|

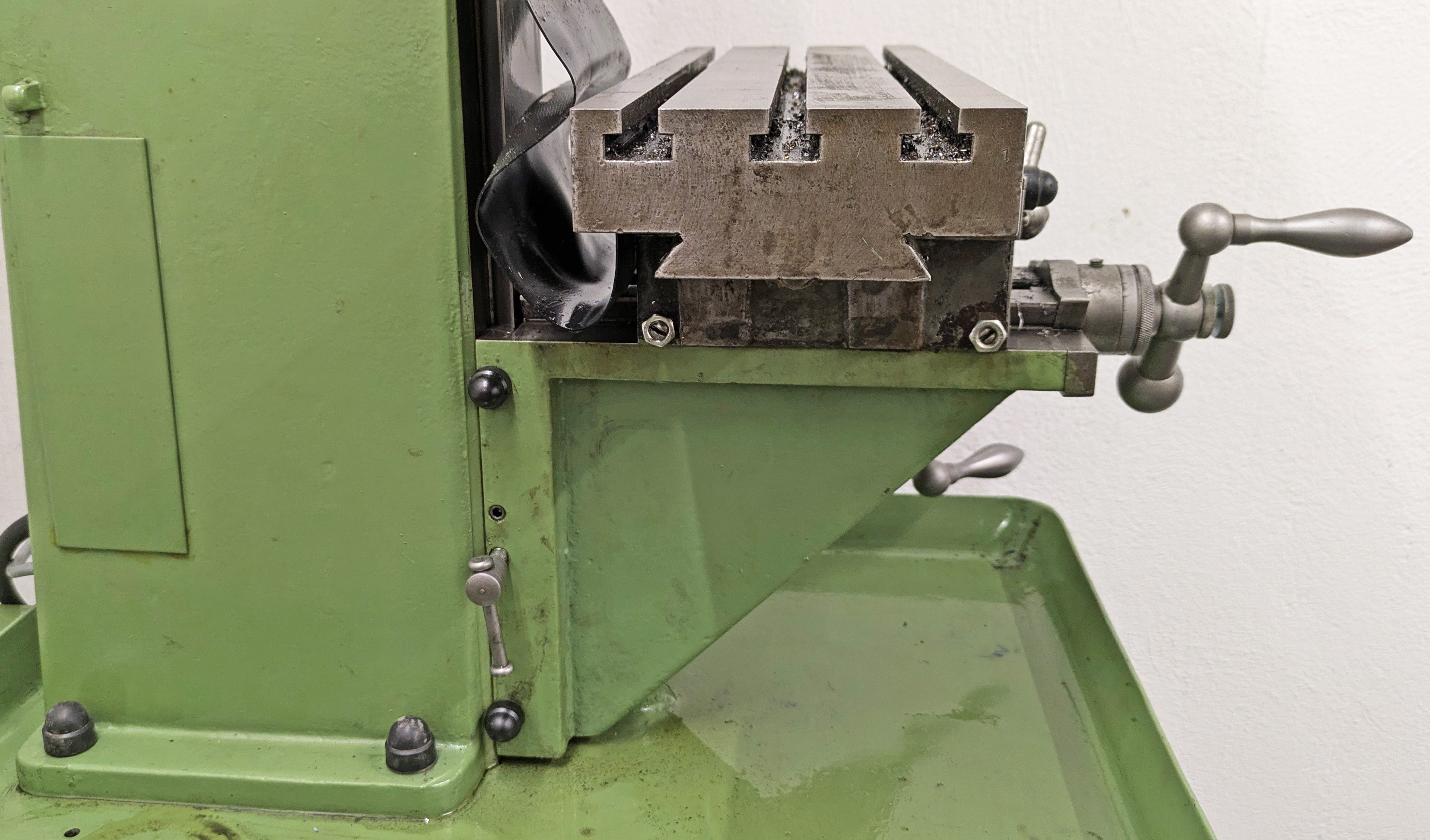

Carstens made their first milling machine in 1928 with the Model HVF 400-130 vertical shown left being as made during the 1930s and 1940s. Typical of its time, the miller carried its drive motor on the back from whence it drove, using a flat belt running over a pair of adjustable jockey pulleys mounted at the top rear of the column, to the 23 mm bore, No. 3 Morse taper headstock spindle (though some machines have been found with an as-yet-to-be-identified fitting. Heavily nitrided and ground, the spindle ran in adjustable taper roller bearings and could accept draw-in collets up to a maximum capacity of 20 mm. A useful touch was the provision of a threaded spindle nose to accept chucks - the thread perhaps being the same as used on the Company's D-Series lathes. |

||

|

|

|

|

||

|

|

||