|

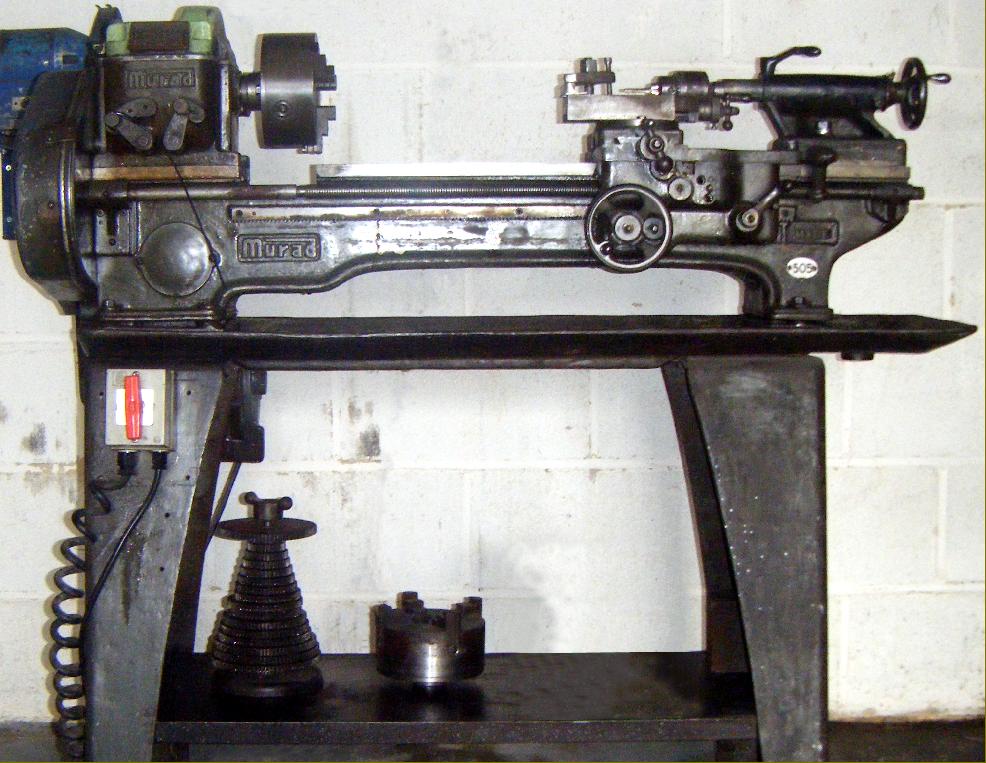

Introduced at a yet-to-be determined date - though probably in 1946 or 1947 - the "Cadet" was the first of Murad's conventional screwcutting centre lathes. With just a 4-inch centre height (and with either 18 or 24 inches between centres) it was, unusually for its capacity and configuration, a geared-head machine that would have been expensive to produce. The soon-to-be-announced belt-drive Boxford (a South Bend 9-inch clone) would have been stiff competition, offering more capacity and the choice of several models from simple, inexpensive stripped-down versions to ones with power cross feed and a screwcutting gearbox. Indeed, in response, Murad then announced the "Antarctica" a belt-drive version of the Cadet that, in the writer's experience ran with commendable smoothness and in almost complete silence.

