|

Home Machine Tool Archive Machine-tools for Sale & Wanted Books Accessories Raglan Home Page Factory Jigs & Fixtures Little John Mk. 1 Raglan Capstan Lathes Raglan Miller Raglan Wood Lathe Raglan Loughborough Training Lathe Accessories |

|

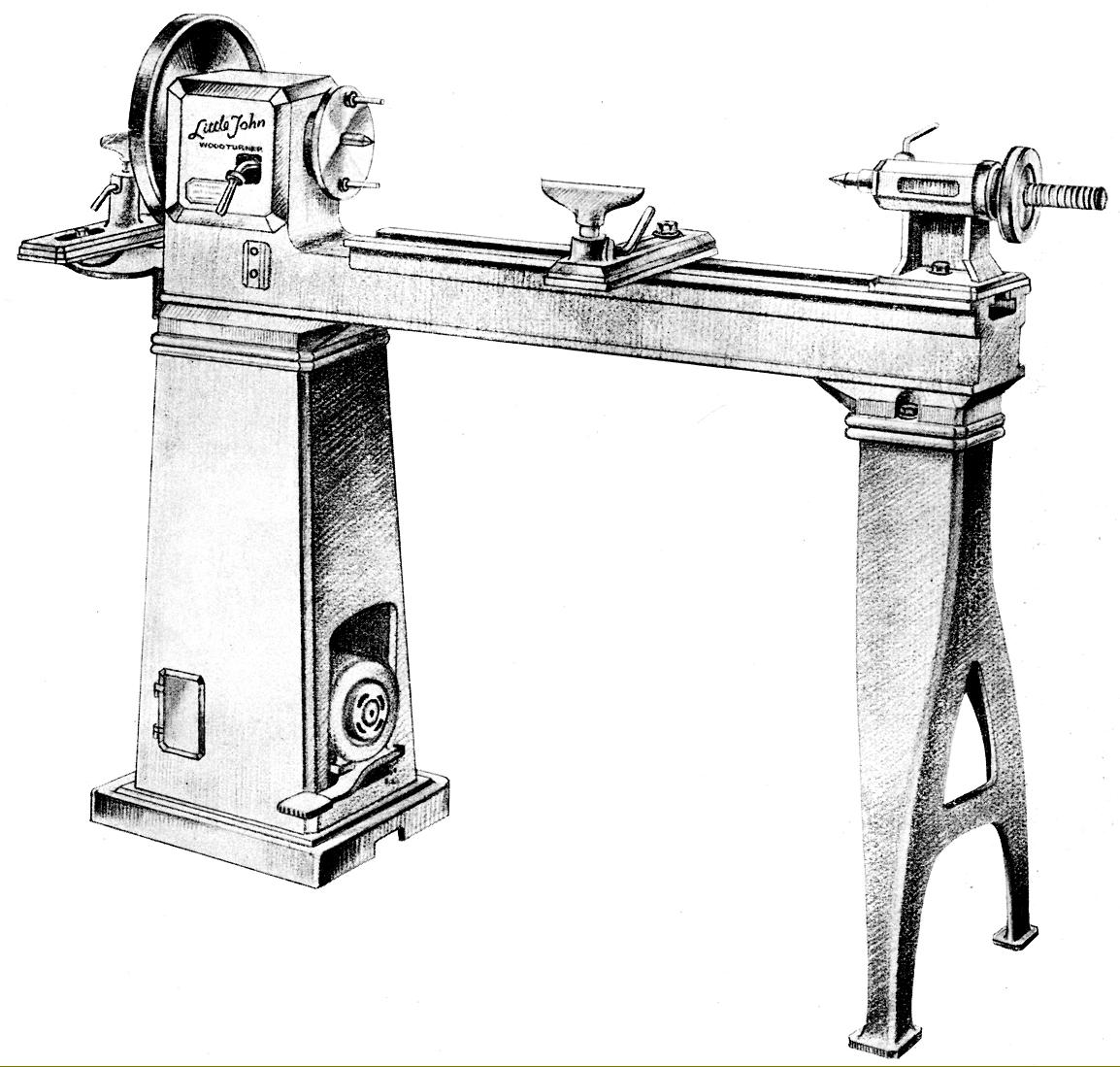

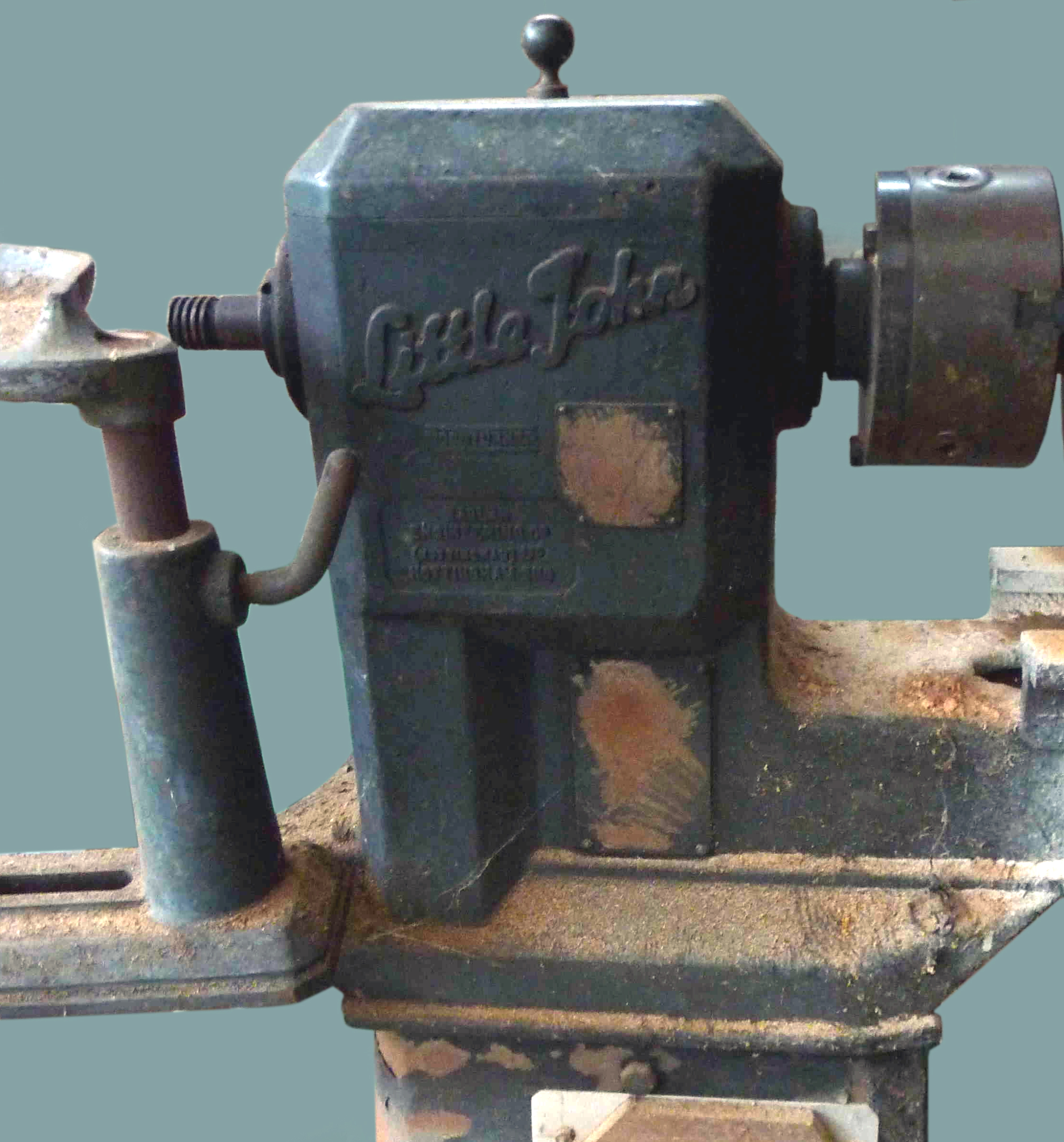

Manufactured only during the 1940s - probably from 1947 to 1949 - The Little John Woodturner looked not dissimilar to the Harrison Union Jubilee and (much heavier) Wadkin Type BZL. Made only in very limited numbers, the lathe is rare, with few survivors, and hardly any appearing on the second-hand market. As a simple wood-turning lathe this was an impressively engineered machine for it was, of course, based on the heavily-built Little John metal lathe - but stripped to its essential components and with a speed range more suitable for wood turning. The lathe had its headstock and bed cast as one piece with a centre height of 5.125-inches and a choice of between-centres capacities - 30 or 40 inches. |

|

Factory Jigs & Fixtures Little John Mk. 1 Raglan Capstan Lathes Raglan Miller Raglan Wood Lathe Raglan Loughborough Training Lathe Accessories Home Machine Tool Archive Machine-tools for Sale & Wanted Books Accessories |