|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Petermann P4 automatic lathe. With a spindle bore of 5 mm (0.197") the P4 was able to turn steel parts with a maximum diameter of 3 mm (0.12") in brass of 4 mm ( 0.16") with both up to 42.4 mm (1.67") long. A 2 h.p. motor provided ten spindle speed that ranged from 3050 to 12,200 r.p.m. with each having 40 corresponding camshaft speeds that varied from 0.5 to 48 r.p.m.

|

|

|

|

|

|

|

|

|

|

|

|

|

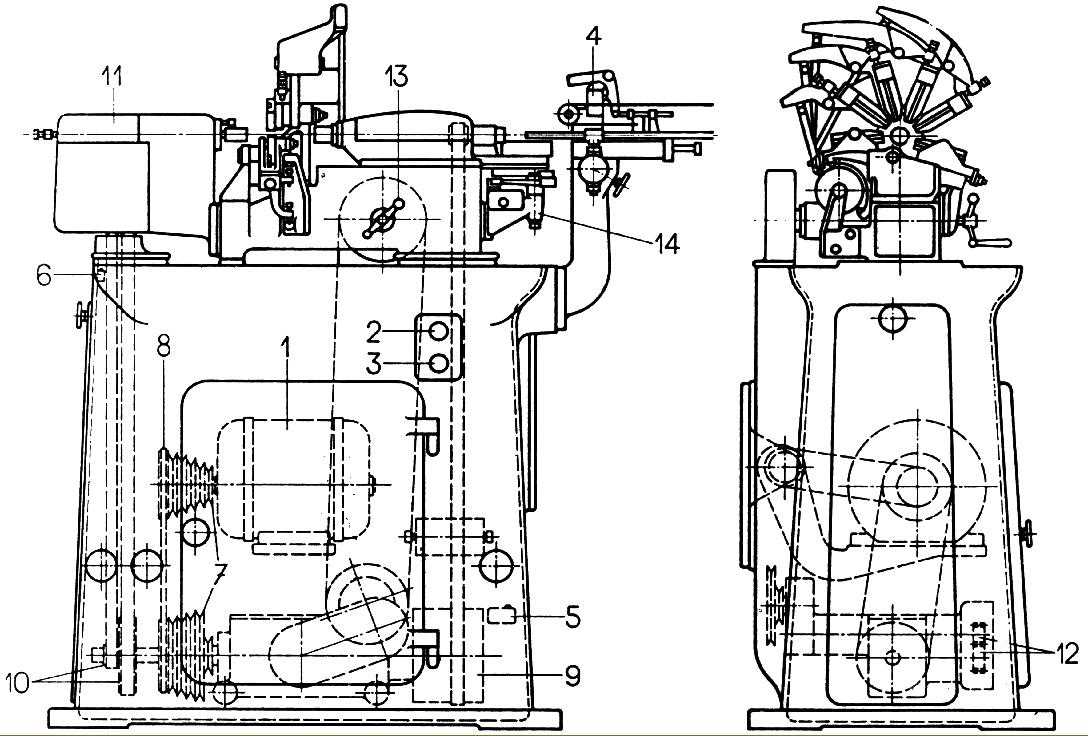

Petermann P4 drive system

|

|

|

|

|

|

|

|

|

|

|

|

|

|

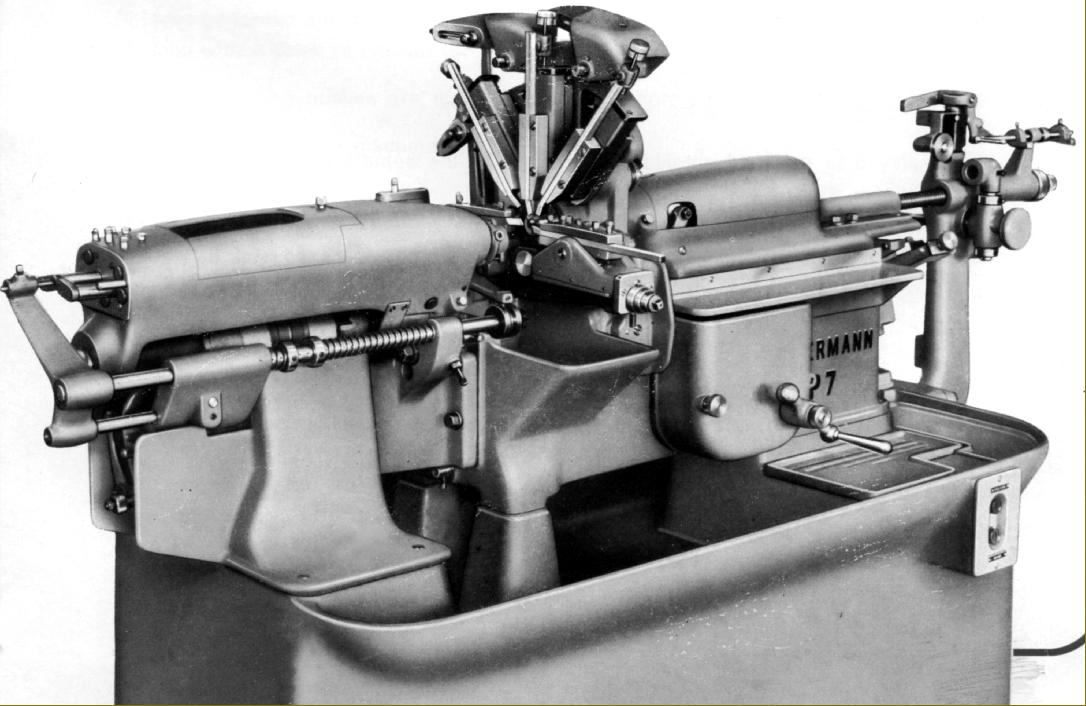

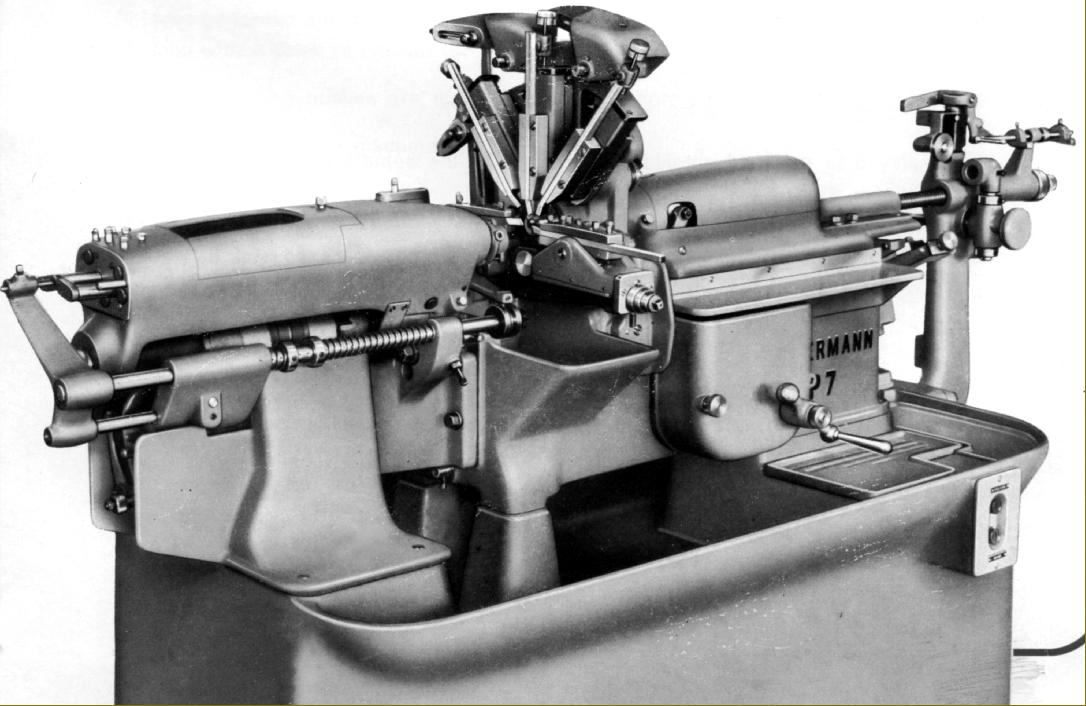

Petermann P7 automatic lathe. Two versions were available, a standard machine (P7) with a spindle bore of 7 mm (9/32") and a heavier-duty version (P7-R) with a bore of "Reinforced" model with a bore of 10 mm (25/64"). Both had the same turning capacity of 4 mm (5/32") in steel and 6.3 mm (1/4") in brass. A 3 h.p. motor provided 16 spindle speed for the headstock with bronze bearings and 18 for those with needle roller races. Speeds ranged from 1500 to 7,500 r.p.m. for the former and from 1500 to 10,000 r.p.m. for the latter. Each spindle speed had 44 camshaft speeds available that ranged from a low of 0.6 to 45 r.p.m. with electronic drive and from 0.38 to 71 r.p.m.. with all-mechanical drive.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

