|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools for Sale & Wanted

Machine Tool Manuals Machine Tool Catalogues Belts

Books Accessories

Pittler Lathes

Pittler B on Trumpet Stand Pittler Pattern B Pittler Pattern C3

How to Make and Use Pittler Worms & Wheels Pittler Turret Lathes

Accessories Story of Wilhelm von Pittler Milnes Pittler Pittler Factory

Pittler literature can be found here

Pittler lathes were made in Germany, at a factory in Actien Gesellschaft, Leipzig-Gohlis, and under Licence in England by Henry Milnes. The form and function of Pittler lathes were both unusual: they were immensely versatile machines and capable of being ingeniously adapted to solve many difficult machining operations. The Pattern B and C were the most popular, with manufacturing of the highest quality and today they are greatly sort after by knowledgeable machine-tool enthusiasts. Pittler advertising literature of the late 1800s claimed that the company's products were "universal lathes" and pointed out that the trapezoidal bed, with its saddle capable of being rotated round it, both by hand and, with the necessary accessories, under power, provided the basis for a machine tool capable of undertaking over 200 different discrete turning, milling and gear-cutting operations. (click here for an outline history of Pittler and his company).

Screwcutting on Pittler lathes depends upon matched sets of worms and wheels which, for many years, have been in short supply - however, if you would like to make your own you might like to know that the B2 used a set of 17 worms and wheels (able to cut 27 pitches) of 20 diametral pitch, with a pressure angle of 14.5 degrees for wheels over 30 teeth, and 20 degrees under this number. The single start worm was of 1.026" O/D with a pitch of 0.164", the five, ten, and fifteen start worms were of the same helix angle (different to the single start) but further data is only relevant to the ten-start worm, of 2.880" O/D with a pitch of 0.1853.

Interestingly, all Pattern B lathes, at least those imported into the British Isles, appear to have been held together throughout with Whitworth fasteners; research has shown that Pittler worked in English units until 1898, by which time their use was thought to be damaging sales in France and Belgium. The SI system of units was then adopted, but this in turn brought sales resistance in England, Pittler's chief export market; the problem was solved by using both systems, side by side, depending on the machines' destination - although recent investigations have shown, interestingly, that Pittler simply cut English threads on studs of metric dimensions. The full S.I. system was finally approved by the German Standards Committee in December, 1917..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PITTLER LATHE CHRONOLGY

The following research was complied by John Anning john.jabus@hotmail.co.uk

who would welcome comments and additions from Pittler enthusiasts.

1854

June 21st Julius Wilhelm von Pittler born in Kirschitten Kreis East Prussia.

c- 1868 to 1872

Serves an apprenticeship as a gardener and becomes interested in the drawing of plants, flowers, garlands and decorations; this leads to an interest in technical draughtsmanship and he is soon able to interpret technical drawings for machines used in the workshops

1876

Arrives in Leipzig. Finds his true destiny- the world of machines. Works for a flag maker, designs badges, club standards, table cloths, etc. Makes a crank-handled embroidery machine

1878

Starts his own embroidery company in Quandt's Hof, between Nikolai and Ritterstasse, selling embroidered table cloths and aprons to the ladies of Leipzig. Makes an automatic machine for the folding and gluing of paper bags.

1879

Machine exhibited at the Altona Trade and Industry show. Marries Martha Albrecht and lives comfortably from the profits of the embroidery business.

1880 1st July.

Applies for a patent for a steam engine for a bus, and installs it in a vehicle of his own design. Forms W. von Pittler, Elze & Co. - the Elze brothers being family friends. Patent No 12931 for a small, compact steam engine that has many advantages. Unfortunately, it cannot compete with the Otto 4-cycle gasoline engine and, with the resignation of the Elze brothers, the firm ceases trading in 1884.

Using profits from the embroidery works he becomes a full-time inventor and between 1880 and 1889 is said to have taken out some 200 patents, ranging from new methods for printing, new kinds of stitching machines, electric-light apparatus and automatic piano, etc. Sets up a small workshop for experimental work attached to his home in Gohlis, a suburb of Leipzig. This largely experimental workshop is equipped with simple lathes, drilling, shaping and milling machines. Designs, manufactures and sells the Pittler sewing and darning machines, which were mainly exported to England. It was in 1887 that he was inspired to develop the "Universal Machine Tool" because he felt there was no suitable, all-purpose device available.

