|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

Deckel Tool & Cutter Grinders

GSO, SO and S0E (and Copies by Alexander) and S11

Operation Manuals are available for the SO and SOE

and S11 and other Deckel machines

Deckel Home Page Deckel Tool & Cutter Grinders Deckel FP2 Deckel FP3 Deckel FP3L

FP1 1920s Photo Essay Deckel FP4A, FP41A, FP42A & Early NC Versions Deckel Factory Tour

Deckel DZ4 Series FPA and FPNC CNC Deckel 1988 Full-range Catalogue

Deckel Die Sinkers & Engravers

GSO, SO and SOE

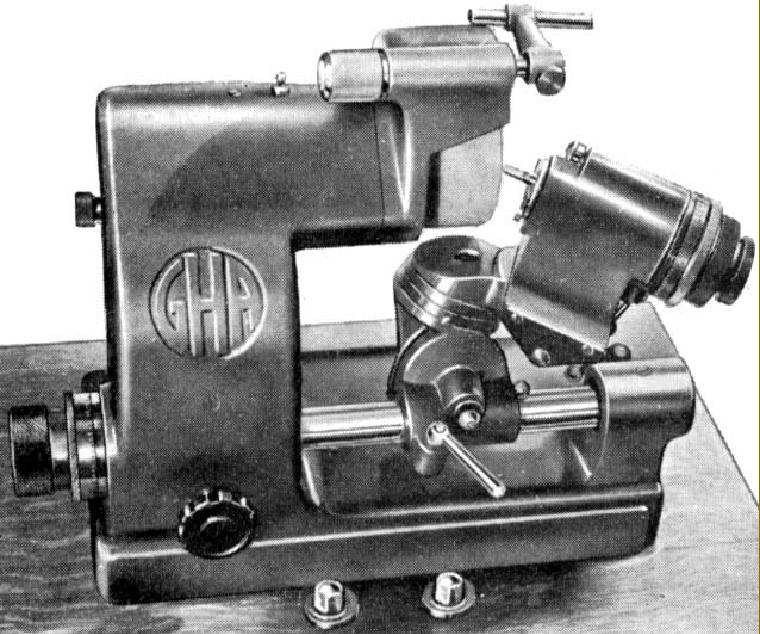

Intended original to compliment the Deckel range of pantograph engravers and die sinkers, the long-lived Deckel tool and cutter is known as a "single-lip type" and, due to its success, has been widely cloned with many examples (of varying quality) now made in China. In the UK the best-known copy was by Alex ander, who produced a version to the same very high standard of the original (as well as a simplified version intended mainly for sharpening the D-bit cutters of the firm's well-known engraving machines).

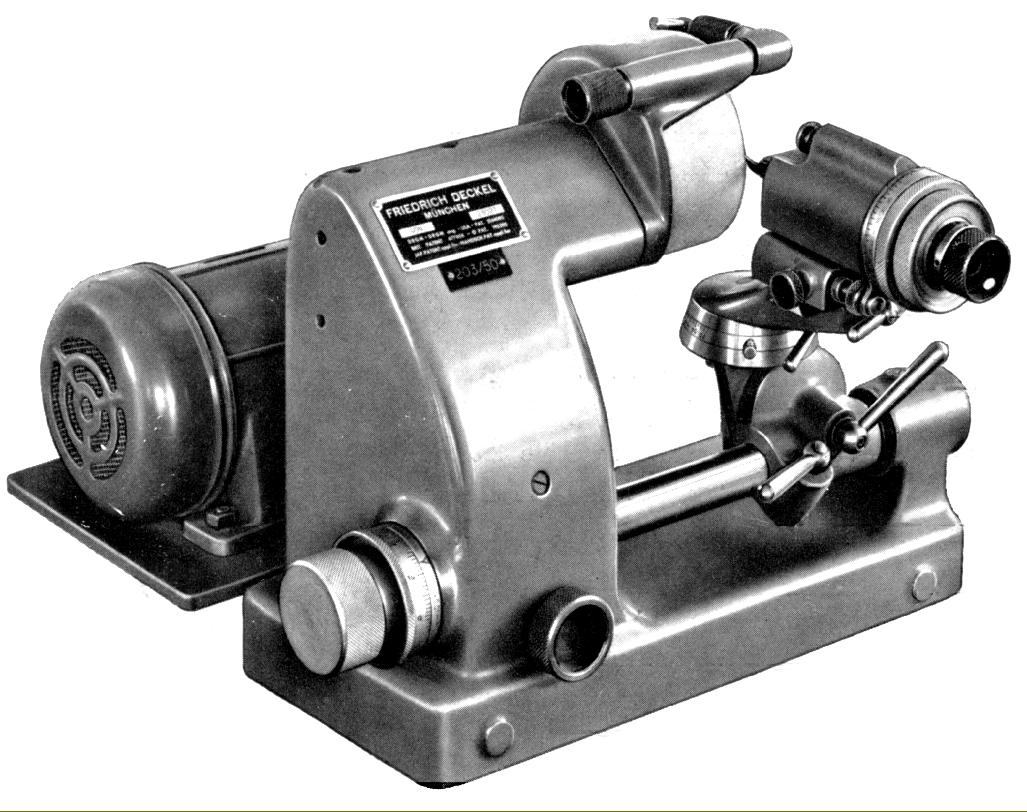

It's believed that the ranged started before 1945 with the introduction of the Type GSO, with a nameplate still says "D.R.G.M - Deutsches Reichsgebrauchsmuster. Unlike later versions, this model has no roller bearings but plain ones. Apart from that, the construction is alsot identical to the SO save for a few minor details. The writer hopes to receive more details of this model and devote an extended section to it.

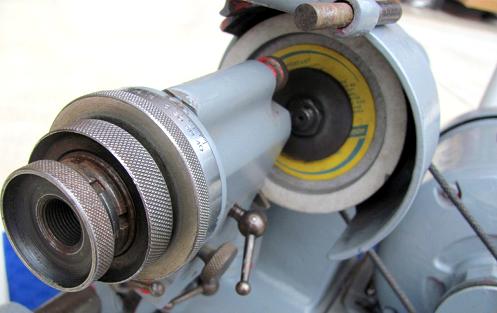

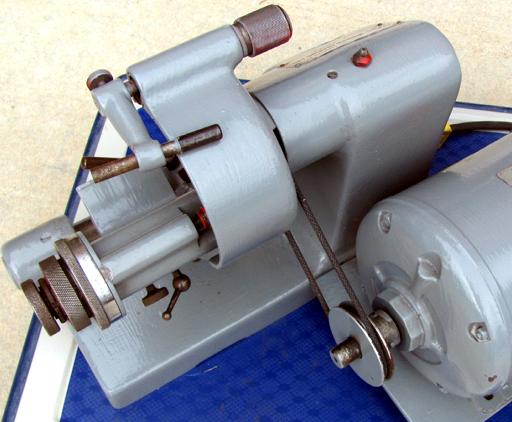

Able to mount a grinding wheel 4" in diameter by 2" wide with a 25/32" bore, the Deckel/Alexander SO was fitted with a 3-phase, 0.25 hp, 2800 rpm motor with the wheel running at around 5000 r.p.m. The cutter to be sharpened was secured in, on early models, an unknown type of collet with a 16 mm shank that had a maximum capacity of 1/2" (12 mm). Later (and by far the more common type) used what the makers listed as a Schaublin Type L20 with a 5/8" capacity (17 mm), collet angle being 15-degrees and the thread 19.7 x 2 and 45/5 degrees. Hence, as the early collets are now unobtainable (though they can be specially made), before buying one of these machines (or ordering new collets) do check what the situation is, An early model without a complete set of collets, or with ones that are worn, will be very expensive to rectify - and should be far cheaper to buy than one fully equipped. A further problem arises with regard to the later collets sold around the world as the Type U2 and often listed as being: "suitable for Alexander and Deckel grinders". Owners report that these fit the Alexander version, but not the Deckel - or the threads, at least, are different. If you have direct experience of this situation and any difficulties it has caused, the writer would be pleased to hear from you.

