|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

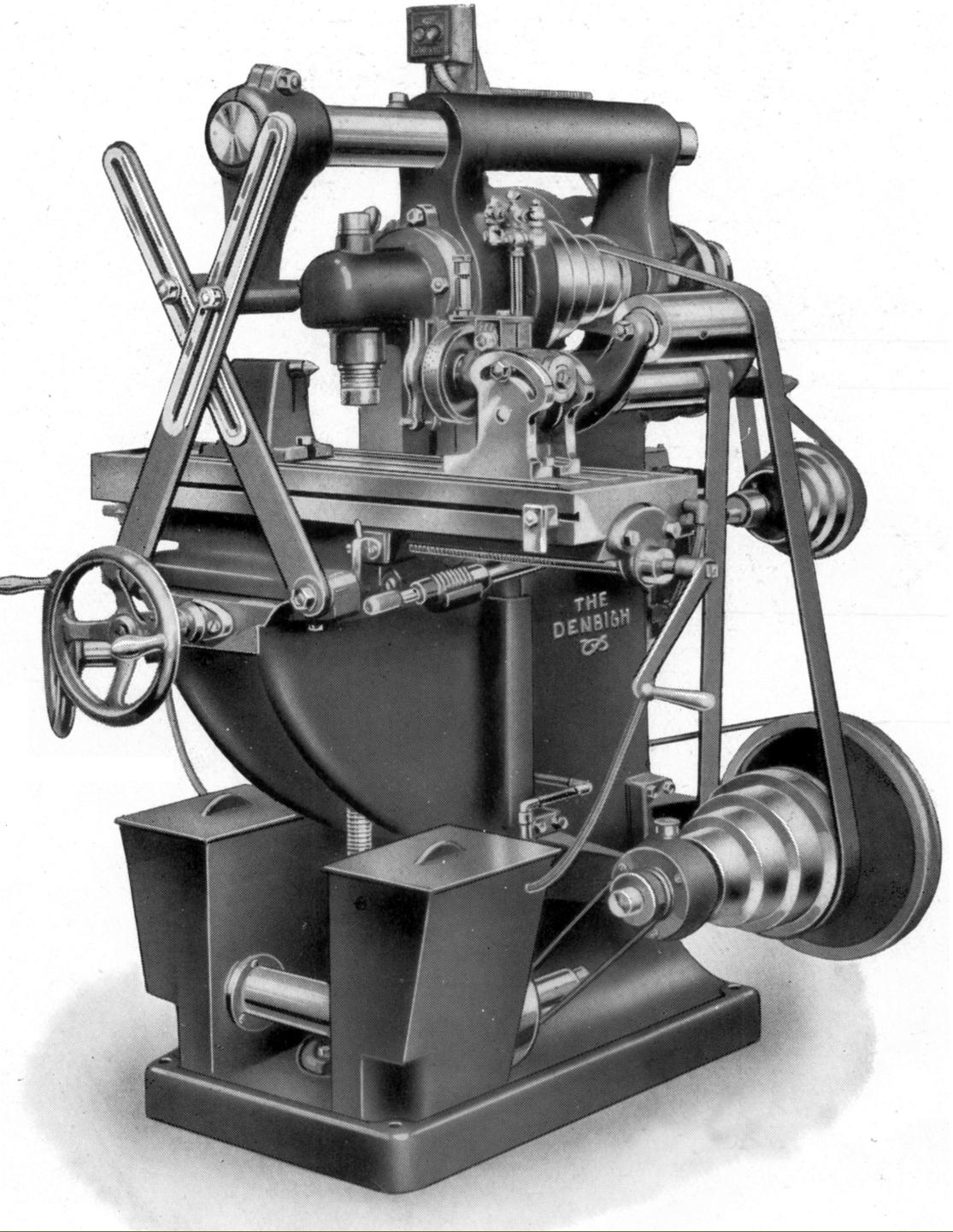

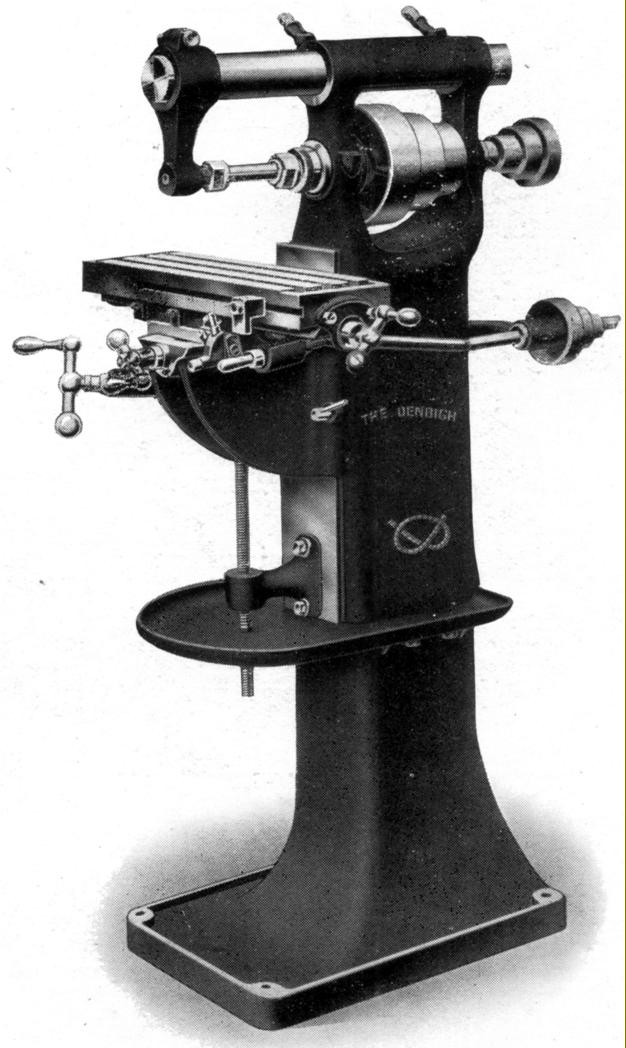