1888

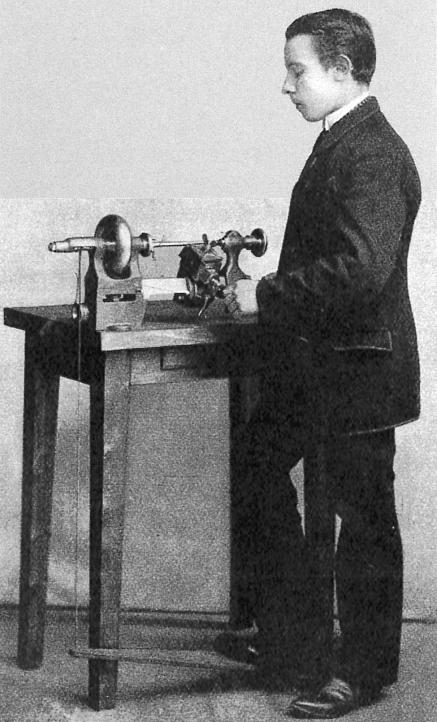

Produces the Model B mechanic's lathe the forerunner of all Pittler lathes. Leaves behind the embroidery business and concentrates all his future talents on machine-tool design.

1889

11th July. Machinenfabrik "Invention" W. von Pittler formed in Gohlis

Supplies the Model B2 "Universal Metal Working Machine" a 90 mm centre height (3.5 inch) and 270 mm between centres (10.5 inch) screwcutting lathe with a trapezoidal bed. In this year the famous patent No.74951 was granted for a metalworking machine with turret. (note:- this patent, which included a design for a sixteen-station vertical turret, is one of the seminal machine-tool patents taken out during the last 150 years, and Pittler has never been given the due credit)

1890

Model C and derivatives first produced with a 5-inch centre height. The range of Models B and C introduced onto the market, with many exported to England.

1891

Messrs Lotz Abbot & Co , 66 Queen Street, Cannon Street, London EC, appointed sole selling agents, representing Great Britain and the Colonies and the United States of America.

1893

"English Mechanic" Sept 1 No 1484 Article by J.H. Evans: "The von Pittler Lathe and Automatic Tool" created considerable interest. W von Pittler forms The Pittler Company at 155 Farringdon Street on 1 January 1893, keeping Lotz Abbot & Co as agents. Mr George Adams is appointed assistant manager. The Pittler sewing machine is included in the product range.

1884

January. Mr George Adams is appointed manager of The Pittler Company and moves to 144 High Holborn, London W.C. The catalogue lists the following machines.

Model A. A very small lathe on a tripod stand. Ratchet drive, 2.5-inch centre height, 7 inches between centres. Price £23*

Model A1. Screwcutting lathe with 2.5-inch centre height, 7 inches between centres. Tripod-mounted with flywheel and treadle complete with an automatic gear for spherical turning. Price £40

Model B Tripod-mounted with ratchet drive, 3-inch centre height, 7 inches between centres

Price £23

Model B2 Screwcutting lathe mounted on pedestal with treadle and flywheel. 3.5-inch centre height, 11 inches between centres. Complete with a range of fittings. Price £38.

The Model B2 was also available mounted on twin standards (legs) with treadle and either twin or single flywheel drive, 16 or 24 inches between centres.

Model B3 As model B2 but with a 5-inch centre height and 15 inches between centres (not screwcutting) Price £36

Model C A strong, 5-inch centre height screwcutting lathe with backgear, etc. and 15 inches between centres. Price £48

Model C2 as above, but with a stronger headstock. Price £50

Model C3 as above, but 18 inches between centres. Price £60. A 36 inches between-centres machine was supplied later, but not listed in the 1893/94 catalogue.

Lathes for general engineering included:

Model D 7-inch centre height, basic price £212

Model E . 12-inch centre height, basic price £195

1891-1896

The Universal Metal Working Machine was demonstrated throughout Europe, winning many gold medals. The turret lathe version was described in the first catalogue (of 1895) as: "incontestably the best turret lathe in the world" . Machine shops in Germany become known as "Pittleries"

Note: I have seen no evidence that George Adams handled sales of the Pittler turret lathe in the UK. Perhaps his sales agreement only extended to The Universal Metal Working Machine.

1895

Company goes public and the name changed to "Leipziger Wekzeugmaschinenfabrik Atkiengesellschaft vorm W.von Pittler".

1899

Company moves to Wahren, then a village 5 kilometres from Leipzig. 500 works employees, 50 staff and 10 apprentices.

1901

Pittler automatic-screw machine first introduced.

1902

Severe competition from the USA, and the low value of the dollar, meant cheap imports brought a serious recession to the German machine tool industry, necessitating redundancies and management changes at Wahren. Manufacture of NAMCO multi-spindle automatic was arranged under licence from the USA. W.von Pittler resigned from the company, as there was no place for an inventor with expensive tastes; he was never to return. It appears that he enjoyed the good life, and spent time travelling throughout Europe visiting clients. He spent some two years at his home in Gohlis and then moved to Berlin, looking after his other companies before settling in London in 1909.

