|

Home Machine Tool Archive Machine-tools Sale & Wanted Milling Machines Perfecto Lathes Perfecto Shapers Perfect Tool & Cutter Grinder |

|

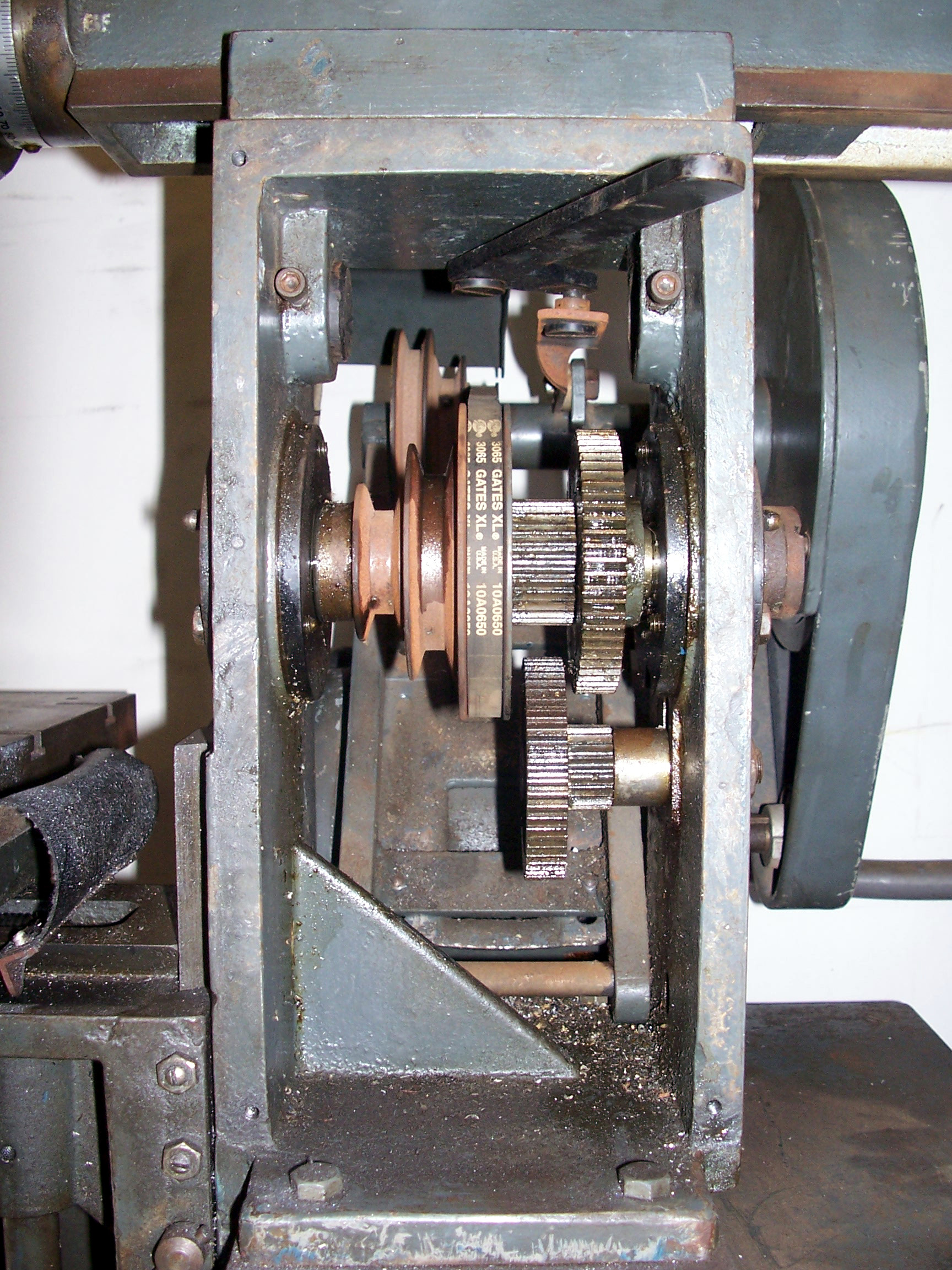

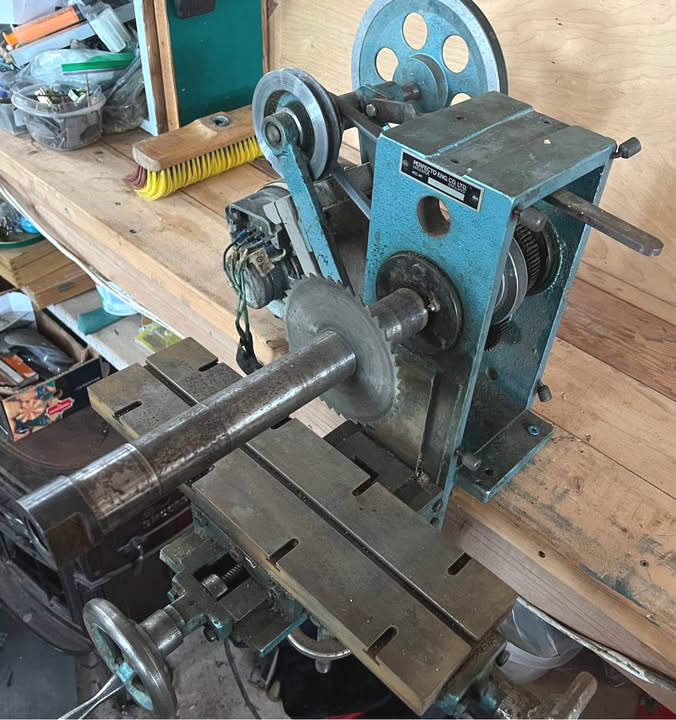

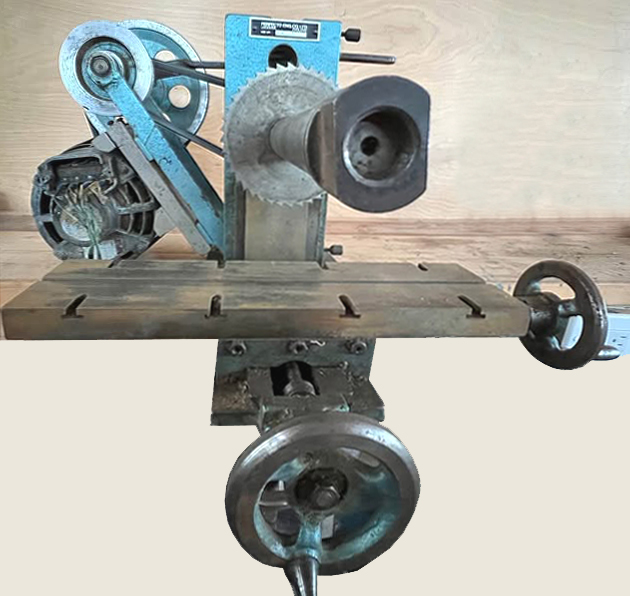

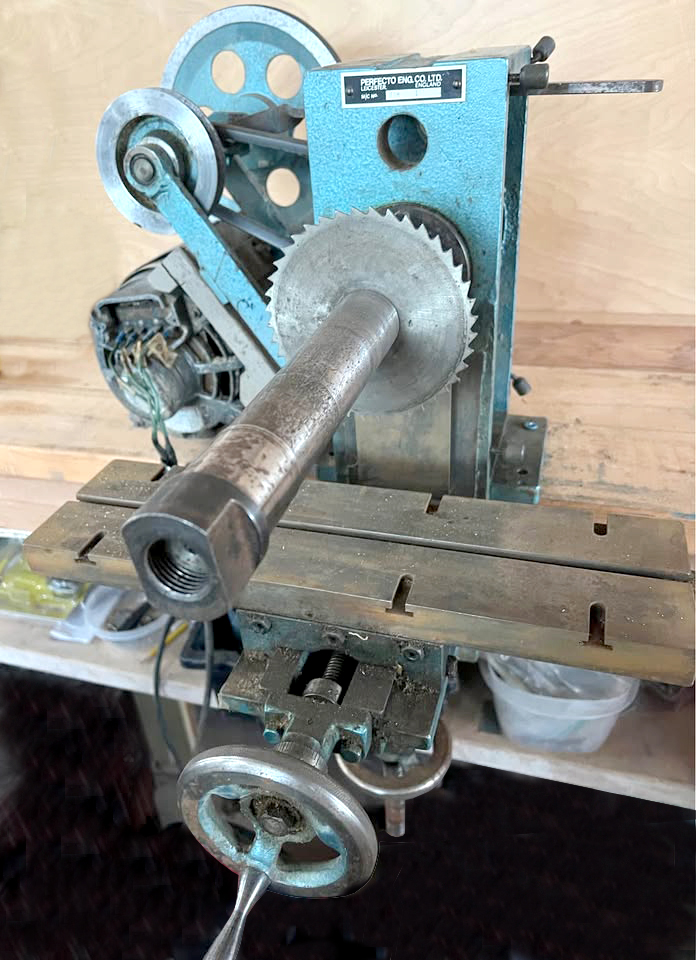

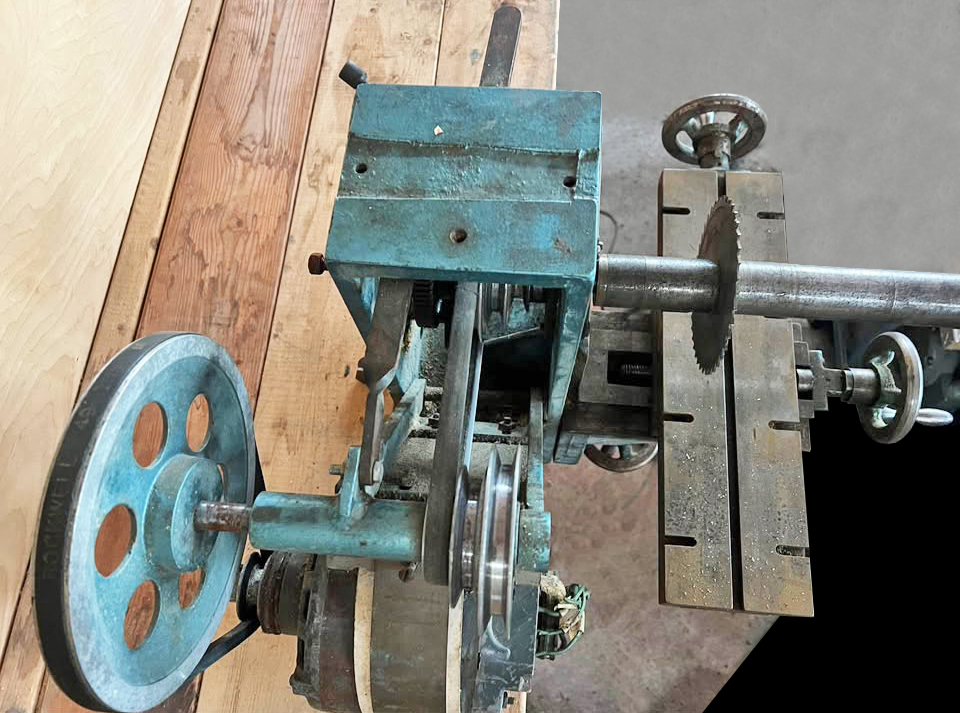

Unfortunately, with only two examples found, details of the Perfecto Universal milling machine are scanty. However, it appears to have been developed from an equally rare horizontal type with the addition, at the top of its rectangular main column, of a bolt-on plate that carried, like the Dore Westbury, Beaver Mk. 1 and Elliott Ominimil 00, a vertical head carried on a ram that could be slid backwards and forwards. Drive came from a rear mounted single-phase motor to the spindle by standard A-section V-belt. Unusually for a small miller, the ram on the Universal, instead of being the expected round steel bar, was of the much more rigid dovetail type with the head arranged to swivel on the end, Bridgeport style. In addition to the vertical head, the miller also kept the horizontal spindle, this being driven by V-belt countershaft system from a second motor mounted on the left-hand face of the column; this drive was (usefully) equipped with a low-speed, lathe-like backgear system almost certainly borrowed, judging by its appearance, from the Perfecto lathe. Oddly, instead of using the dovetail ram as the overarm to support the end of a cutter-holding horizontal arbor, the makers employed a round bar that passed, in the usual way, through the column just above the spindle line. |

|

Perfecto "Universal" milling machine on what appears to be the maker's purpose-built stand. The drive system is not original - but the incorporation of a mid-way pulley assembly gives a far better speed range and hence extended versatility |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||