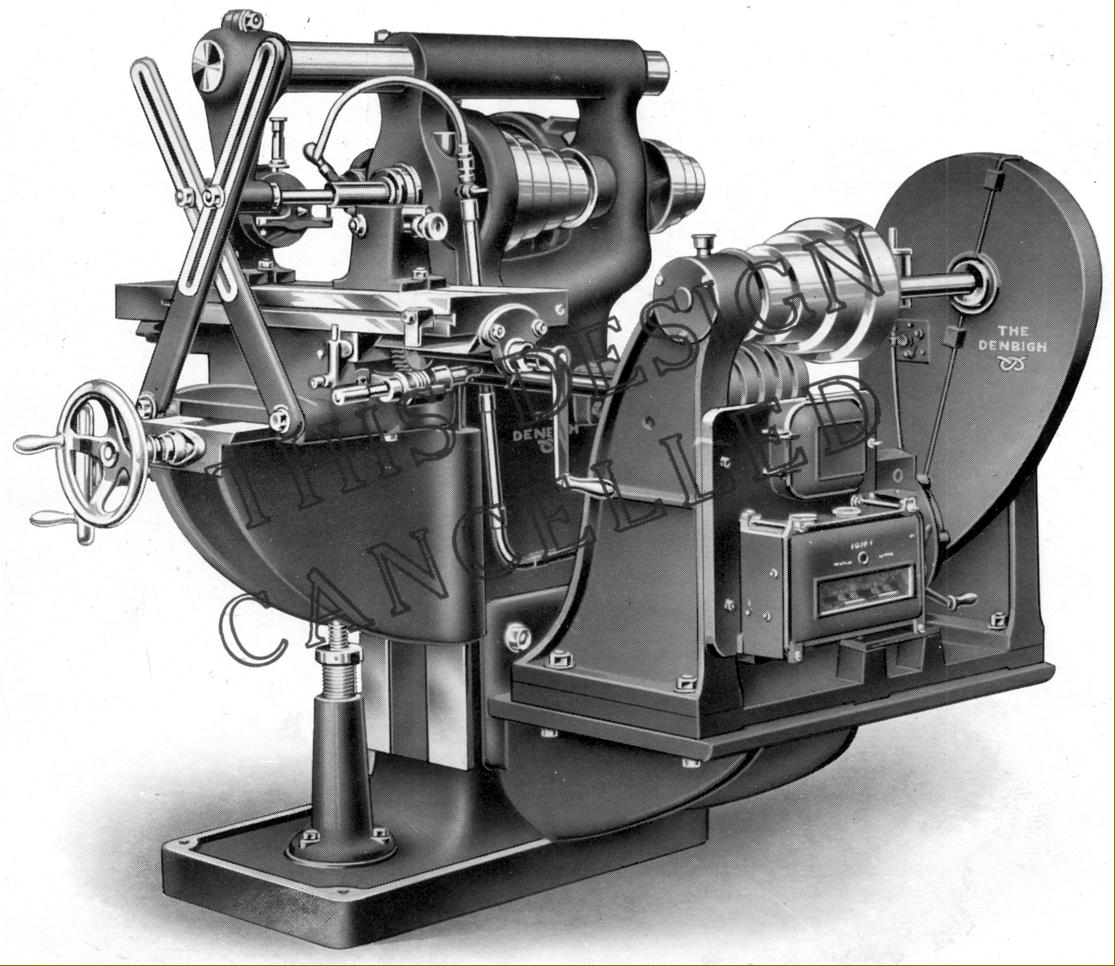

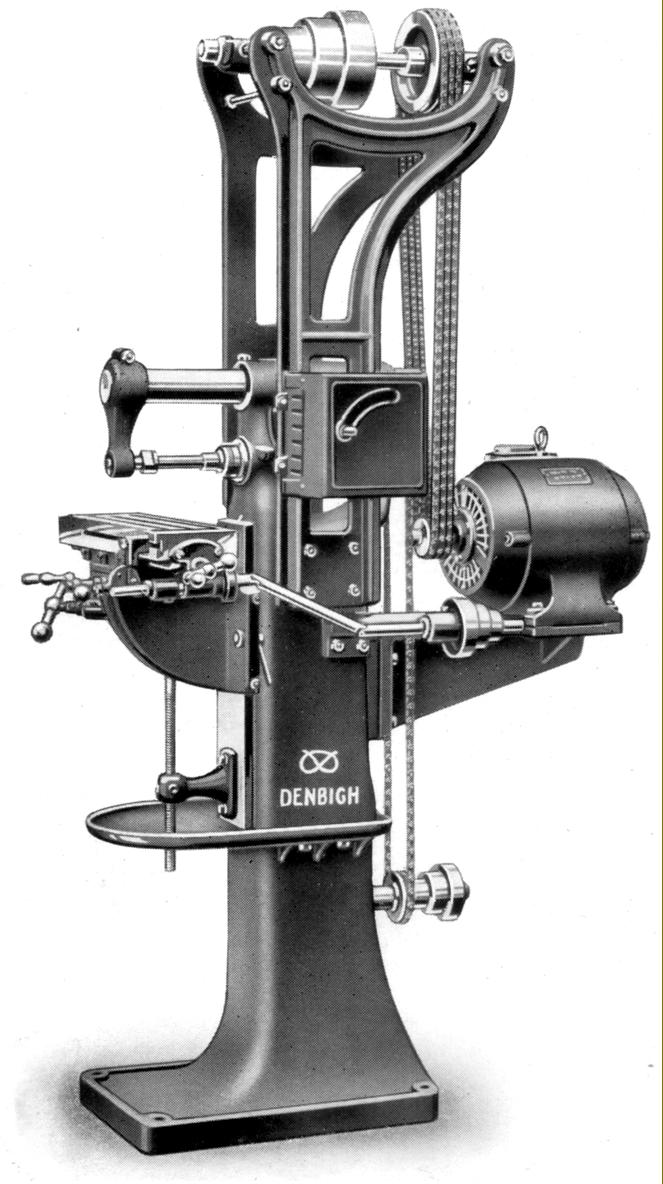

Denbigh Type "New B" milling machine. Later model with a simplified self-contained motor drive

