|

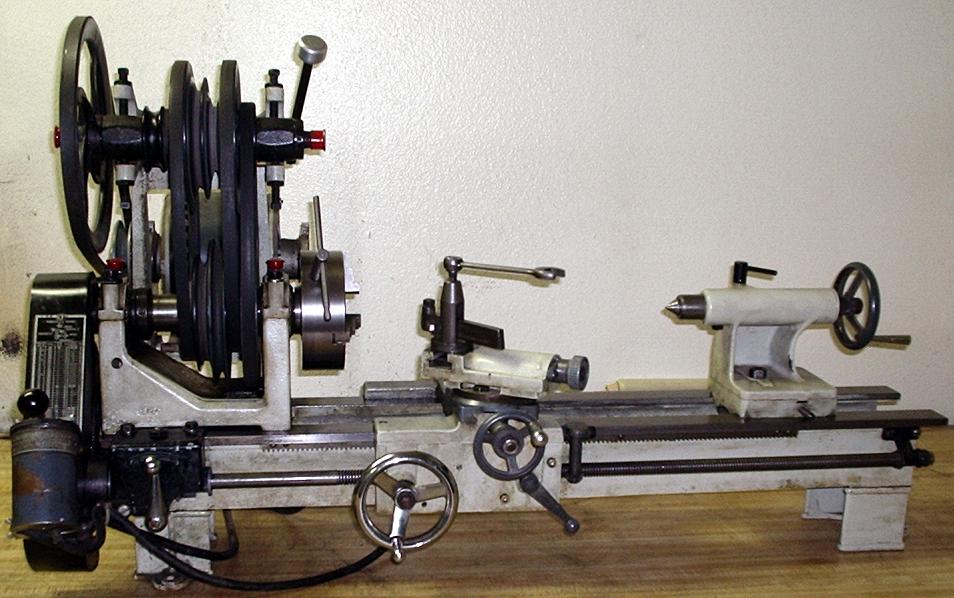

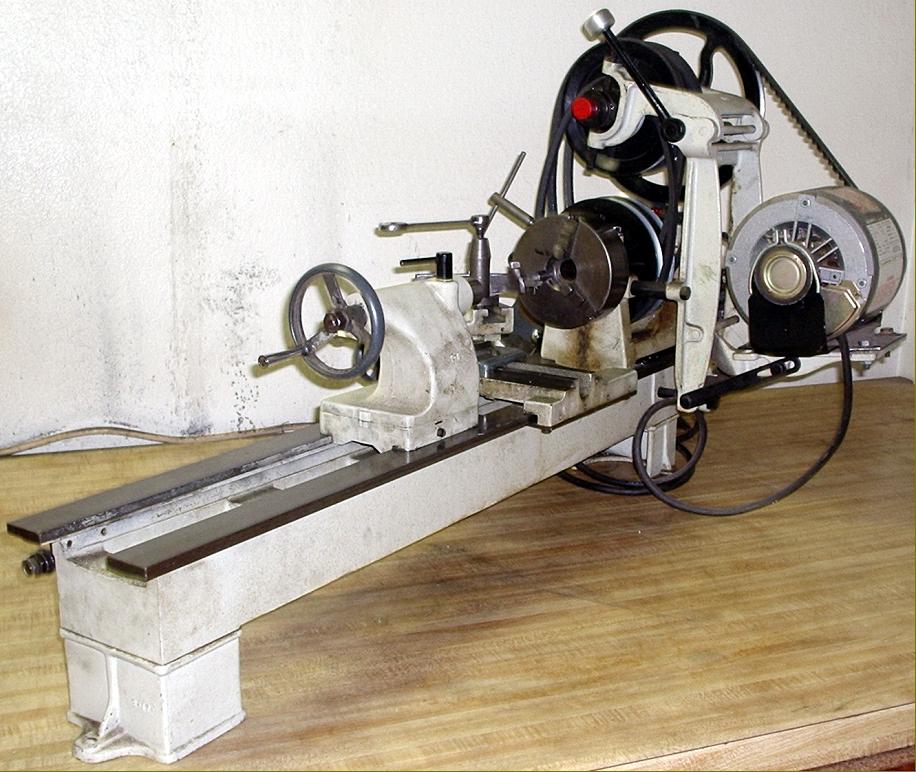

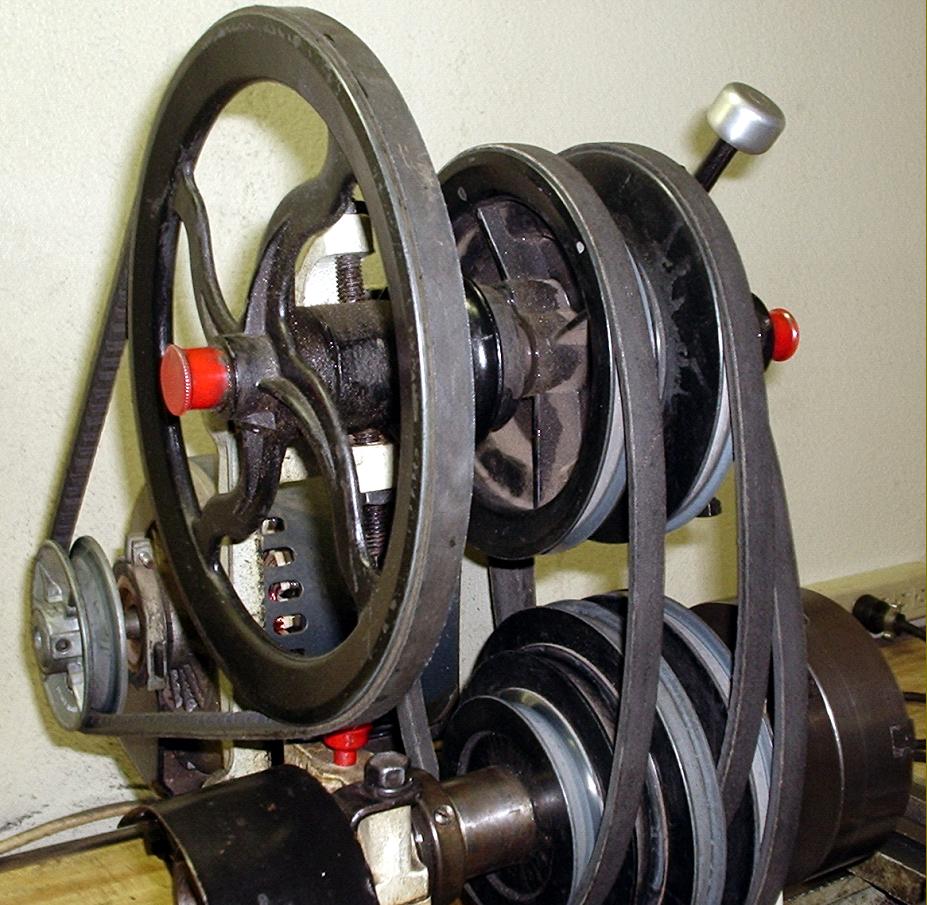

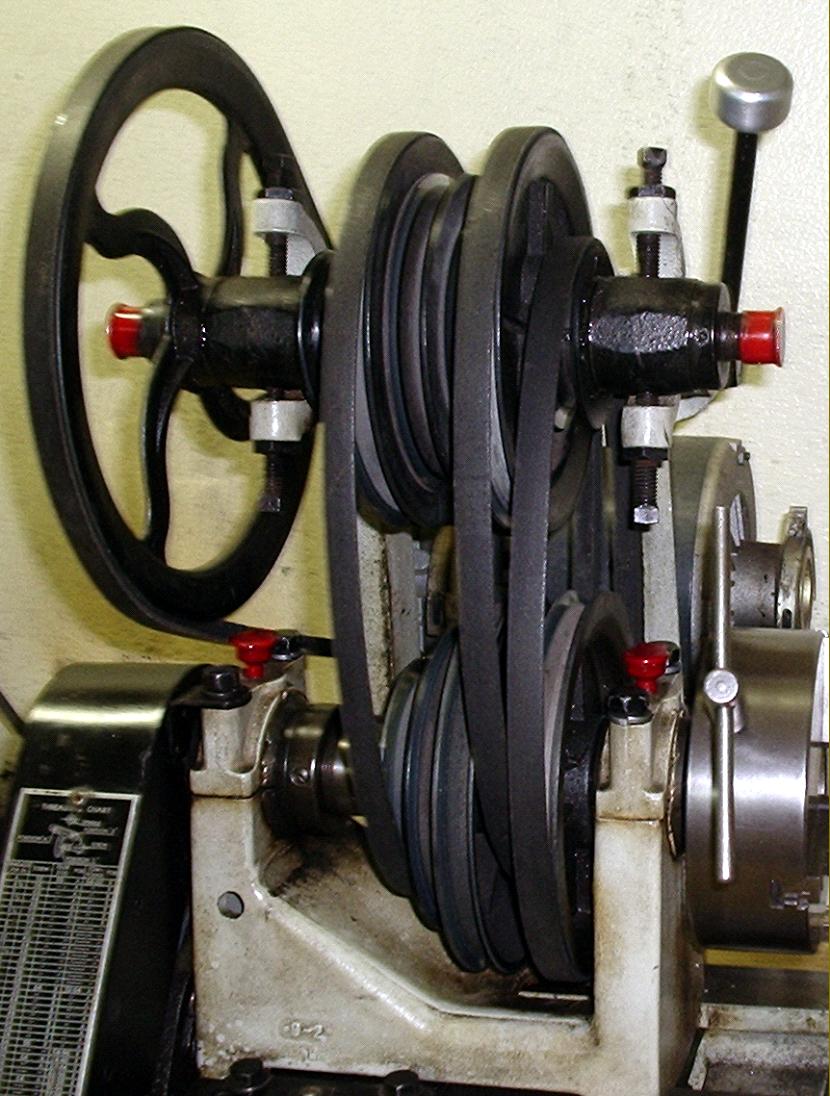

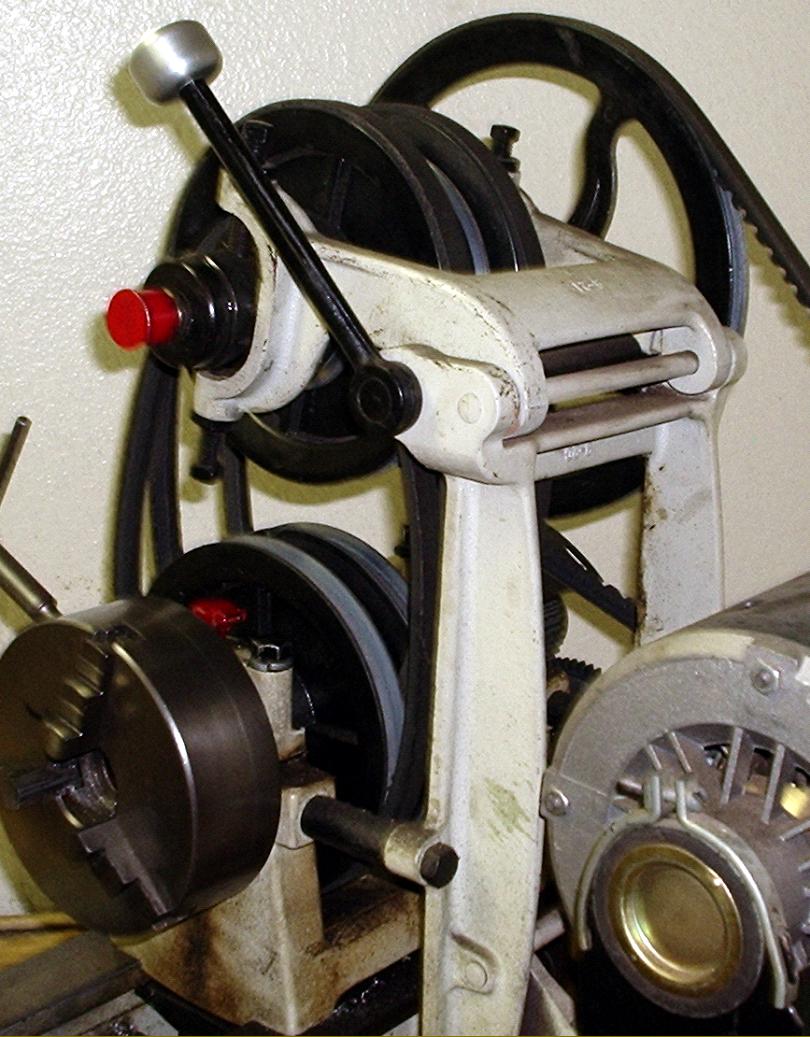

Home Machine Tool Archive Machine-tools for Sale & Wanted A complete data pack is available for the Atlas 9-inch and other Lathes Restored 10-D & 10F Acorn, Halifax & Sphere Copies Early 9-inch Metalmaster Lathes Atlas Factory Catalogue Covers Accessories Atlas Wood Lathes Countershafts Atlas Miller Atlas Shaper Atlas Drill Presses Notable as the world's first lathe for model and experimental engineers with an integrated all-V-belt drive system, the Atlas manufactured 9-inch "compound-drive" lathe was also sold as the Craftsman "Metalcraft" and has also been found with Atlas "Metalmaster" badges. |

