|

Machine Tool Manuals Machine Tool Catalogues Belts Precision Plain-turning & Bench Lathes Lorch Home Page Schmidt - a Restored Example Precision Plain Lathe 1920s/30s and well-illustrated Sales & Technical Specification Brochures and can be purchased on-line here Lorch Schmidt offered a very wide variety of precision plain-turning, backgeared and production lathes based around interchangeable components. A number of centre heights and bed lengths was offered - both with and without a gap piece - and a wide range of accessories listed allowing almost every task associated with high-class fitting or production work to be carried on just one machine.. |

|

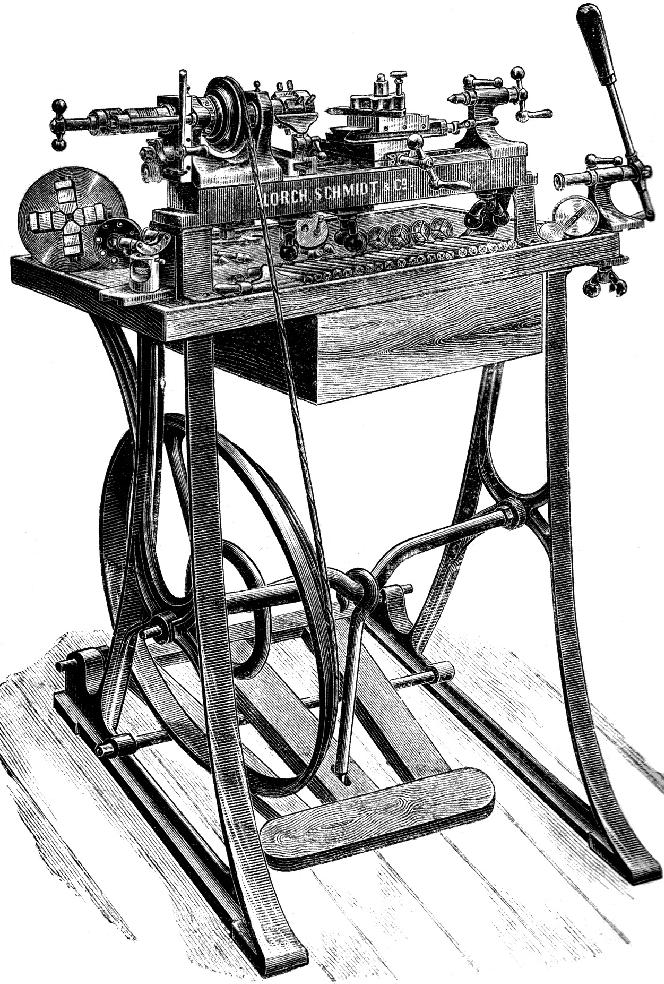

Pre-1900 Lorch Schmidt production lathe with treadle drive and chase screwcutting by sliding headstock spindle. This effective, high-speed threading system was used for many years on Lorch and other high-quality lathes. For an explanation of how sliding-spindle screwcutting works see the section on Karger lathes |

