|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

Bridgeport Horizontal Stub Miller

and other Special One-off Machine Tools

High-quality Handbooks, Parts Lists and Spares are available

for most Bridgeport machines

Bridgeport Home Page

Bridgeport Vertical Heads & Attachments

Original Bridgeport Round-ram Model

Bridgeport Accessories

The Bridgeport Miller at Work

Vertical Attachments by Halco and Kerney & Trecker (Dalrae)

Bridgeport Table Power-feed Units

Bridgeport Serial Numbers

Bridgeport Horizontal Stub Miller and other One-off Machine Tools

Further Bridgeport Company History and "Building a Bridgeport"

Bridgeport Series 1 CNC Miller (based on the standard machine)

Bridgeport Larger CNC Millers (Interact, APC, BPC)

Late Edition, Series 1 Ram-head Miller Catalogue

Computer-modelled Illustration

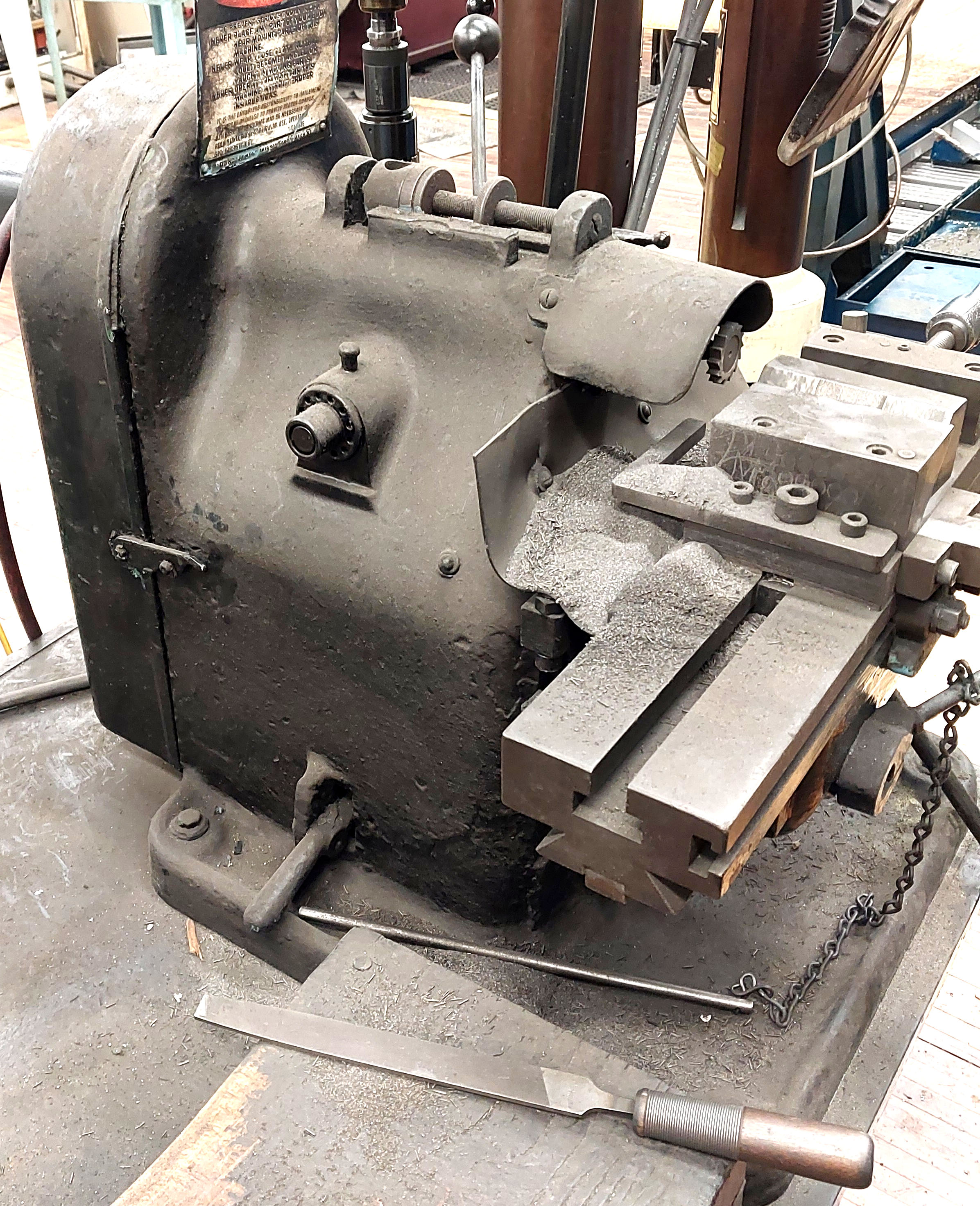

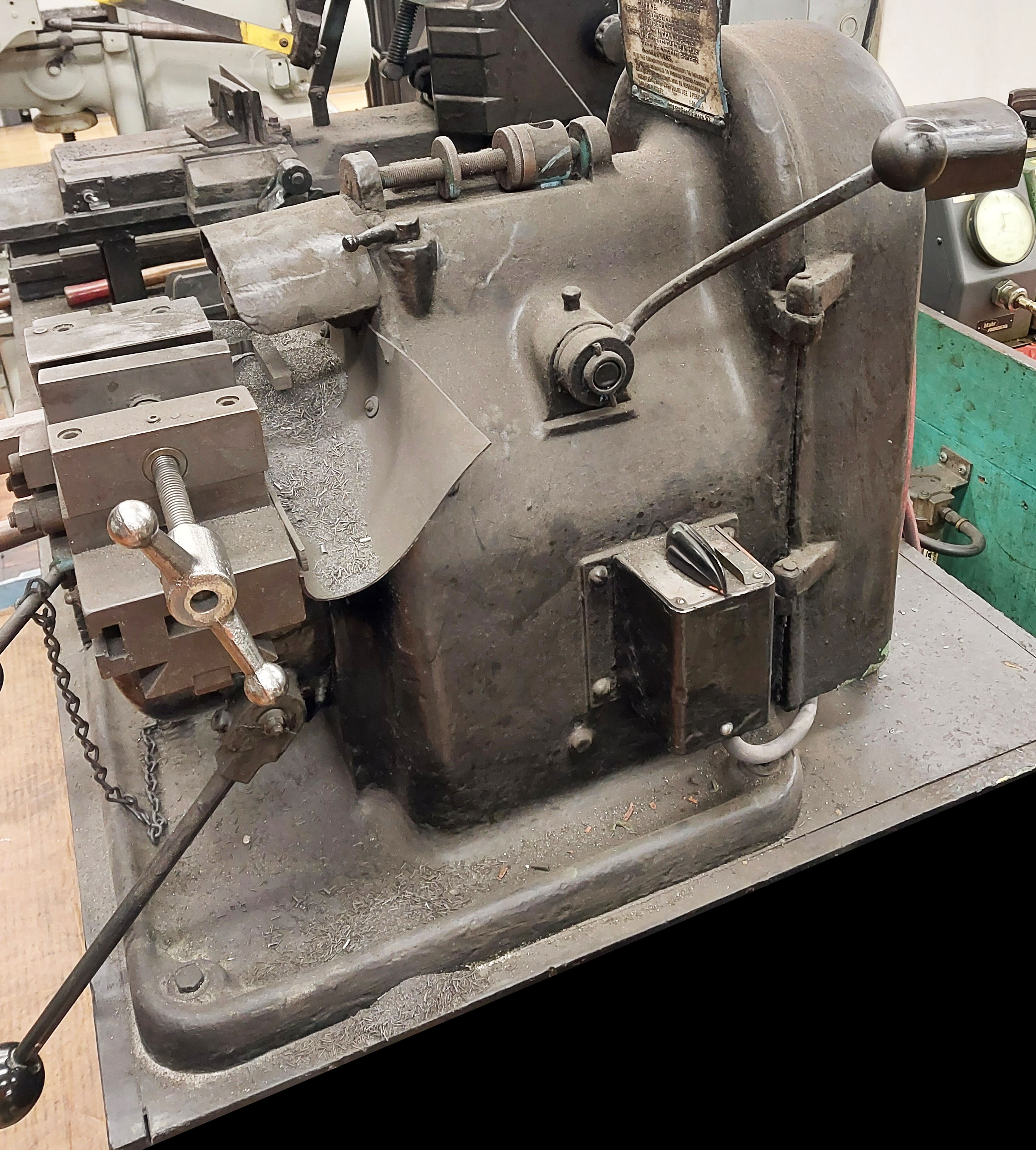

Not made as a commercial undertaking (only one is thought to have been sold out of the three manufactured), the Bridgeport Horizontal miller was used in the factory for various production processes. For its limited capacity the miller was very heavily built - but absolutely straightforward in design, being rather like a giant vertical head set on its back face and completely self-contained with a motor in the base driving the horizontal spindle through (it is thought), a 5-step V-belt pulley. Of the simple stub type without a supporting overarm, the spindle assembly was obviously intended for the simplest of operations. The table had lever feeds for the x and Y feeds, an ideal arrangement for production processes such as slotting.

Further interesting information has now come to light about this machine:

"Hi Tony!

