|

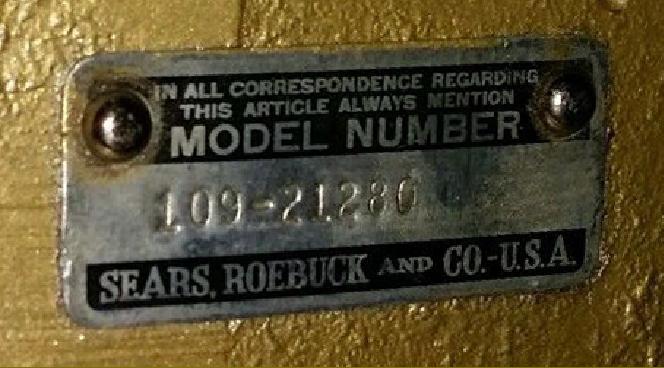

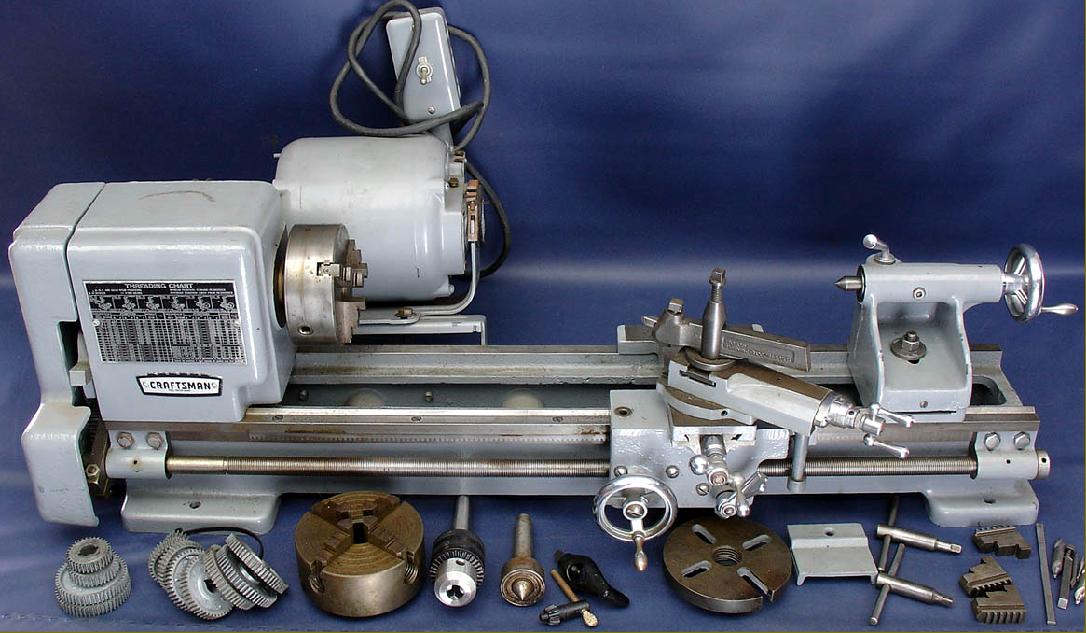

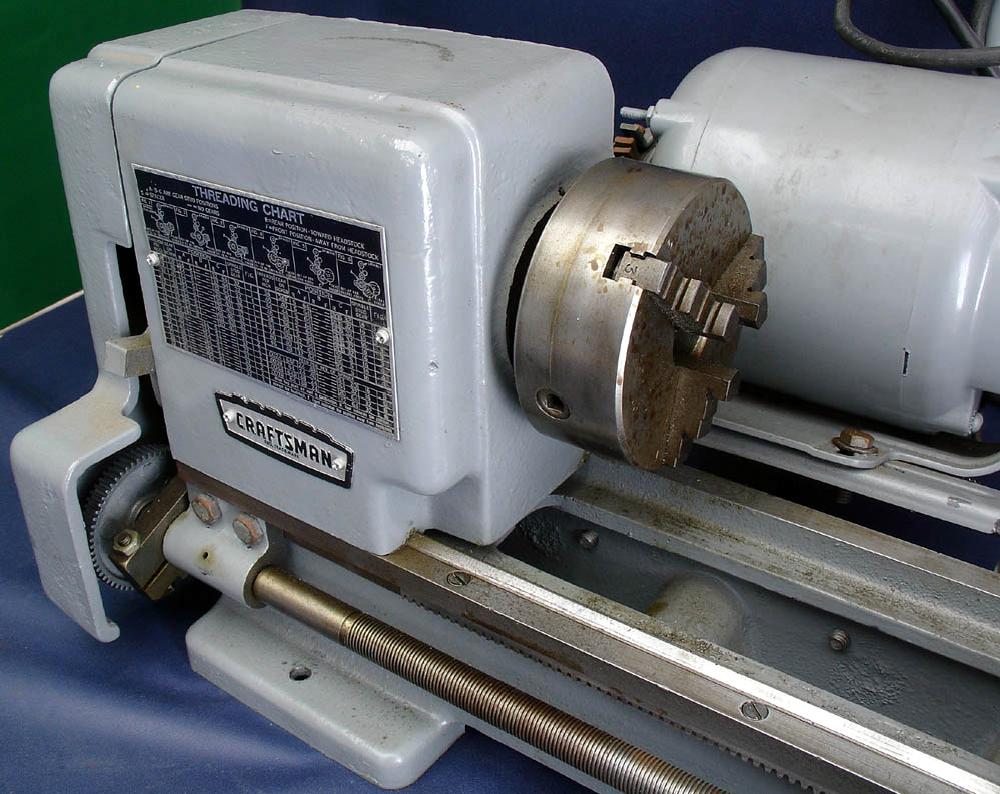

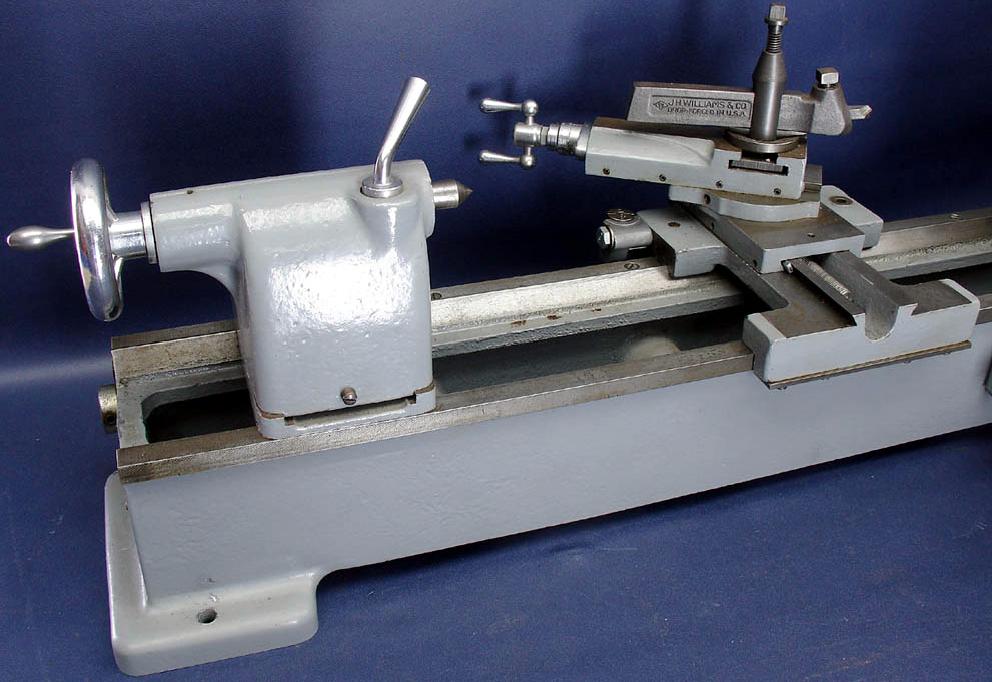

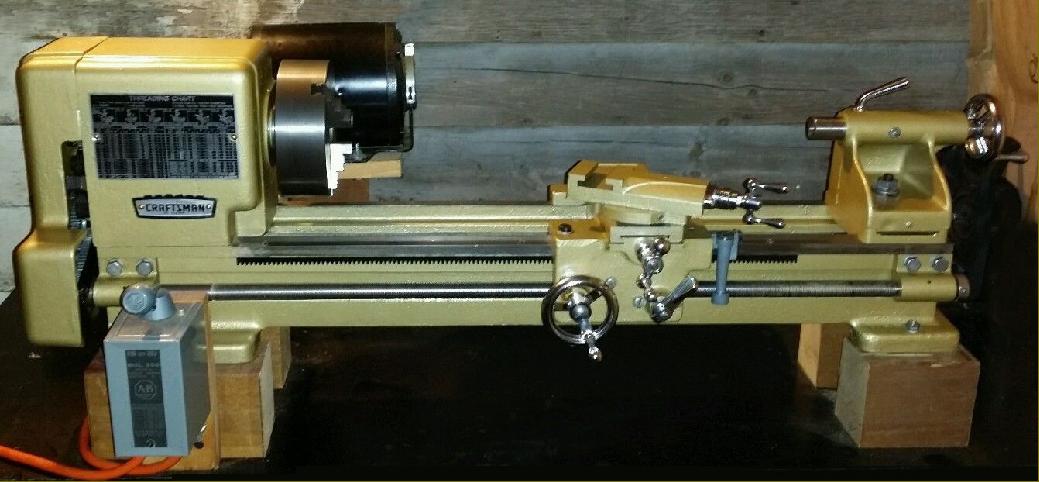

Originally finished in gold paint, the 3-inch centre height by 19.25" between centres Model 109.21280 was the last lathe made by the AA company and listed in the Sears, Roebuck Craftsman catalog until the late 1960s. Although rather crudely finished and detailed, its build was considerable more robust than early versions of the 109, with a distinctly "square" appearance to the headstock - the styling of which has sometimes caused it to be confused with the later Atlas Mk. 2 6-inch, also sold branded as a Craftsman but with no connection at all to the AA lathe. The machine at the top of this page has been repainted grey - the one lower down is in its factory finish and, almost certainly, the very best of its type yet to be offered for sale. |

