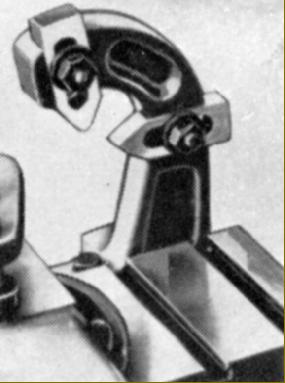

Lever-action collet closer. On early examples of the ML7 this pivoted on a bronze housing that clamped to the stiffening

ribs at the rear of the front spindle bearing. Later machines were provided with a tapped hole and clevis arrangement

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

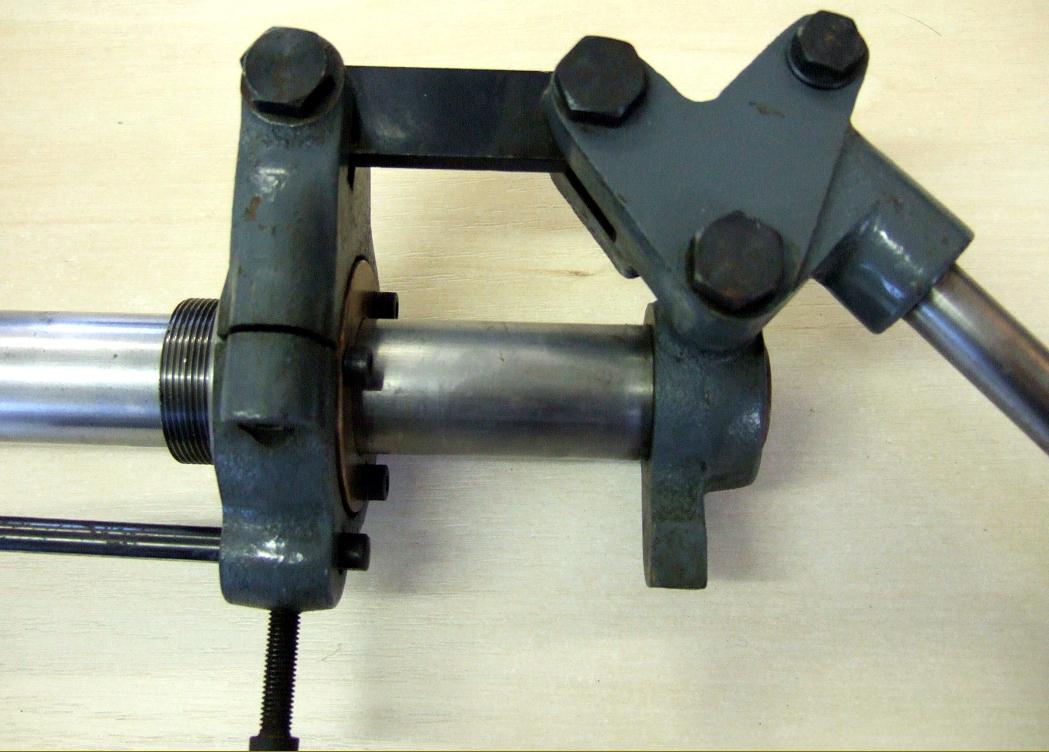

Lever-action tailstock assembly for the Super 7

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Myford Dividing Head with all 4 plates

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Raiser block for dividing head - at the rear, a standard Myford angle plate

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Taper-turning unit to fir ML7 and Super 7 lathes

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|