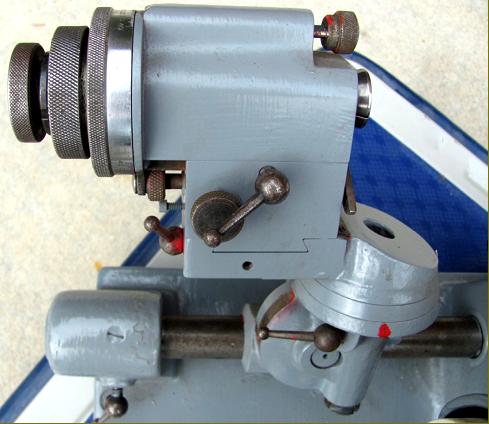

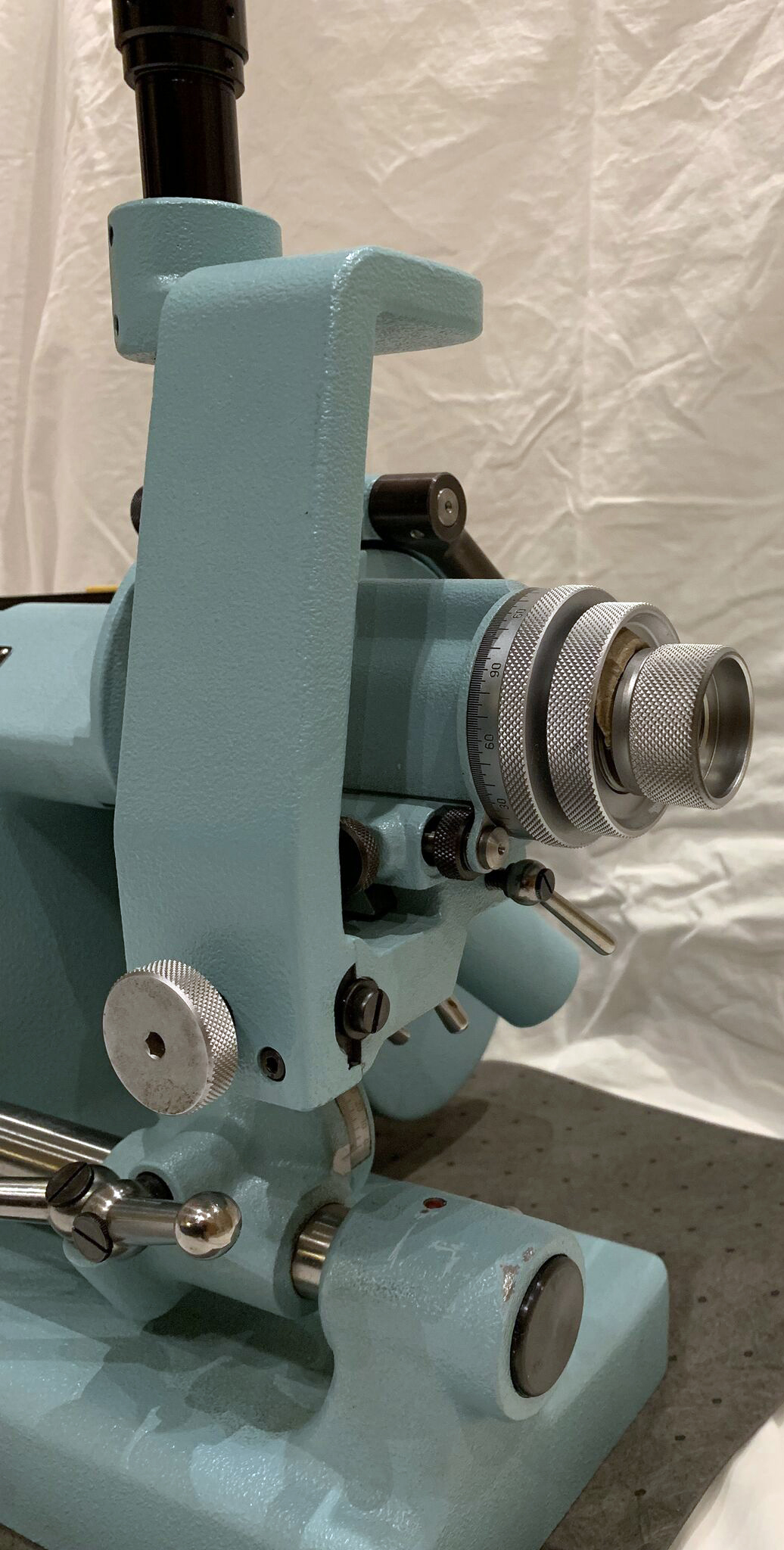

Collets were mounted in a housing (the index carrier) on top of a short-travel slide fitted with a vernier scale. The slide was fastened to the end of a swan-necked arm, mounted on a double-swivel base which itself was carried on a boss that could be slid along and rotated around a horizontal bar. In addition the bar was finely adjustable "left and right" by a micrometer screw with its dial and handwheel on the left-hand face of the machine.

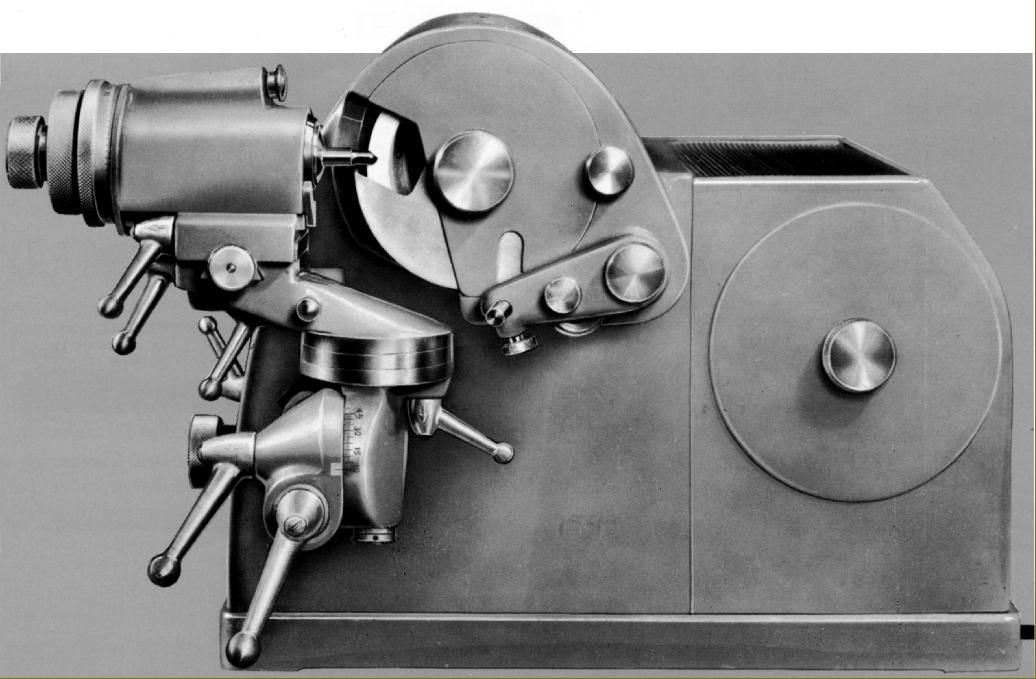

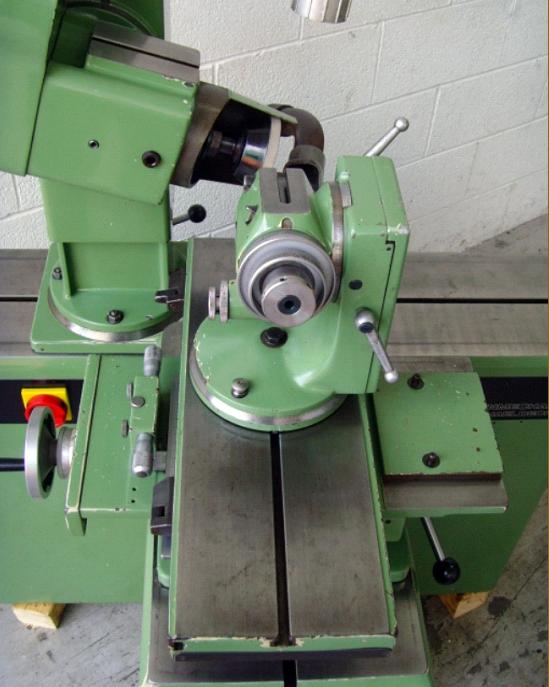

In the 1970s Deckel introduced the Model S0E (to run alongside the S0) an improved design but one that was operated in exactly the same way. Besides modern, sleeker line, modifications included: a built-in motor with an adjustable dust exhaust hood (it could be repositioned to allow wheel dressing); more complete guarding of the wheel; an axially moveable wheel spindle (under the control of a micrometer dial) that allowed precise wheel dressing and a telescopic, stub-mounted horizontal support bar - an arrangement which, with the removal of the end-support bracket, afforded much greater clearance around the job.

