|

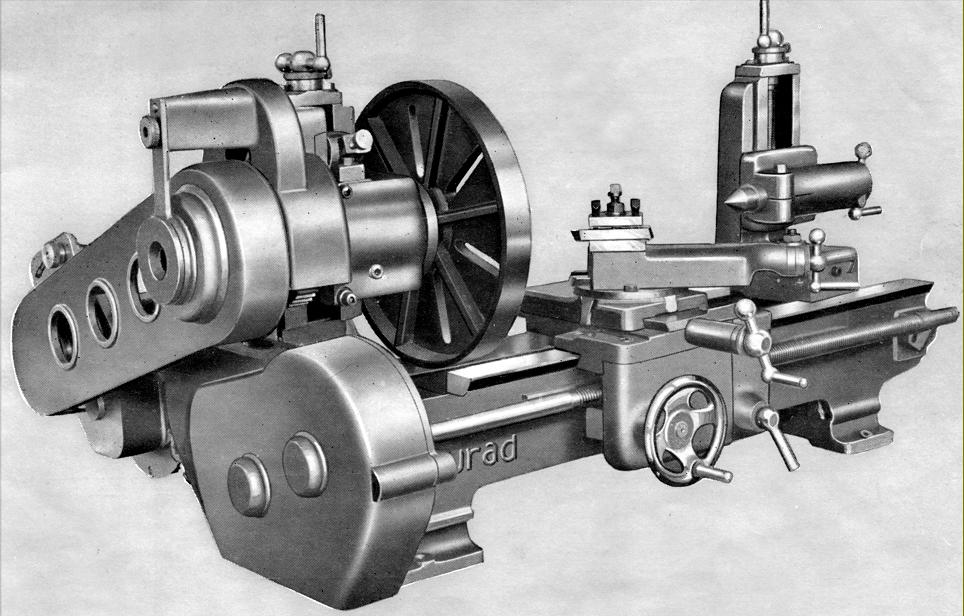

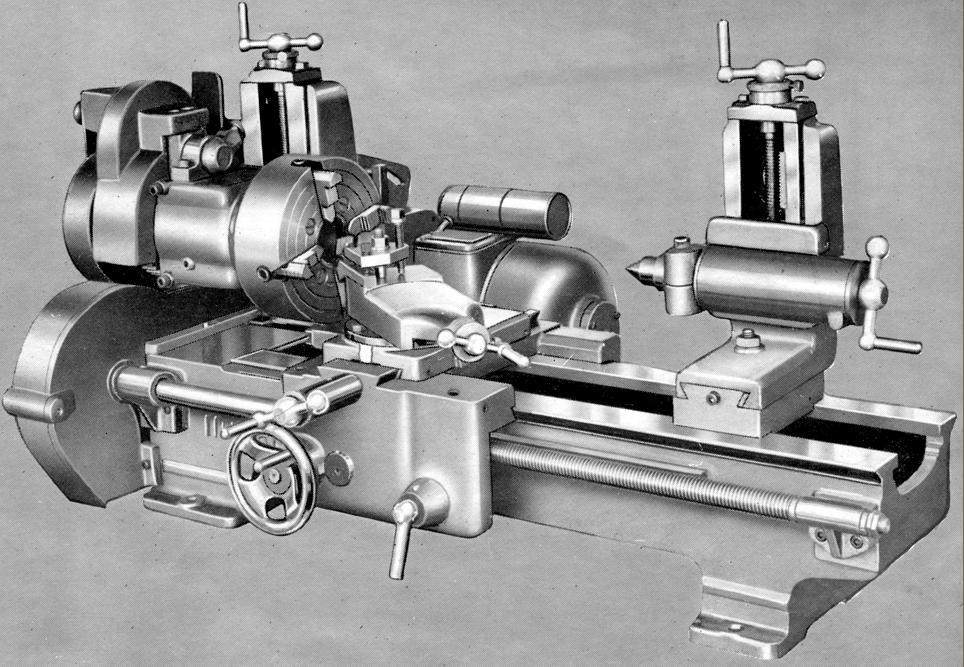

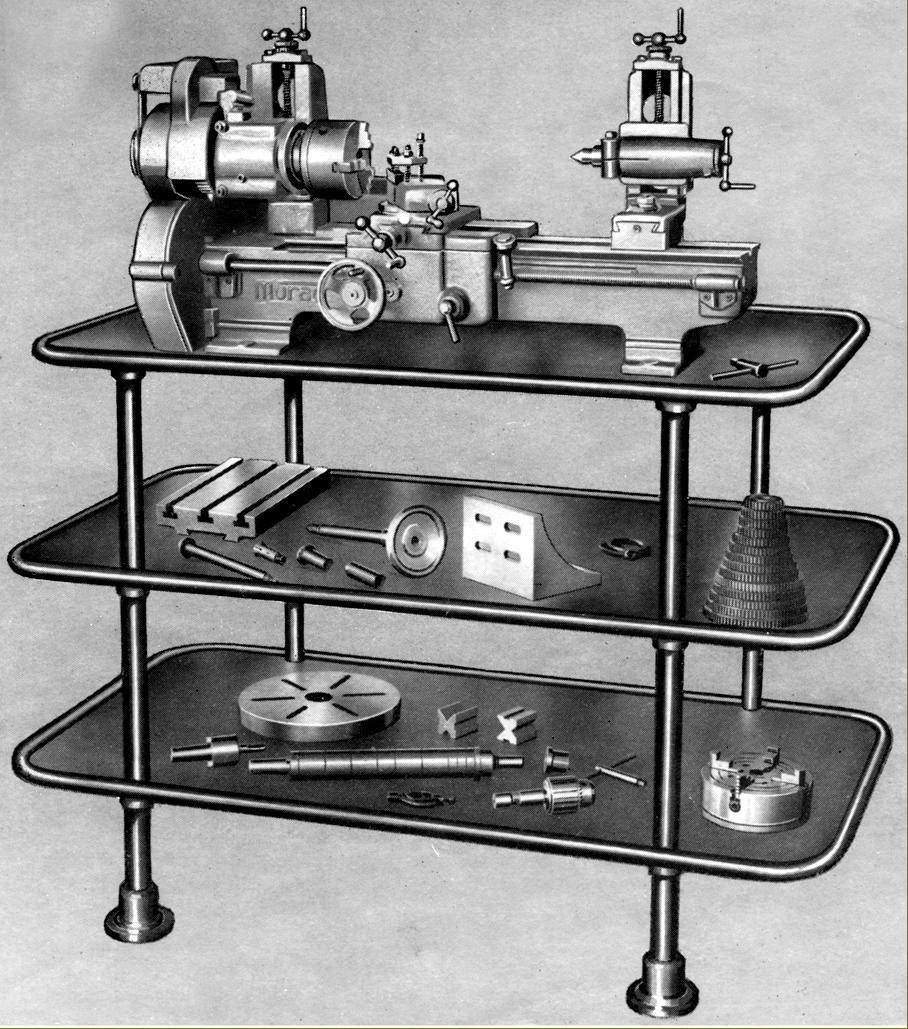

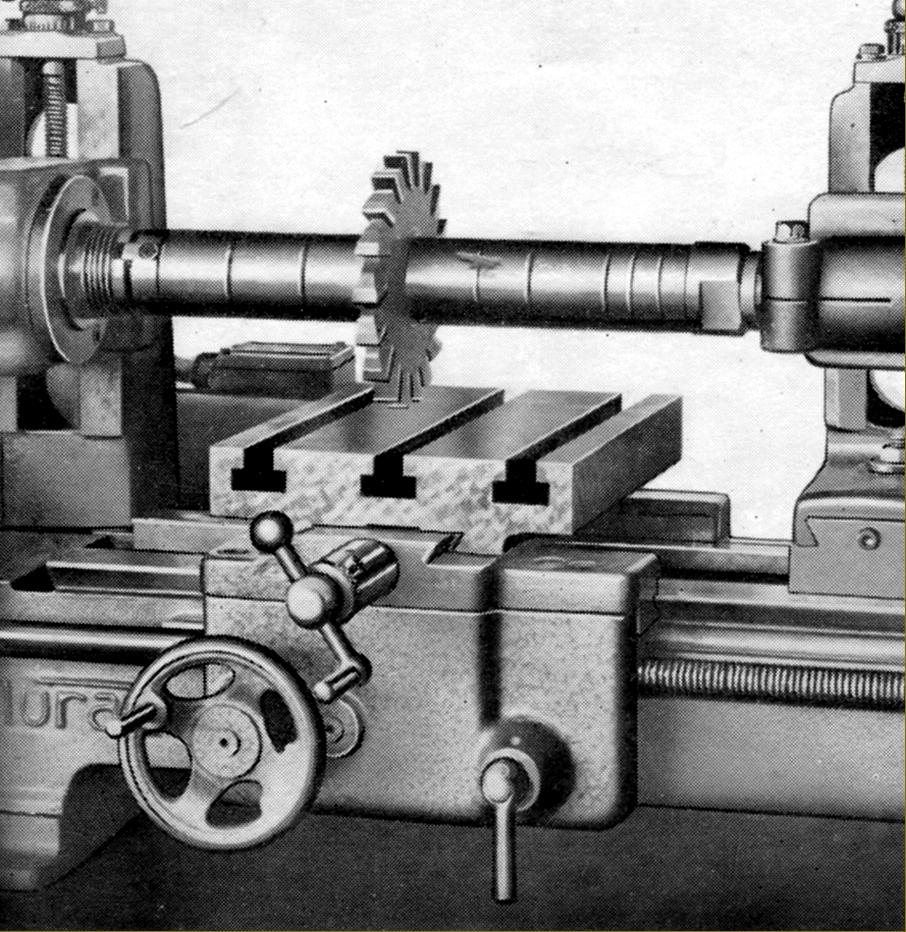

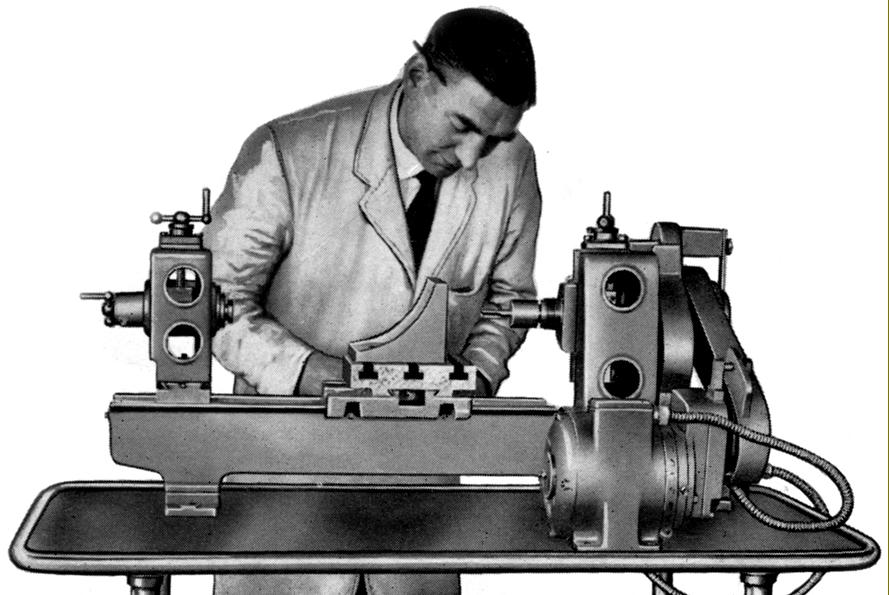

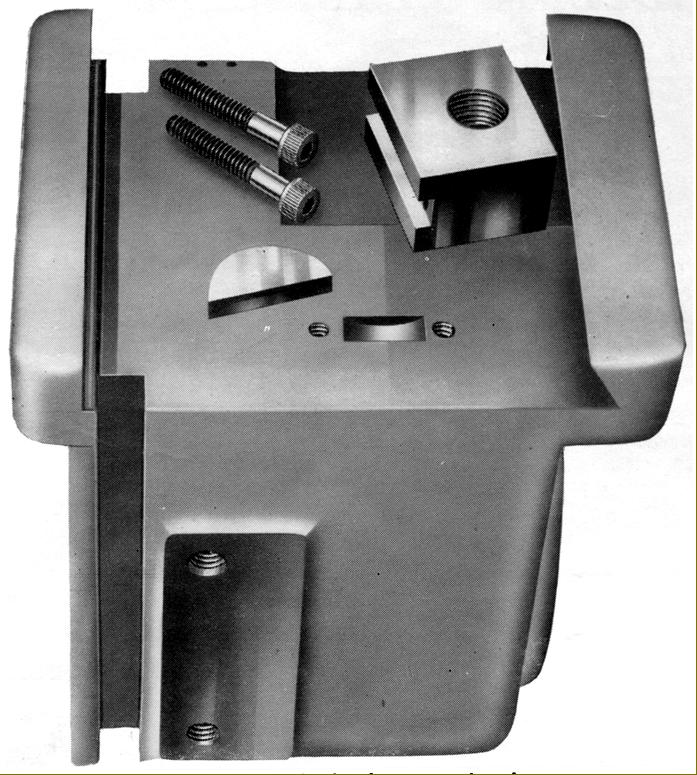

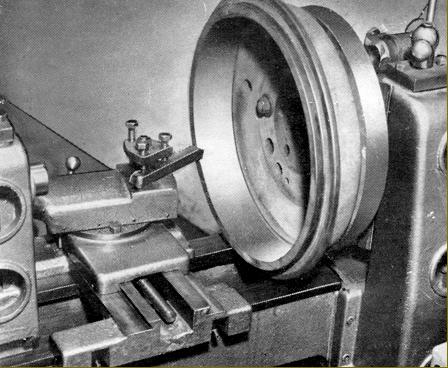

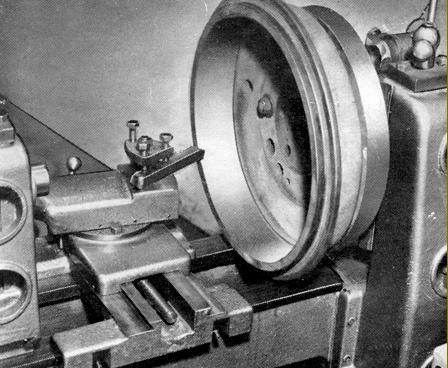

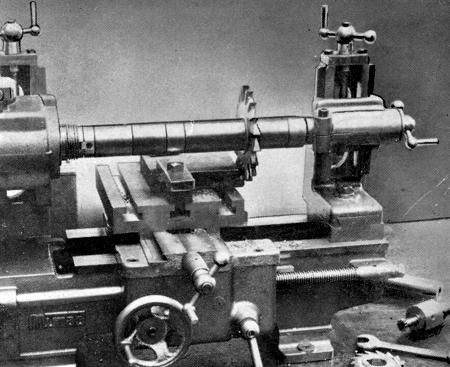

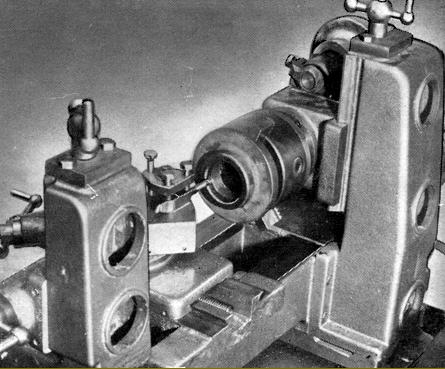

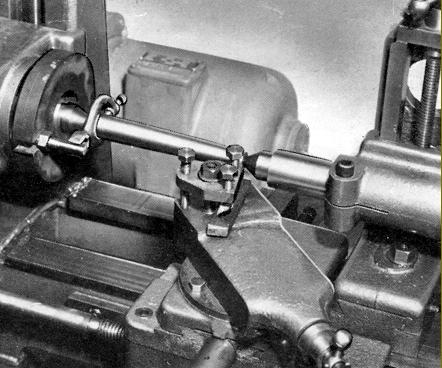

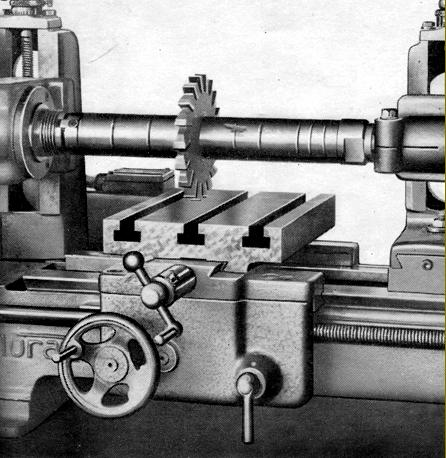

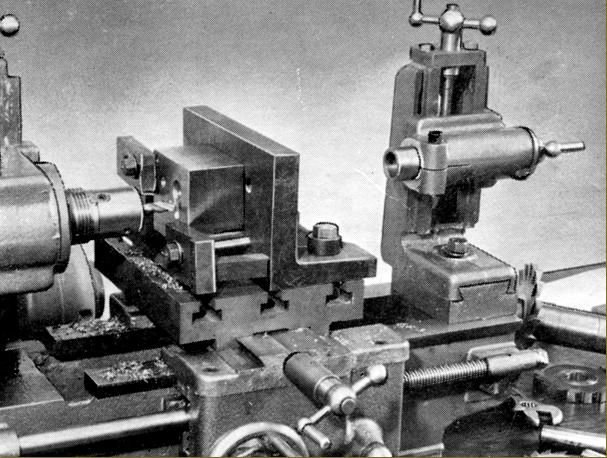

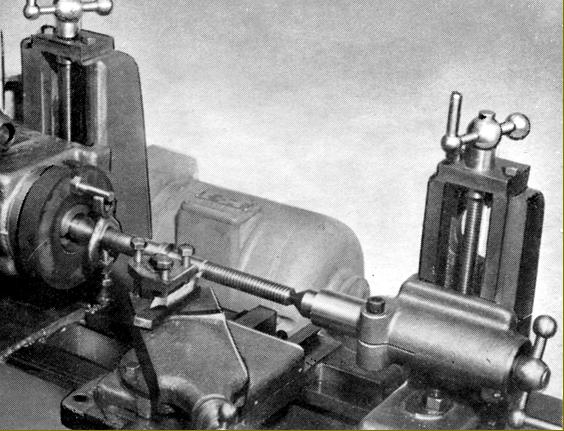

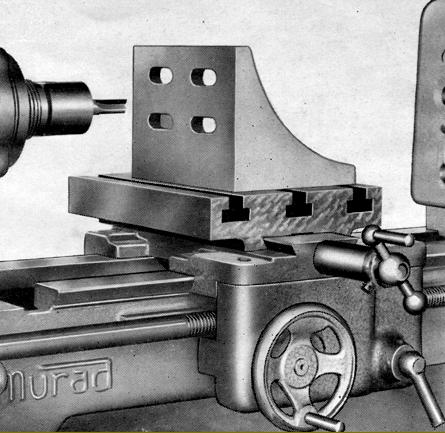

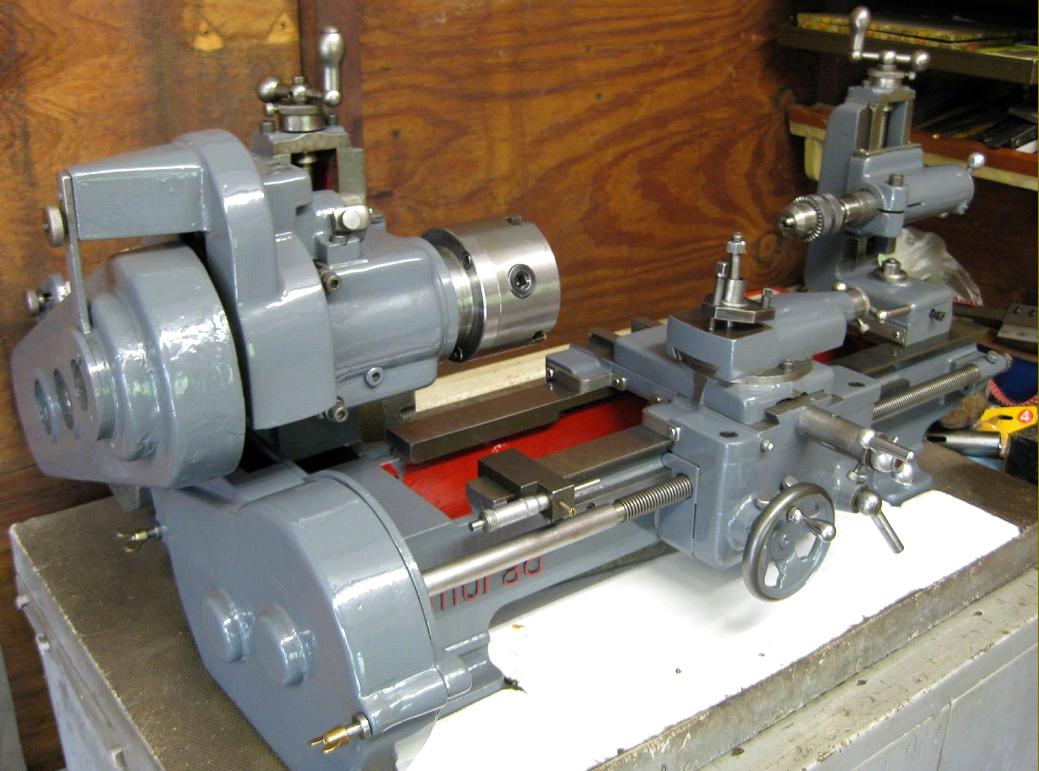

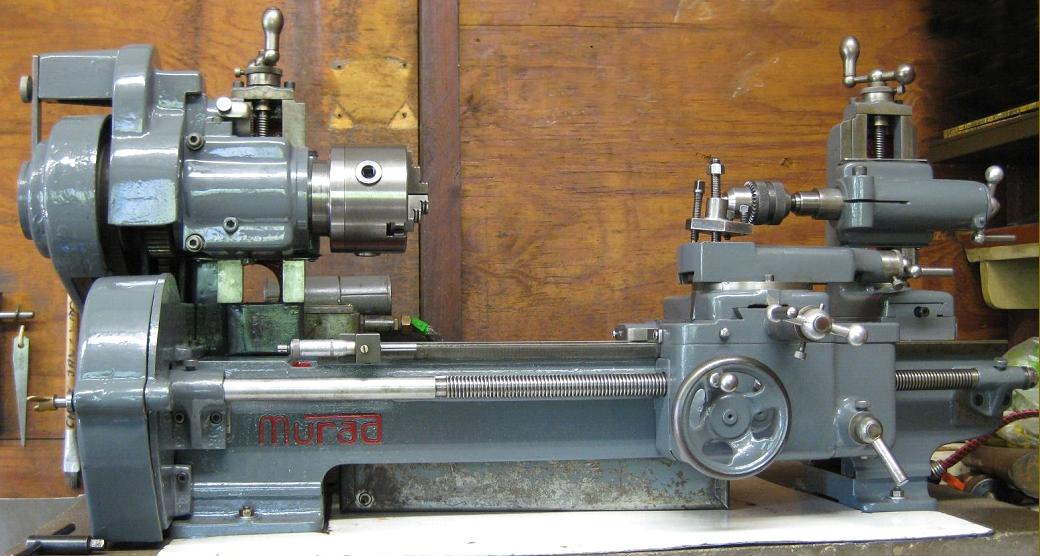

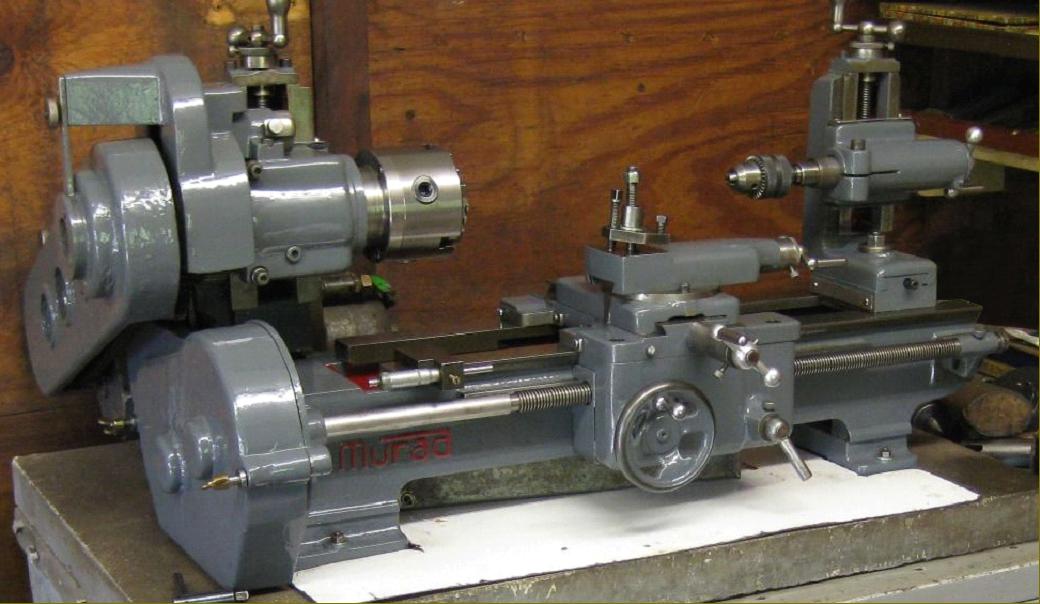

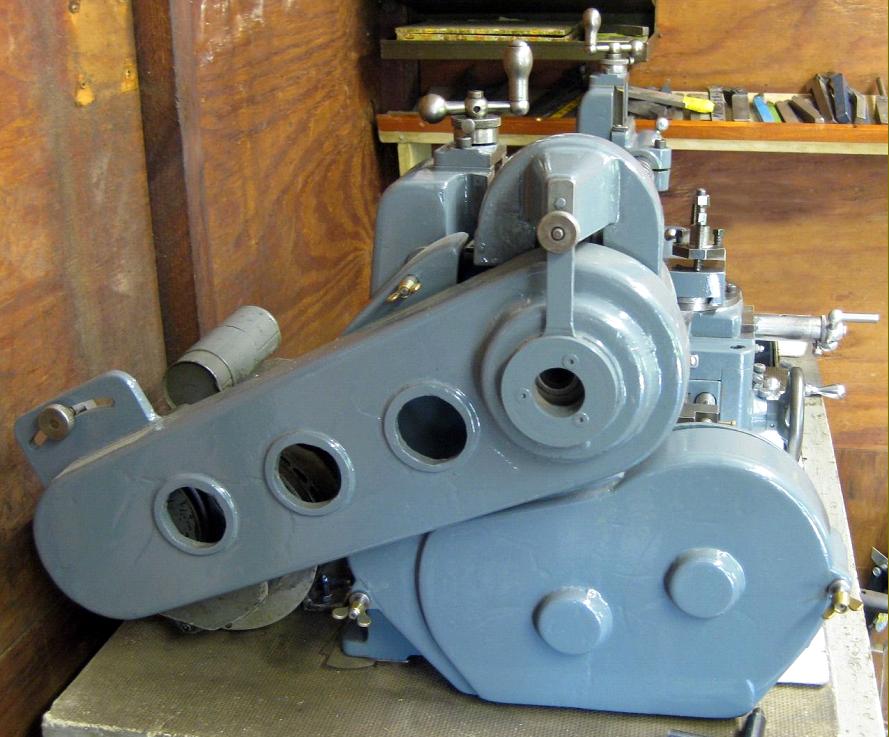

