Home Machine Tool Archive Machine-tools Sale & Wanted

A Data Pack is available for the Smart & Brown Model A

|

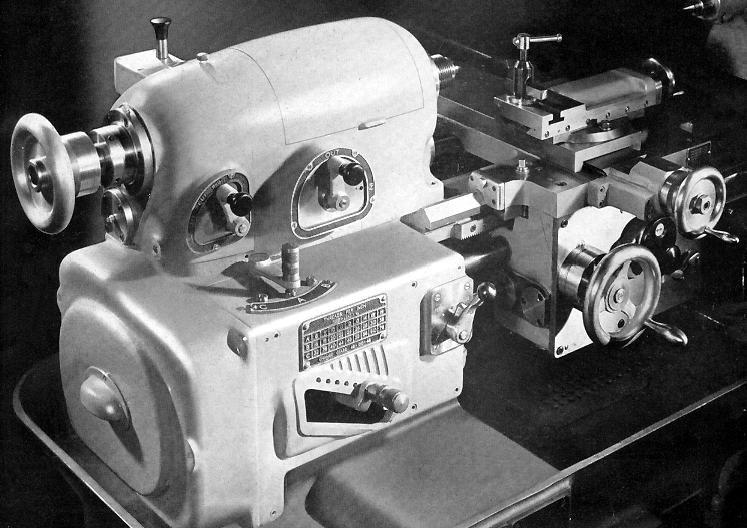

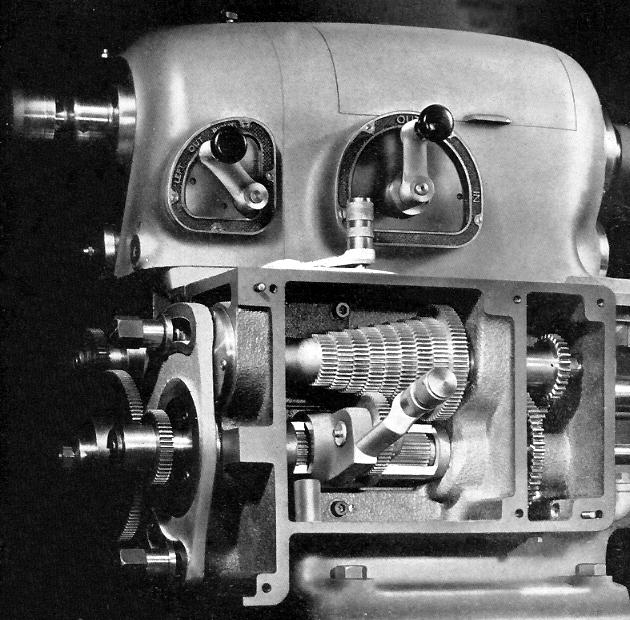

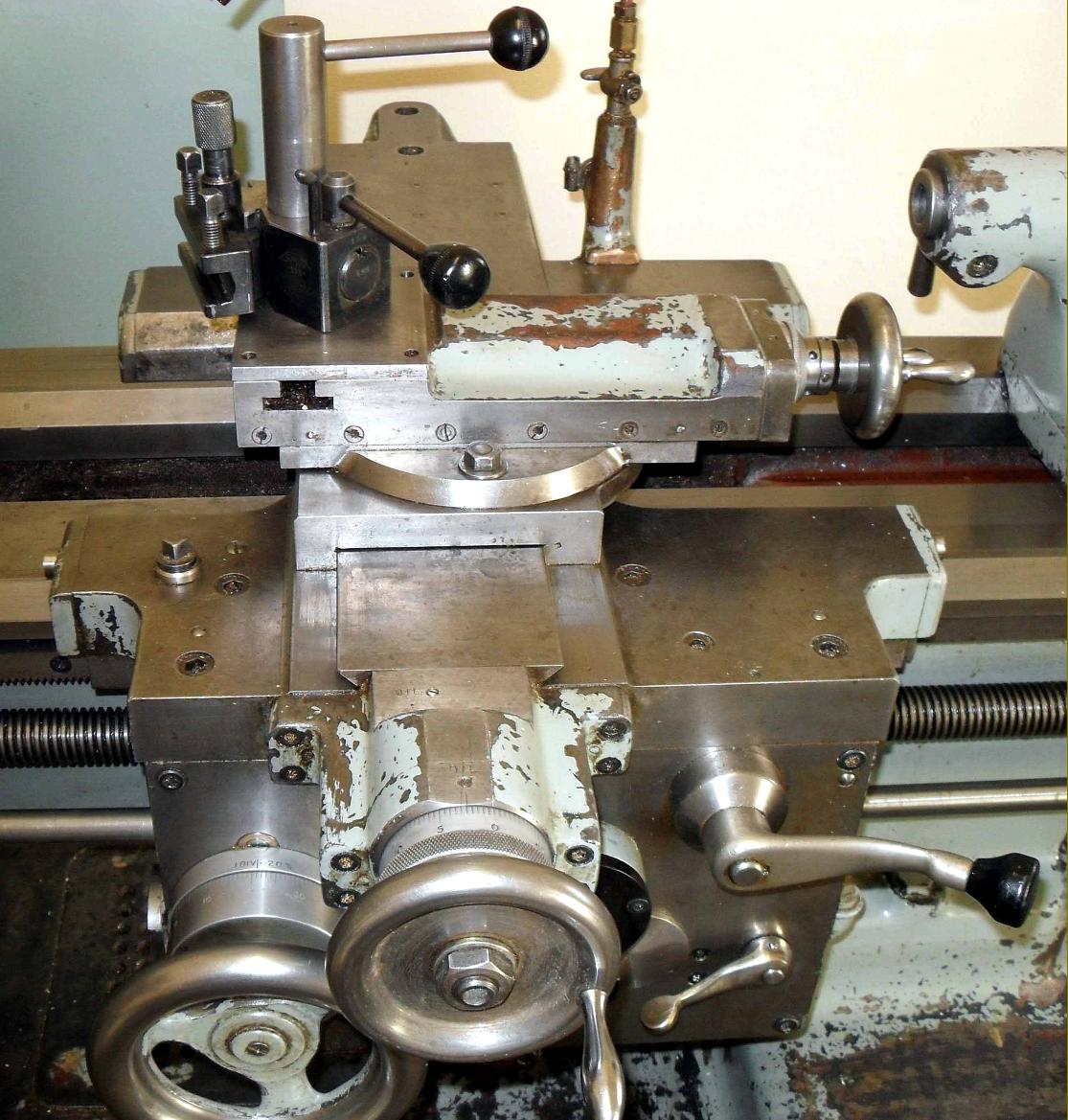

Early Smart & Brown Model A Mk 1 4.5" x 18" (118 mm x 508 mm) circa 1947 - 1957 Like all the larger toolroom S & B lathes the speed-change gearbox of the model A was mounted inside the base of the cast-iron cabinet stand and the drive transmitted smoothly to the plain-bearing headstock by a flat belt. The apron contained an automatic oil pump whilst the headstock bearings, and gear drive to the screwcutting gearbox, were lubricated by a hand pump - the plunger handle of which can be seen protruding through the headstock cover. |