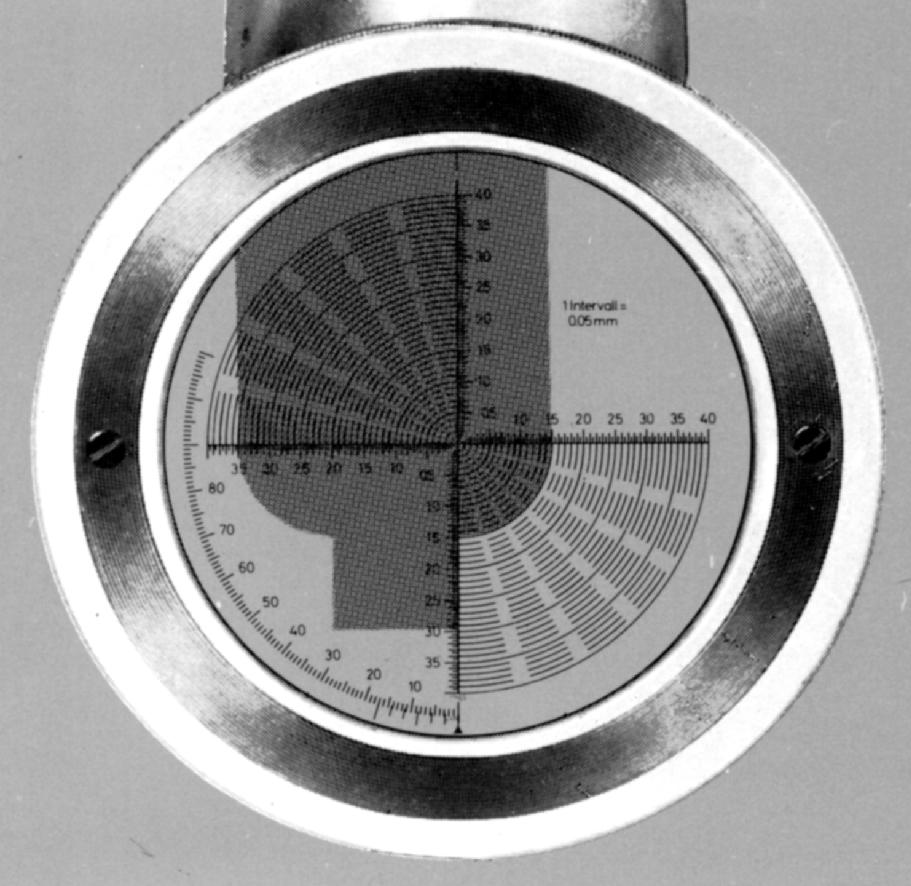

One option available for the SOE was a bolt-on Optical Measuring Projector. This enabled the operator to view the profile of a cutter mounted in the holder and assess, from a scale, the various dimensions and angles. The unit consisted of a housing to hold the optical system and a ground glass reticule on which rested a second reticule that could be rotated through 90°. The measuring projector could only be used on the index head carrier for which it was supplied - the image plane of the ground glass being adjusted so that the axis of the reticule coincided with the tilting axis of the index head and the distance from the object plane corresponded correctly to the magnification ratio.

S11

Designed to be as versatile a machine as possible, the S11 is still in full production and now available with a number of electroic control systems to enhance its appeal...