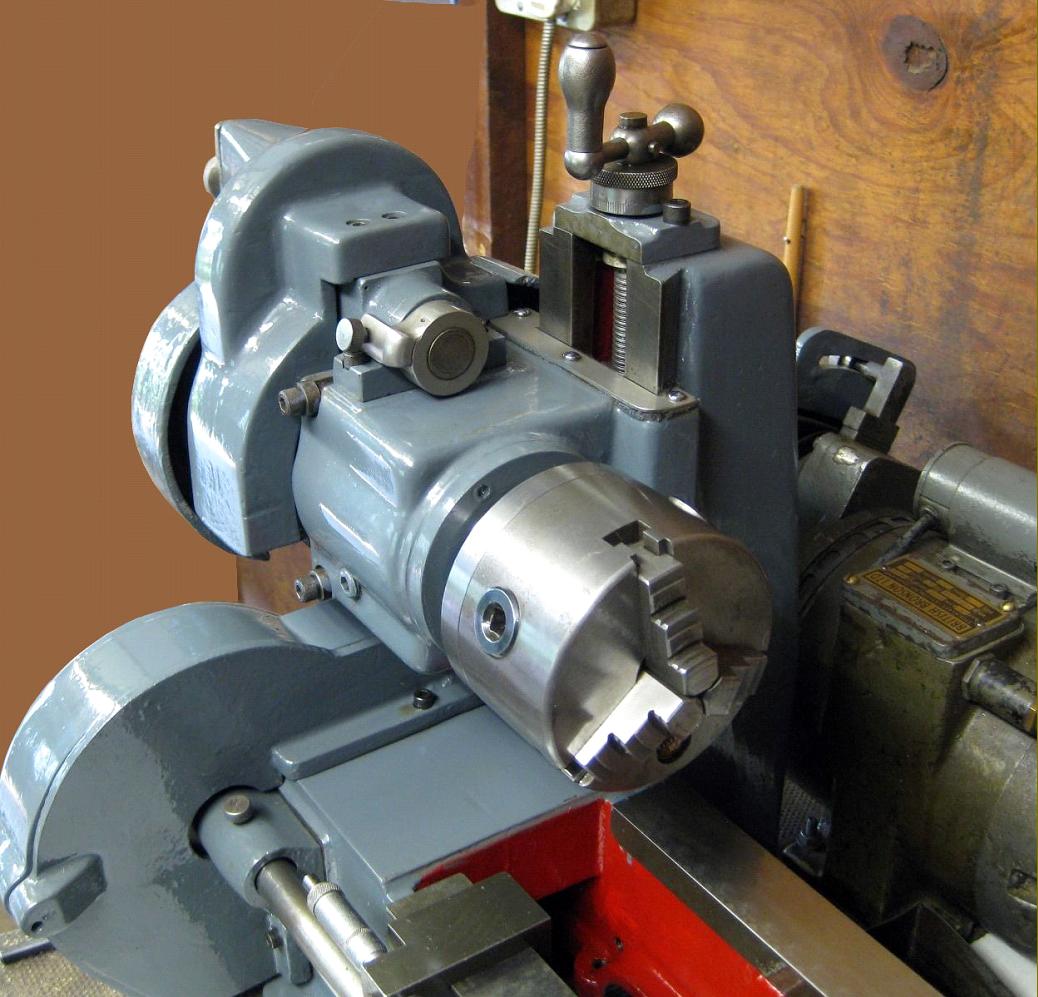

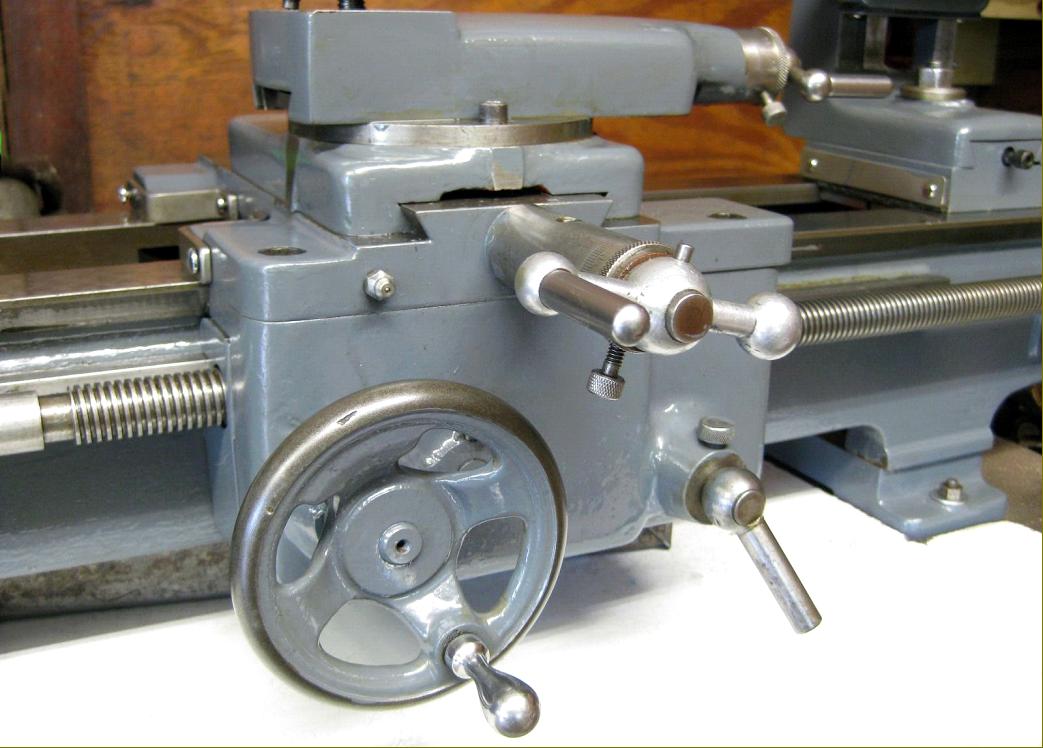

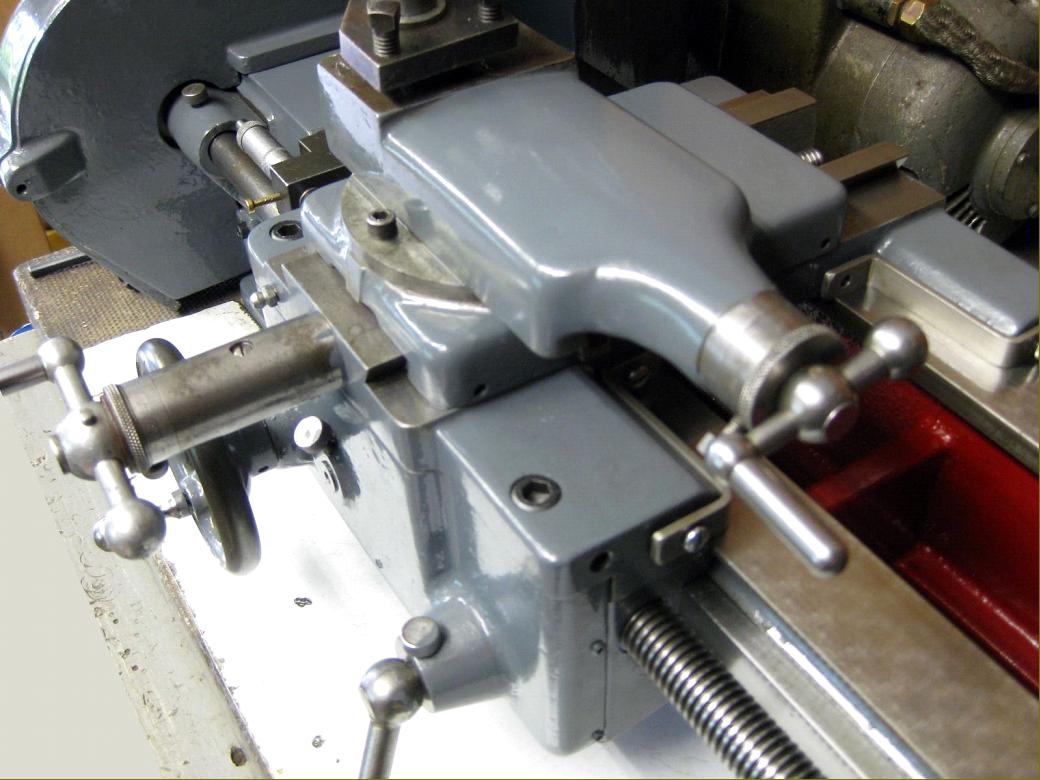

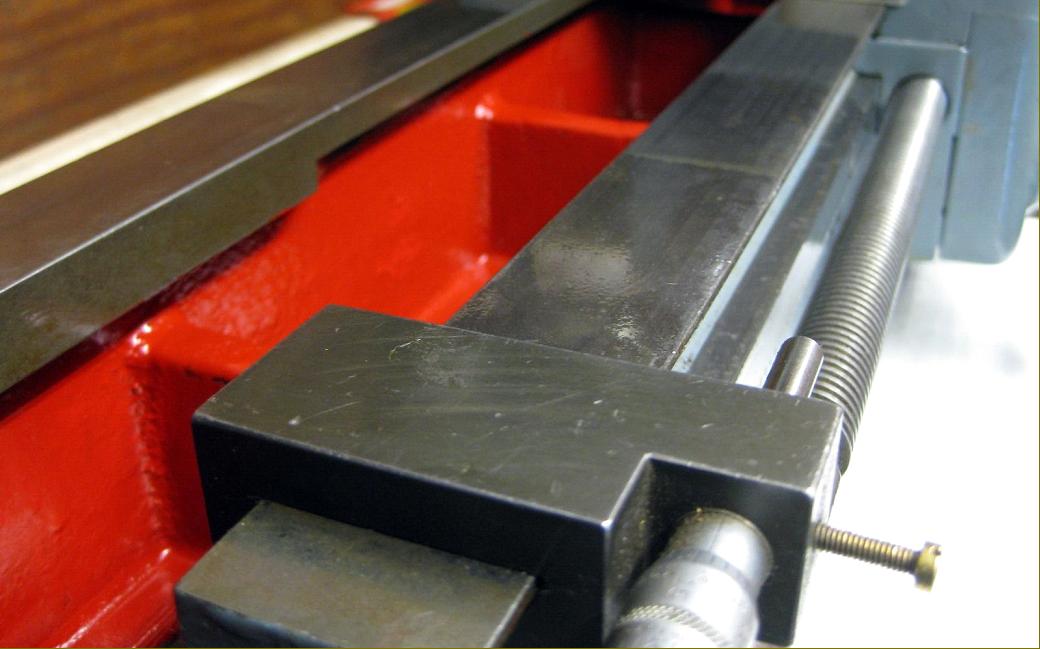

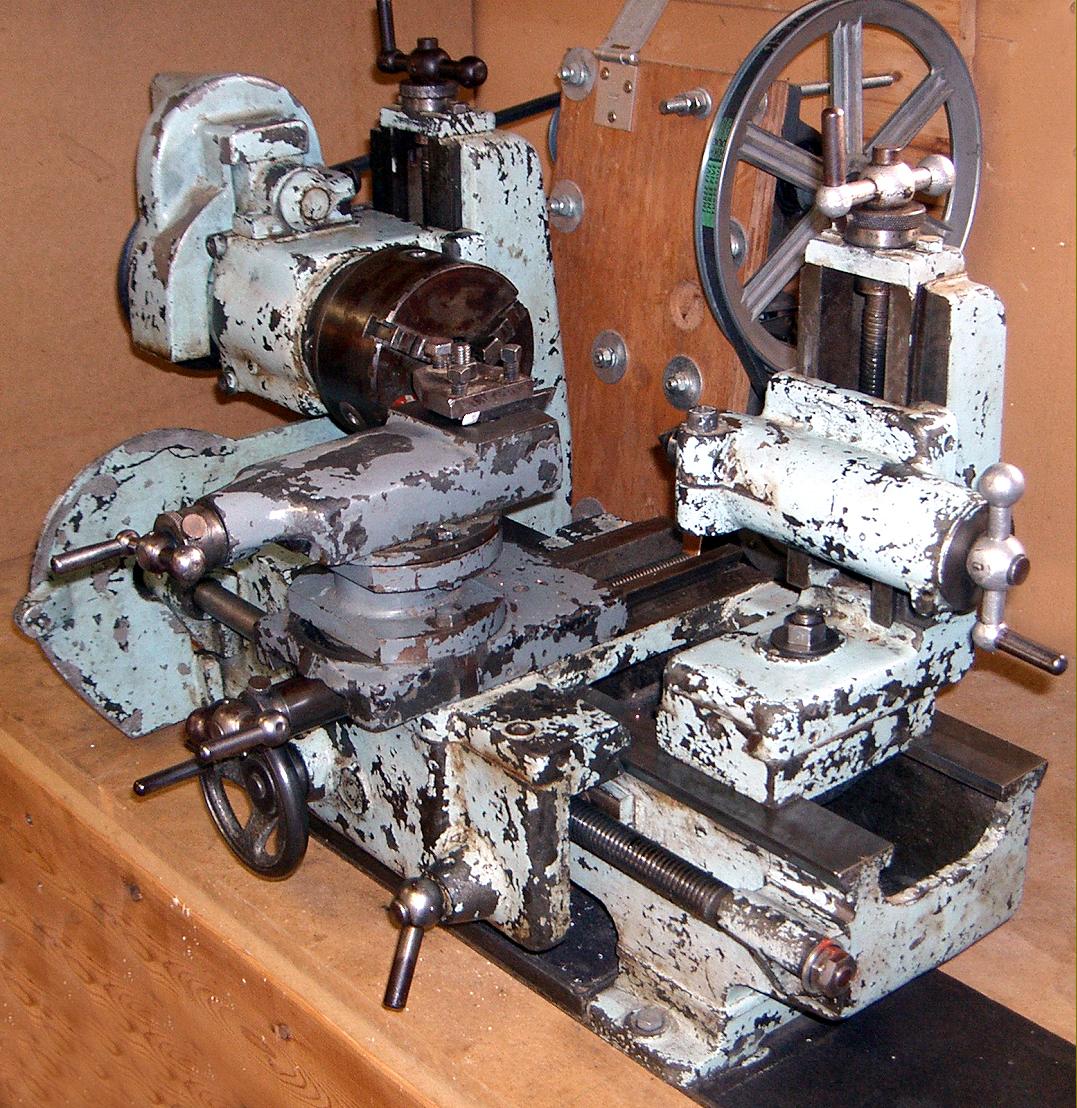

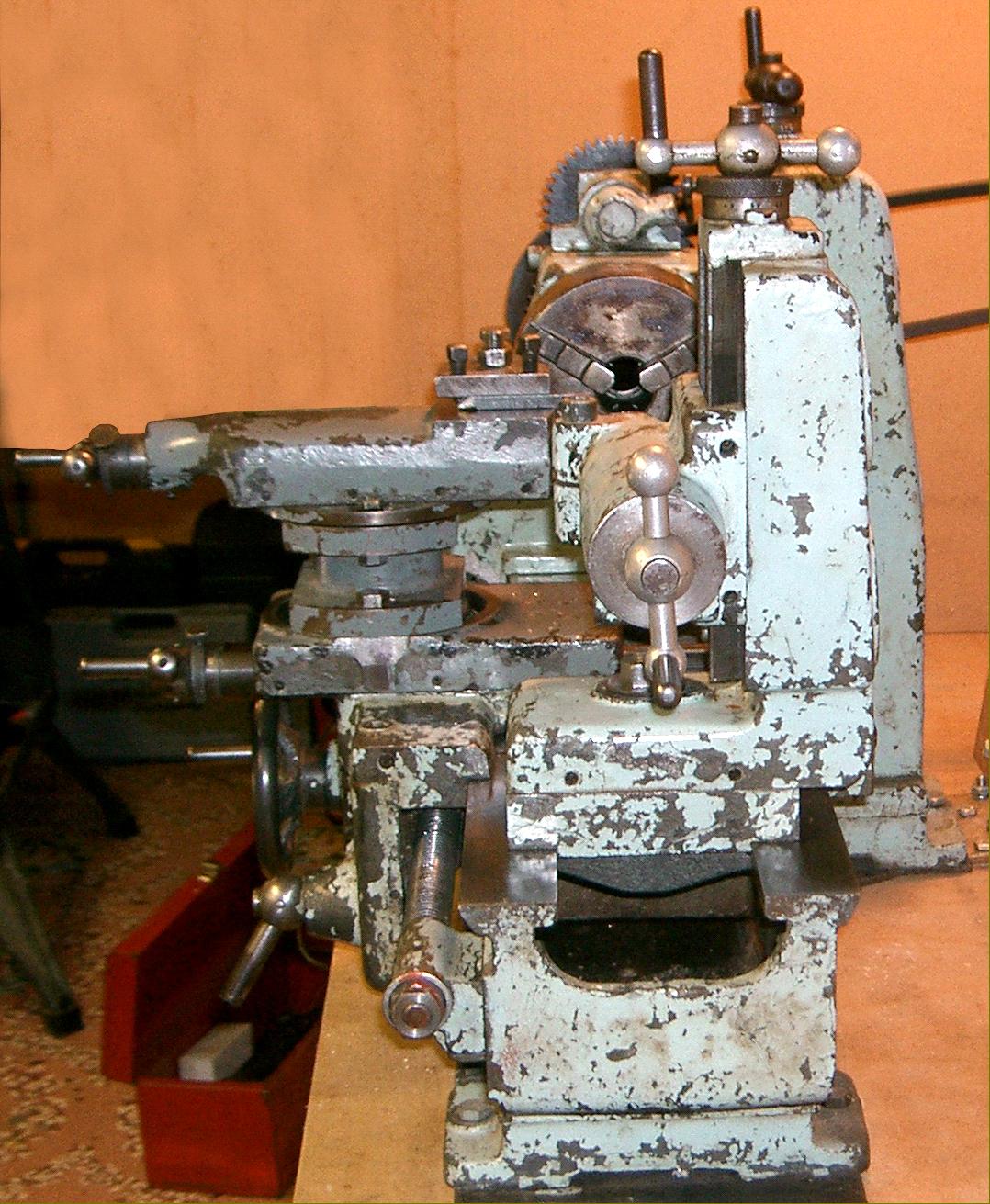

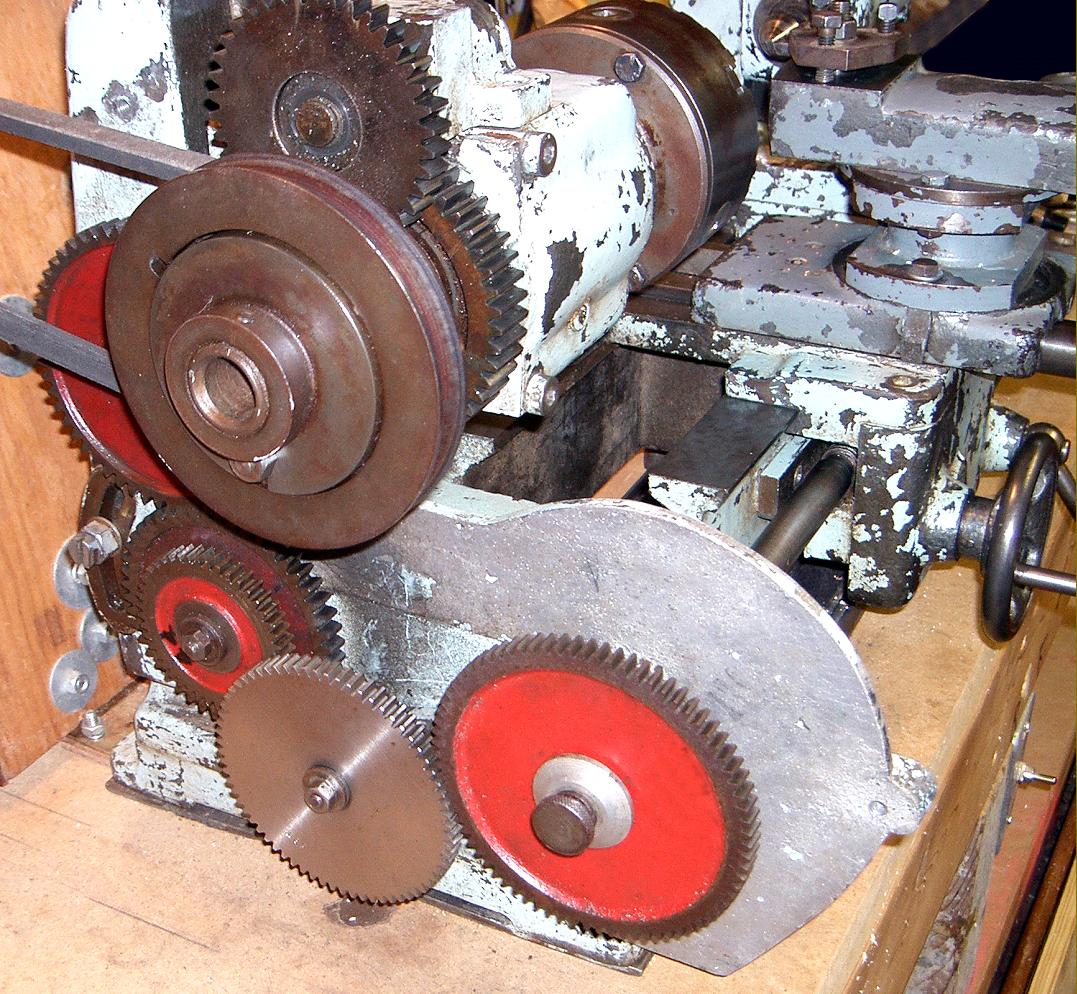

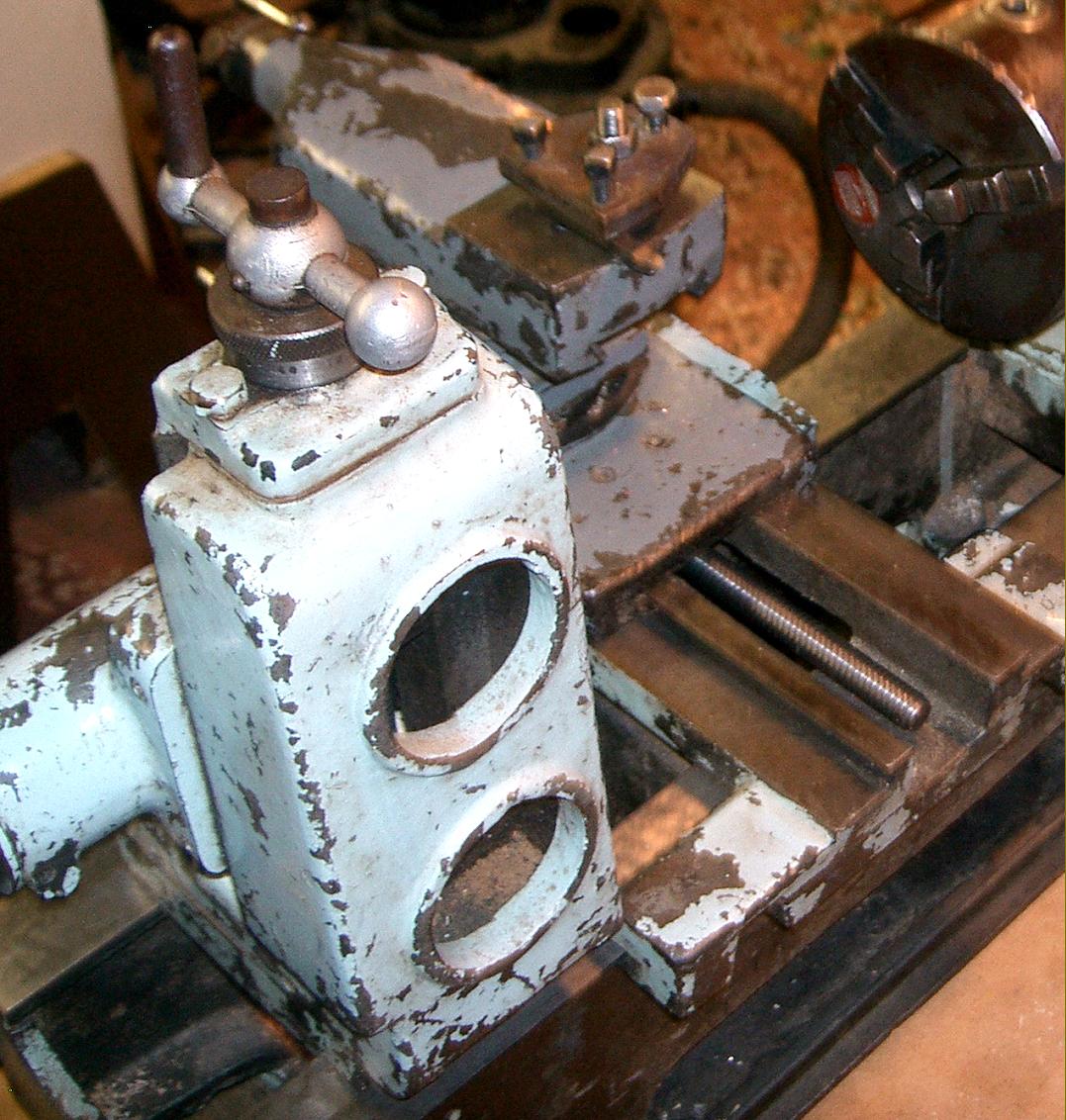

The Murad Bormilathe (provisional Patent 18077/59) was first produced in the late 1950s and manufactured until the late 1960s. It was certainly an unusual machine; the headstock and No. 3 Morse taper tailstock each being mounted on independent vertical slides and capable of adjustment to give a centre height of between 3.5 and 7 inches. The lathe, which was backgeared and screwcutting with cast-iron clasp nuts to the 0.75" diameter, Acme-form