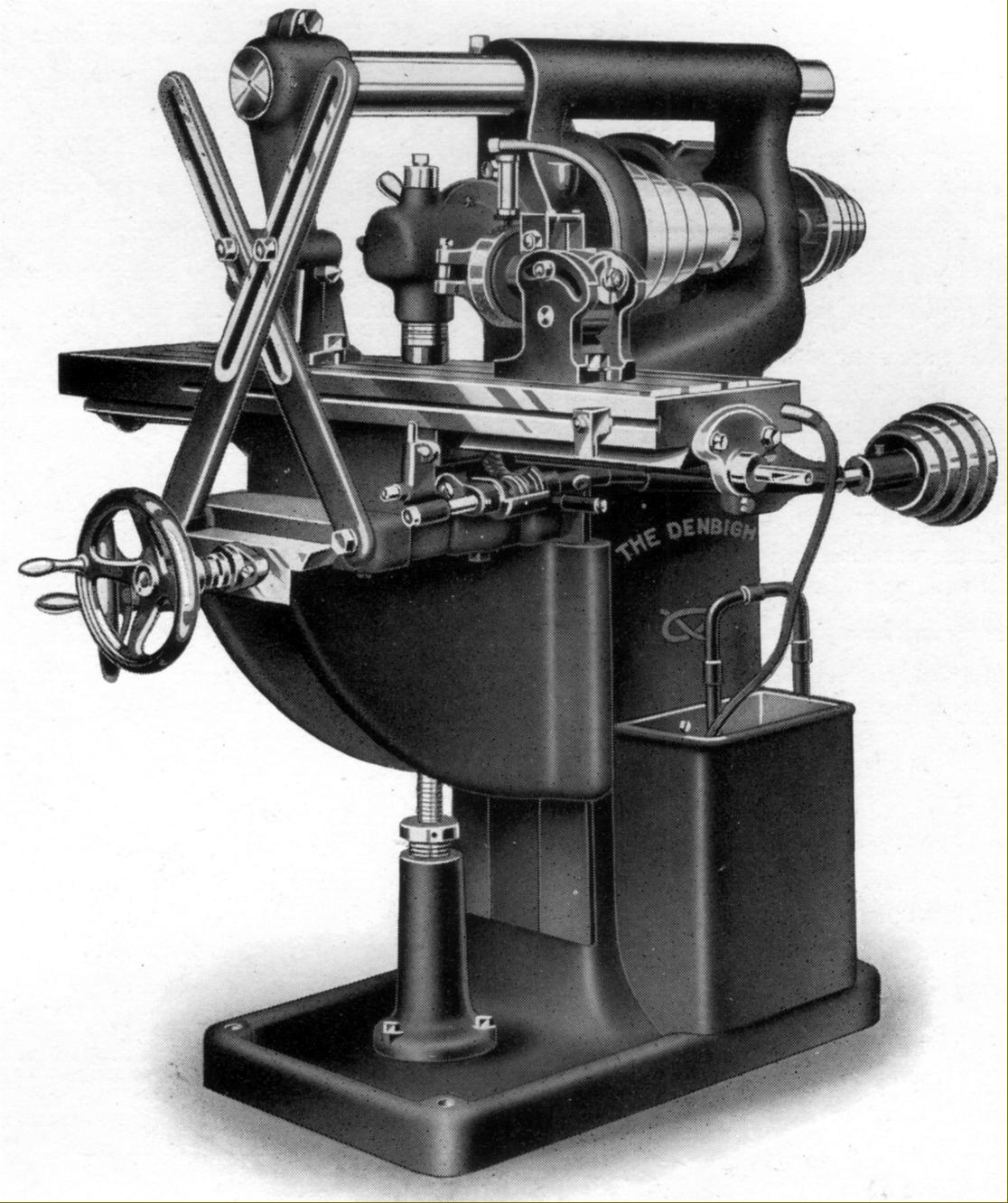

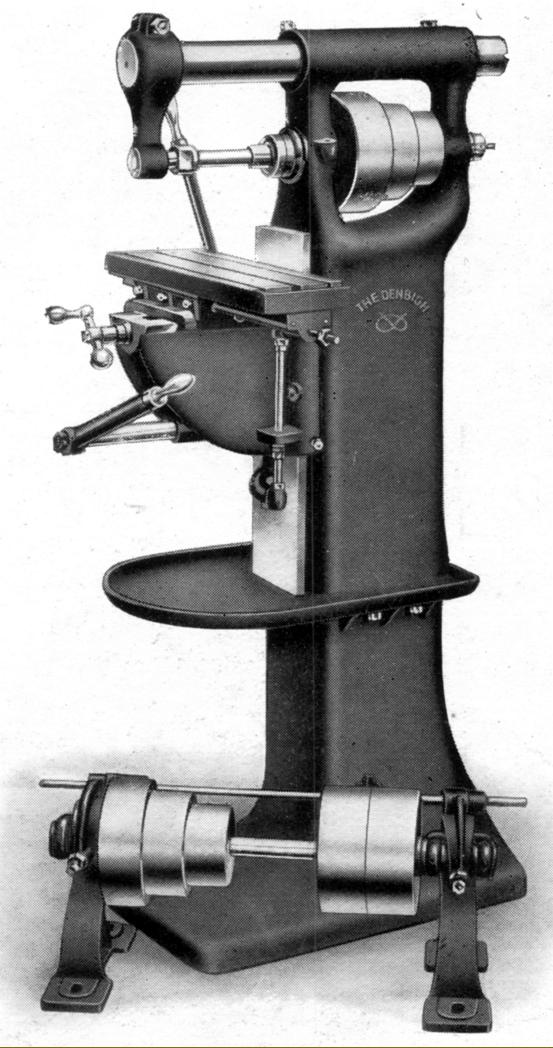

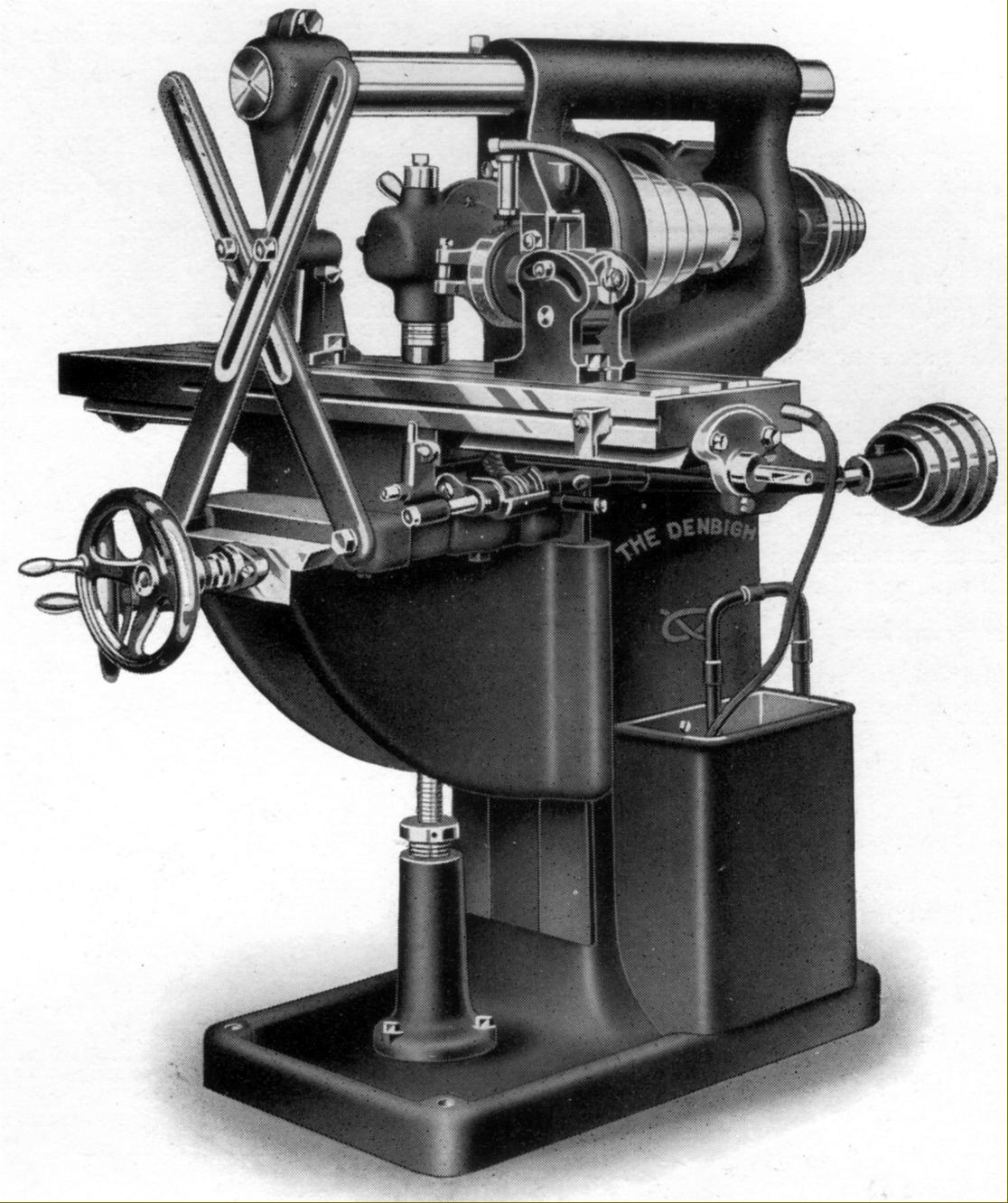

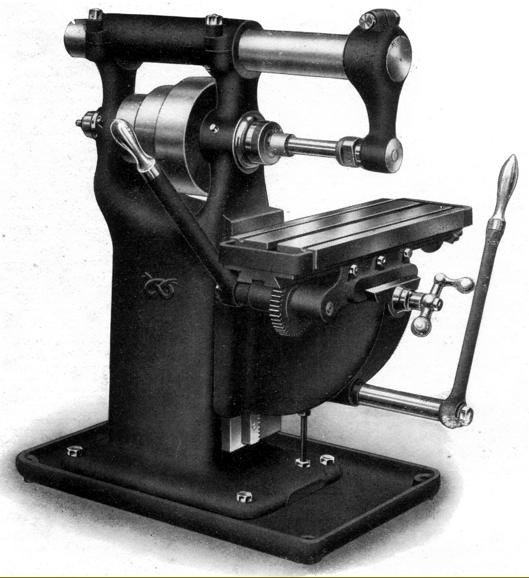

Sold during the 1930s, this larger model was robustly built and constructed around a well-ribbed, vibration-resistant column in a close-grained cast iron with the coolant supply held a tank held against the right-hand face of the column. It was offered with two sizes of table in four models with both "Plain" and swivelling "Universal" tables. The Type "New B" No. 1 "Plain" and Type "New B" No. 2 "Universal" both had a 34" x 10" (864 mm x 254 mm) table with three 3/4" (19 mm) T-slots and an automatic longitudinal feed of 24" (610 mm), a cross feed of 7.5" (190 mm) and vertically of 18" - the latter two motions by hand feed only. The Type "New B" No. 3 "Plain" and Type "New B" No. 4 "Universal" both had a 46" x 10" (1168 mm x 254 mm) table with three 3/4" (19 mm) T-slots and an automatic longitudinal feed of 30" (762 mm), a cross feed of 7.5" (190 mm) and vertically of 16" - the latter two motions by hand feed only.