|

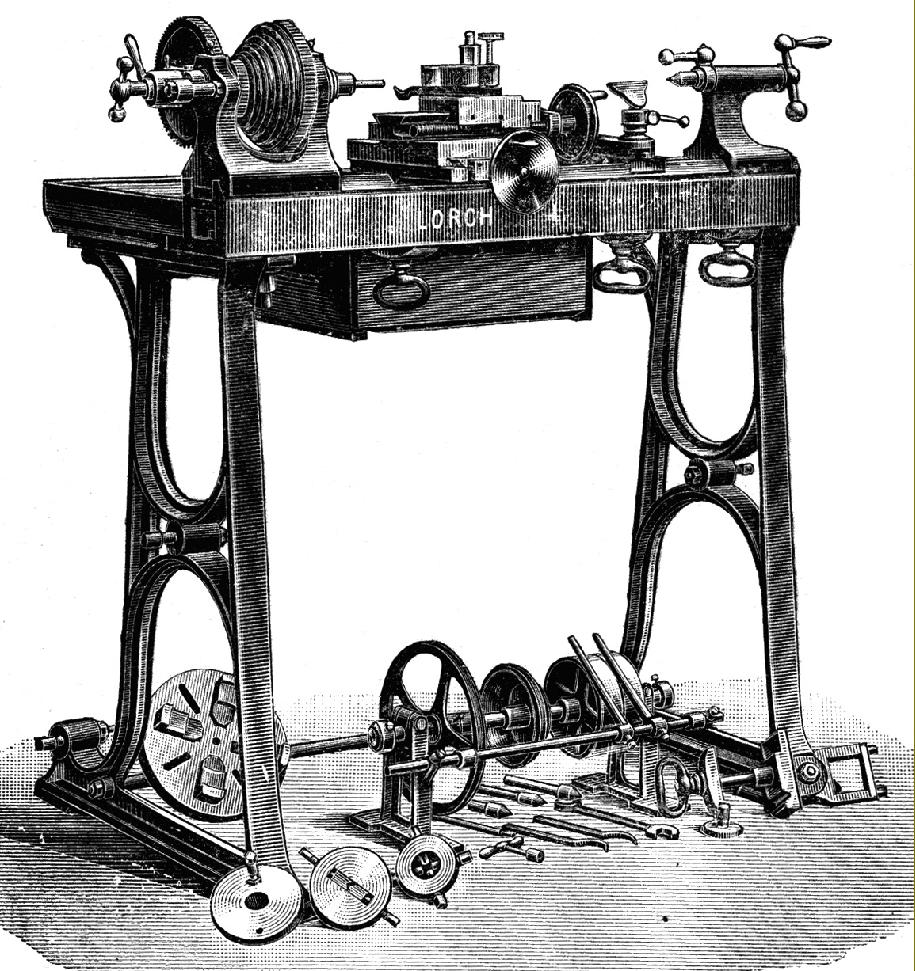

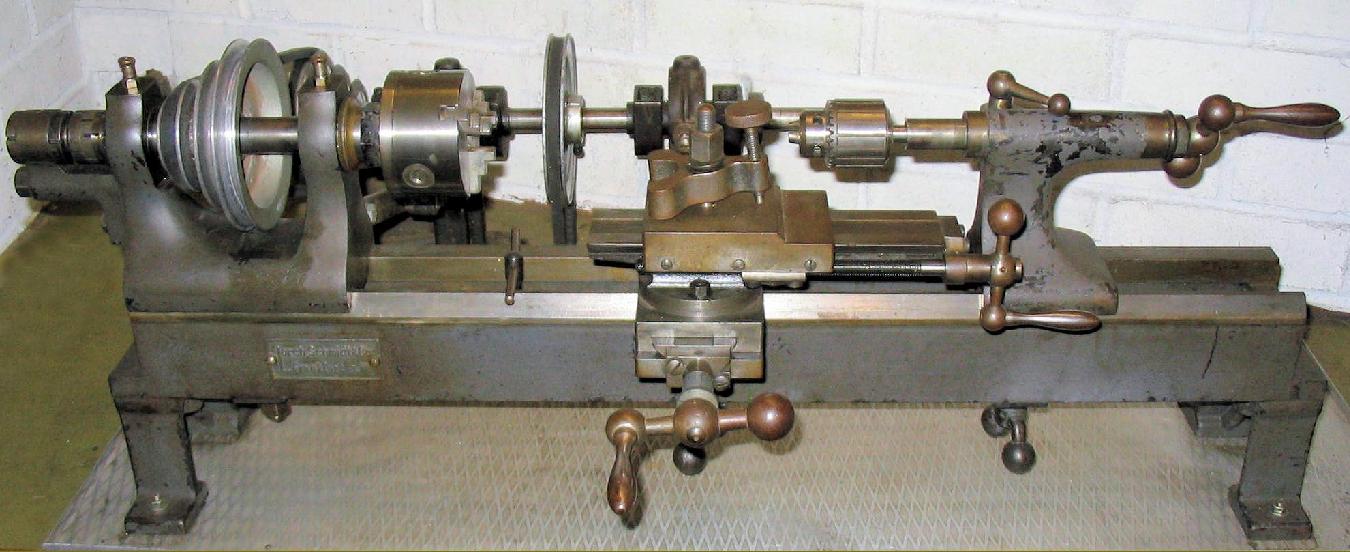

Pre-1900 Lorch "Triumph" precision backgeared plain-turning lathe Model "A" of 120 mm centre height by 1000 mm between centres. Note the 19th century) design of the fixed steady, 2-jaw chuck and 4-screw bell chuck |