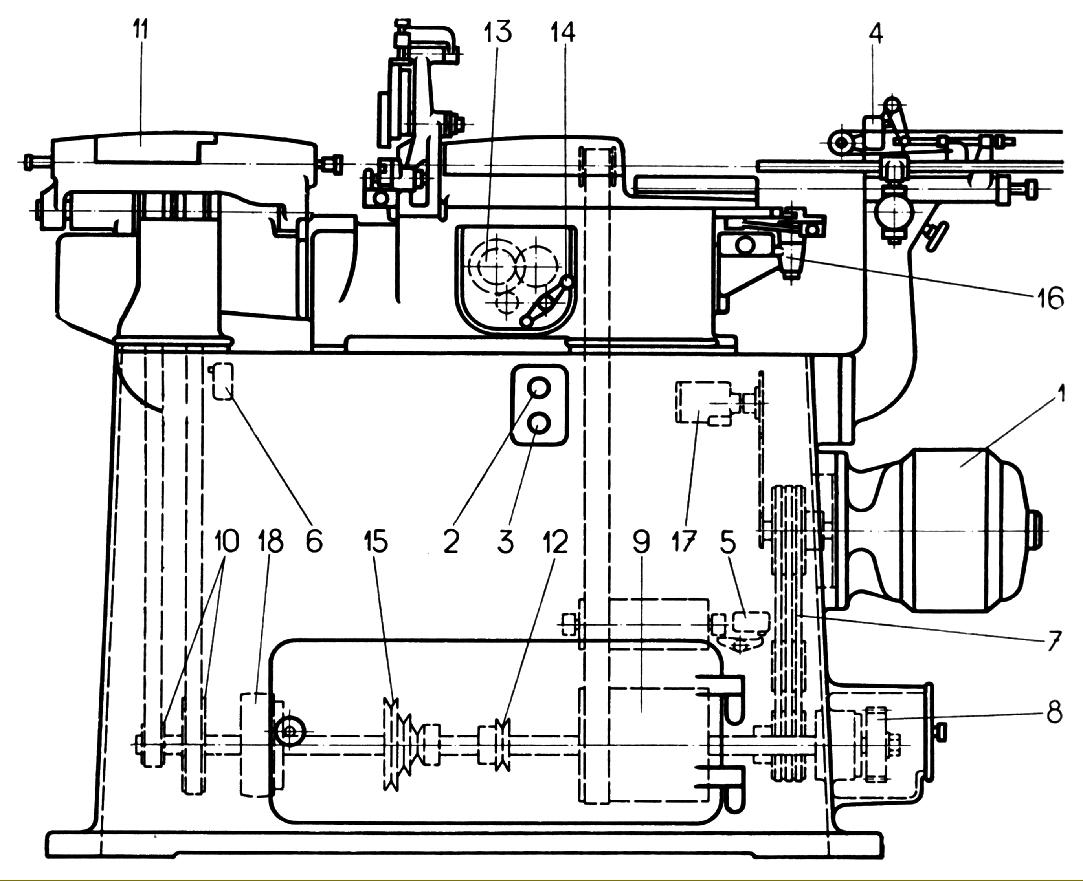

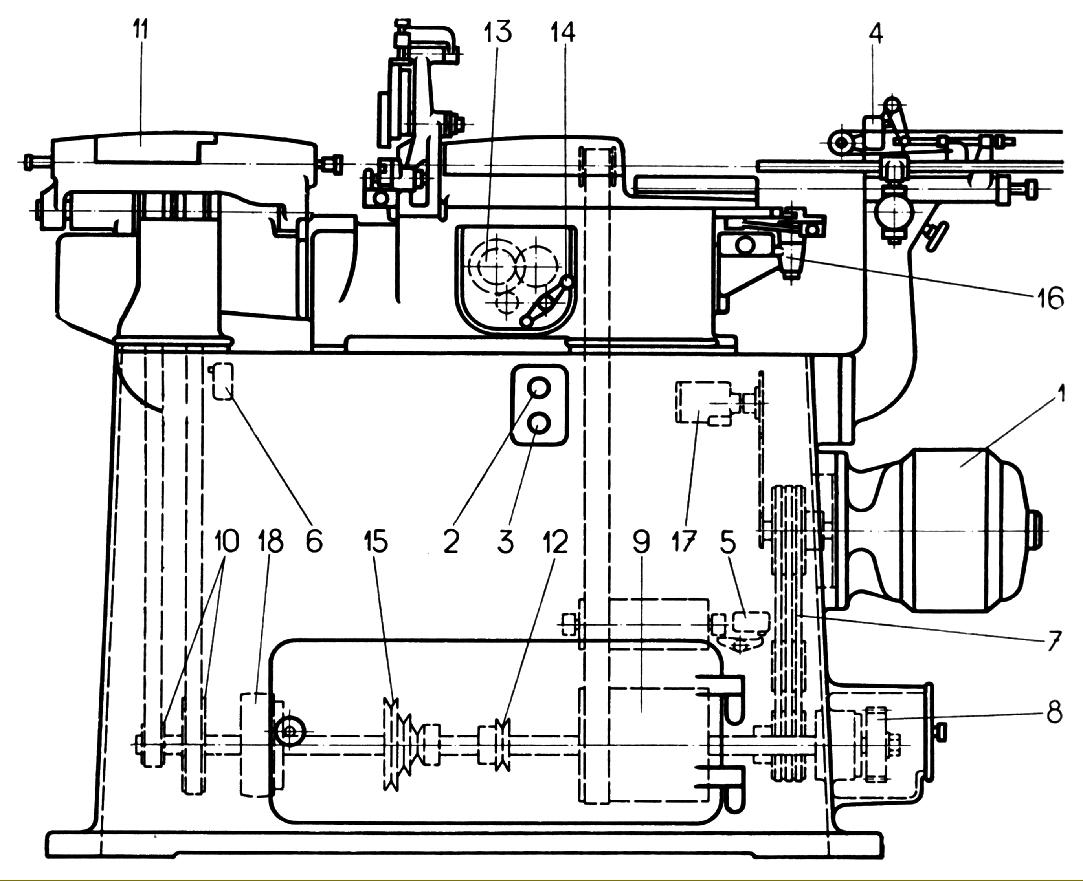

Petermann P7 Drive system

|

|

|

|

|

|

|

|

|

|

|

|

|

|

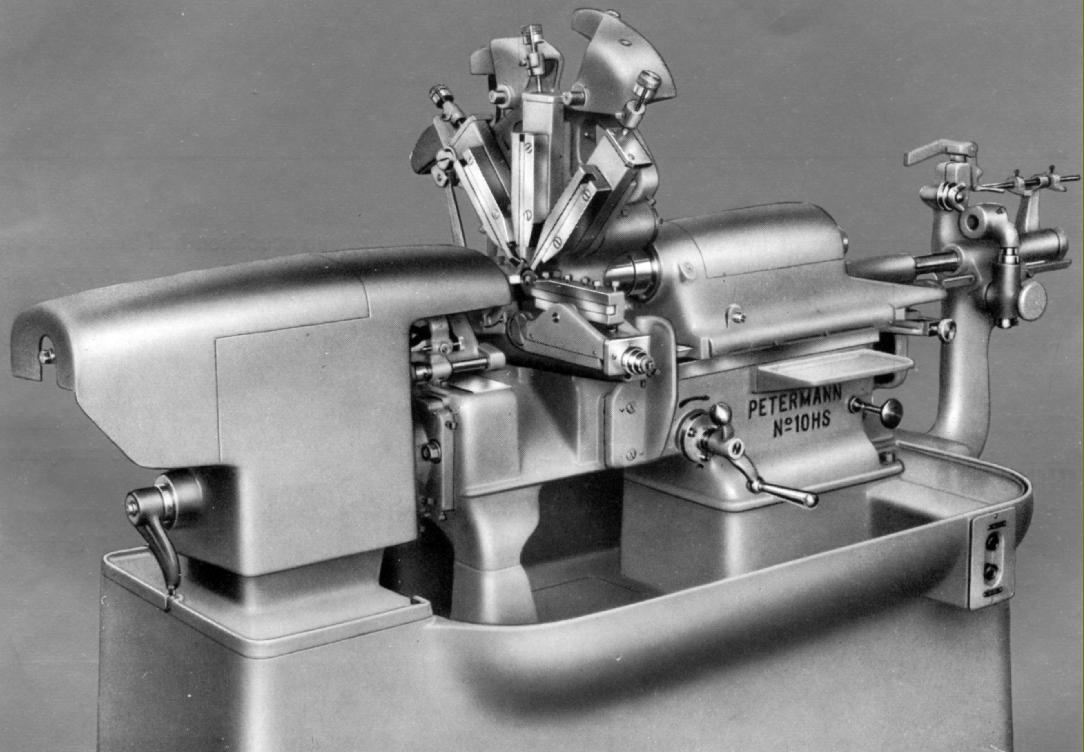

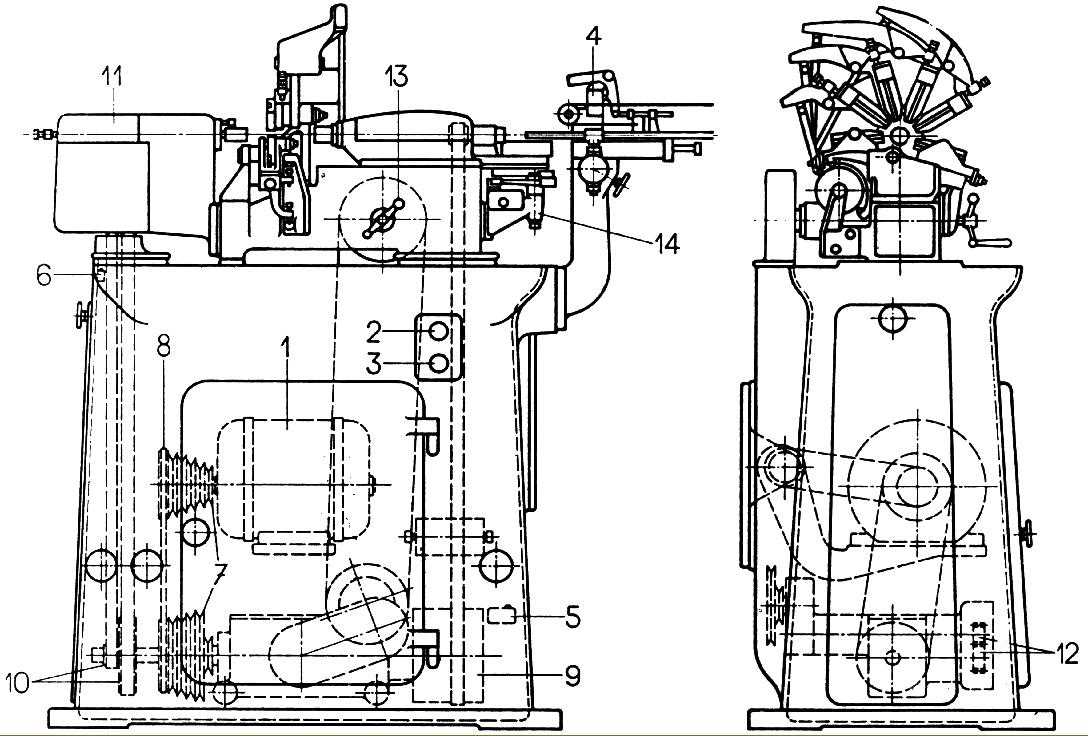

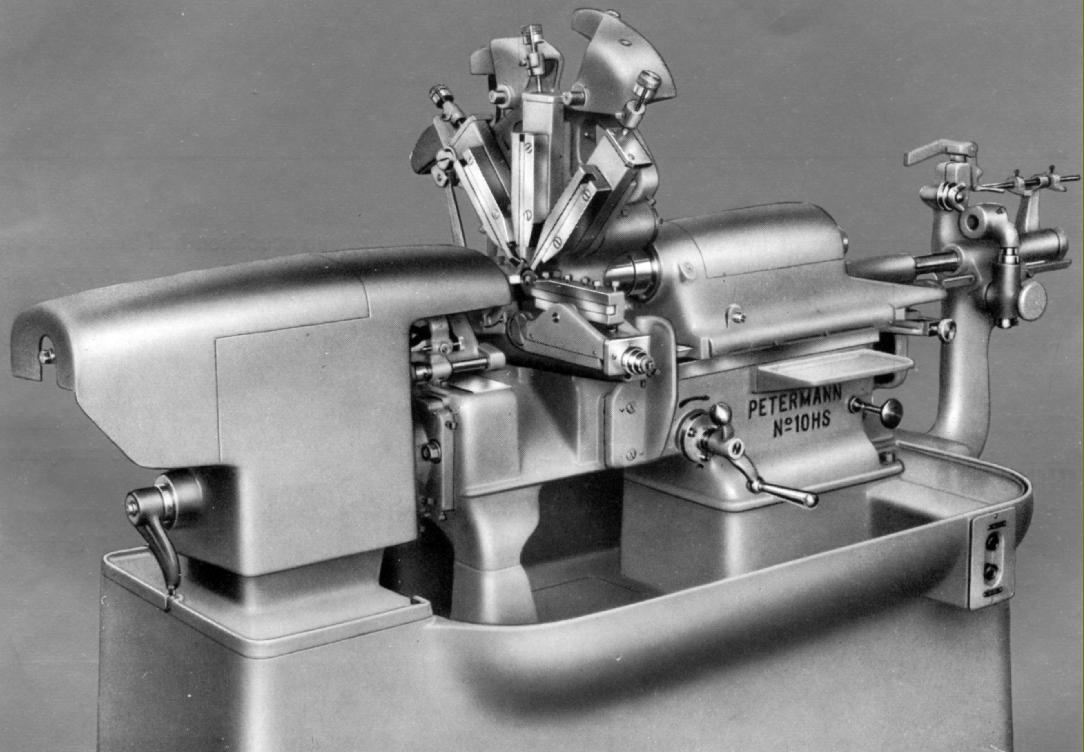

Petermann No. 10HS automatic lathe. This model was built in two versions: the Standard 10 and Oversize 10R. Each machine was further available as either an ordinary model (with two plain bronze bearings in the headstock) or in a high-speed form denoted by the suffix "HS" in which case a headstock that used two high-precision ball races was used. Standard types had a 12.5 mm (0.5") spindle bore and the Oversize 15 mm (0.6"). Spindle speeds for the ordinary models ran from 1250 to 3950 r.p.m. (with a 2 h.p. motor) and for the high-speed types from 1900 to 6000 r.p.m. (with a 3 .h.p. motor). In addition to the usual accessories (single, double and triple-drilling units, a single thread-cutting attachment, a combined centring, drilling and threading unit, drill-on-slide attachment, self-opening die-head and a screw-head-slotting device, etc.) a taper-tuning attachment was also available.