|

|

|

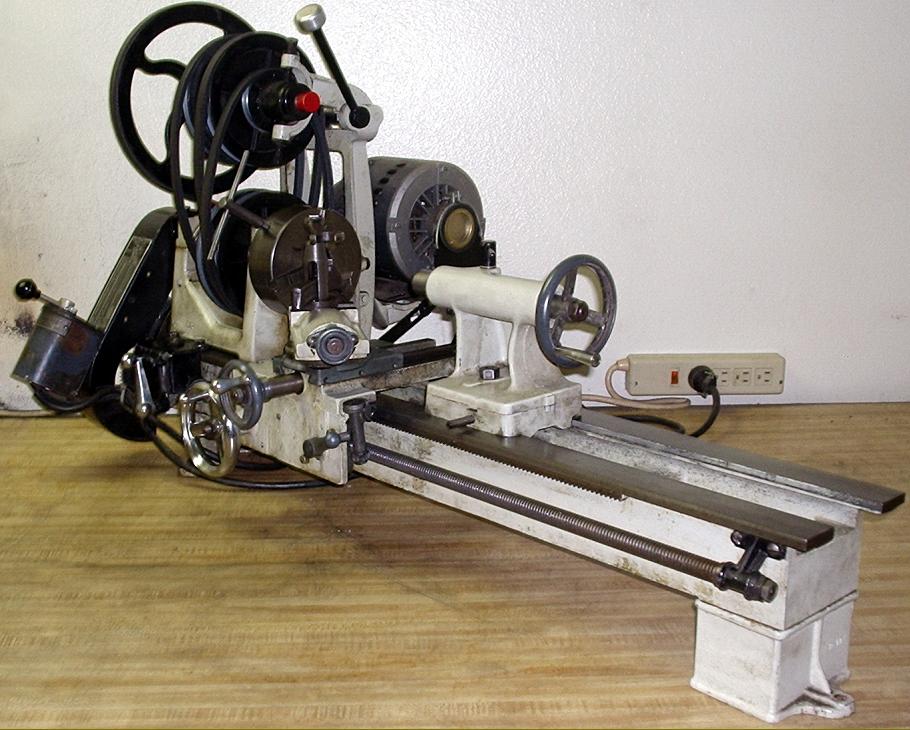

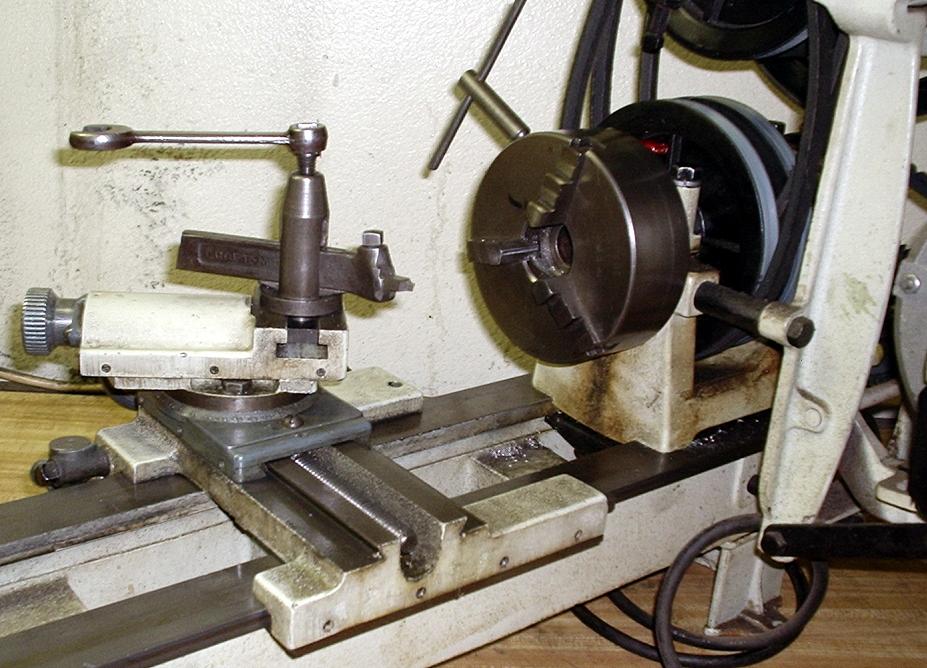

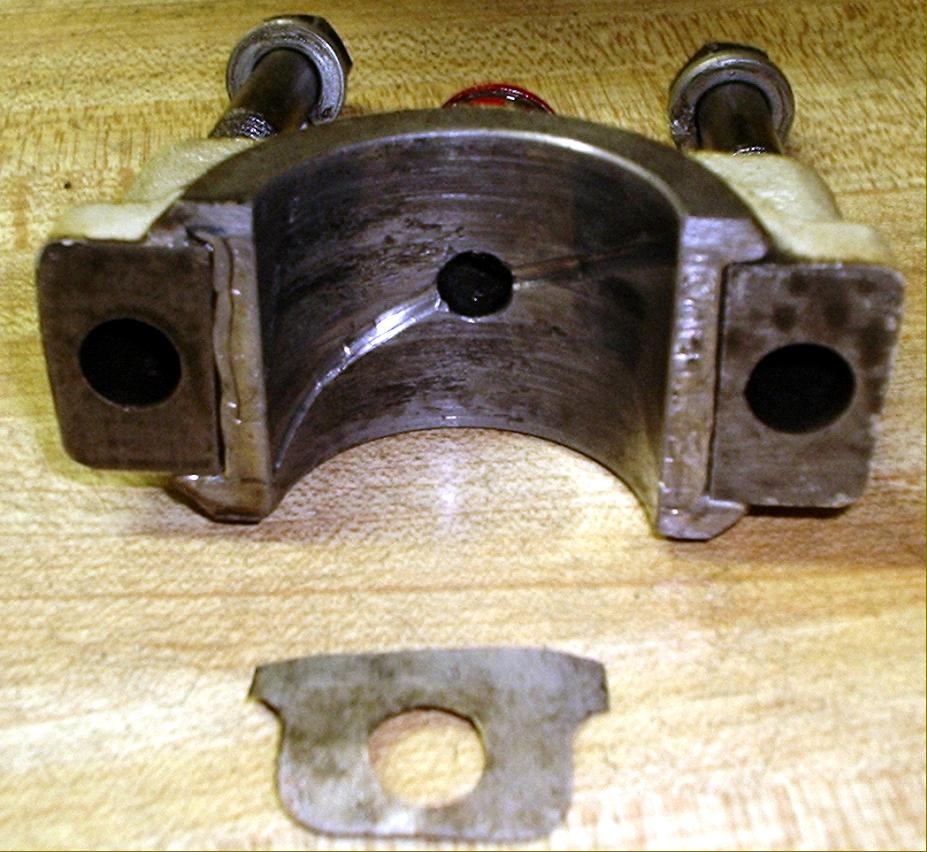

A tailstock-end view showing the very light leadscrew bearing-support bracket. So fragile was this component that it often snapped off - in a usefully sacrificial way - when the carriage was accidentally run into the chuck or tailstock |