Manufacture of the "Universal Metal Working Machine" passed on to Johannes Schulz & Co of Berlin, who continued with production until 1920, but with an output that gradually decreased with the passing years.

1905?

George Adams forms his own company operating from 144 High Holborn as a general supplier of metalworking tools; this was a back-up to the sales of Pittler lathes to increase revenues. By 1912 sales of the Model B range Universal machine tool in the UK had all-but finished. Ceasing totally by 1914, at the start of WW1. Models C, D and E continue in production into the early 1920s

1908

Arthur Drummond, one of the founders of Drummond Bros Guildford was an early customer of Pittler, introduces the Model A Round-bed lathe. This lathe had a number of features copied directly from the Pittler, whose patents for the Universal Metal Working Machine had by this time expired. UK sales of Pittler Model B machines gradually dried up due to their price and complexity - and under competitive pressure from cheaper and less complex machines that were becoming more widely available for amateur machinists. As a comparison, the price of a Drummond was around £8; that of the B2 £40.

Pittler exhibits (at the Olympia motor show) a hydraulically-driven motor car.

1910

Willem von Pittler dies in London, in the office of George Adams, on September 22nd at the age of 56. His body was taken back to Germany by his son - reports say that German engineers raised a fund for this purpose and the grave can be found in the chapel cemetery at Leipztig Gohlis.

The story of the Pittler B range of Universal Machine Tools finishes at the start of WW1, in 1914, but there are still many gaps remaining to be filled. For instance, it has been said that The Pittler Company, under George Adams, imported machines in a partly completed state to be finished off in the UK in their workshops at 144 High Holborn. I have never had any evidence of this - and indeed I am not sure if George Adams was anything other than a factor of machines and relied solely on sub-contracting from outside suppliers.

I have also heard it mentioned that Henry Milnes of Bradford, a well known maker of machine tools and lathes prior to WW1 and during the 1920s manufactured Pittler lathes under licence. As Pittler lathes complete with "Made by Henry Milnes" exist this must be true and lathes must have been built in the UK under licence; certainly the Model B was, Tony Griffiths having an example with a Pittler/Milnes plate. It is likely the Johannes Schulz arranged various sub-licences, but again hard facts are lacking because it is not known whether Pittler AG (as the company became) sold the designs to Schulz or, during a recession in 1902, licensed their manufacture when the company decided to make only automatic machine tools. (In addition, a Pittler lathe badged "Adams & Butler" was also, apparently produced; Mr. Butler being George Adams' shop manager circa 1910/11 - Tony Griffiths).

I have always been fascinated by the slight changes to detail design from model to model. In fact, I have never seen any two model B2 machines exactly the same. Dating can be made, to some extent, from the design of the lathe engine plate but the machine-numbering system seems to be a minefield, with machine numbers not necessarily relating to dates. My lathe, a pedestal mounted B2 (with a George Adams Pittler plate) is numbered 1110 yet, because of detail differences in design compared with others I have inspected, makes me believe that it was made circa 1903-4 by Johannes Schulz.

I have seen no evidence that Pittler Gohlis or Wahren supplied an overhead drive for the B range, only a drive countershaft system, and it was left to individual owners to rig-up their own arrangements. George Adams supplied such a unit as an accessory during the 1920s, and this is detailed in the Gentry articles in Model Engineer of 1940 Vol. 83.

The Pittler company went from strength to strength over the next few decades, and the factory was even lucky enough to survived the intensive bombing by the Allies of Leipzig during WW2; fortunately the personnel, drawings and undamaged plant were rescued by the Allies who arrived just in time to prevent the company falling into Russian hands. It is now the parent of one of the major German machine-tool groups, with world-wide connections and associations - but that is a story outside of our immediate interest.

If any Pittler owner can add further details of either the machines or the Pittler companies, the writer will be pleased to hear from you..

* It has been suggested that a multiplying factor of around 135 should be applied to late 19th century prices to bring them up to date. This indicates that Pittler prices were beyond the average amateur and explains why sales of the B range were never great - and fell dramatically after 1908 when the Round-bed Drummond Model A was introduced.

References:-

Much of the information included (particularly dates and biographical information on W. von Pittler) was obtained from the anniversary book, 100 YEARS PITTLER 1889-1989 published by Britting Verlag. The early years are rather light on useful facts relating to "the invention" and most of the book is devoted to the post WW1 period. The remaining data is from contemporary catalogues and various articles, etc..

|

|

|

|