|

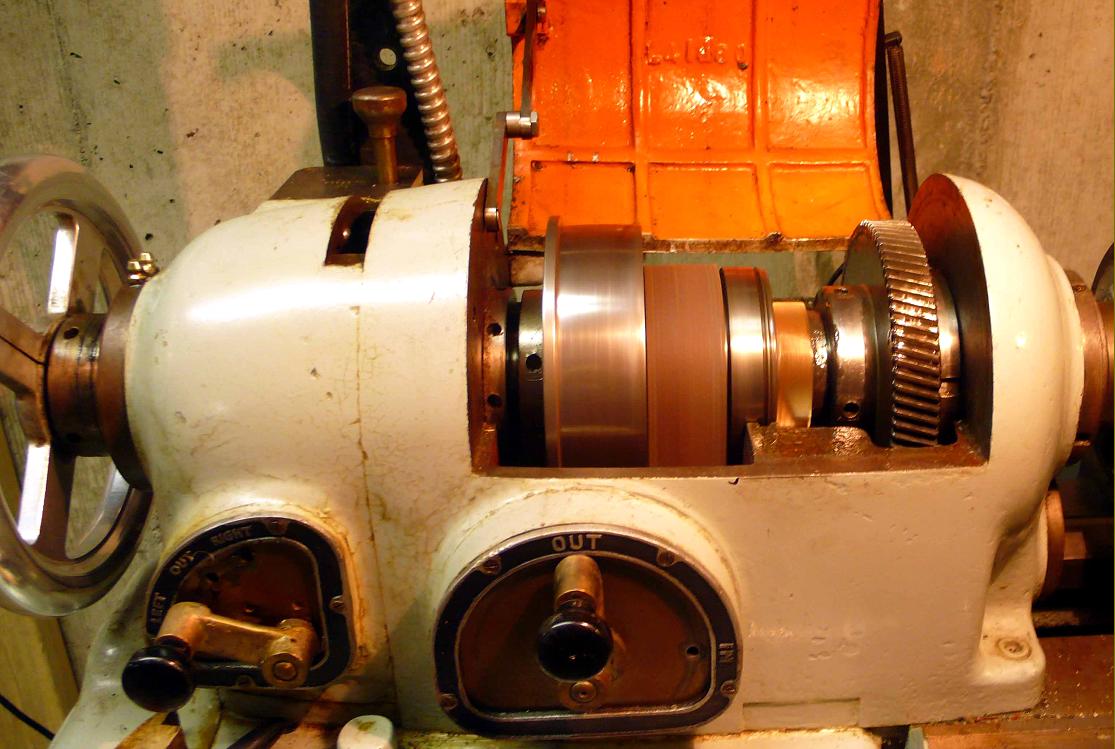

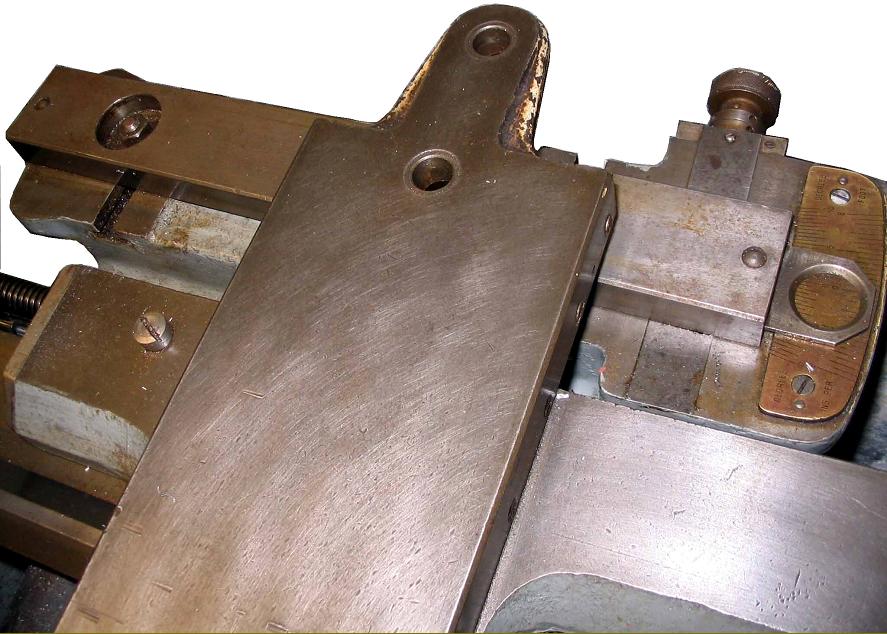

Smart & Brown Model A Mk 2 4.5" x 18" (118 mm x 508 mm) |

||

|

A rare glimpse inside the factory's development department as it was in the summer of 1968. Although little can be seen of the machine tools, the fact that each member of staff appears to be wearing what is, no doubt, a crisply laundered white shirt together with a tie, tells you a lot about the standards of the era. |