leadscrew, could, on early models accommodate just 10" between centres, this later being increased to nearly 20 inches - a much more useful figure. By replacing the cross slide with a 7" x 8.375" boring table, the lathe could also be used for horizontal milling - the milling arbor being held securely by a 3 Morse taper in the spindle nose complete with drive slots. Few accessories were available but included a saw-bench attachment and various sizes of faceplate.

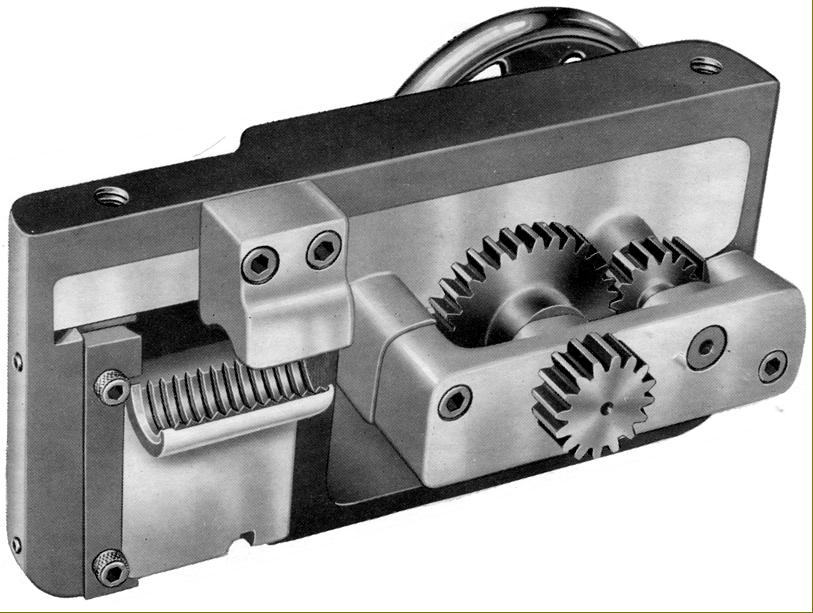

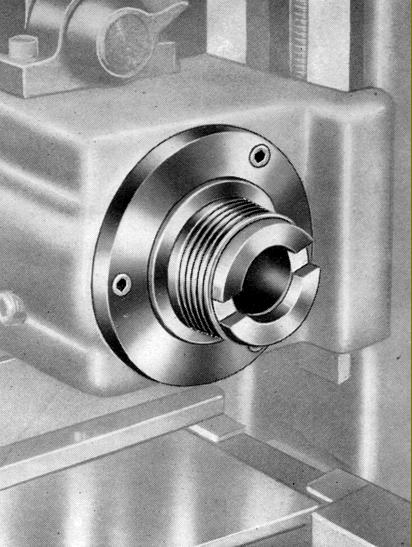

Although the official specification sheets had the headstock spindle listed as running in pre-loaded angular-contact bearings (with no obvious means of lubrications and so presumably grease-filled "for life") upon stripping one example of the