|

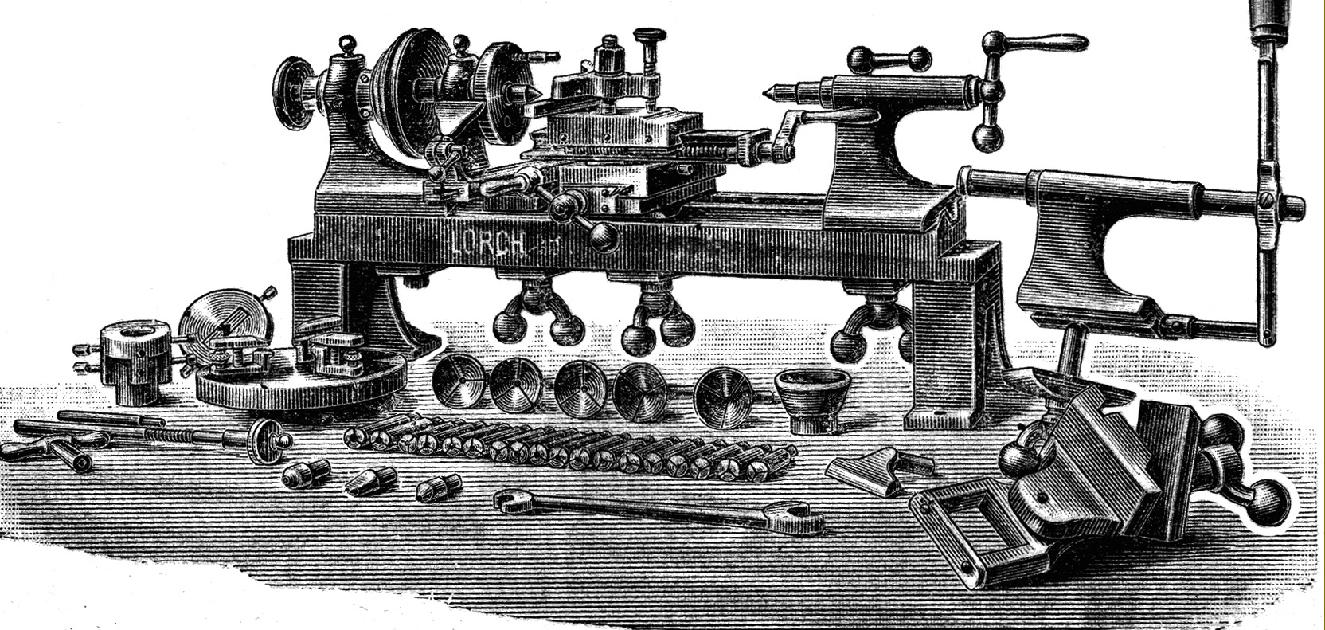

Lorch 80 mm centre height plain-turning bench precision lathe pre 1900. This model was available with 210, 310, 410 or 510 mm between centres. Note the watch-lathe-like faceplate with removable screw clamps. All early smaller Lorch Schmidt lathes featured the distinctive "steps" at the end of the bed. |