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

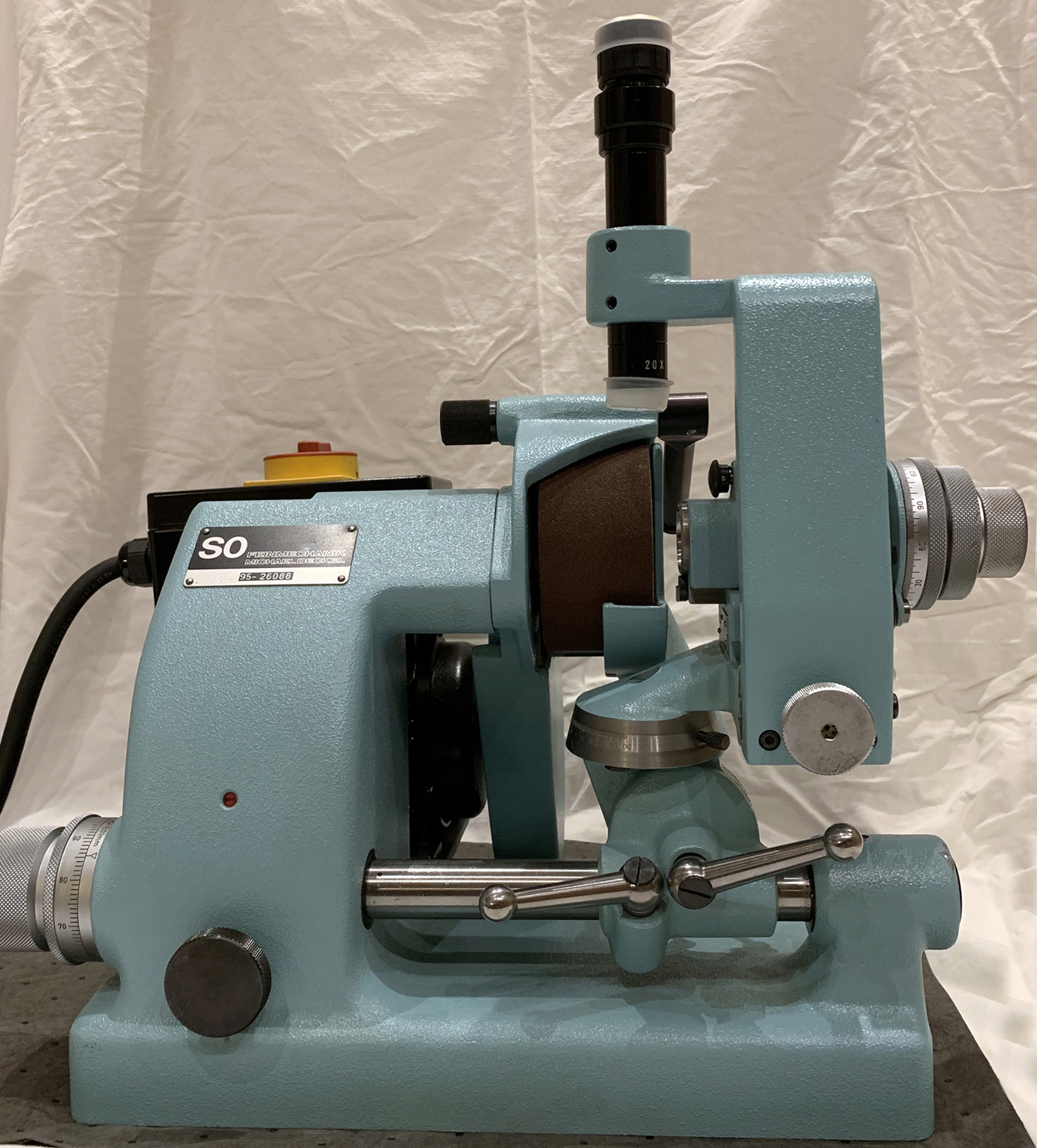

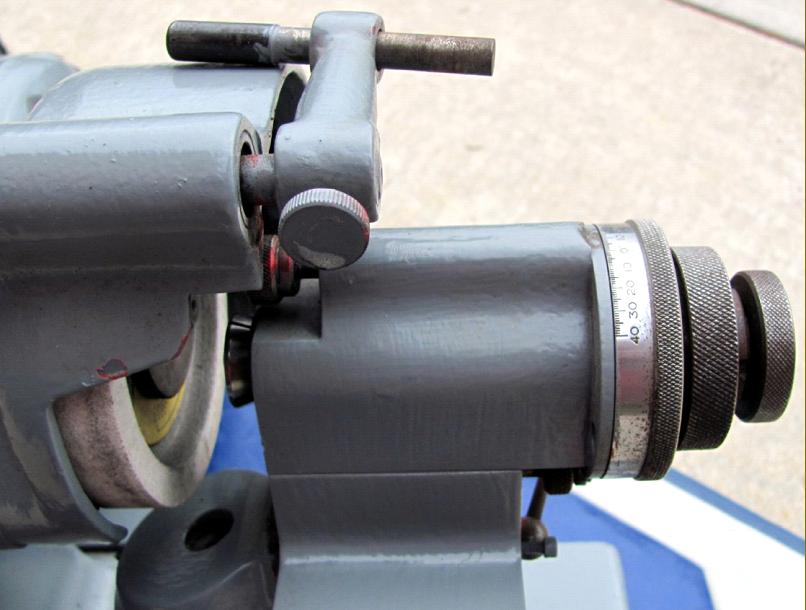

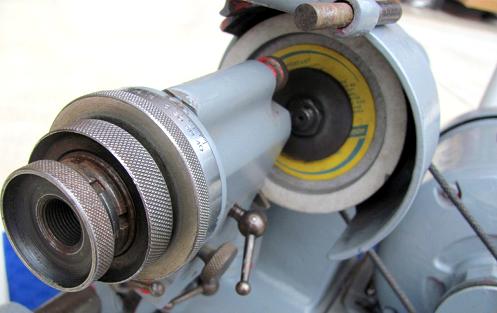

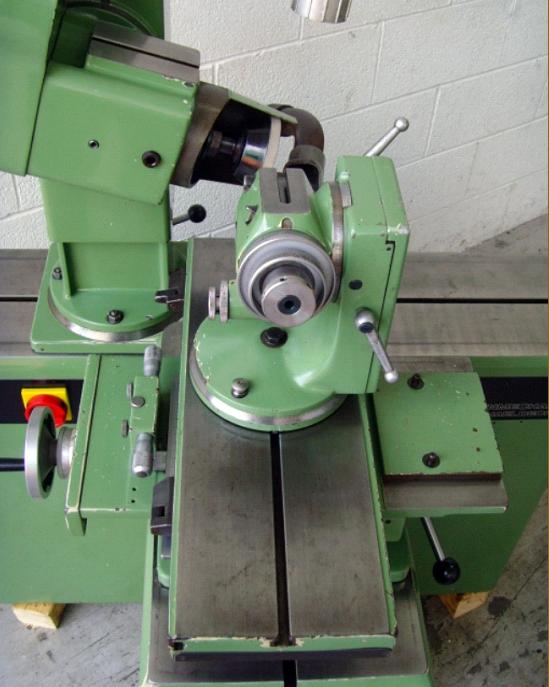

Deckel Tool & Cutter Grinder Model S0 as manufactured in 1995

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

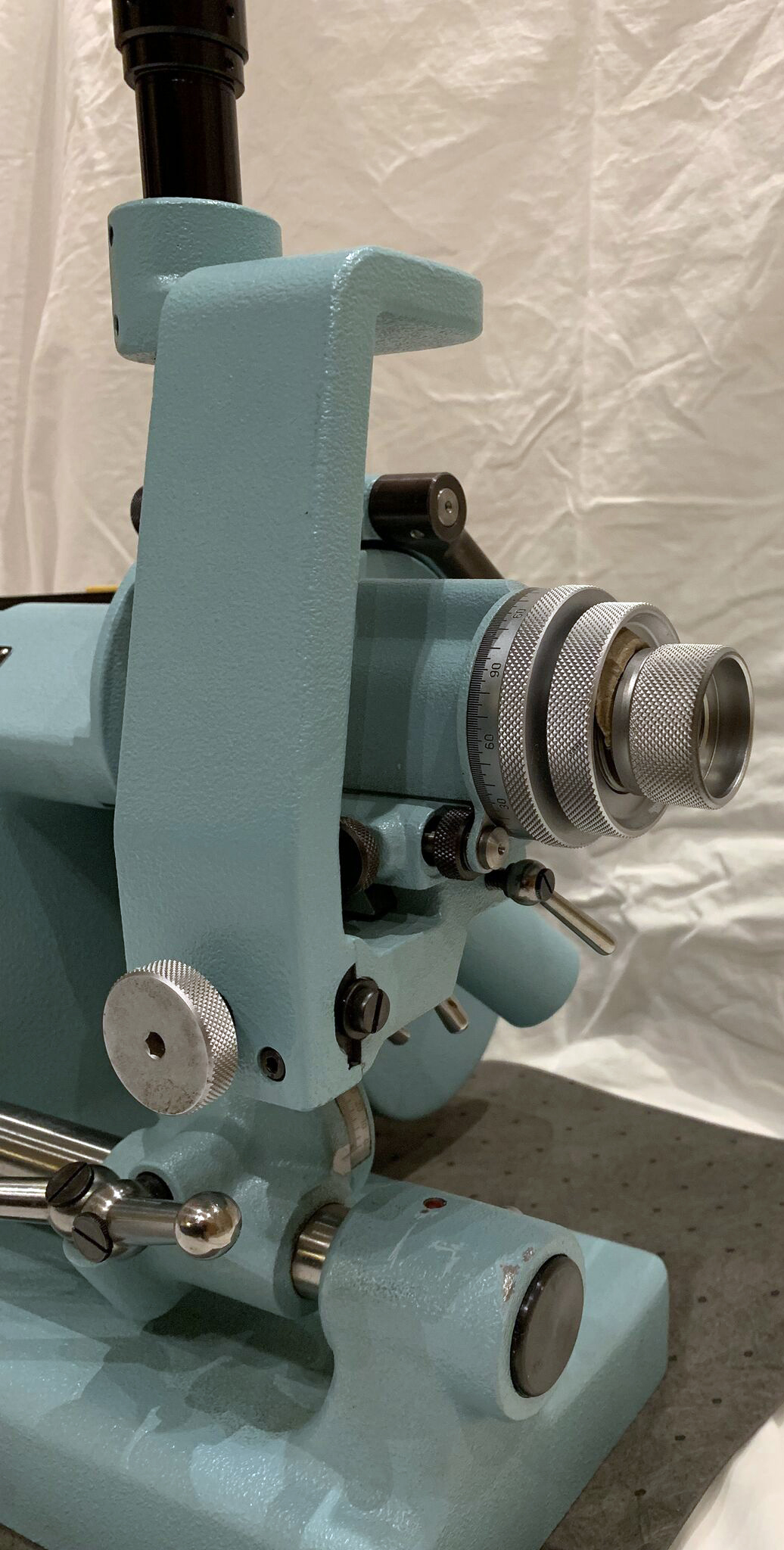

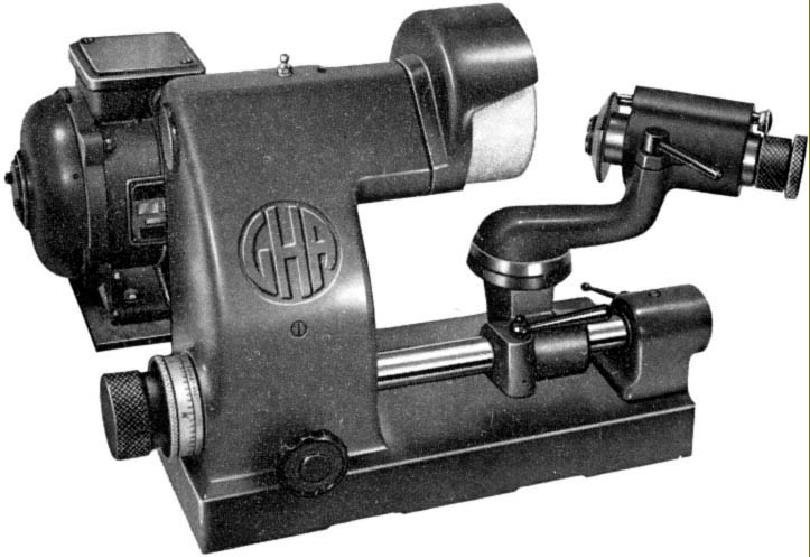

