Spindle and Bearings

During the first 6 months of use on the ML7 after it was cleaned up I managed to produce a lot of perfectly acceptable work with it, but it was obvious that there was some wear on the headstock bearings.

I had some runout and chatter apparant, and with the front bearing wear, the total-loss oil system on these meant that the oil would pass through much too quickly, and puddle on the tray, although the rear bearings were in much better condition.

When the ML7 was designed, provision was made to adjust for wear by using clever laminated shim packs under the bearings. Shims of 0.0015" thick were stuck together before being press-cut to shape, and the idea was that you could peel off a shim or two to take up the clearance. When I took the top bearing caps off mine, one side was shimmed around 0.004" thicker than the other, and years of running like this meant that the spindle would 'nip up' too tight if I tried to match the shim thicknesses, so I ran it like this, but probably had around 0.005" runout on the spindle nose as a consequence. There was also quite a bit of wear on the front white metal bearings. These bearings are soft and will wear and pick-up if not correctly lubricated, and the original ML7 Spindle was not hardened, so if not properly looked after these will quickly gall and become damaged.

This is how the bearings looked when the headstock was stripped down. You can clearly see the wear, and if you compare the depth of the oil grooves on the front and rear bearings you'll get an idea of how much it has worn.

Despite this, the spindle itself was in good condition with no galling or wear lines. The problem is that Myford no longer make these soft white-metal bearings, and can only supply new Phosphor Bronze bearings, which are too hard to run with the original un-hardened spindle, as in this case it would cause the soft spindle to wear badly.

So I had no option but to go for both a new hardened Spindle and new Phosphor Bronze Bearings. Ouch! Not cheap - the cost from Myford was £333.08 including VAT.

Here you can see the old spindle assembly as removed, and the new spindle still in it's packaging, and the lack of wear on the old Spindle, and the two side-by-side.

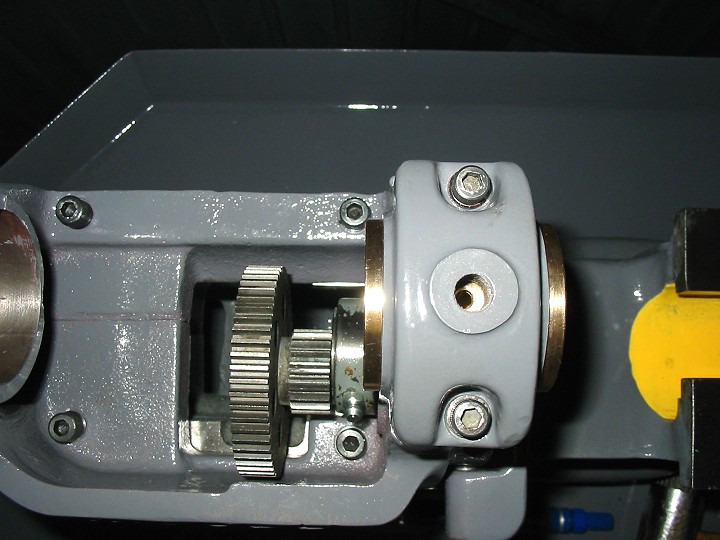

And here they are fitted into the rebuilt headstock. Now they look even better.

You can also spot one of the many new oil nipples sticking out from the backgear.

The next step was taking the pulley, backgear drive, and thrust bearings off the old Spindle and re-fitting them onto the new one, and murphys law on camera batteries struck again here, so no pictures of that stage.