|

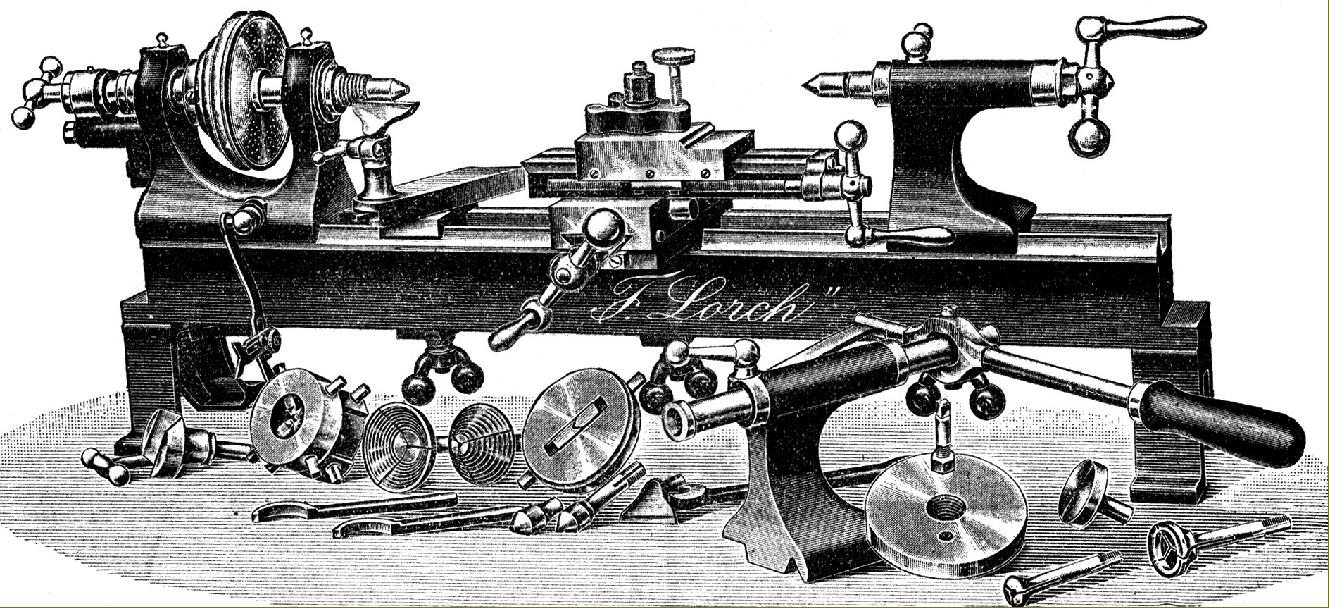

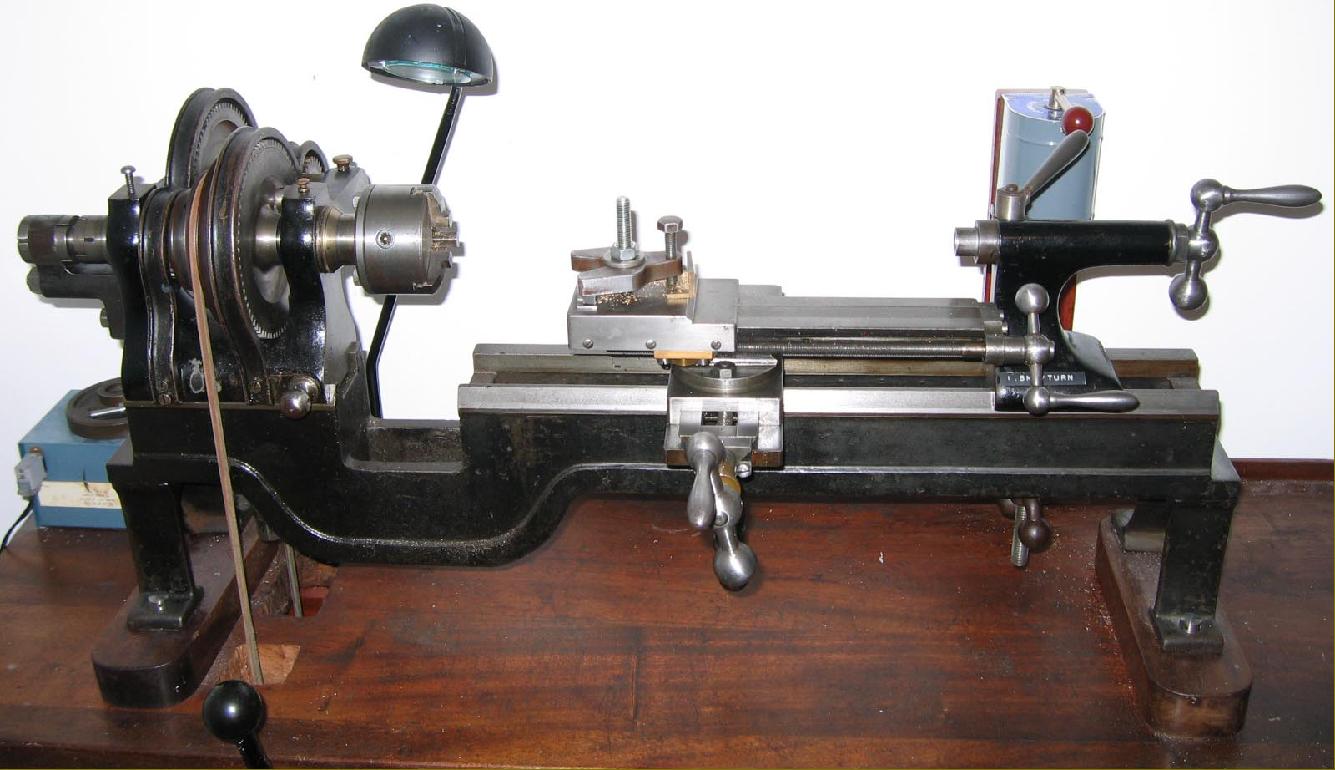

Lorch precision bench lathe available with 80, 100 or 120 mm centre heights from a French catalogue of 1910. This is a later, improved version of the pre-1900 80 mm model above - note the stronger end plates supporting the compound slide feed screws, the balanced ball handle on the longer-travel top slide replacing the (by then old-fashioned) crank type, a more sophisticated pivot arrangement on the lever-feed tailstock, multiple rings of indexing holes on the headstock pulley face and improved retention, by a nut, of the tailstock spindle insert. |

|