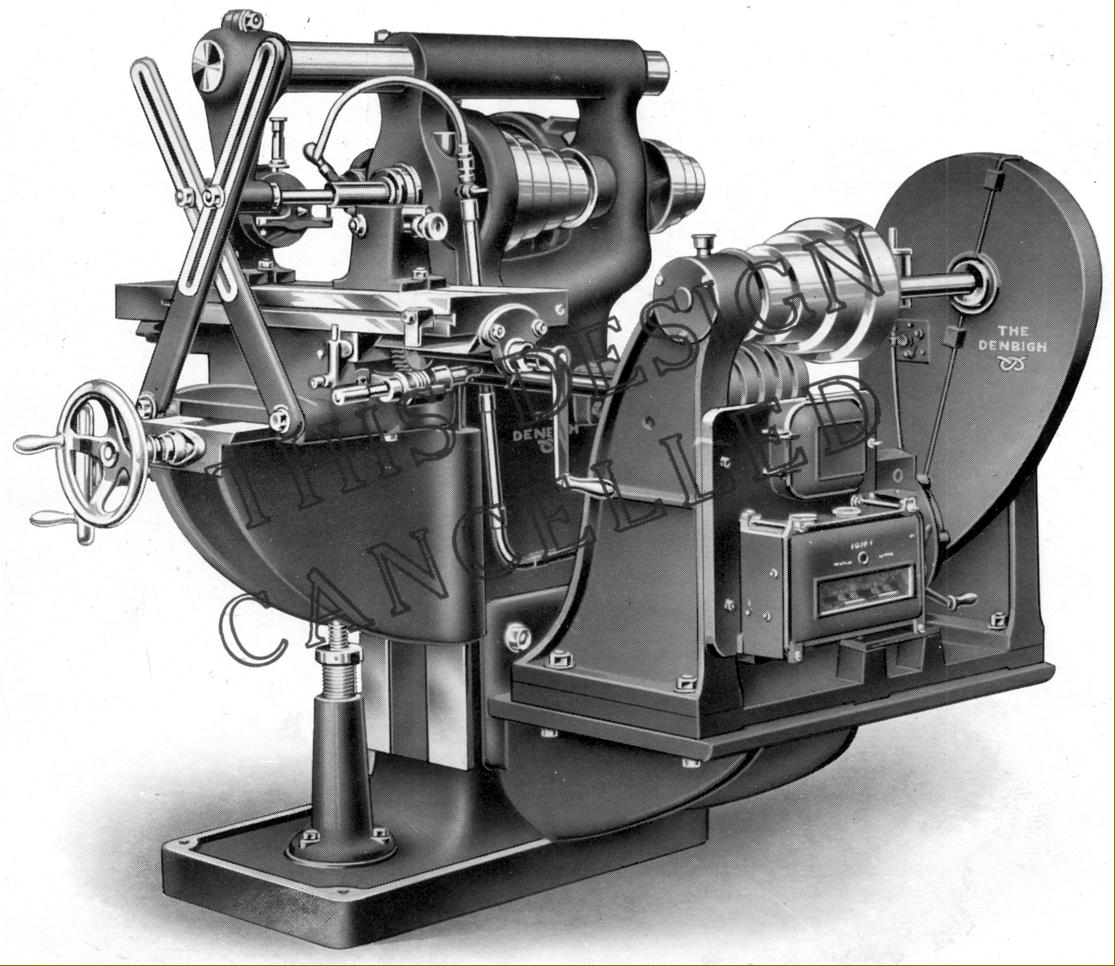

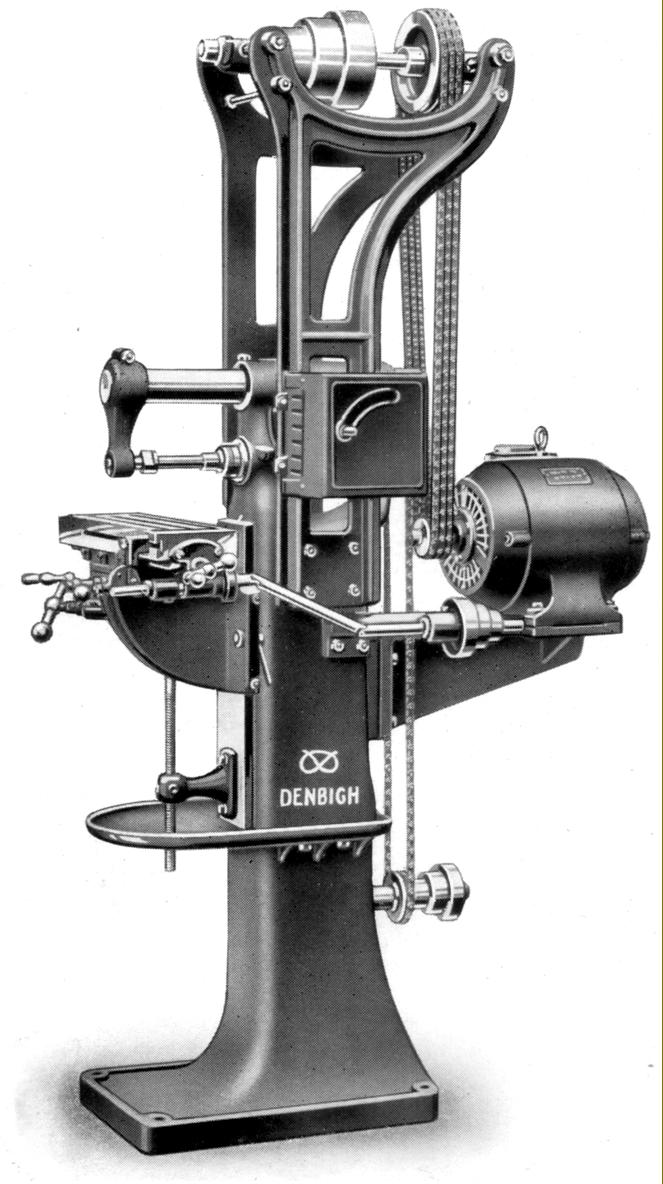

All versions had a spindle made from crucible steel with a No. 4 Morse taper socket and an external thread (protected by a guard collar) for the mounting of chucks or other fittings. Bearings were of the tapered bronze type and adjustable for wear. Fitted to the spindle was a 4-step cone pulley to take a 2.5-inch wide flat belt that could be driven by a variety of means - the simplest being to connect to line shafting in the roof of a factory. The makers also offered countershafts for wall or ceiling mounting, these being fitted with fast-and-loose pulleys and belt strikers to start and stop the machine almost instantly. As what would have been an expensive option the millers could also be ordered with a built-on drive system, the earlier of this type (shwn immediately below) having a massive angle plate bolted to the right-hand face of the column upon which was carried an equally huge countershaft and a 940 r.p.m., 3 h.p. electric motor.

Probably appalled by the cost of this installation the management must have ordered the designer to come up with something just as efficient but both easier and a good deal cheaper to build. In this he succeeded - for the next version (shown above) had the motor bolted to the lower left-hand side of the column driving across by three V-belts to a much simpler countershaft mounted on the right-hand side Final drive to the spindle was by flat belt, running over a wide jockey pulley that acted to apply tension while also changing the belt-run angle from vertical to horizontal..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Denbigh Type "New B" milling machine. Early version with the complex, heavy and expensive-to-build self-contained motor drive