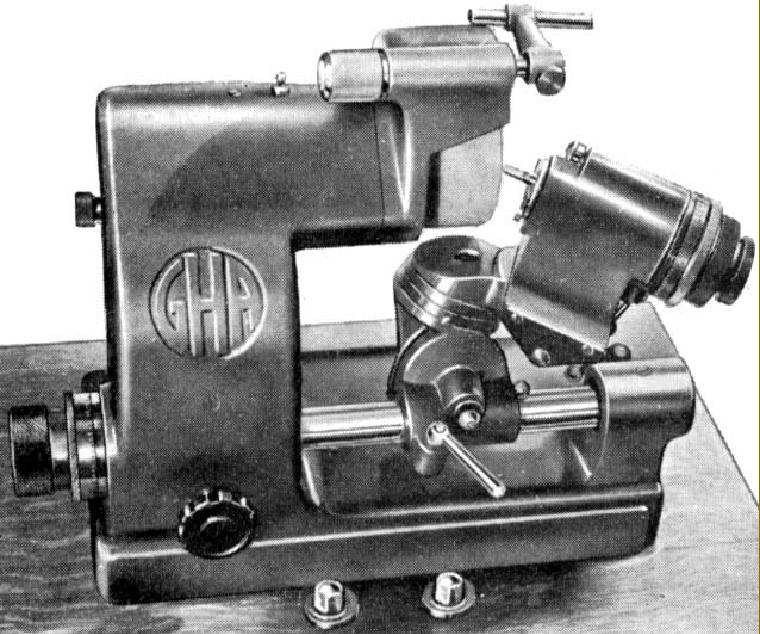

The seldom-found Deckel GSO - probably the forerunner of the SO and SE types

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

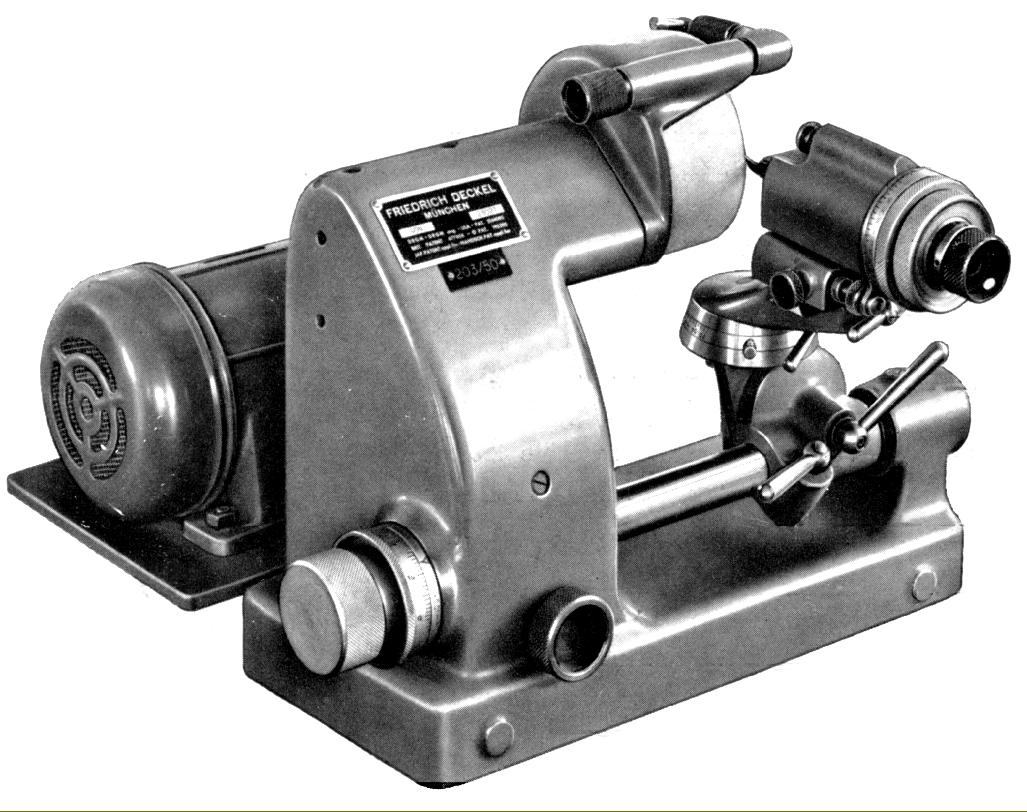

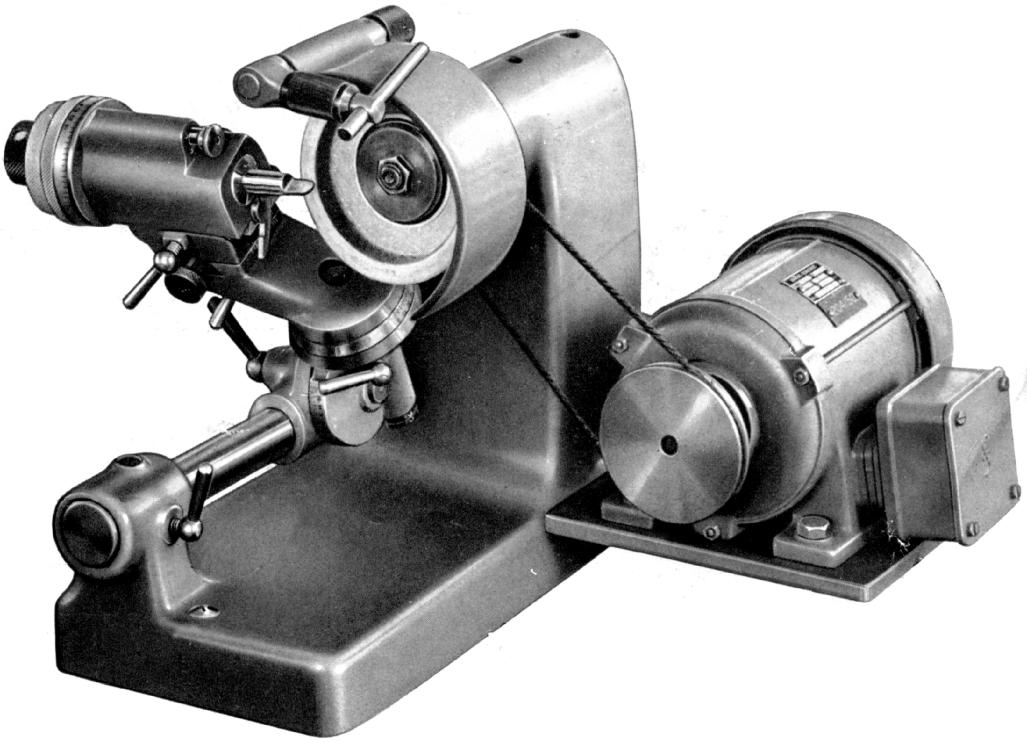

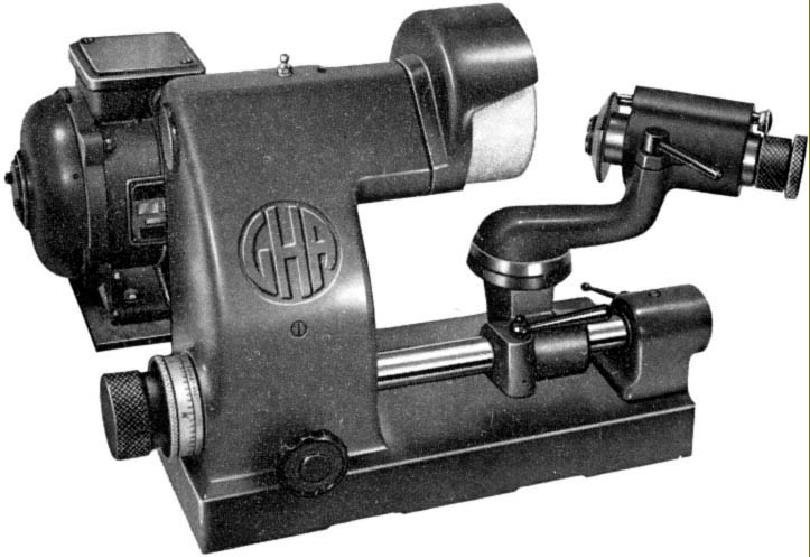

An older Deckel Model S0 tool and cutter grinder from the 1950s

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