lathe, it was discovered that standard deep groove bearings were employed, two at the front and one at the rear with a spacer between the. A further detail, uncovered recently by an owner, is that Mr Murad was a clever engineer and had arranged for the inner face of the back of the front bearing to be surface ground and, when the rear bearing was clamped up with the length of the spacer turned to the correct length, made the assembly act in the same way as very much more expensive angular-contact types would have done. The front bearing dust cap was a slip fit with two radial grooves as an oil seal against the spindle register - while the spindle gear (on the left) had a boss that sealed on the inside of the rear bearing cap. Lubrication was provided by a grub screw, low down on the front face of the headstock, through which oil - a little at a time - could be introduced into the casting. This system was possibly to prevent filling the casting up to the brim, the bearings being submersed only to between 5 to 10 mm above their lower surface. With a bore of 0.78", the spindle was just on the limit of acceptably for the tasks it was expected to handle.

The electric motor, a special "Bronson" unit (built in the Murad factory) was made for the Bormilathe and featured a swinging bracket on the end designed to keep the belt tension correct as the headstock was elevated. It was available as either a standard single-speed model or (at considerable extra cost) with an integral gearbox with three ratios of 1:1, 1:2 and 1:3; with this type fitted, and in conjunction with belt changes and backgear, a total of twelve spindle speeds was available between 44 and 1750 r.p.m. With the motor set to the 1:1 ratio, spindle speeds were 132, 328, 700 and 1750 rpm; at 2:1 the speeds became 66, 164, 350 and 875 rpm while at 3:1 they changed to 44, 109, 233 and 583 rpm. The expensive Bronson motor was also offered by the Murad Company to drive other small machine tools.

A Bormilathe was taken on the Sir Vivian Fuchs's Trans-Antarctic Expedition and numbers were employed in the workshops of the UK Atomic Energy Authority and various universities. The Royal navy also used them and it confirmed that during the 1960s the frigate HMS Scarborough was so equipped.