|

|

|

|

|

|

|

|

|

|

|

|

|

|

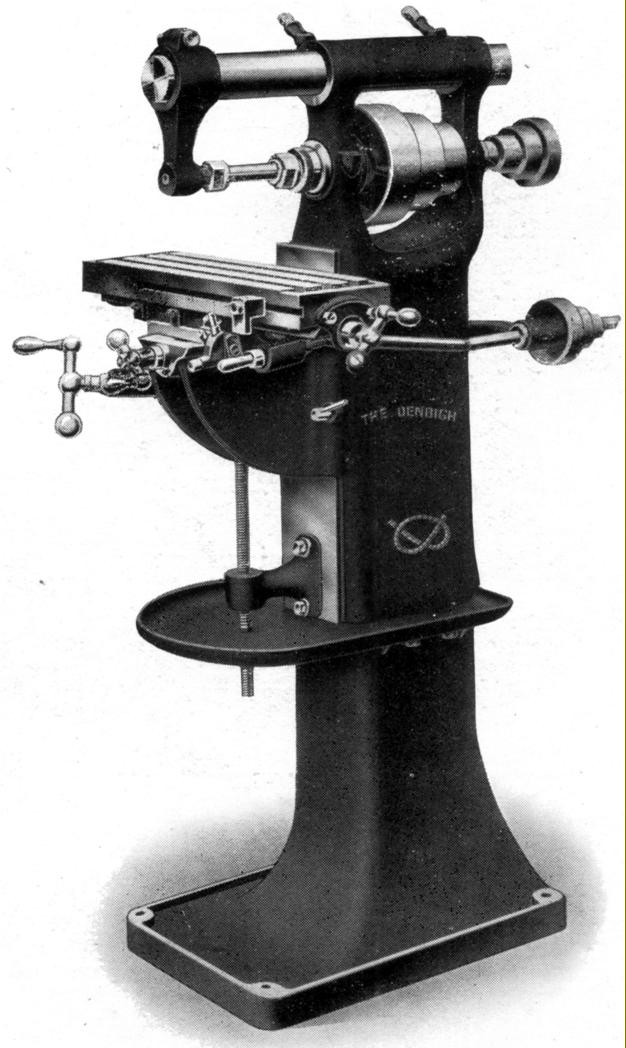

Denbigh Type "New B" milling machine. Basic version intended for drive by a remote countershaft

