|

The History of "Newall" is both complicated - and uncertain. The Company appears to have its origin in the Newall Engineering Company of Atherton's Quay, Warrington, a firm established around 1890. At the time the need to eliminate expensive and time-consuming hand fitting of machined parts (by "fitters") was becoming obvious and to do this it was necessary to introduce some form of accurate checking - and it was to this market that the Newall Engineering Company turned its attention. The solution was the use of highly accurate gauges, these allowing the mass manufacture of truly interchangeable parts by a "standard limit" system - some of the gauges being of the "go-no-go" type where an operator could check that a part either passed through a gap or did not. In practice, as parts came of a lathe or grinder, etc, it was now simple to check if tolerances were being held and, if not, to stop the machine and make the necessary adjustments.

By 1909 Newall was making not only limit gauges but measuring machines, and micrometers and must have been seen as a good investment as it was purchased in its entirety - plant, stock, patents and goodwill - by a Mr. Peter Hooker.

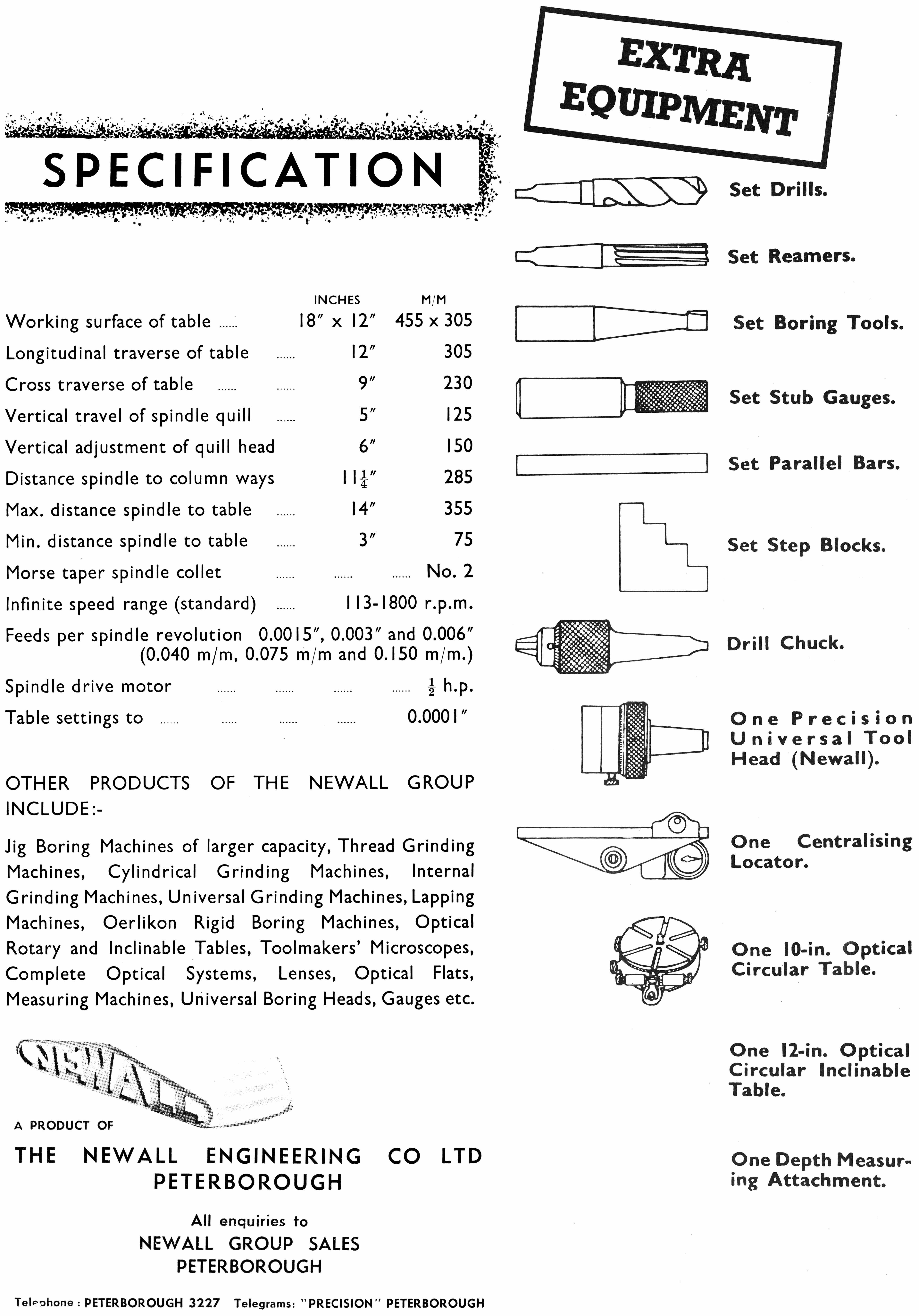

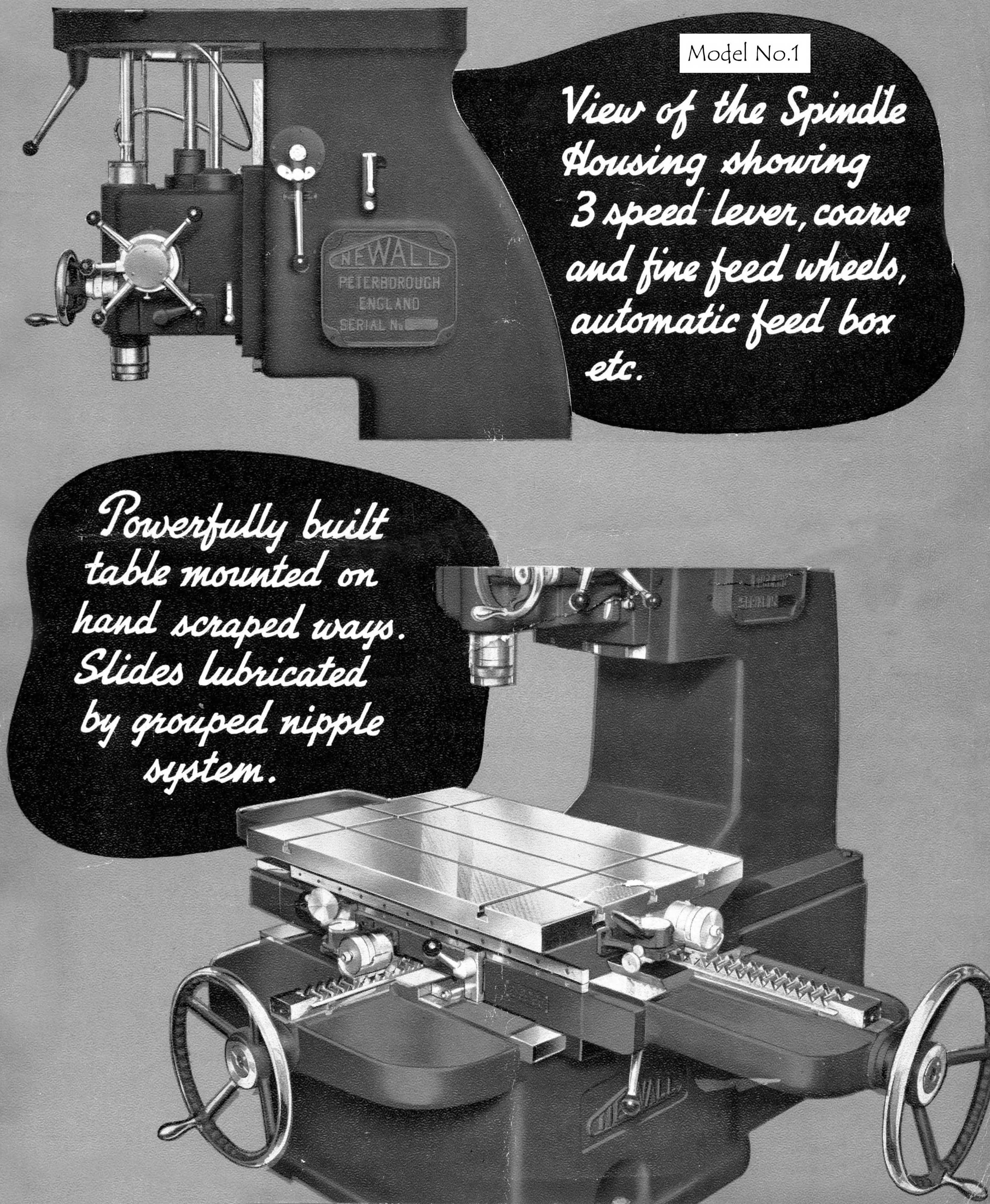

The next stage of the firm's development is uncertain, but it appears that, with his extensive business interests, Hooker might have set it up under a slightly different name in 1900. By 1933, a move had been made to the manufacture of machine tools with a new factory being built in Peterborough in 1935 and a second opened in 1957. By 1961 the Company was at its zenith with 