Very similar to the model in the woodcut above this slightly later plain-turning precision Lorch Schmidt is unusual in having a gap bed and backgeared headstock. Even for this type of lathe the top slide on this example has an exceptionally long travel. |

|

|

|

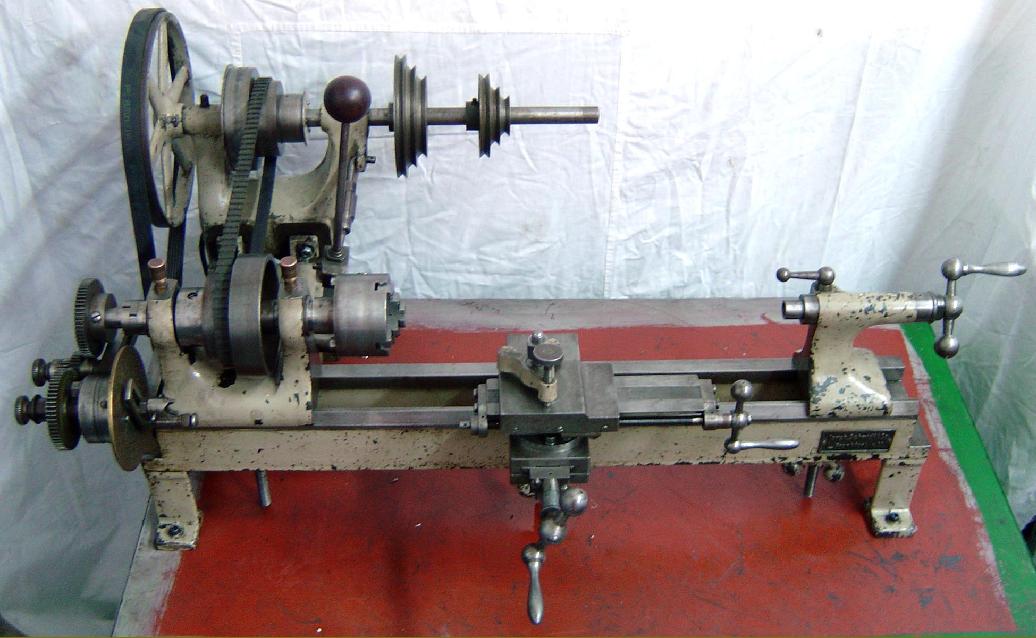

Lorch plain-turning bench lathe from around 1920 fitted with headstock dividing through a unit working though changewheels. This lathe was originally fitted with screwcutting & power feed to the top slide - notice the bracket on the end of the latter to pick up the drive from a (removed) universally-joined shaft. The countershaft is from a South Bend 9-inch |