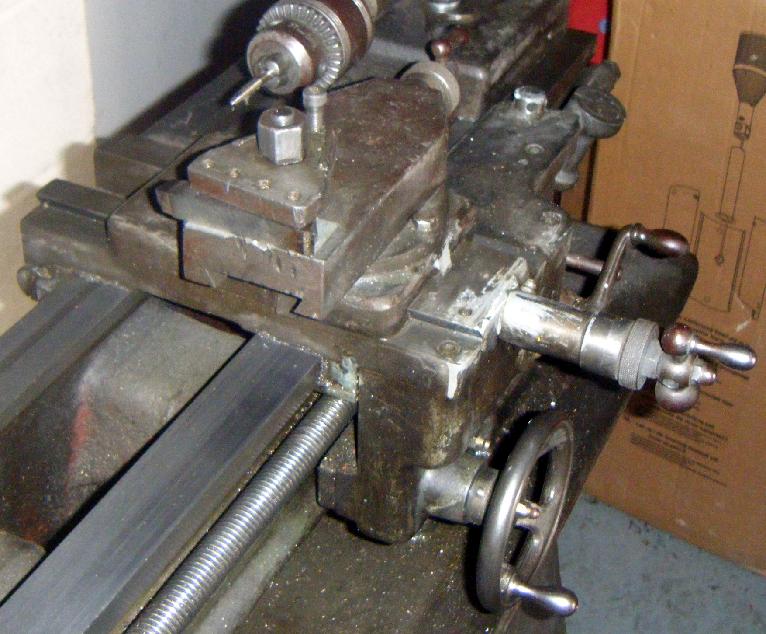

Appearing to be a completely new design, conceived in-house, the Cadet had simple, English-style flat bed ways, a permanent gap in the bed (that admitted a maximum of 11 inches in diameter), a particularly heavy tailstock and was available mounted on a pair of cast-iron legs or, in addition, bolted to a heavy cast-iron tray that help to stiffen the assembly. Murad claimed that: "We have been tempted more than once to mount it on a 'tin-box' type of cabinet so fashionable at the moment but feel that that type of construction, whilst ideal for office machines, cannot be justified in a machine tool." So there we have it: old-fashioned, ugly - but effective. The 0.5 h.p. 3-phase electric motor was fastened to the back of the headstock-end leg and drove, by a single V-belt, to the headstock input pulley, the six speeds available spanning 43 to 818 r.p.m. The design of the geared head, with plain bearings, was difficult to make oil tight, the top cover having to reach down to the bearing caps to give sufficient clearance to reach their retaining bolts. However, unlike the Denham Junior and first Harrison L5 lathes with their impossible-to-seal, drop-on caps, on the Murad not only was a wide joint face was provided but a cover that bolted into place. The "shall-type" headstock spindle bearings were unusual and (having cost so much to tool up for) were also used on the Company's next lathe, the belt-driven Antarctica . Realising that the recently introduced (American-designed) steel-backed white-metal lined "Thinwall" shells for the main and big end bearings of IC engines were items of very high precision, Murad engineers decided it would be a useful short cut to use those instead of more traditional components: cast-in white metal, bronze, ball-bearing or taper roller races. Taking advantage of the in-house shell-bearing manufacturing facility (installed as part of the development program for the Murad car), these bearings were duly installed in the lathes; once fitted they were line-bored and, despite being fed lubricant from wicks dipping into wells within the headstock casting (instead of being supplied with high-pressure oil) appear to have been a success - certainly the very well-worn lathe examined by the author in the early 1980s still had a perfectly serviceable spindle assembly.

Screwcutting was by changewheels - there being no option of a screwcutting and feeds gearbox - with a rather large set of around 23 supplied that gave a range of pitches from 2.5 to 96 t.p.i. The drive passed through a tumble reverse mechanism sited, unusually, behind the headstock. As a money-saving measure the tumbler arm was located by a spring-loaded plunger indenting into holes formed in the edge of the thick, cast-aluminium inner changewheel guard - a method also employed on the inexpensive American AA lathes marketed under the Craftsman badge by Sears, Roebuck.

With its heavy castings finished to a good standard (and a pleasing, easy manner of working) the cadet would have been expensive to produce and must have sold in very limited numbers - and today is very rare. Those who have owned both the Bormilathe and conventional Murad lathes comment on the superiority of the latter in terms of detailing and finish - the Bormilathe being decidedly crude in comparison.

Little was supplied with the lathe, just a catch plate, two Morse taper centres, a set of screwcutting changewheels and the necessary spanners. At extra cost the usual accessories could be provided: fixed and travelling steadies, 4-way toolpost, 3 and 4-jaw chucks, thread-dial indicator and a collet set.

If you have a Murad Cadet lathe the writer would be interested to hear from you

For further details of the Cadet's construction, see the Antarctica pages..

|

|