1000 employees and had been organised as the Newall Group, consisting of the main Newall Engineering Co. Ltd. (Peterborough), Optical Measuring Tools Ltd (OMT), Keighley Grinders Ltd. (Keighley), James C. Kay & Co. Ltd. (Newall Precision Foundries, Ironfounders in Bury), and Machine Tool Electrics Ltd. (Leigh-on-Sea) and Stockdale Newall Machine Tools.

In 1968 a licence agreement was arranged with Burgmaster of USA for sales of their machining centres into Europe with a wholly-owned subsidiary Newall-Burgmaster being formed with premises in Croydon.

By the early 1970s, the British machine tool industry was starting to struggle and Government support was needed, Newall receiving money, in 1972, to further develop their grinding machines. Even so, losses continued to mount and forced the closure of two factories - though by 1976 the Group was back in profit and in 1977 was acquired by the ever-expanding B. Elliott and Company.

By 1986 manufacturing was limited to completing existing orders and a move was made to Keighley with the design and development department transferring in 1988 from Peterborough where the No. 2 factory finally closed - through Newall Electronics and the Re-Newall companies continue to operate in the town (the former being eventually acquired by J M Clarke (Leicester) Ltd. Finally, in 2003, the remains of the Newall Company are acquired by Danobat.

Items manufactured over the years by Newall and its associated companies, included gauges, jig borers, jig erosion machines, a range of grinders including plain and thread types, electrical switch and control gear and electronic equipment, a small precision