Mr Wadia Murad was, by all accounts, an interesting person, widely gifted in engineering matters and with several inventions to his name. His original factory was in Watford and his second (with permission granted from the Ministry of Supply in 1946) in Stocklake, Aylesbury; from there a final move was made to an industrial development area in remote Sheppy. During the Second World war he laid down plans for a Murad car, roughly along the lines of a large English Humber with an engine of Murad's own design and execution - of which only one example was built. By the late 1970s a combination of industrial recession and a particular downturn in the market for small capstan lathes led Murad to advertise his concern for sale in October 1980. Unfortunately there were no takers and the company closed. When the Sheppey factory was being cleared in the early 1980s the prototype car and boxes of parts and plans came to light. Fortunately the plans were saved from the demolition men's fire by, literally, the snatch of a hand and secured for safe keeping.

Murad also made two versions of a conventional 5-inch centre height lathe that was fitted with car-type "Thinwall" white-metal bearing shells in the headstock - the Cadet and Antarctica. However, the Company was perhaps best known for a range of small, compact but strongly-built capstan lathes. Those who have owned both the Bormilathe and conventional Murad lathes comment upon the superiority of the latter in terms of detailing and finish - the Bormilathe being decidedly crude in comparison.

If anyone has an example of the conventional 5-inch lathe, or a Murad Capstan, the writer would be interested to hear from you..

|

|