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

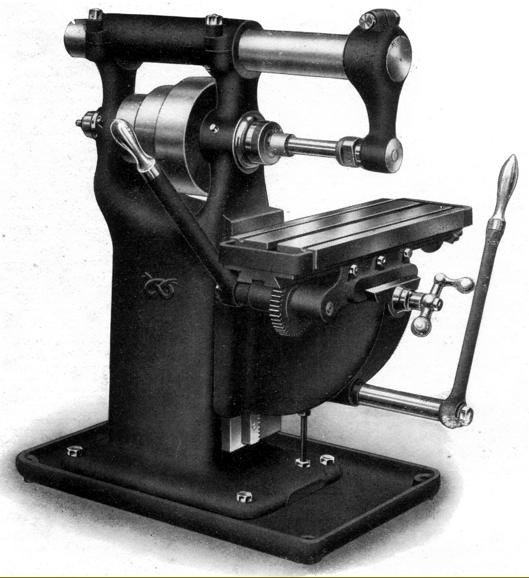

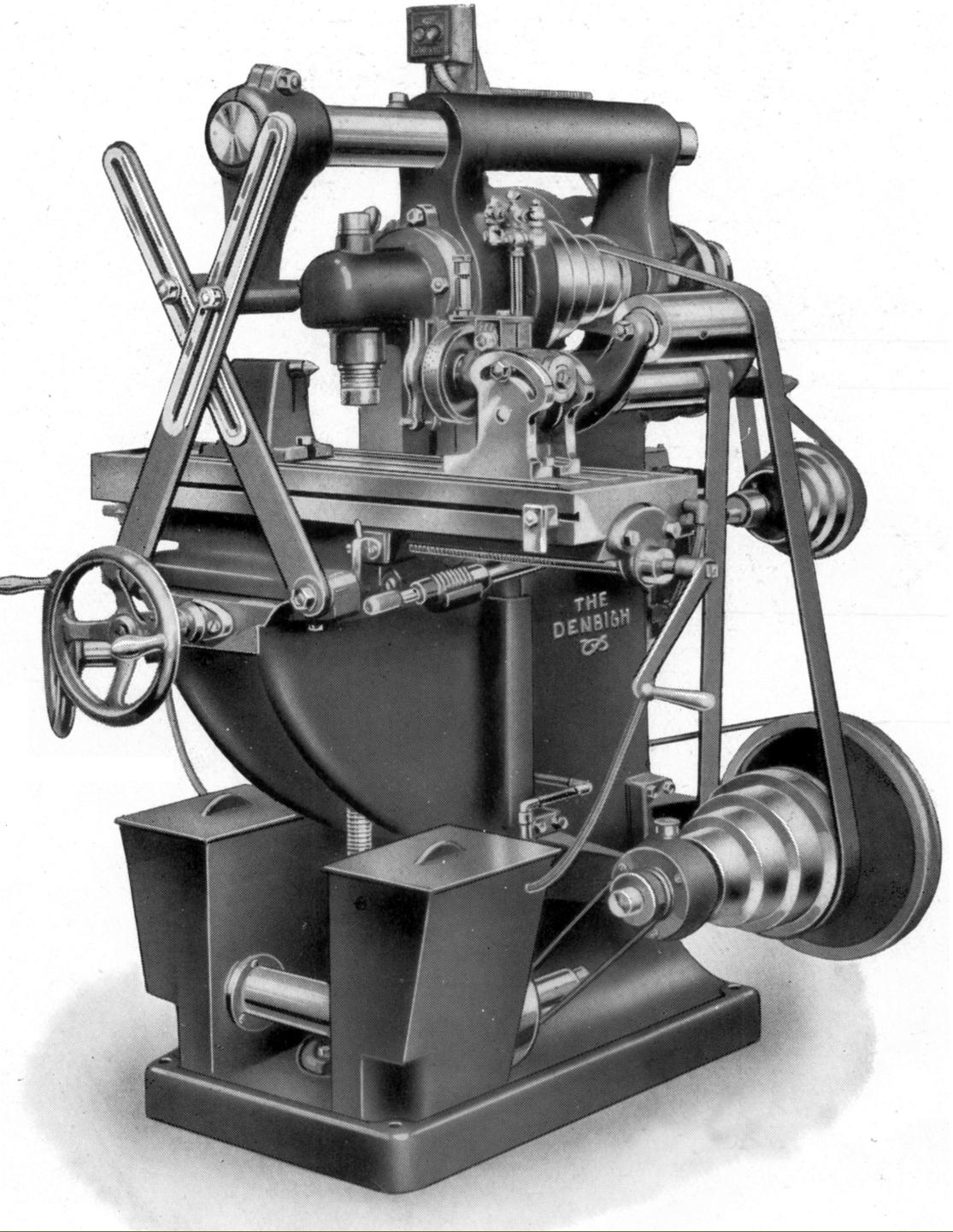

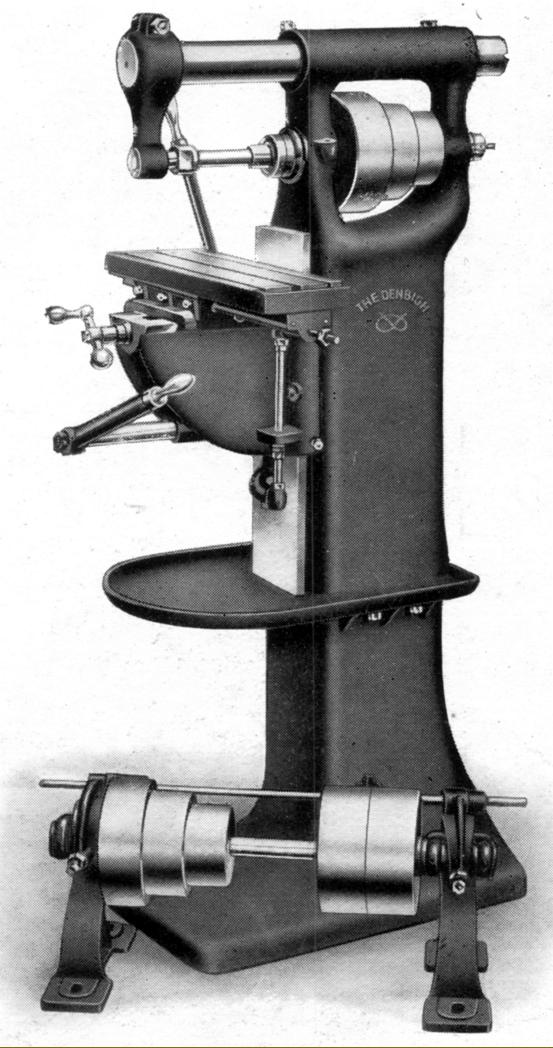

Denbigh "Type H1" light-duty, bench-mount, stub arbor milling machine

The type H was in production during the 1920s and 1930s and ranged in style from simple stub millers - like the one above - to versions mounted on cast-iron plinths with integral motor-countershaft systems. Sitting on a 23" x 14.5" (585 mm x 367 mm) cast-iron pan, the H1 had a 16" x 5.5" (406 mm x 140 mm) table with a single T slot and a lever-actuated longitudinal travel of 7" (178 mm) a cross feed of 3.25" (83") and vertically of 7" (178 mm). The spindle, fitted with a No. 3 Morse taper nose ran in tapered, adjustable bronze bearings.

|

|

|

|

|

|

|

|

|

|

|

|

Denbigh "Type H3 light-duty bench-mount, with an overarm-supported cutter arbor

Apart from the addition of an arbor-supported overarm the H3 was identical to the H1. The miller could also be had as the Type H2, mounted ion a cast-iron plinth similar in appearance to that used for the H4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Denbigh "Type H4" horizontal milling machine with lever-operated longitudinal and vertical travels and screw-feed to the cross movement. The single T-slot table was identical to that on the "Type H Auto" with a cross feed of 3.25" (83 mm), vertically 7" (178 mm) and longitudinally 12.75" (324 mm). Fitted with a No. 3 Morse taper socket the spindle ran in conical, adjustable bronze bearings ands was supported at its out end by a 2.5-inch (64 mm) diameter, round solid steel overarm.

|

|

|

|

|

|

|

Denbigh "Type H4 Auto" horizontal milling machine with power feed to the 17" x 6" (432 mm x 153 mm) table with a single T-slot and all-screw feed movements.

Cross feed was 3.25" (83 mm), vertically 7" (178 mm) and longitudinally under power 12.75" (324 mm). Fitted with a No. 3 Morse taper socket the spindle ran in conical, adjustable bronze bearings ands was supported at its out end by a 2.5-inch (64 mm) diameter, round solid steel overarm.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Denbigh "Type H4" Hand-feed model with a rather ungainly bolt-on countershaft drive system.

This miller had a spindle made from crucible steel (a method of producing a small quantity of carefully regulated mixture) with a No. 3 Morse taper socket and an external thread (protected by a guard collar) for the mounting of chucks or other fittings. Bearings were of the tapered bronze type, adjustable for wear. 16" x 5.5" mm x 140 mm) the table had a longitudinal travel of 7", across of an inadequate 2.375" and vertically of 7" of just 2.375".

Oddly, when they were so relatively easy to fit, the belts fitted were Brammer link, a far more expensive proposition than the standard wedge type.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|