bench lathe, a range of high-precision optical measuring and inspection instruments, the OMT-built Precision Measuring Machine, tank telescope gun sights for the army, ordinary and inclinable circular tables with and without optical scales, a 30-inch automatic indexing rotary table, standard and major horizontal omtimeters, a vertical omtimeter, bench-mounted microscopes for use in the toolroom, lathe-tool setting and thread-form inspecting microscopes, optical flats, large and small form of projector to magnify and check manufactured parts, camera lenses, prisms and a range of precision boring heads. Items added in later years included a 35 mm motion picture projector, some 200 film cameras costing up to £8000 each for the rank organisation, a roundness measuring machine (in competition with the well-known and still-manufactured Taylor Hobson Talyrond), a projection pantometer for the inspection of parts with three-dimensional contours such as turbine blades, specialised, universal and very large projectors (some of the latter weighing over 4 tons), equipment to inspect thread forms, surface-coated mirrors, anti-reflecting coatings, multi-layer films, neutral filters, metallic electrical conducting coatings, 35 mm film printers, cinéradiography cameras, Newall-branded 35 mm cameras for Technicolor Ltd. and even polyhedral prisms designed for experimental colour television in the United States. With the takeover by Elliott, the range expanded to include an involvement in the products of Butler, Churchill and Snow.

There was also a department devoted to producing items to meet the special requirements of a customer.

|

|