|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

Centec Automil, Automil Duplex, 3 Series (Types 3C, 3P, 3R, 3RV, 3V) and No. 4

Milling Machines

Centec Home Page Early Centec Horizontal Centec 2C

Centec 2A Photographs Centec 2A Photo Essay

Centec 3 & 4 Series & Automil

Accessories New Vertical Heads Vertical Head Raiser Block

Available for Centec Millers:

Copies of the Original Instruction Book for the

2A, 2B, 2C & Automill

A heavily modified Model 2B/2C, with hydraulic (Mk. 2) and then pneumatic (Mk. 3) drive to the table, the "Automil" was made in much smaller numbers than the conventional machines. Commonly found on a heavy cast-iron stand as a conversion from the 2C, it began life as the Mk. 1 on the ordinary heavy-sheet-steel cabinet as a modified 2B. Later 2C based Mk. 2 and Mk. 3 Automils were fitted with a 30 International spindle, a heavier overarm with a modified bearing in the drop bracket, a wider column, stronger table and knee and 1.5-inches extra clearance under the cutter. If you find an Automil, the rear of the two cylinders upon which the table rides is exactly in line with the original position of the longitudinal feed screw and it is. therefore, a relatively simple task to convert it manual "2B/2C" operation.

Specially designed machines, suitable only for repetition production work, the Centec 3 Series millers had their tables driven by pneumatics, the control being by a simple but effective system of stops. The table could move only longitudinally, the cross and vertical traverses being provided by the head.

Built as the final conventional models was the 2C, a version of the 2B but with the heavier overarm from the Automil and 30 INT tapers in both vertical head and horizontal spindles..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A Mk. 1 Centec Automil with hydraulic table drive. Recognition points for these rare early models include a parallel-sided main column, with a baseplate similar to that used on ordinary 2B, and the sheet-metal cabinet stand.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Centec Mk. 3 Automil Hydraulic Controls

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Centec Automil Mk. 2 and Mk. 3. With a catalogue specification and illustrations that appears identical, the differences between the Mk. 2 and Mk. 3 Automil remain a mystery.

|

|

|

|

|

|

|

|

|

|

|

|

|

Centec 3 & 3R 2-dimensional Production Milling Machines:

With a 34.25" x 11.75" table (8" x 30" working area and 14" of travel) and head both hydraulically driven the 3-Series models were considerable larger and heaver than the maker's conventional machines. The spindle was fitted with a substantial 40 International nose, the spindle drive motor 3.5 h.p. and the hydraulic pump motor 2 h.p.. Infinitely-variable speed drive was fitted which gave a range of 50 to 1400 rpm or, optionally, 200 to 2000 rpm. The 3R was fitted with the refinement of a programme control to the vertical motion of the cutter head in addition to that provided for the table. The aim was to shorten production times by combining, where possible, more than consecutive milling operation in one automatic cycle and also to reduce the length of the cutting path by eliminating unnecessary in-feed of the cutter. Approach movements both horizontally and vertically were 300 inches per minute..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Centec 3R. A rear view with the cover removed from the vertical feed-control mechanism

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rear view of the Centec 3R showing the vertical travel indexing mechanism. The height of the cutter head at any position of the table or point of the cycle was fixed by six adjustable positive stops mounted on an indexing turret head. If a new depth of cut was required the turret rotated to a new position (as the head reached the top of its travel) and the head moved down until it contacted the new stop.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Centec 3 table-control slide. Normally hidden under the front bed cover the unit consisted of a detachable plate with 6 slots holding adjustable buttons. The position of the buttons in the four lower slots determined if the table was to move at a controlled feed rate, or at a fast traverse. Buttons in the upper two slots set the point at which the table motion stopped and the head motion began. The infinitely-variable rate of feed of both head and table was set by the rotary dial seen below the control slide.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Once a job had been set the control slide and its buttons could be removed and stored - in effect a physical memory - that allowed very short set-up times to be achieved

|

|

|

|

|

|

|

|

|

|

|

|

|

Centec 3P. This model was of similar construction and configuration to the Centec 3 and 3R but fitted with a mechanism whereby the height of the cutter above the table was continuously controlled by a template and tracer valve. Shapes with angles up to 80-degrees from the horizontal, and very slow tapers, could be accurately copied without steps.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Centec 3RV and 3V programme-controlled vertical milling machines

These millers had exactly the same programme controls as the horizontal 3 and 3R but were fitted with a vertical head of robust construction carrying a spindle supported in large, closely-spaced roller bearings and with a 30 international or No. 3 Morse taper nose. For setting purposes only the head was provided with a small amount of hand-operated cross movement, operated through a calibrated dial. Spindle speeds ran from 73 to 366 r.p.m in low range and 366 to 2200 r.p.m. in high.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Centec Automil Duplex

An especially low-volume model, this was built up from standard Centec components, mounted on a wide stand, and arranged so that parts could be milled simultaneously on opposing ends. Each spindle was driven by a 1 h.p. motor, the table had 14-inches of travel, with a fast traverse in both directions, and a stepless feed rate from 1 to 400 inches per minute.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A typical Centec "Automil Duplex" job: a component in E.N.35.B with two flat milled simultaneously. Floor to floor time 12 seconds

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Centec No. 4 Production Horizontal Miller with programmed hydraulic table movements.