|

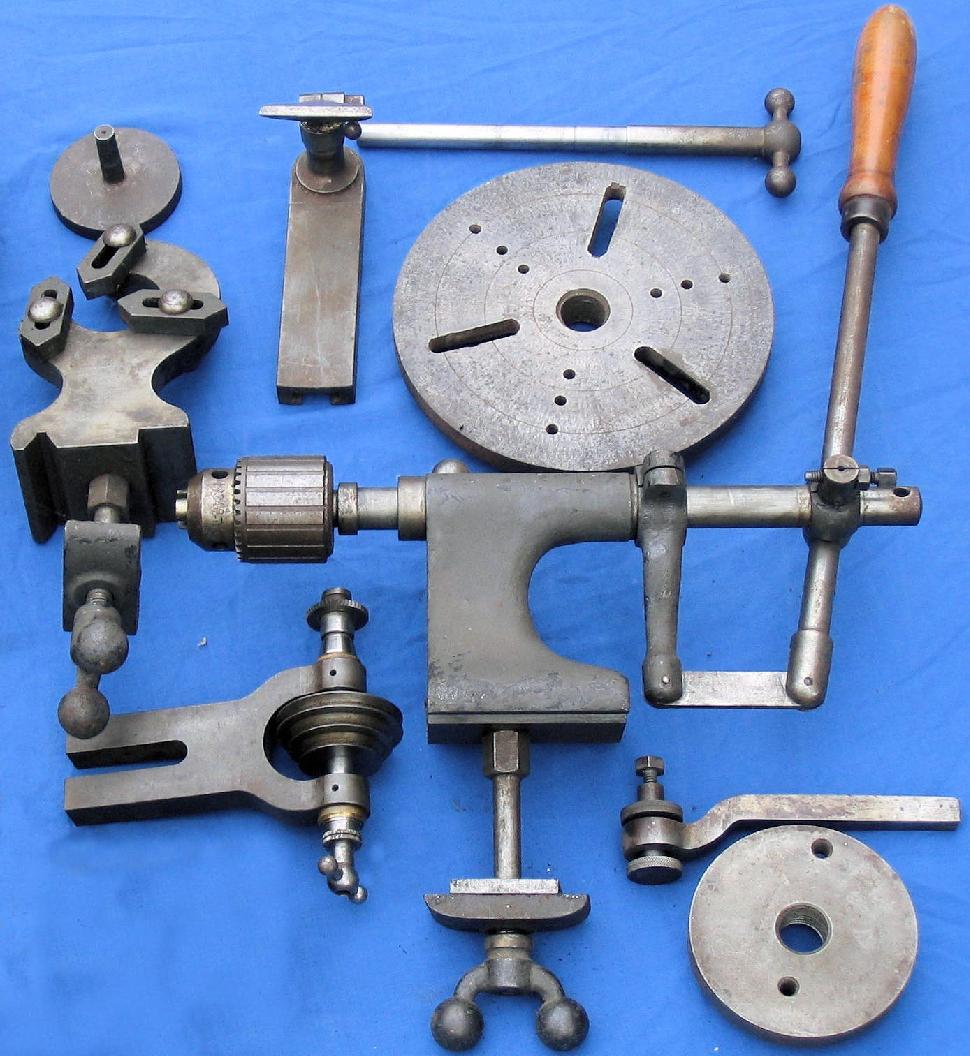

A wide range of (expensive accessories was always available for this type of lathe. Shown here are a fixed steady, dividing plate for the headstock spindle, 4-jaw chuck-cum-faceplate, gear-cutting unit with bevel gearing, raiser blocks for headstock and tailstock, a hand-turning rest, vertical slide with spindle to hold cutters or grinding wheels and a vertical slide with a horizontal boring table If well fitted, and operated by a skilled tradesman, these items enabled even a simple lathe to successfully undertake a huge range of complex workshop tasks. |

|

|

|

and well-illustrated Sales & Technical Specification Brochures and can be purchased on-line here Precision Plain-turning & Bench Lathes E-MAIL tony@lathes.co.uk Machine Tool Manuals Machine Tool Catalogues Belts

|