|

|

|

|

|

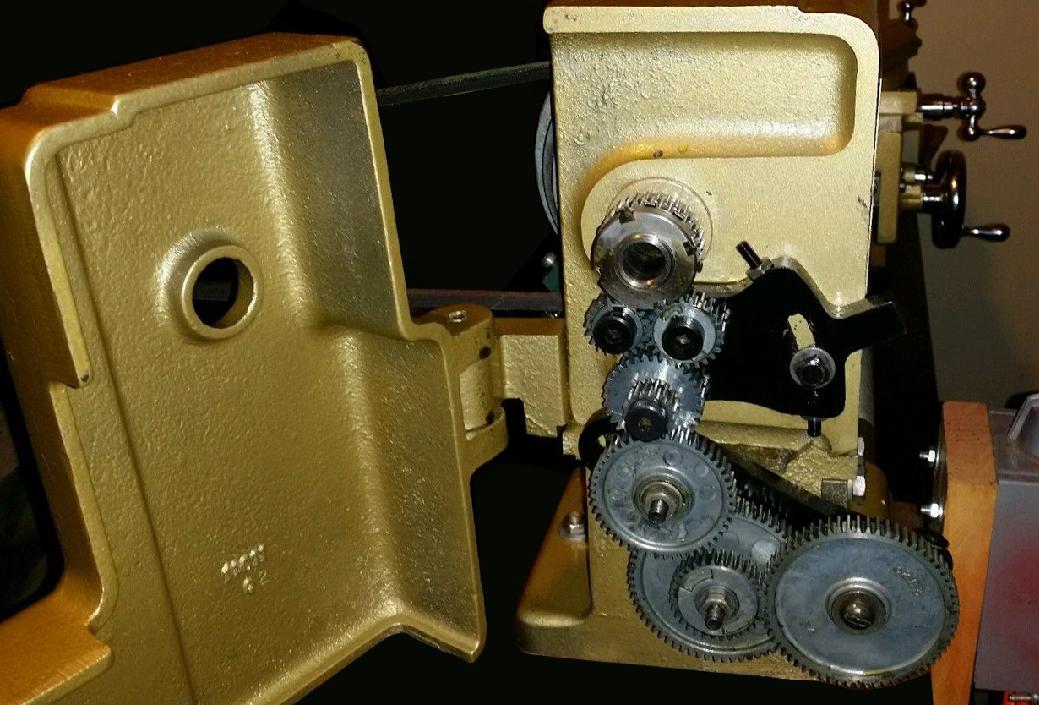

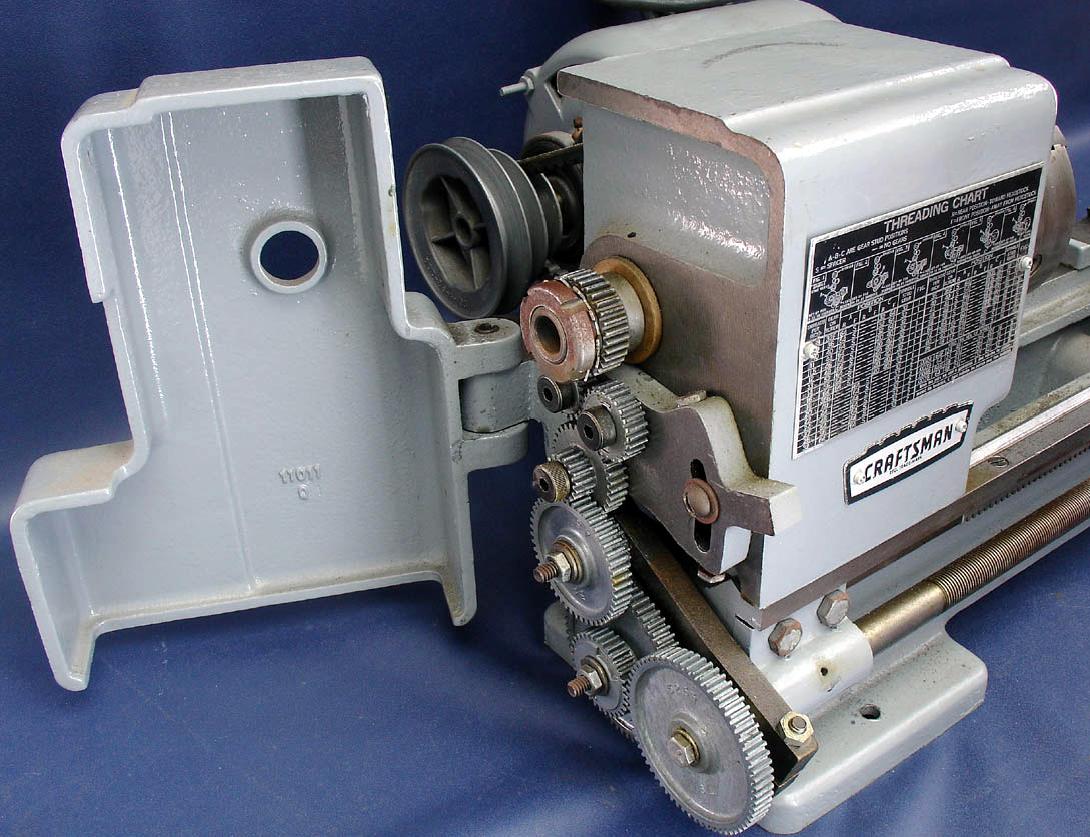

The tumble reverse mechanism, carried on a crude bracket, had to be unbolted before it could be moved and the carriage drive could be reversed in directions. Note the small adjuster screw, to set the mesh of the tumble gears with the headstock spindle gear, running through the casting from the top to impinge against the lock screw. Another adjuster ran through from underneath to set the mesh of the other gear. |