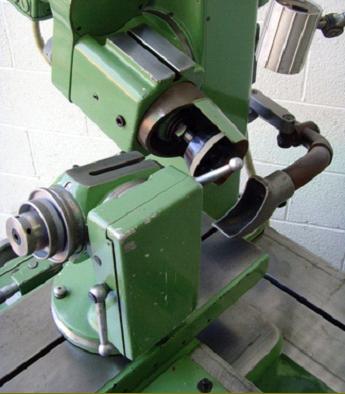

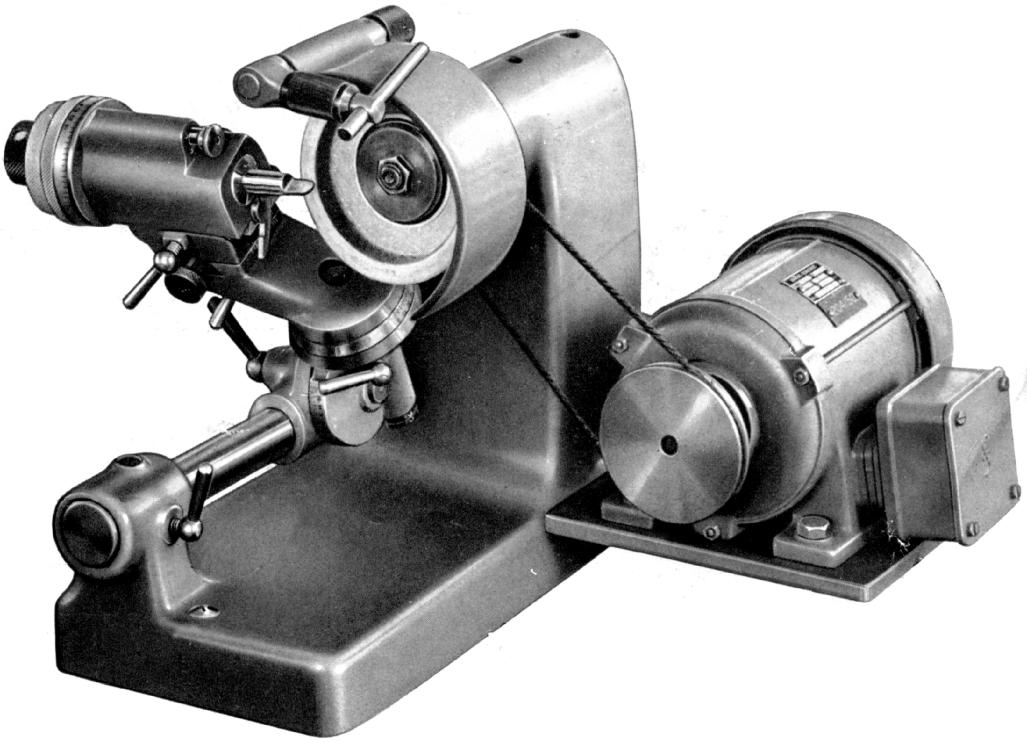

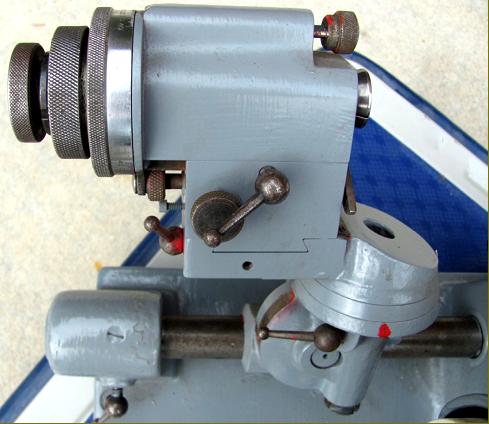

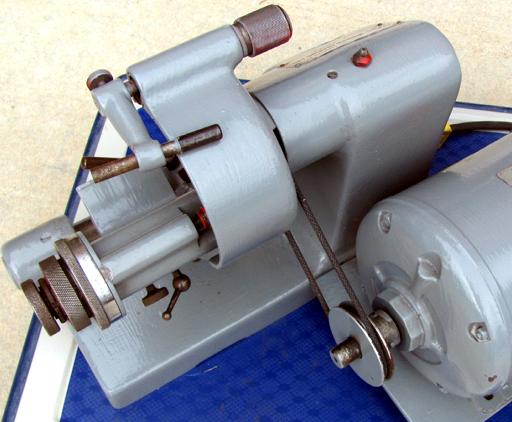

Alexander copy of the Deckel S0

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A simplified Alexander version of the Deckel Model SO with a single swivel, swan-necked support arm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

