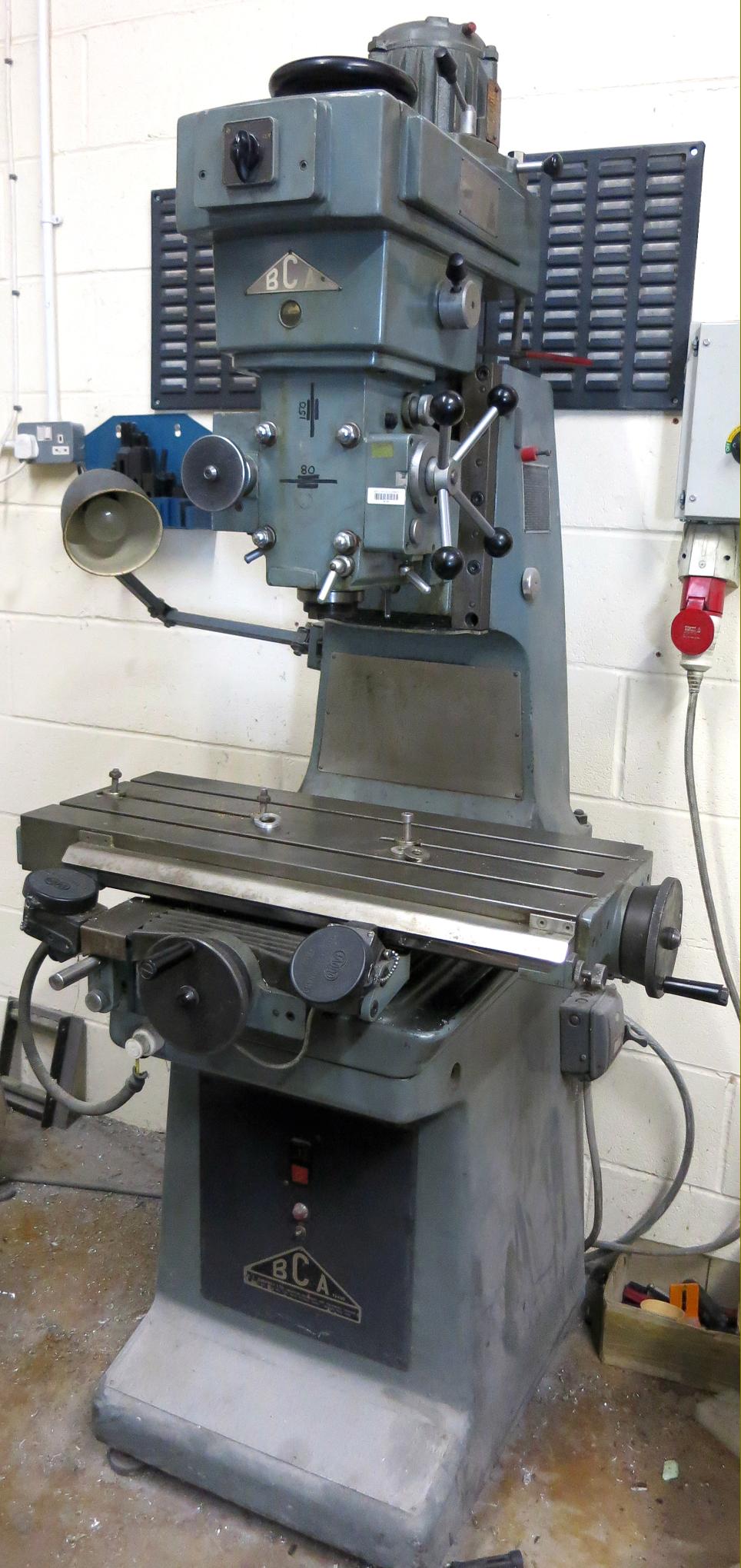

B.C.A. Optical Page 2 BCA Home Page

Manufactured during the 1960s and 1970s by R.E.Godfrey Ltd. of King's Mill, King's Mill Lane, South Nutfield, Redhill, Surrey, England, the BCA "Optical Jig Borer" complimented the company's much smaller but better known Mk. 3 bench-mounted "precision jig borer and driller".

With a fixed height table and its vertical head moving in a ground dovetail slide formed on the front of the main column the "Optical was built along traditional jig borer lines and was, at 14 cwt (711 kg) without a motor, massively constructed for its size. The head assembly (actually from a Mk. 2 Beaver BVRP) with the main drive motor at the back, was completely self-contained and had its 7-inches (178 mm) of travel driven by a 4-handle capstan wheel working through a bevel box and large-diameter vertical screw than ran though a massive bronze nut. The slideway clearance was set by a tapered gib-strip with adjusters at both ends and the vertical adjustable stop was fitted with a dial indicator to ensure absolute accuracy.

The 33/8"-diameter hard-chrome-plated quill carried a 20 INT taper nose and was both bored through to take a draw bar and had a screw fitting on the end for direct-mounting cutters. It could be raised and lowered by both a fine-feed handwheel working through worm-and-wheel-gearing or at one of three rates of power feed: - 0.0015", 0.003" and 0.005" (0.0381 mm, 0.0762 mm, and 0.127 mm) per minute. Using the hand feed 5-inches of quill travel was available but with power engaged the working of an adjustable automatic safety stop caused this figure to be slightly reduced. Machines build during the 1960s had a 3 h.p. motor driving through 5-step V-pulleys that gave, in conjunction with a single-lever-operated reduction gear, a choice of 10 speeds from 70 to 3000 rpm. Later models were fitted with a 3 h.p motor and a mechanical expanding-and-contracting variable speed system that (including the use of the same reduction gearing) gave stepless changes over exactly the same speed range whilst incorporating a useful lever-operated spindle brake. Spindle revolutions on the later models were indicated by dial set into the front face of the head.

Besides a beautifully-engineered, smooth running and rigid head assembly a jig borer requires a particularly well-supported and accurately-made table and the 12" x 10" (305 mm x 762 mm) example on the BCA was a good example of its type. Whilst the outside T slots ran the full length of the table that in the centre was split into two 10-inch lengths (socketed at each end) that left a robust solid section in the middle. The slideways were ground-finished, adjusted by tapered gib strips and the feed screws fitted with ball thrust races to ensure as smooth a feel as possible to the controls. Longitudinal travel was 15 inches (381 mm), cross travel 6 inches (152 mm) and the maximum clearance beneath the spindle nose 17 inches (432 mm). Instead of engraved micrometer dials - and in advance of the yet-to-be-invented digital readouts - the table feed was measured by an Italian-manufactured "O.P.L." system whose circular optical readers incorporated an illumination system and, with a magnification of 10x, the ability to read down to a positional accuracy of 0.0001". Because the readers were necessarily fragile affairs they were protected when not in use by lift-off plastic or metal caps chained in place to ensure that they were not lost.

A full range of accessories was available including: 5 and 8.5-inch capacity universal boring heads, pneumatically-driven high-speed grinding unit, plain 4-inch and 6-inch 2-speed machine vices, 6-inch swivel-base vice' precision-ground 2.25-inch and 4-inch vices, 12-inch rotary table, angle setting block, table clamps, clamping block set, Albrecht keyless drill chucks, Clarkson Autolock chucks and various spindle reducing arbors.

In January 1969 the BCA was listed at £1975 but by October 1972 this had risen, thanks to rampant inflation, by 77% to £3500. Frightened that a subsequent user might kill themselves and sue, during the early 2000s, one of the country's leading universities sold a mint-condition early model for the scrap price of £150…