|

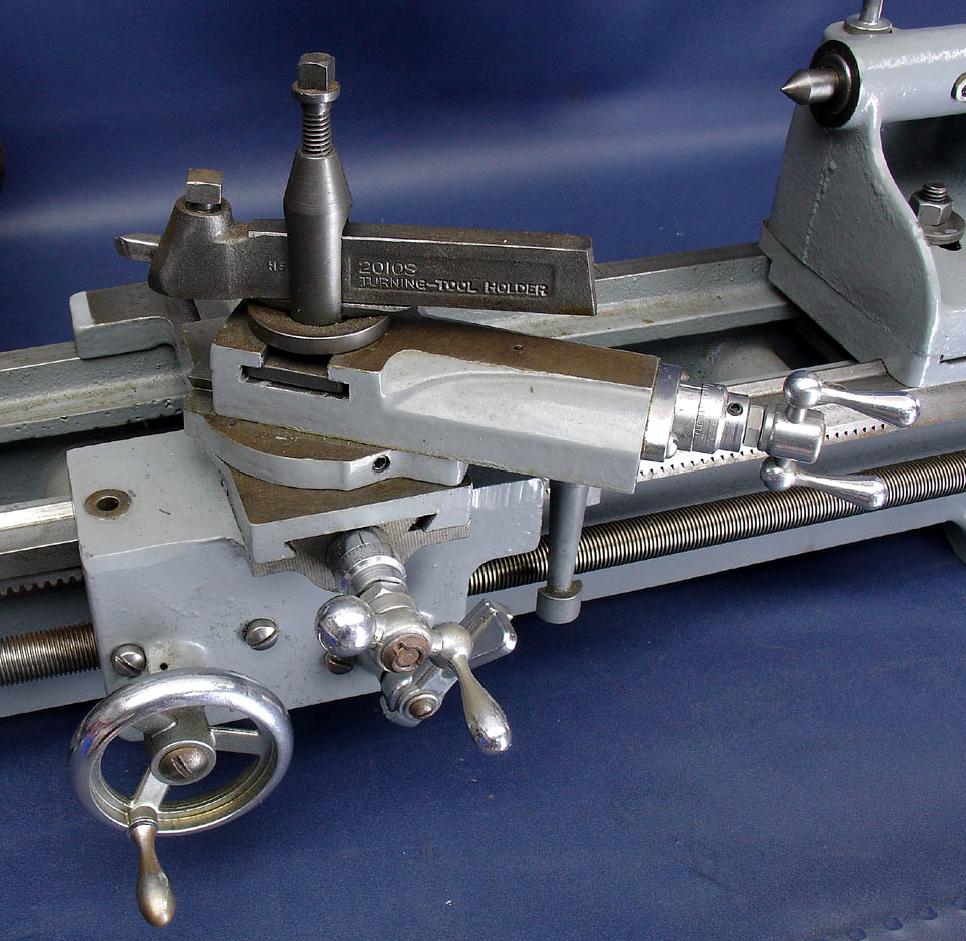

Although constructed as previous 109 models - with apron and saddle cast as one unit - the entire carriage assembly was completely re-engineered. The full-depth apron carried a proper handwheel, driving through rack and pinion gearing (instead of a handwheel on a leadscrew that ran though a full-nut on the apron), and both cross and top slides were fitted with micrometer dials. |