|

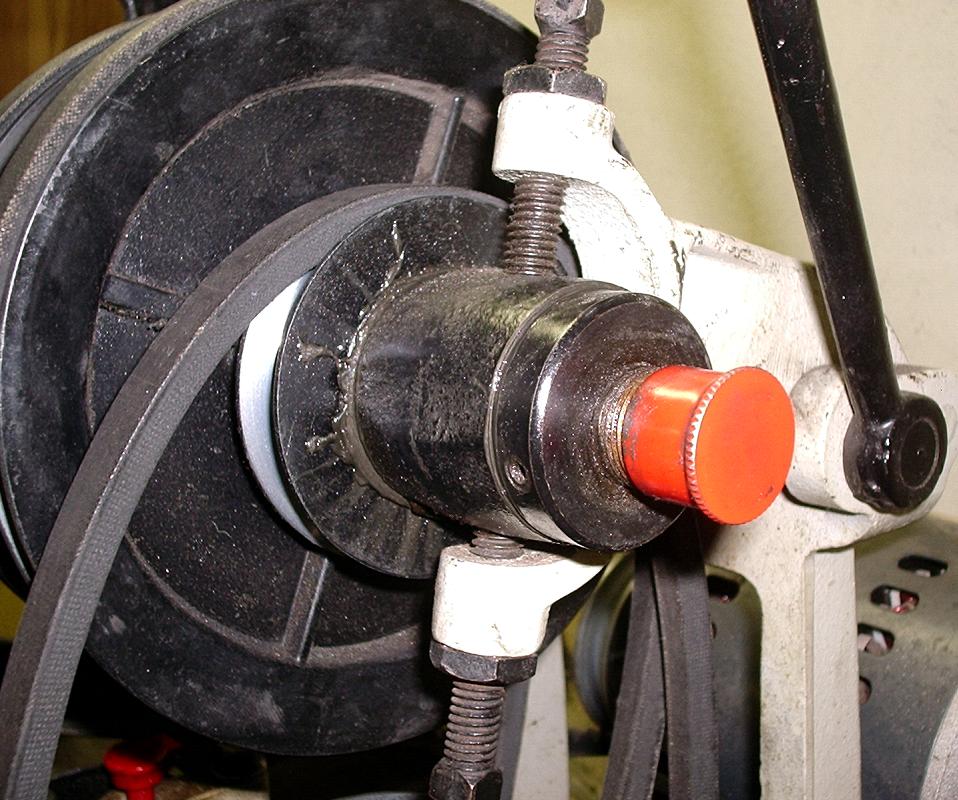

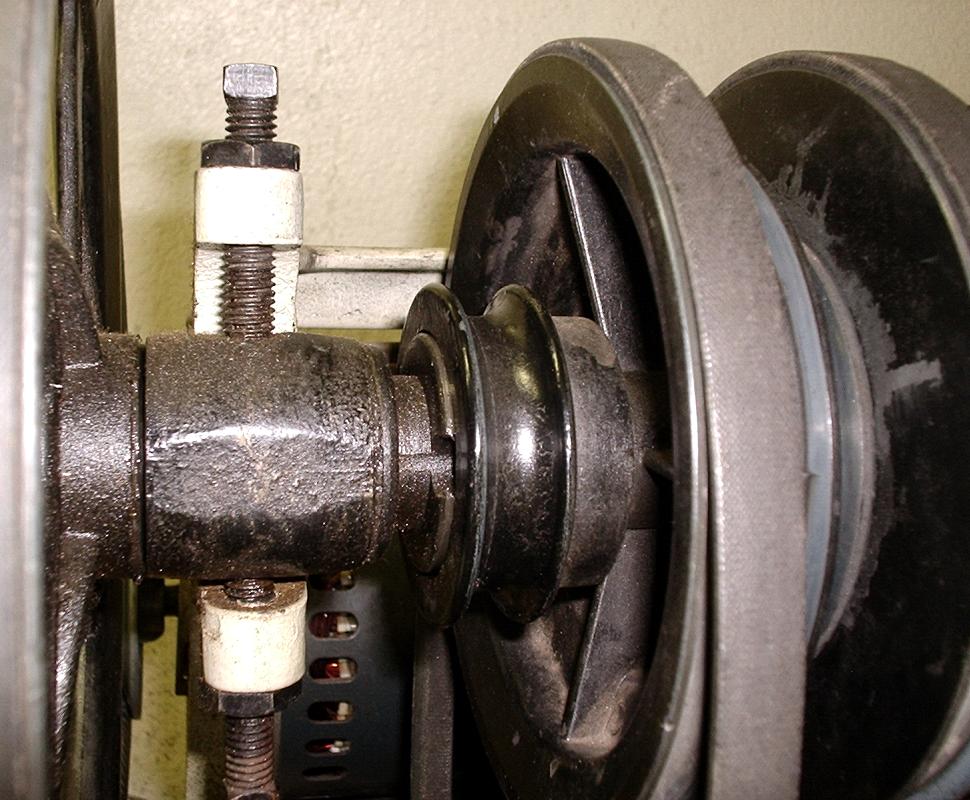

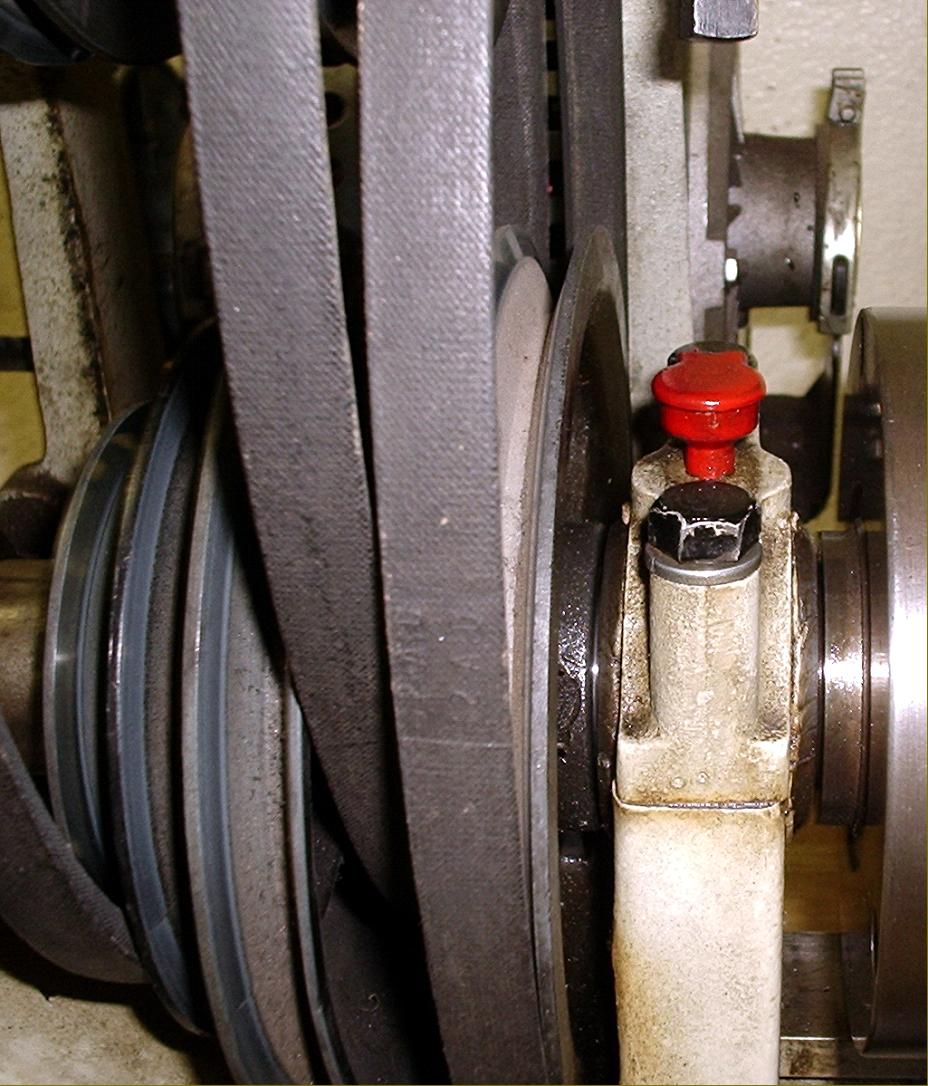

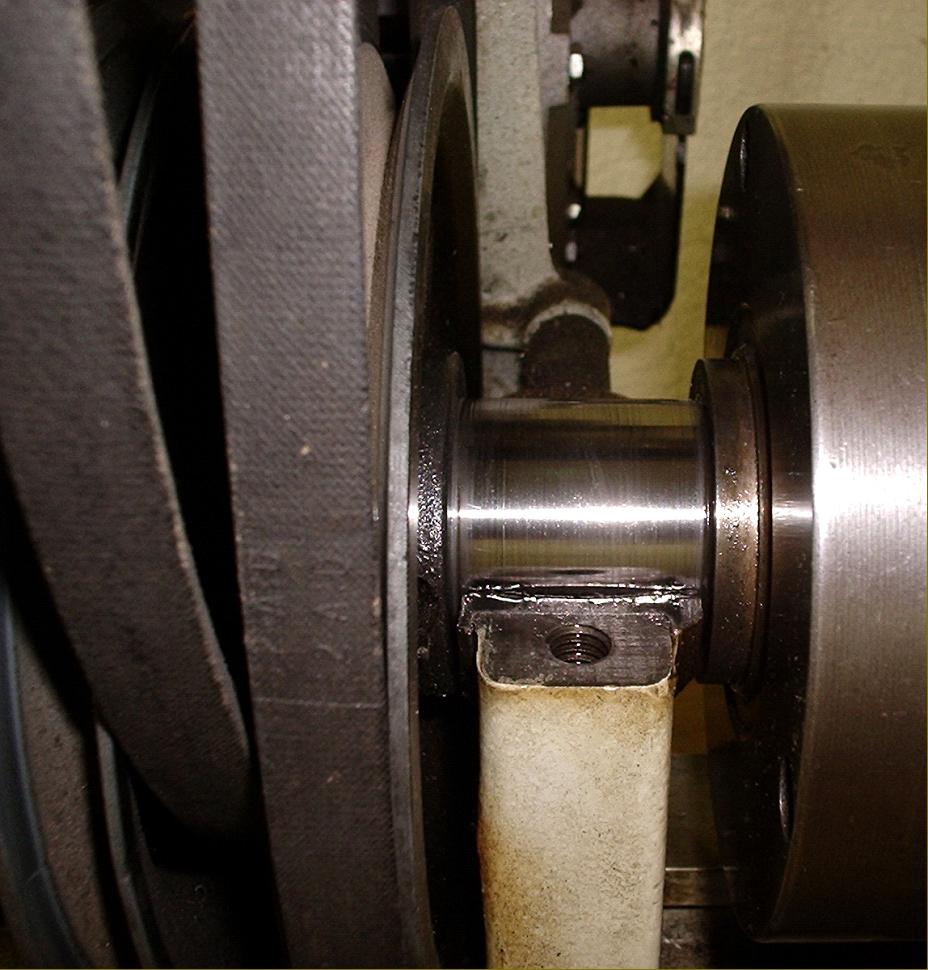

On its introduction in 1932 the Metalmaster caused a sensation - instead of flat-belt drive from a clumsy wall-or ceiling mounted countershaft and motor, here was the world's first lathe for model and experimental engineers with a neat, built-on countershaft unit and all-V-belt drive - an arrangement quickly taken up by other makers |