|

|

|

|

|

|

|

|

|

|

|

|

|

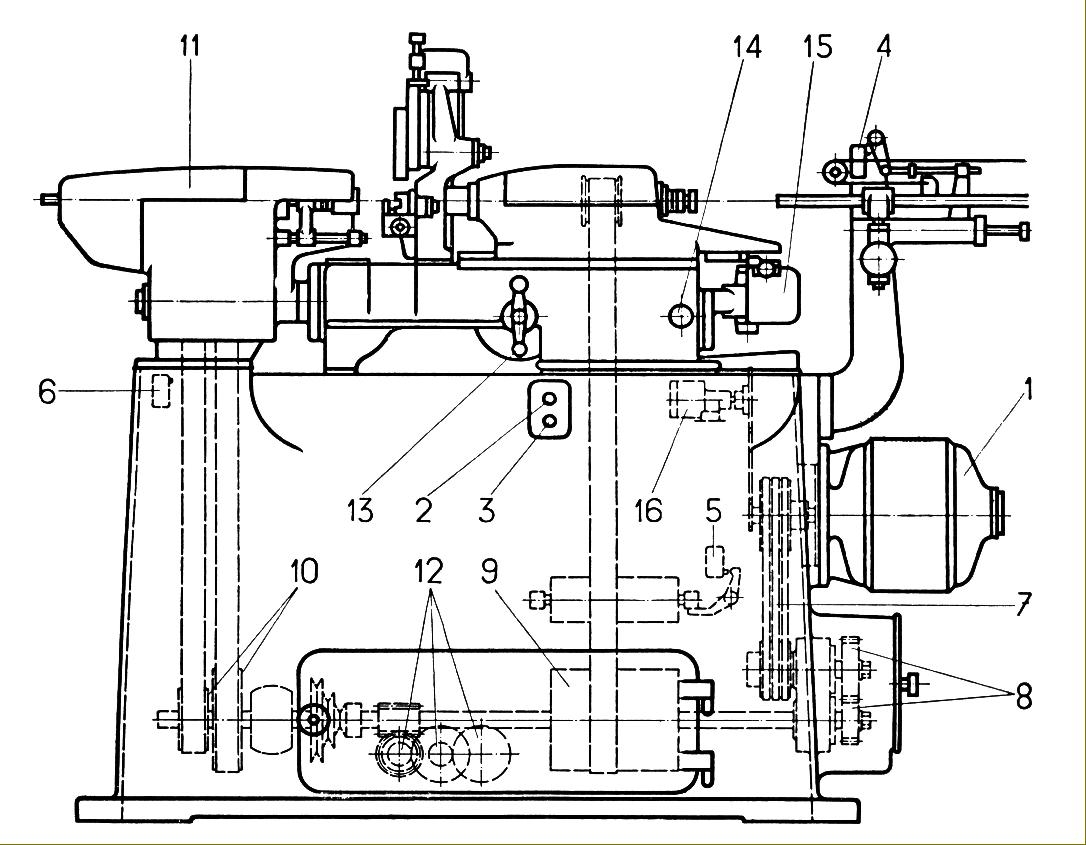

Petermann No. 10 drive system

|

|

|

|

|

|

|

|

|

|

|

|

|

|

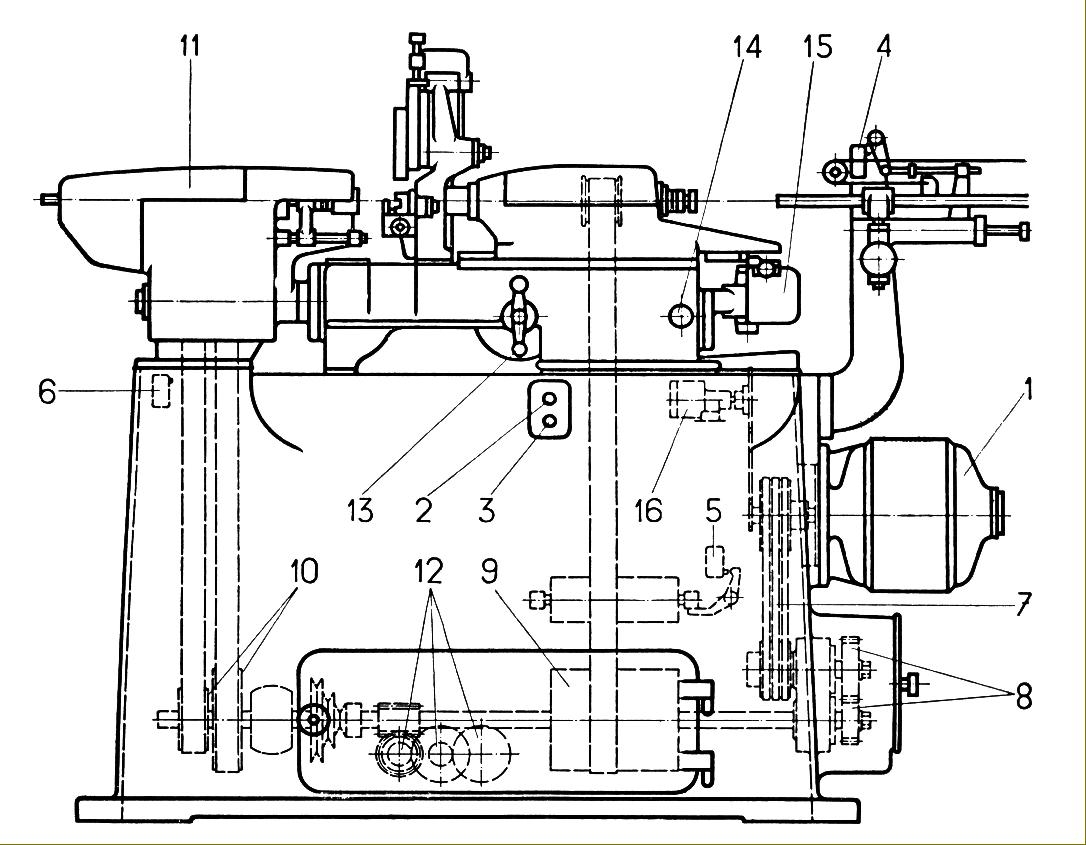

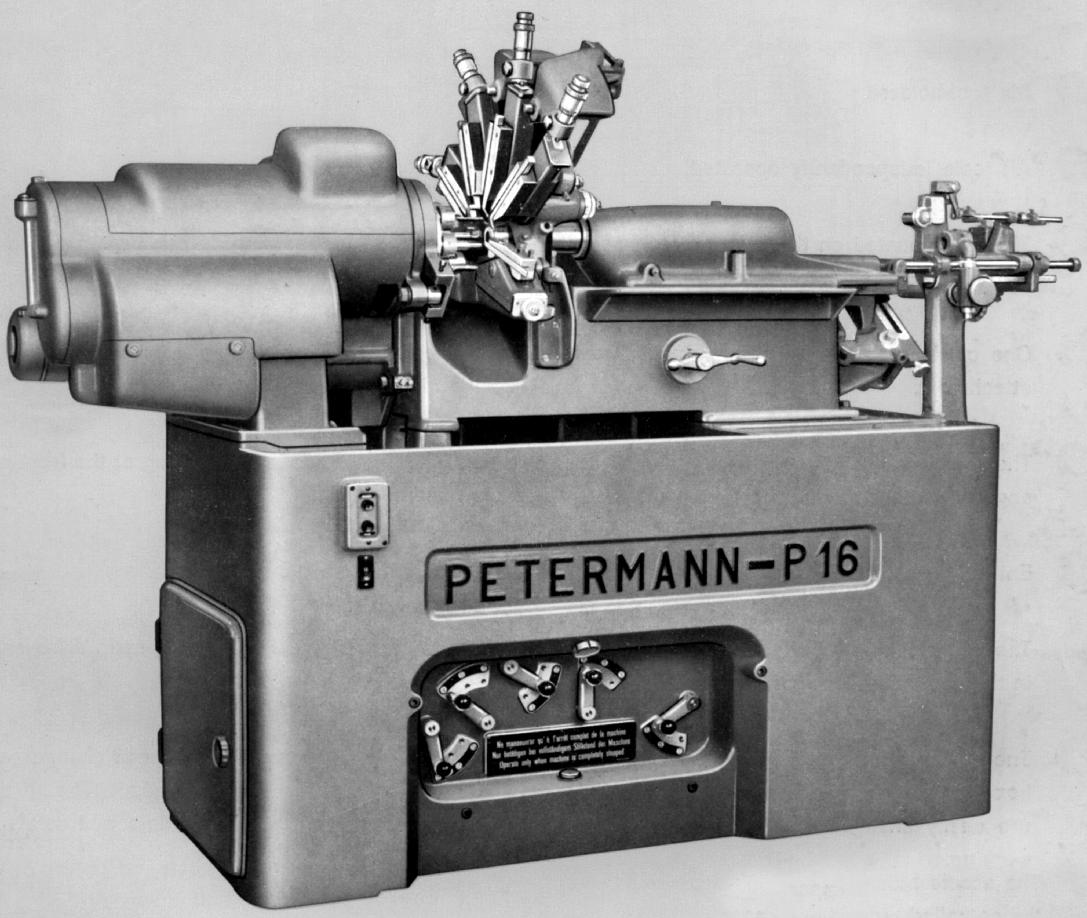

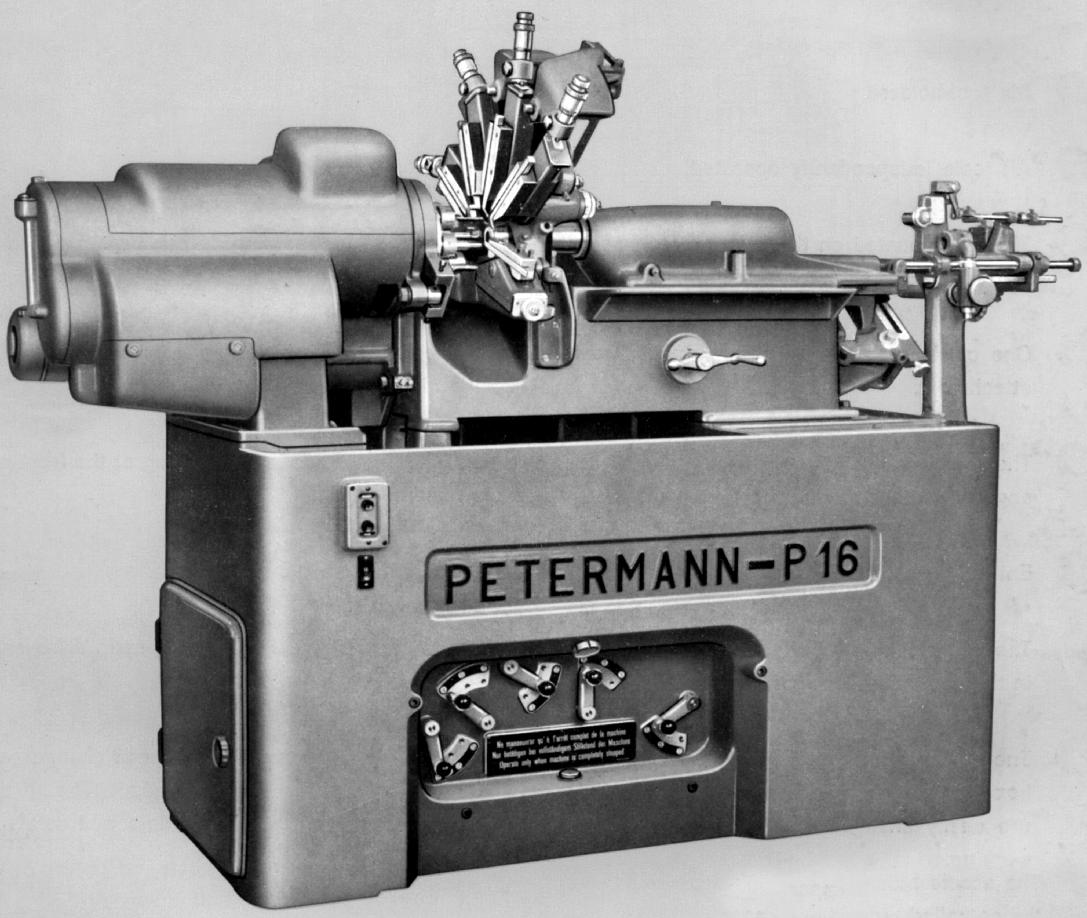

Petermann P16 automatic lathe. Alone amongst its contemporaries, the P16 had its 10 spindle speeds (spanning 1000 to 5000 r.p.m.) generated by a stand-mounted gearbox. Available with just one design of 16 mm (5/8") bore precision ball-bearing spindle, the maximum diameter that could be screwed in mild steel was 9.5 mm (3/8") in hard steel 12.5 mm (1/2") and in brass 16 mm (5/8").