Another Centec produced in smaller numbers - and one of the last to be made - was the No. 4. A much larger and heavier machine than the 2A and 2B, it supplied as a horizontal miller only with a program-controlled and hydraulically-powered 10.5" x 40.5" table with 18 inches of longitudinal movement, 7 inches in traverse and 13 inches vertically. The table-drive system, powered by a 1.5 hp motor, used Centec patents (which were applied for, but probably never granted) that gave a very high thrust with a 300-inch-per-minute fast-traverse facility; the feed was stepless and could be set to run from 0.5 to 50-inches per minute. The main spindle, with a 40 Int. nose, ran in three precision bearings with the one immediately behind the nose being a taper-roller type with an inside diameter of three inches. 10 speeds were provided, of 50 to 2000 rpm, by either a 3 hp or 5 hp motor. The machine was intended for high rates of production with one end of the table was left open so that swarf and coolant could drain away quickly into a detachable collector. Rigid stops with micrometer adjustment collars were fitted at each end of the table to allow precise setting for dead stop and reversing - as might be used in plunge cutting - and the spindle was arranged to stop automatically during rapid table returns in either direction. Four slots in the front end of the table were used to house adjustable trip dogs by which means the required horizontal program could be quickly and easily set. To help cope with arduous, continuous use, a one-shot centralised lubrication system was fitted that supplied oil to all the slideways..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The machine was intended for high rates of production and one end of the table was left open so that swarf and coolant could drain away easily into a detachable collector. One of the micrometer stops is visible on the front face of the table.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table controls: 5 - the trip dogs to set longitudinal program; 6 - Micrometer-adjustable stop; 8 - one-shot lubrication; 9: automatic spindle-stop control.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

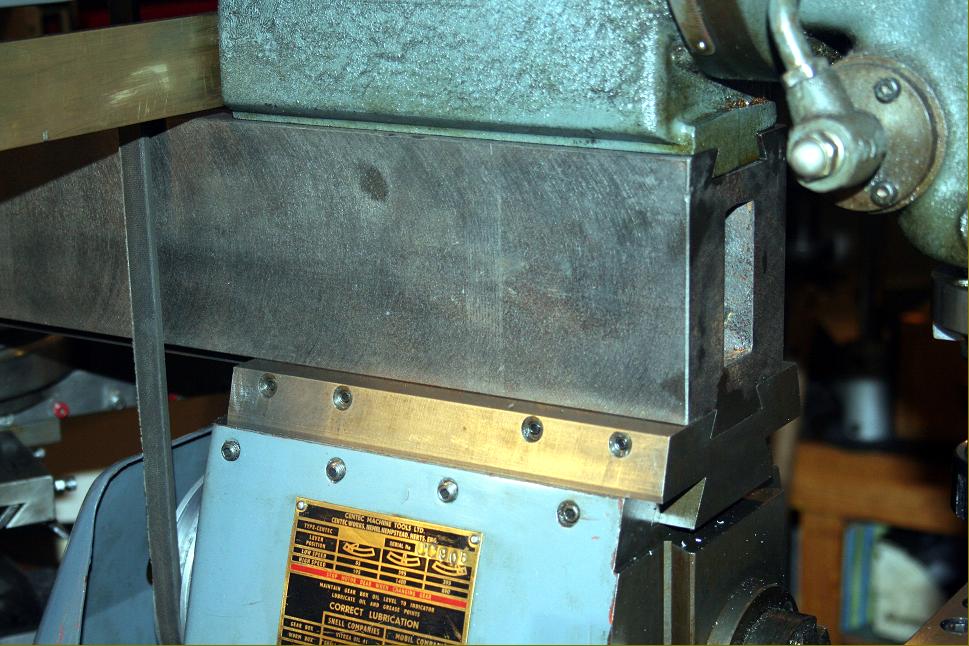

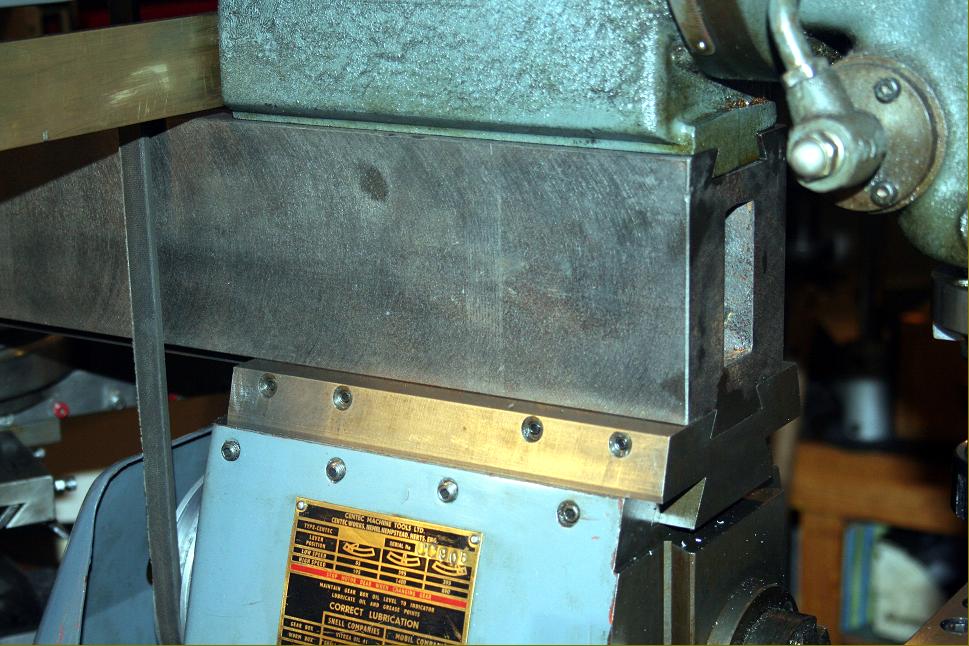

An interesting picture showing a Centec 2C with both the maker's adaptor plate (to allow the standard vertical head to be fitted to its wider column) and the lathes.co.uk raiser block in place

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|