|

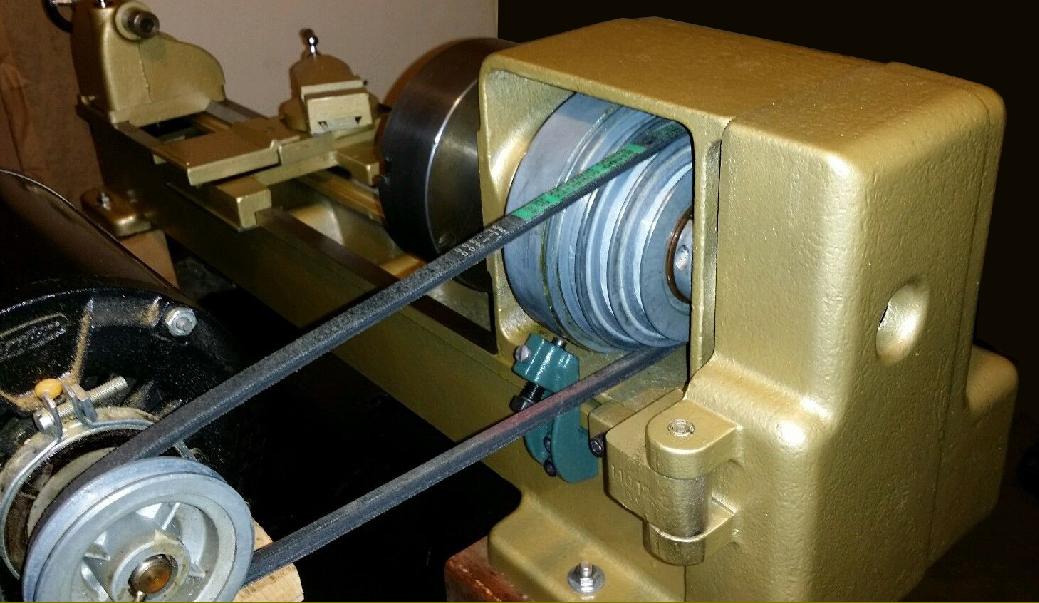

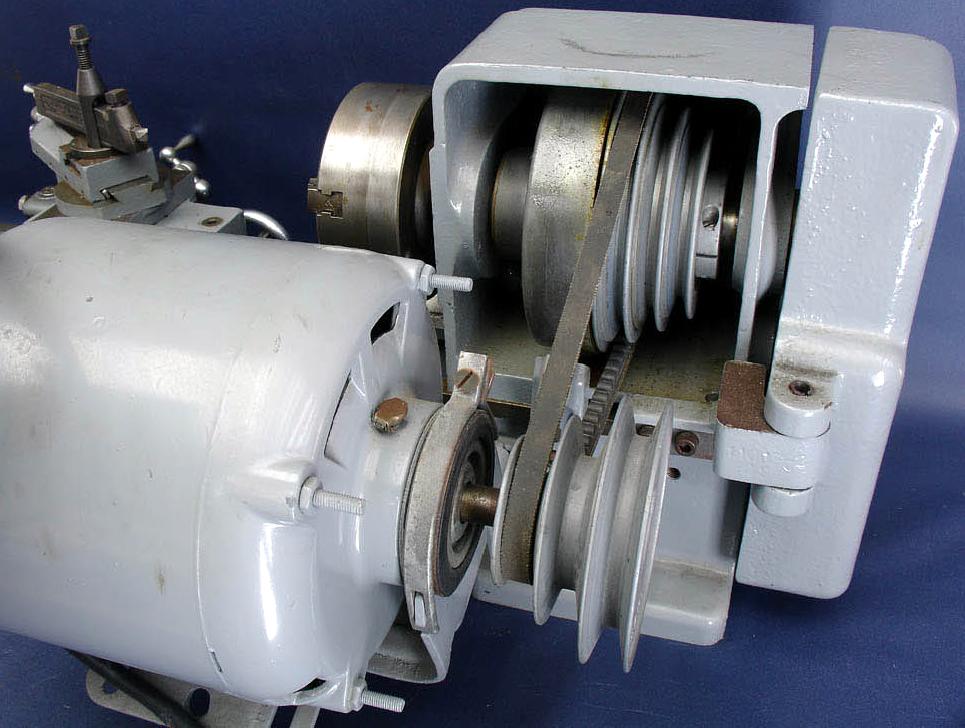

Direct belt drive from the motor - the lack of an integral countershaft being a common failing on many Craftsman-branded lathes - was partially compensated for by the inclusion of an effective and neat epicyclic "backgear" built into the 3-step headstock pulley. It was engaged by preventing the rotation of the outer casing by a simple bolt, carried on a bracket bolted to the back of the bed. A small pin, visible on the front face of the pulley, would have required moving (though sideways or by extraction is not known) to allow the "planet" gears to be rotated by the "sun" gear attached to the 3-step pulley. Although the back of the headstock was completely open, as on previous 109 lathes, in this case the casting had not been further cut way over the top of the bearings but arranged to go as far back as possible to improve stiffness. |

|

|

|

|