|

|

|

|

|

|

|

|

|

|

|

|

|

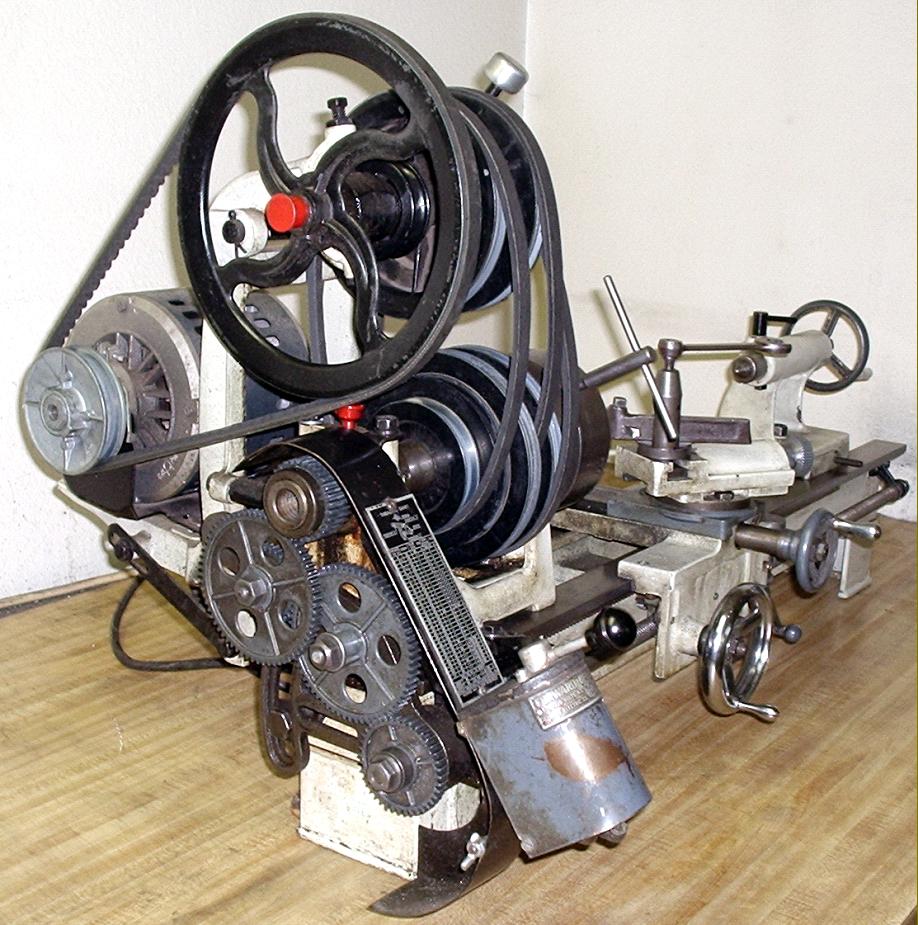

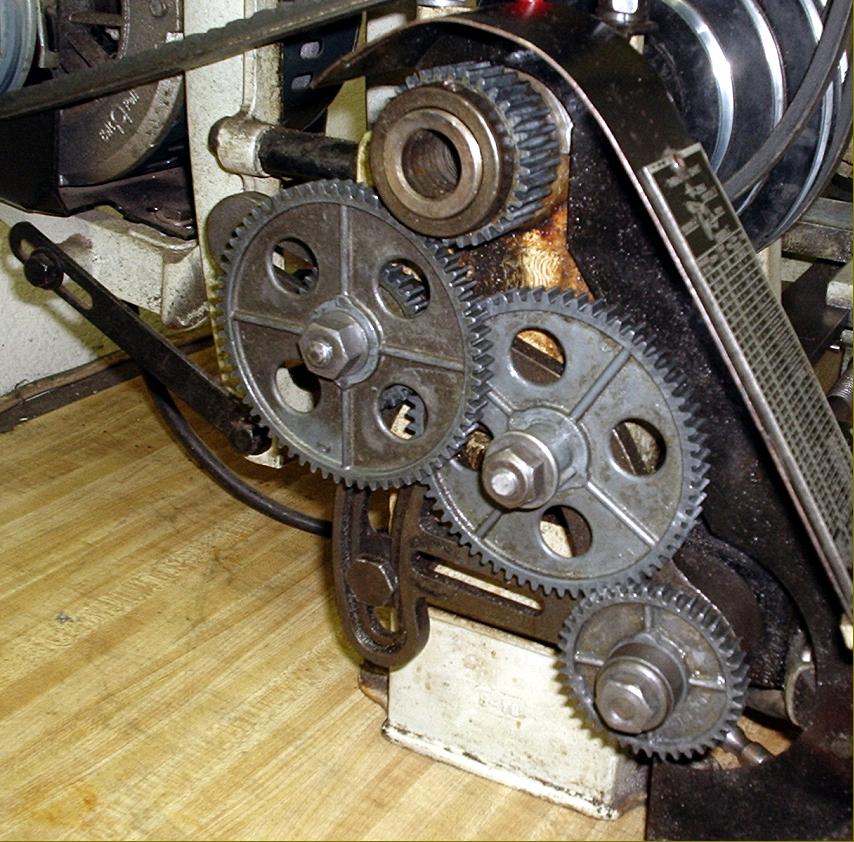

Leadscrew reversing gearbox comparison: instead of face dogs on the outside of the ZAMAK bevel gears (as on later machines and shown in the gearbox at the top of the picture and the gear in the right of the foreground), this early lathe had a "half-the-circumference" dog cast onto the inside of the bevel gears - with a matching dog on the slider - so giving (because of its single location in/out setting) a "dog-clutch" that could be used to exactly pick up the thread-engagement point when screwcutting. The disadvantage would have been a reluctance to engage quickly - and hence the change to a multi-dog arrangement that was much faster to operate. |

|

|