I work for Machine Builders of New England (the company that took over Bridgeport 2J head production when Hardinge bought Bridgeport). As part of the sale of the Bridgeport brand from Hardinge to Clausing, we were tasked with manufacturing additional parts that Hardinge had been making for us. Hardinge very generously allowed me to train on the production cells we were taking over before the equipment was moved, and during that time I found one of the stub millers in another cell where it was being used to notch gibs. I asked the powers that be at Clausing if we could take it with the other machines, and they agreed. It's now in our plant in Milford, CT. We rebuild Bridgeports in addition to head production; I'm hoping to give this little mill that treatment at some point in time. If it happens I'll be sure to take pictures of the disassembly and reassembly. At a cursory glance, it looks like an M head laid on its back. It seems to use an M head quill and spindle. It definitely uses an M drawbar and 6-position pulley configuration. The movement of the table and knee is via a gear rack cast into the base and the bottom of the table. It seems plausible (but unverifiable) that Bannow (one of the Company's founders) may have designed this; the original Bridgeport Pattern & Model Co. was in a small building (8,000 sq ft) and space efficiency would have been a high priority. Why buy a full size horizontal mill to cut a 3/4 inch notch in an 8 inch part when a table top version will do the same and take up less valuable space?

I also have details of another unique Bridgeport creation, a burnishing machine that is used in quill production. It's made of two early or pre-production (unserialized) J heads without the power quill feed or backgear components. The spindles are ground to a Morse taper and there is no drawbar holding the burnishing head in place. The pair of J heads are mounted to surplus round rams with custom-cast adapters. The rams are bolted to a table that may have been custom patterned or perhaps repurposed from some other machine.

Hope this information is useful to you, if there's anything else you're curious about don't hesitate to ask. Thank you for maintaining such a large repository of both common and uncommon machine tools!"

|

|

|

|