|

|

|

|

|

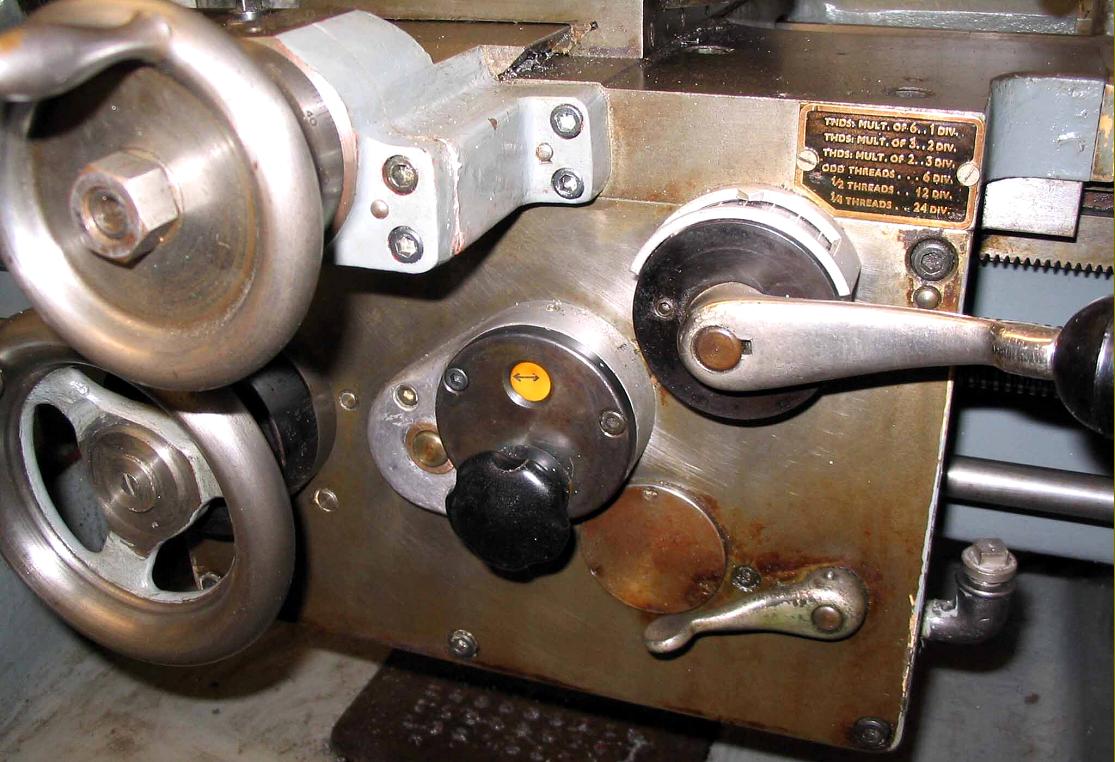

One important point about early versions of the Model A concerns the sometimes-encountered difficulty of changing speeds - this being done by a 3-position quadrant lever on the front face of the stand connected to a three-speed gearbox mounted inside the cabinet stand. The design of this mechanism is faulty, the shaft connecting the lever to the gearbox being fixed rigidly in position on the lever, but free to move up and down with gearbox motor-support plate. As the latter is adjusted up and down to set the tension of the headstock drive belt, the shaft is deflected out of line making gear section difficult or impossible. The solution? Make sure that the belt is kept as short as possible; this means that any adjustment of the final tension is as small as possible and so the shaft misalignment minimised. As temporary short cut, if gear changing is difficult, before moving the quadrant lever, use the belt tensioning lever to slacken the belt, change the speed and then re-tension the belt. |

||

A Data Pack is available for the Smart & Brown Model A

Home Machine Tool Archive Machine-tools Sale & Wanted