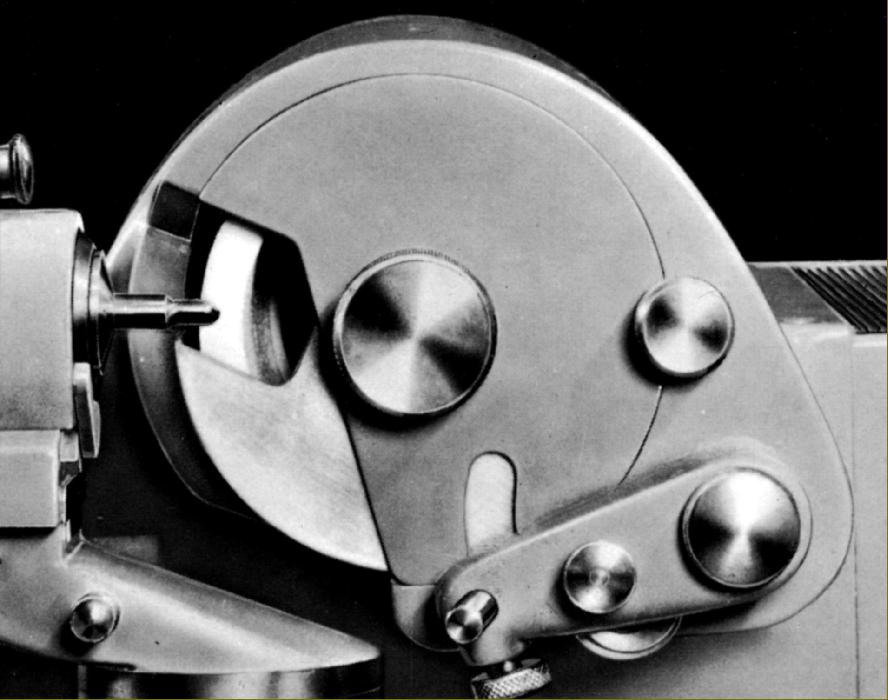

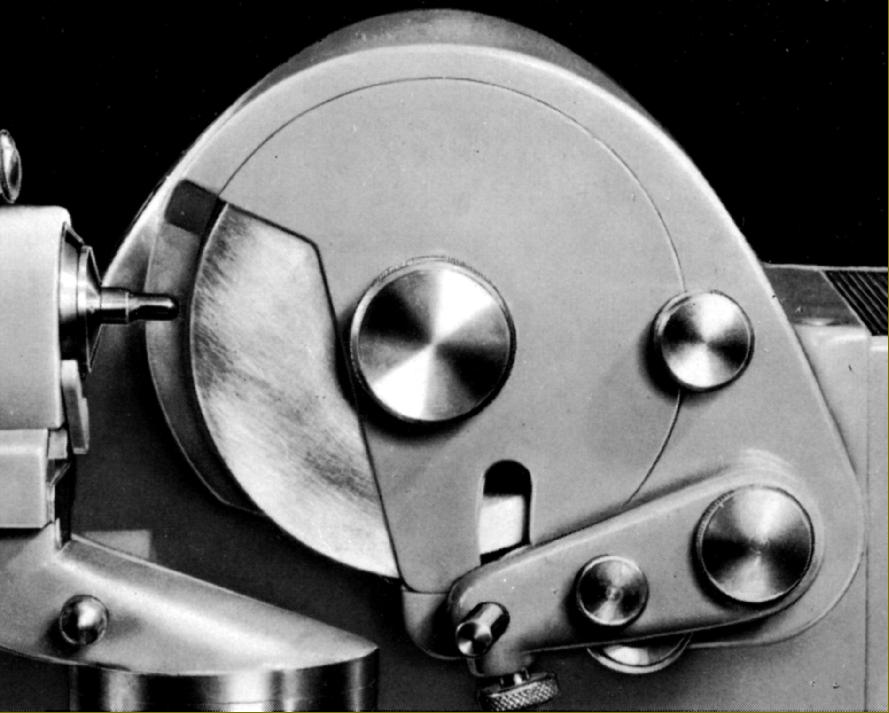

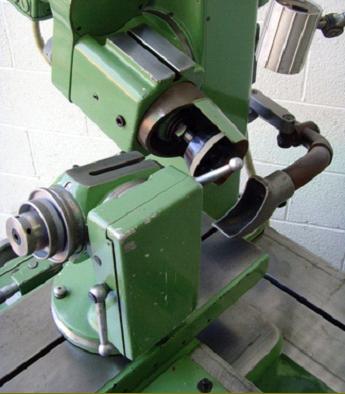

Another view of the Deckel/Alexander Model S0

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

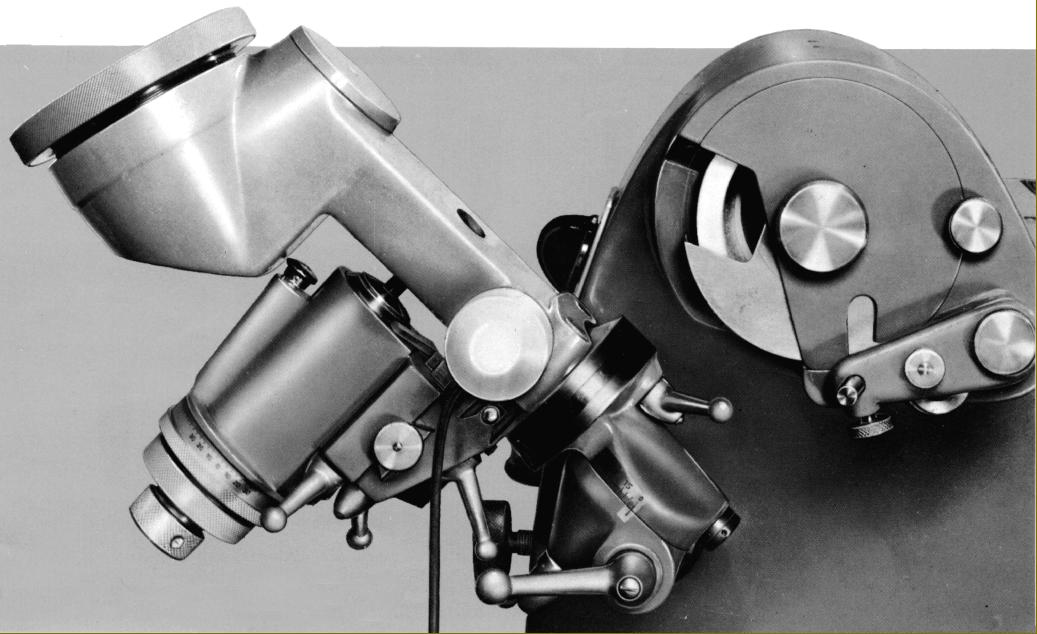

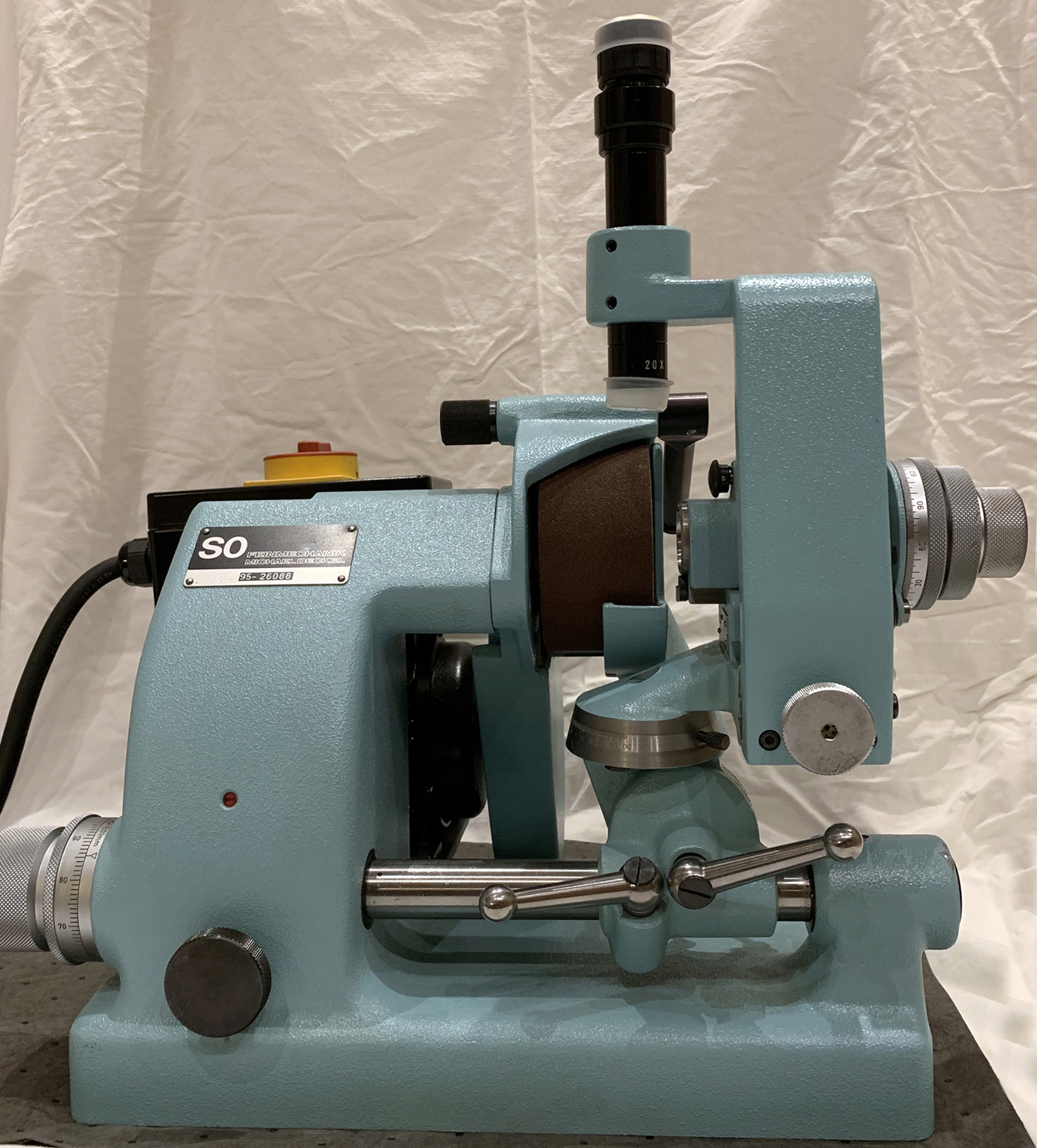

Deckel S0E Tool & Cutter Grinder with a telescopic, stub-mounted horizontal cutter-holding support bar

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Another view of the Deckel S0E

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

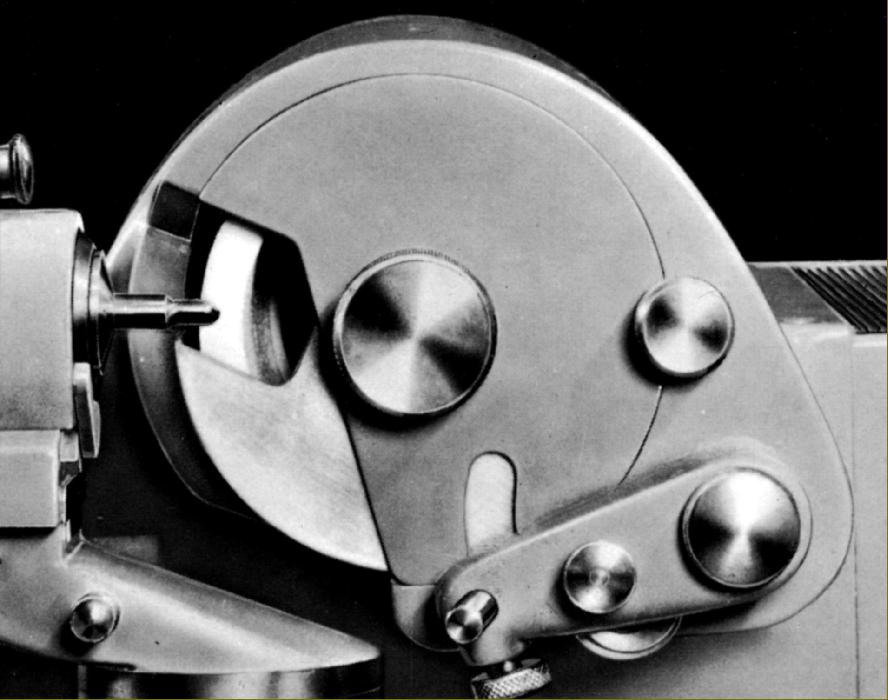

End view of the Deckel S0E showing the motor enclosure and adjustable dust exhaust guard

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjustable dust exhaust hood in the position for position

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjustable dust exhaust hood in the position for wheel dressing

