|

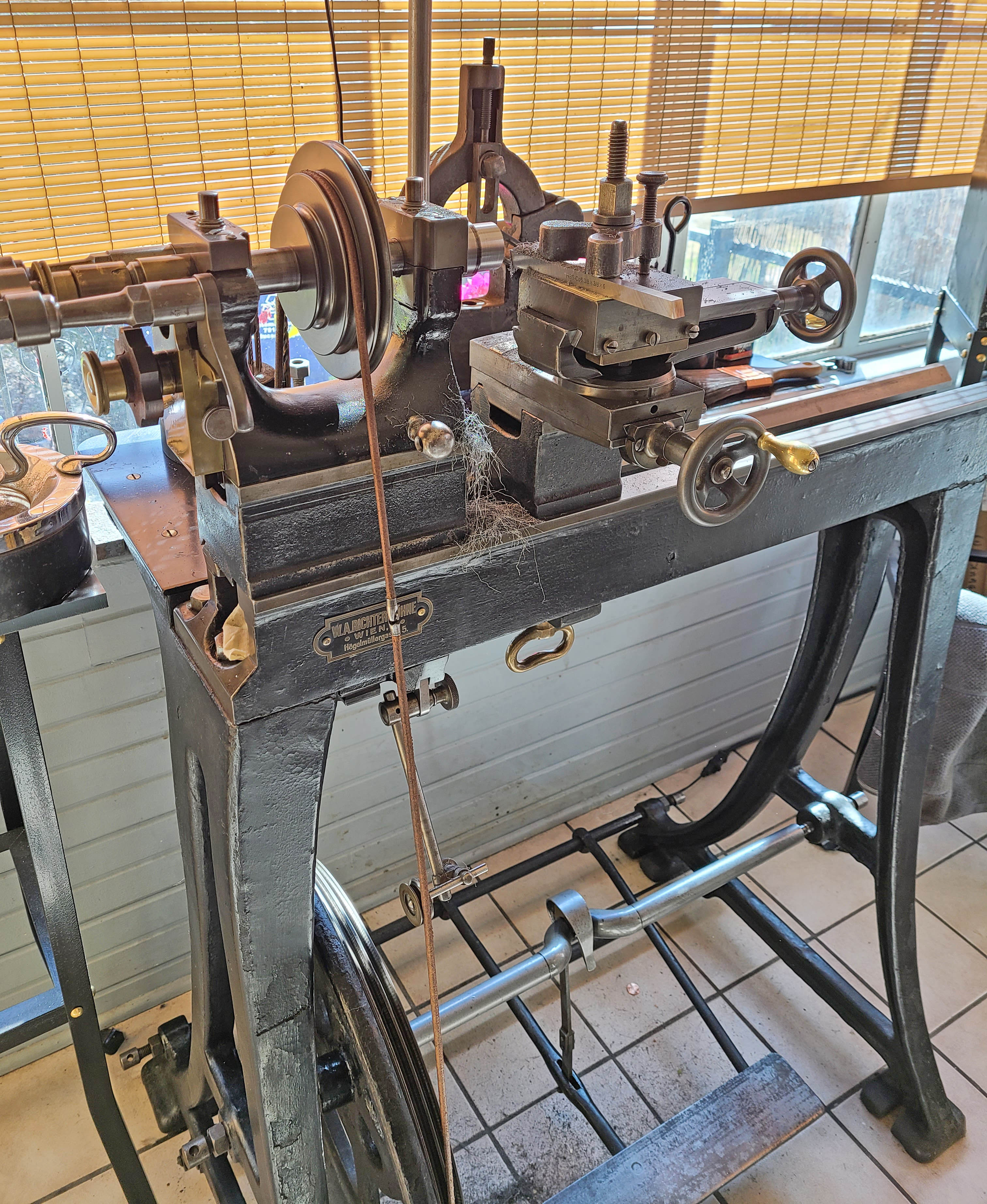

Believed to have been built around 1888, this Richter lathe has a sliding headstock spindle for "chase screwcutting" and has survived with its original treadle-drive stand, the maker's centre-height raiser blocks, overhead drive system and several useful accessories. It is still in regular, daily use by its enthusiatic American owner,

In the pictures below, details of the sliding headstock spindle arrangement can be seen. A thick plate, able to be moved vertically to engage the threading, is dovetailed to the outside face of the headstock casting. Instead of the threading tool being made to move along the job, as with an ordinary chase-type or changewheel-driven screwcutting, the headstock spindle is arranged to slide forwards and backwards in its bearings with the cutting tool remaining stationary. Widely used on ornamental turning lathes in the 1800s, in the 20th century, the system was adopted by such German firms as Lorch ,Wolf Jahn, and Auerbach and the Swiss Schaublin. The smallest lathe thought to have incorporated the system was a version of the Wolf Jahn Model AA with a centre height of just 50 mm. The arrangement was also a feature of most "Swiss-Auto" mass-production lathes used for the manufacture of tiny parts - and is still in widespread use today on such machines, though these are now, of course, fitted with CNC control. The last conventional lathe on which sliding-spindle screwcutting appears to have been available was a version of the Schaublin 102 marketed in the early years of the 21st century.

Designed originally for use by optical instrument makers, who needed short but very accurate threads, a disadvantage of the "chase" system was the need to keep in stock a range of master threads and their matching star-shaped bronze followers. However, with the limited range of thread pitches needed, this was not unduly expensive--though usually included in the set was a coarse-pitch pair able to generate the thread used on the lathe's spindle nose and so enable the manufacture of such items as chuck backplates and other spindle attachments.

|

|