|

|

|

|

|

|

|

|

|

|

|

|

|

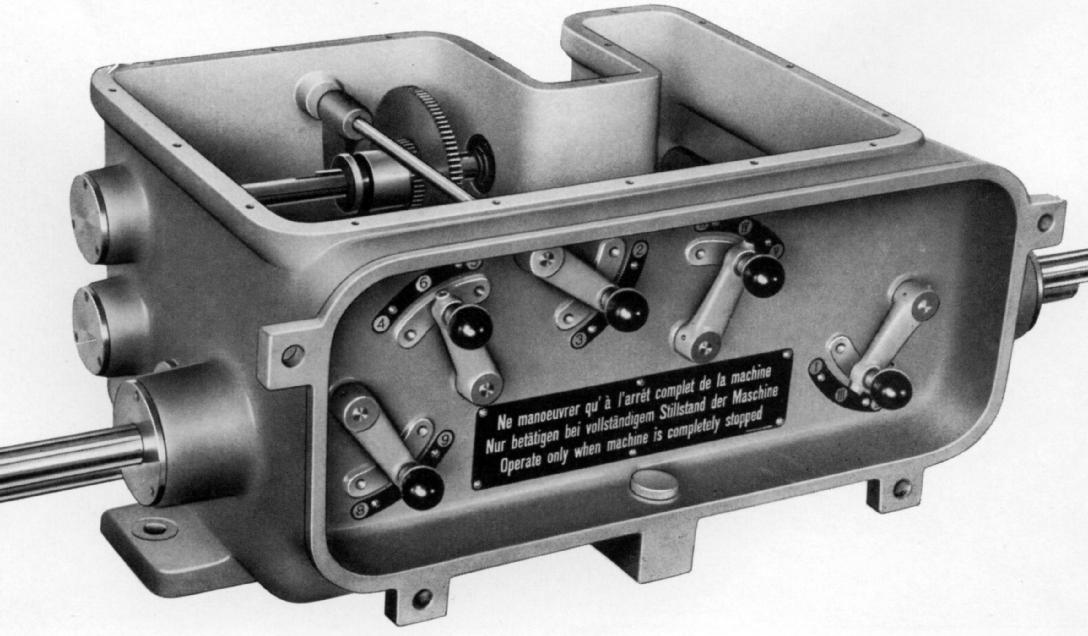

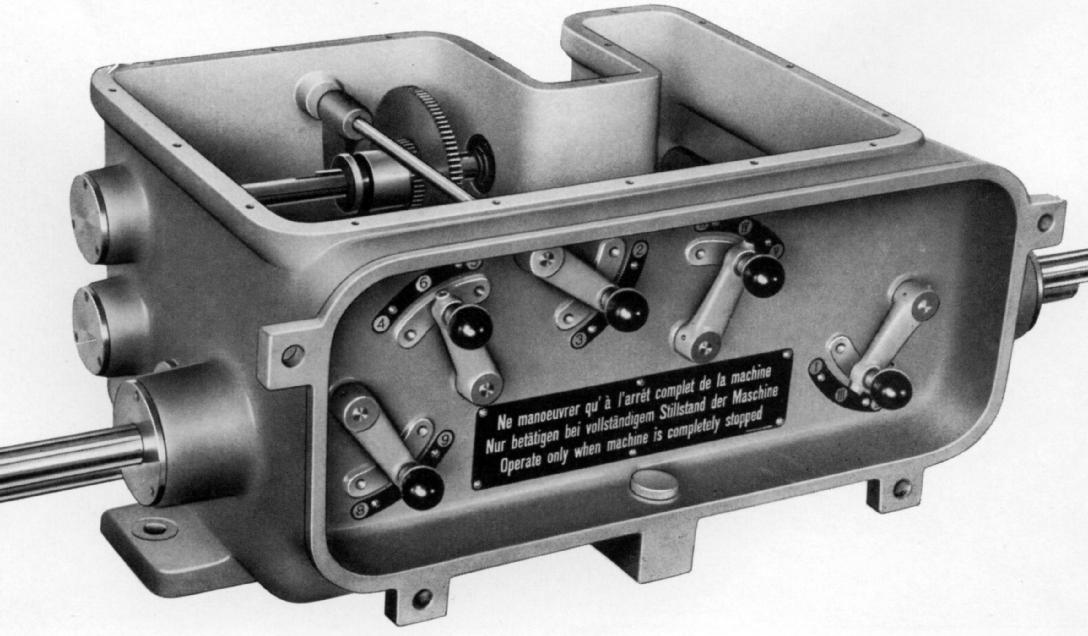

Petermann No. 10 oil-bath speed-change gearbox. Driven from a 5 h.p. motor by three V-belts, the main gearbox shaft protruded through both left and right hand walls of the casing. A pulley on the right-hand side drove the headstock spindle and another on the left was available to power various attachments. The pulley for the camshaft was driven by a separate shaft, only one end of which emerged from the box. A forest of levers on the face of the box changed spindle and camshaft speeds (two for the spindle and three for the camshaft) though for this to happen the box had to be completely stationary.

|

|

|

|

|

|

|

|

|

|

|

|

|

View down into the spindle and camshaft speed-change gearbox of the Petermann No. 10

|

|

|

|

|

|

|

|

|

|

|

|

|

|