|

Home Machine Tool Archive Machine-tools for Sale & Wanted Books Accessories If any reader has an immaculate Firth or "Atlas" or "JSB" branded machine tool, the writer would be delighted to feature it in the Archive |

||

|

From what little evidence survives, it appears that the few lathes advertised by Tom Senior were not constructed in his works, but by Arthur Firth Ltd., the Company where he served his apprentice. Firth were long-established in the area and advertised widely in the engineering press selling machines under their own name and also branded as "Atlas" and "JSB". Senior must have had a particularly well-developed mechanical aptitude for, by the age of 19, in 1919 he had risen to the position of foreman Although this is pure conjecture, he must have found such a position of responsibility difficult to handle, not through any lack of practical knowledge or skill, but because of what must have been many awkward situations when he had to deal with men far older and more experienced than himself - "T'young bugger, he knows nowt…". So, with just £3 in savings, and not yet at his majority (at the time 21 years), he decided that the time was right to branch out on his own. Fortunately, he had excellent relations with his previous employers and would, as was the custom, have undertaken a good deal of (not very profitable) sub-contact work on their behalf. As Senior's business grew he began to take on the role of tool and machine-tool distribution, handling the Firth lathes and hand planers - long a staple of the company according to contemporary advertisements - and possibly buying in casting made from Firth-owned patterns as demand dictated. By 1925 Senior had expanded sufficiently to take over the Firth business with an advertisement in the Model Engineer and Light Machinery Review announcing that "Atlas" products would now be made by Senior. |

|

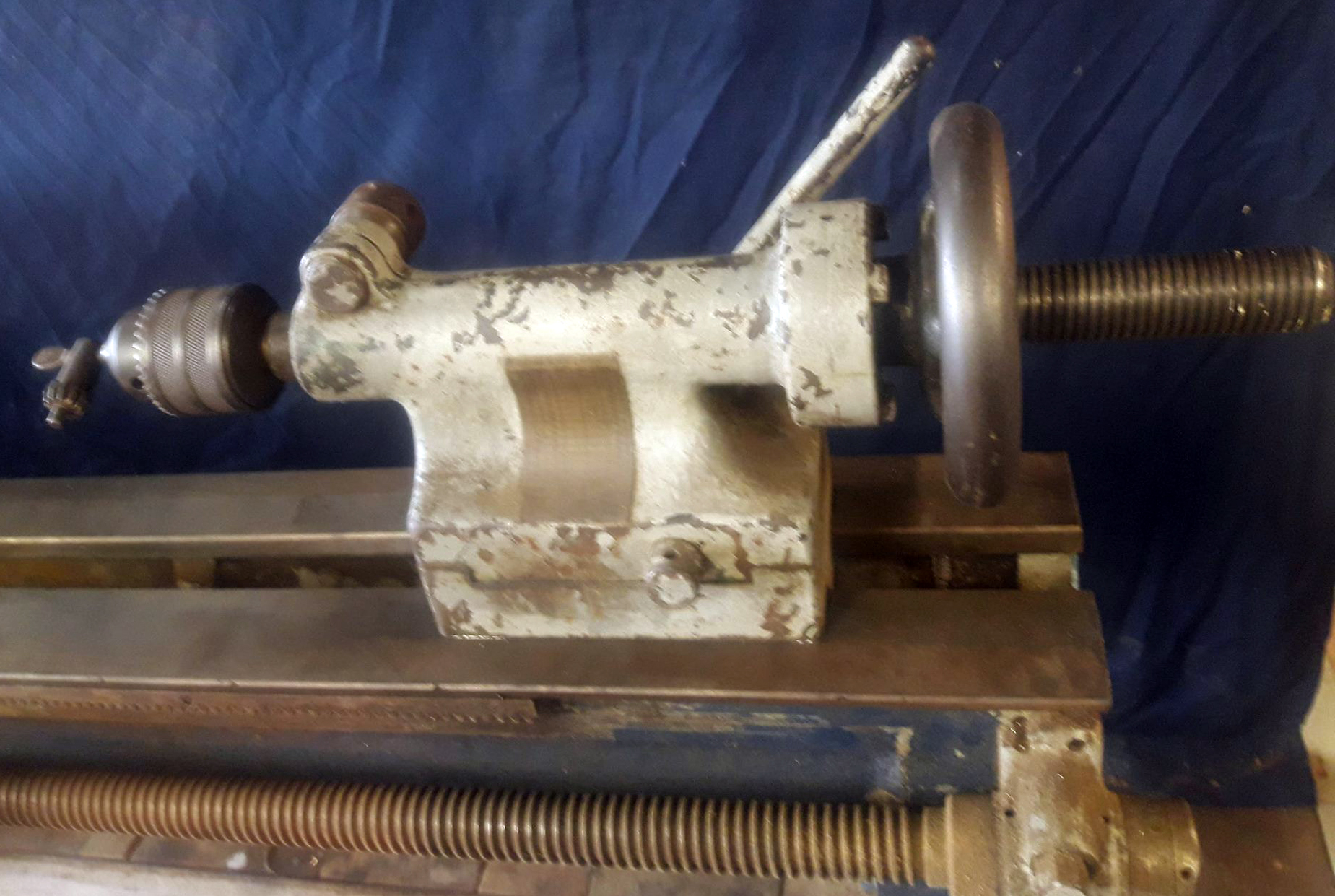

Arthur Firth 3.5 x 15.5" lathe of the 1930s as marketed by Tom Senior. An instant identification point is the enormous boss on the leadscrew clasp-nut operating handle. |

|

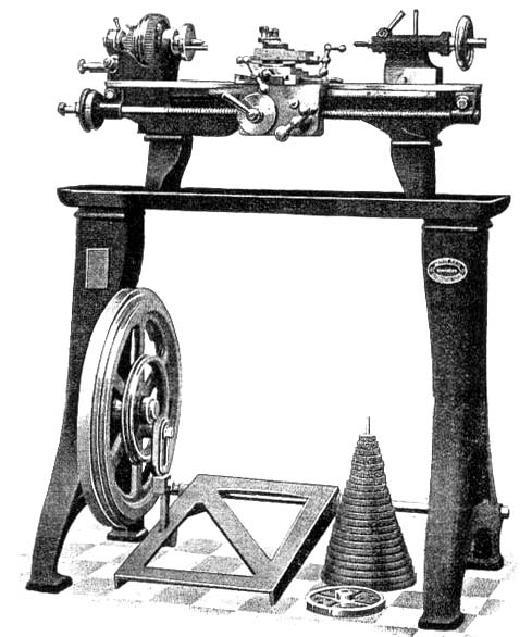

A long-bed version of the Firth lathe with increased centre height. Note the enormous overhang of the bed from its headstock-end foot. |

|

really is blank, then the rear-mounted, motor-driven countershaft might well be original |

|

|

|

|

|

|

||

|

|

||

|

Machine Tool Manuals Machine Tool Catalogues Belts If any reader has an immaculate Senior machine tool, the writer would be delighted to feature it in the Archive |

||