|

Home Machine Tool Archive Machine-tools for Sale & Wanted Monarch 10EE Lathe Early Version |

|

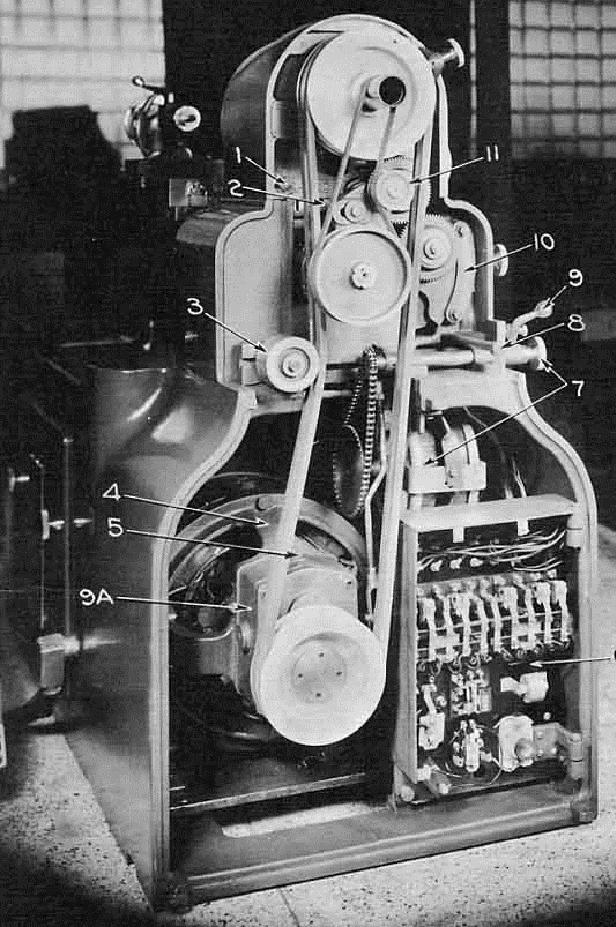

The first monarch 10EE lathes (this illustration is from an operator's Manual dated April 11, 1941) can be easily distinguished by the round gearbox selector plate with its push/pull/twist handle arrangement. |

||

|

The gear drive to the screwcutting gearbox was left open on the first lathes of the series. The general arrangement of the various drives remained the same throughout the life of the machine. |

||

|

Massive, imposing and handsome - an early 10EE refurbished by its enthusiastic owner. The version the keeper reports was built during WW2, the dials and name plates being made from brass instead of the usual aluminium the latter being, according to some sources, a strategic material and not to be used unless essential. Other examples of the 10EE have their dials and plates pressure die cast in ZAMAK - an initially expensive process when counting the cost of the dies but thereafter only a few dollars each. |

||

|

|

|

|

|

Above: thought to be a very early example, this 10EE has a distinctly-different rectangular-form threading selector box on the front face of the headstock and a long rod running parallel to the top edge of the bed. The selector box, instead of just a dial selector on its front as on normal machines, had a chrome-plated, left-to-right travel lever fitted on top - these modifications indicating that the machine is a round-dial version of the ELSR Type (Electronic Leadscrew Reverse). However, the ELSR was misleadingly named, for it did not actually reverse the leadscrew, its function was to provide a repeatable method of stopping the spindle at some chosen point for operations such as threading to a shoulder, or into the bottom of a blind hole, without the risk of over-running. |

|

Lathes fitted with ELSR (Electronic Leadscrew Reverse) can be easily identified by a rectangular-form threading selector box with a chrome-plated, left-to-right travel lever fitted on top and a long rod running from headstock to tailstock with support at its far end in a curved bracket. |

|

|

||

|

Home Machine Tool Archive Machine-tools for Sale & Wanted |