|

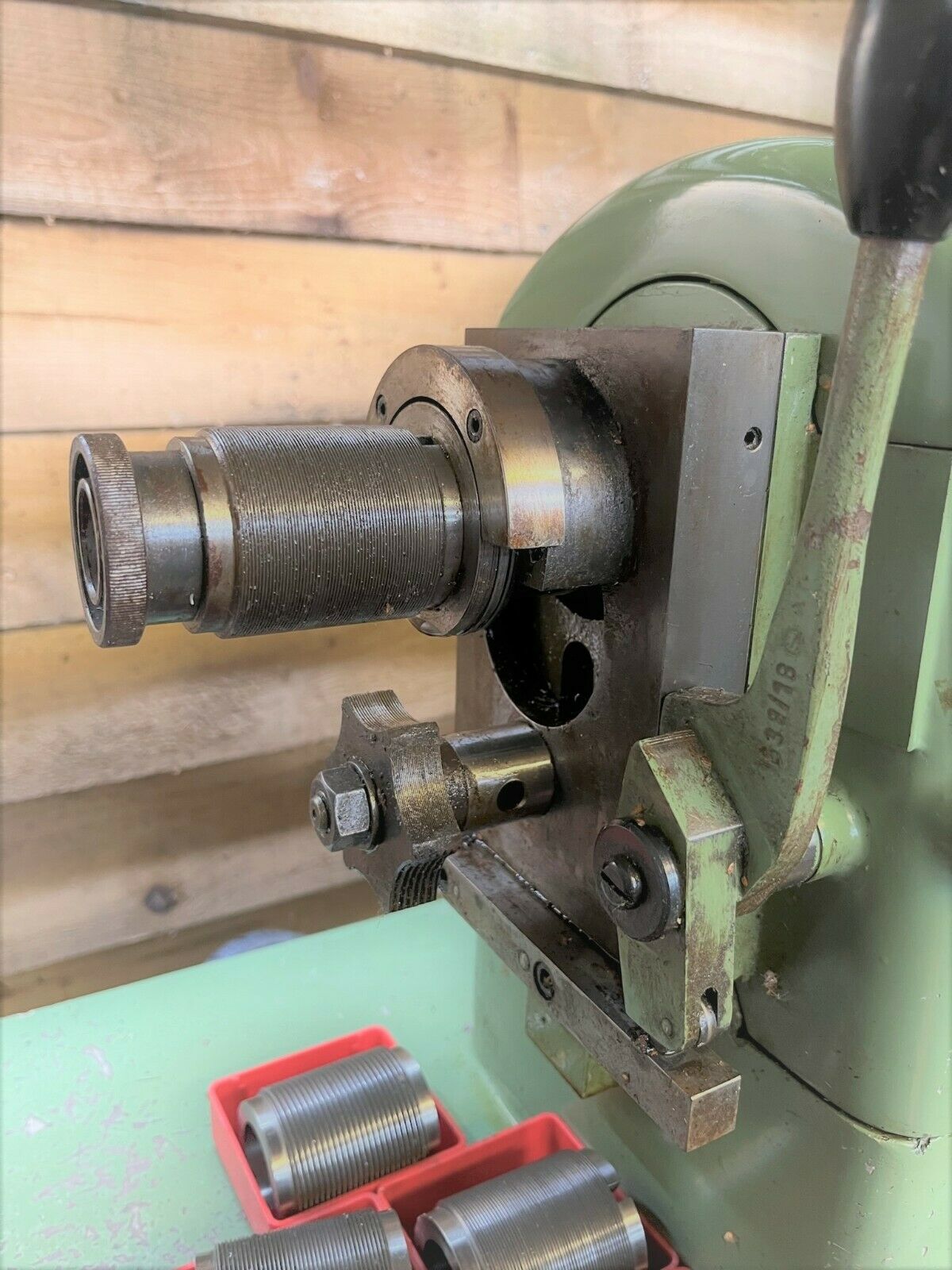

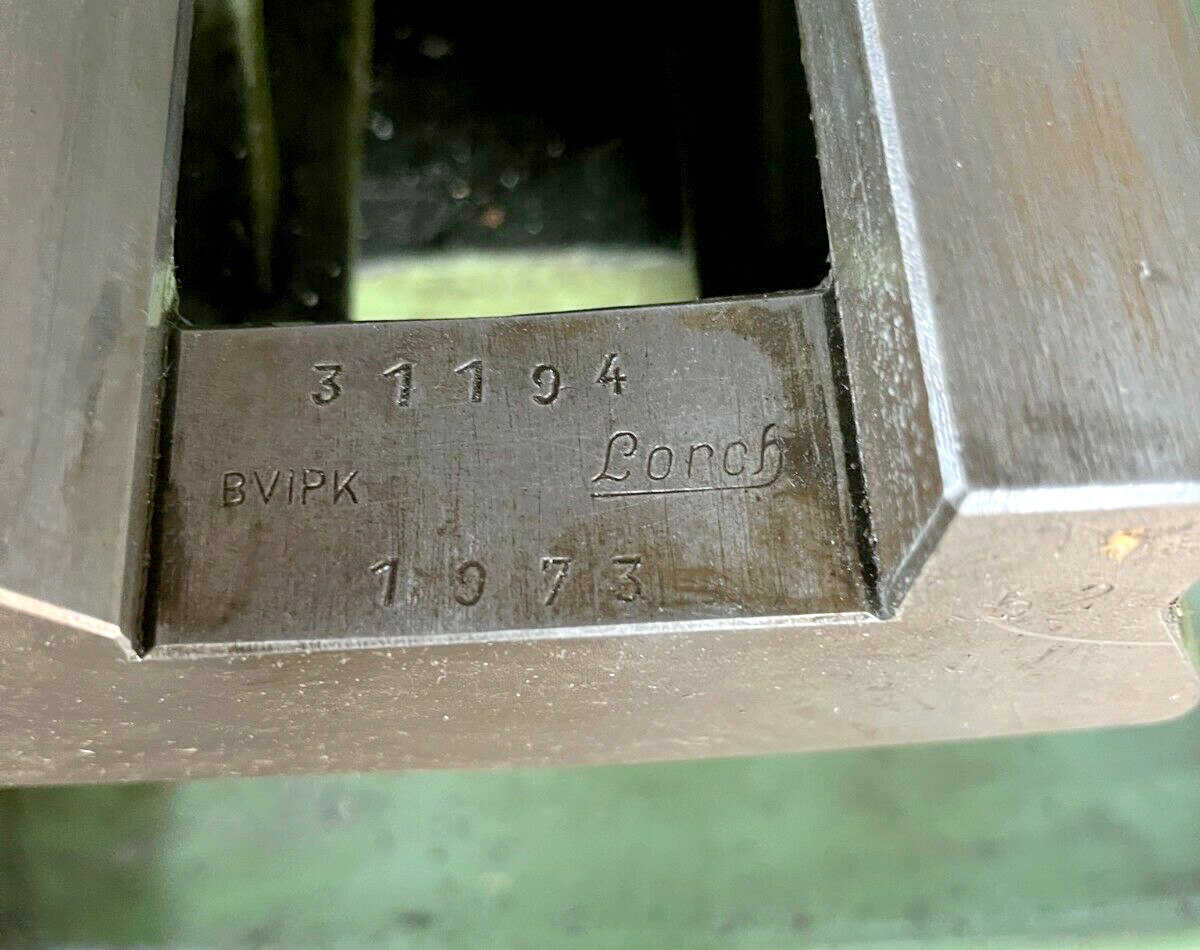

An uncommon model, the late-model Lorch BVIPK was a screwcutting lathe that used, in place of changewheels, a sliding headstock system in conjunction with a set of star-shaped "master threads". The threading system was carried on a thick plate, dovetailed to the outside face of the headstock casting with engagement and disengagement by a lever that lifted it up and down. Each master thread carried six different pitches with a set of twenty or so covering all likely requirements. As the master thread was lifted, it meshed with a matching thread carried on the outer end of the headstock spindle and, as the spindle rotated, it was driven forwards through its bearings. A stationary cutting tool, held in a normal toolpost, then generated required thread on the workpiece as it emerged from the chuck or collet. Widely employed on ornamental turning lathes in the 1800s, by the early 1900s it was in widespread use by such Swiss companies as Schaublin and Mikron and by German makers including Boley, Lorch ,Wolf Jahn, Karger and Auerbach (the smallest model to incorporate it being the Wolf Jahn Model AA with a centre height of just 50 mm). The arrangement was also a feature of most "Swiss-Auto" mass-production lathes used for the manufacture of tiny parts - and is still in widespread use today on such machines - though these are now, of course, fitted with CNC control. The last conventional lathe on which sliding-spindle screwcutting appears to have been available was a version of the Schaublin 102 marketed in in the early years of the 21st century. Usually included in the set of threads (to allow the manufacture chuck backplates and other work-holding units) would have been a coarse-pitch pair with the thread as used on the lathe's spindle nose. |