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

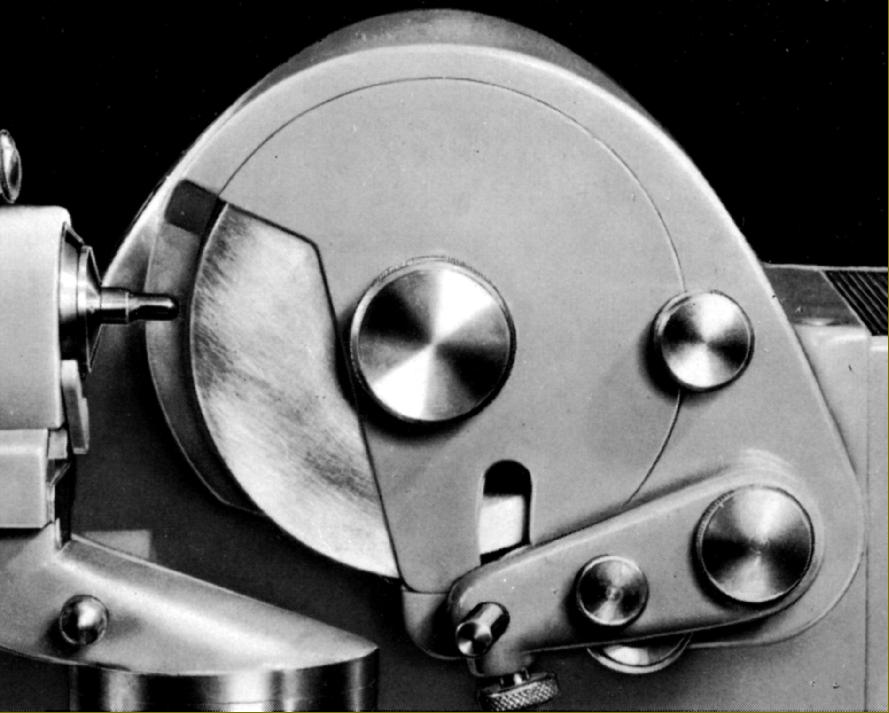

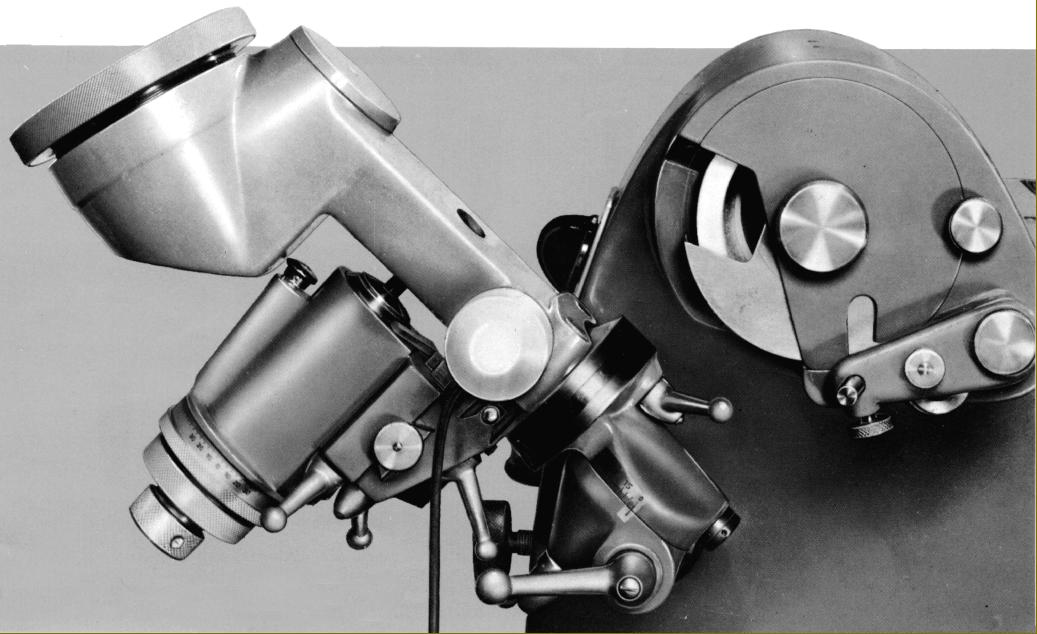

Measuring projector: this unit served to measure and check the profiles of cutting tools when mounted in the holder

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

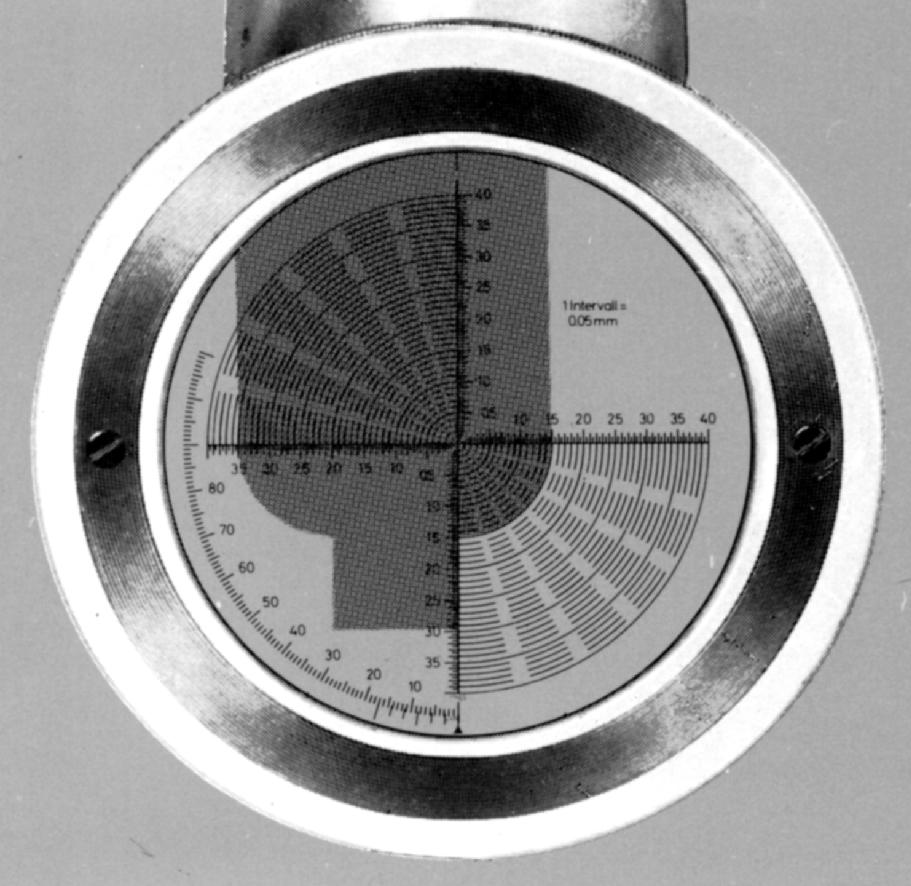

Example of view through the measuring projector

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

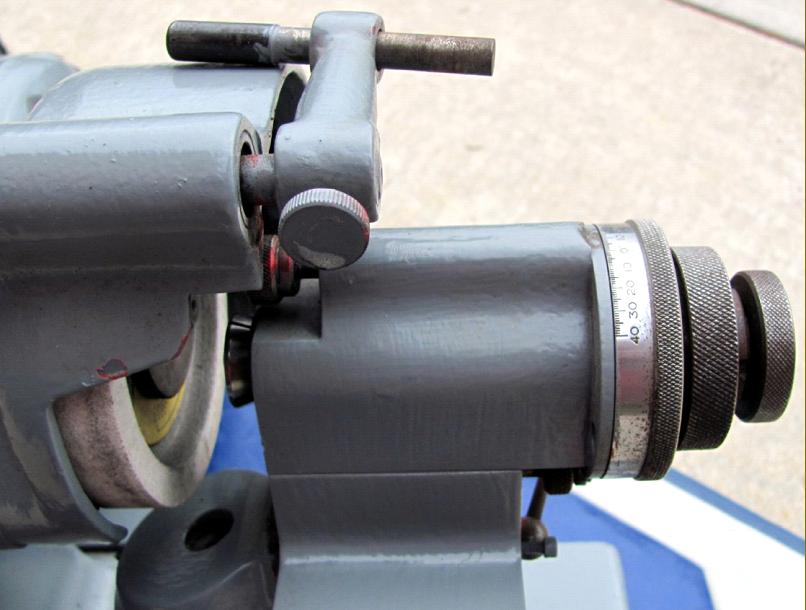

Alexander SO tool & cutter grinder

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

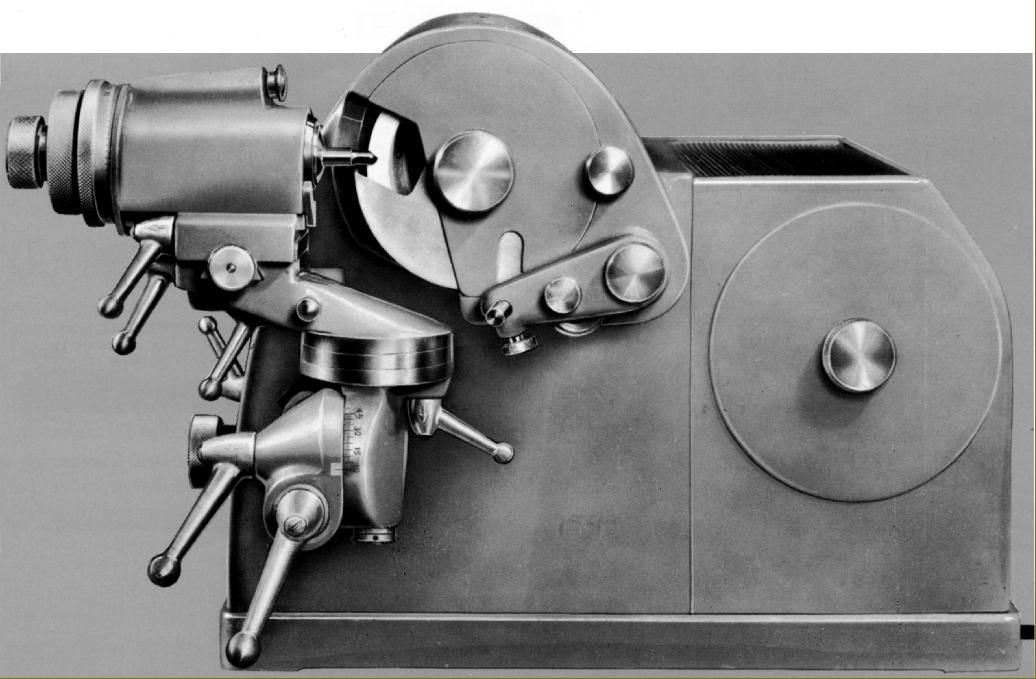

Catalogue illustration of the Deckel S11 Tool and cutter grinder

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|