|

Home Machine Tool Archive Machine-tools Sale & Wanted |

|

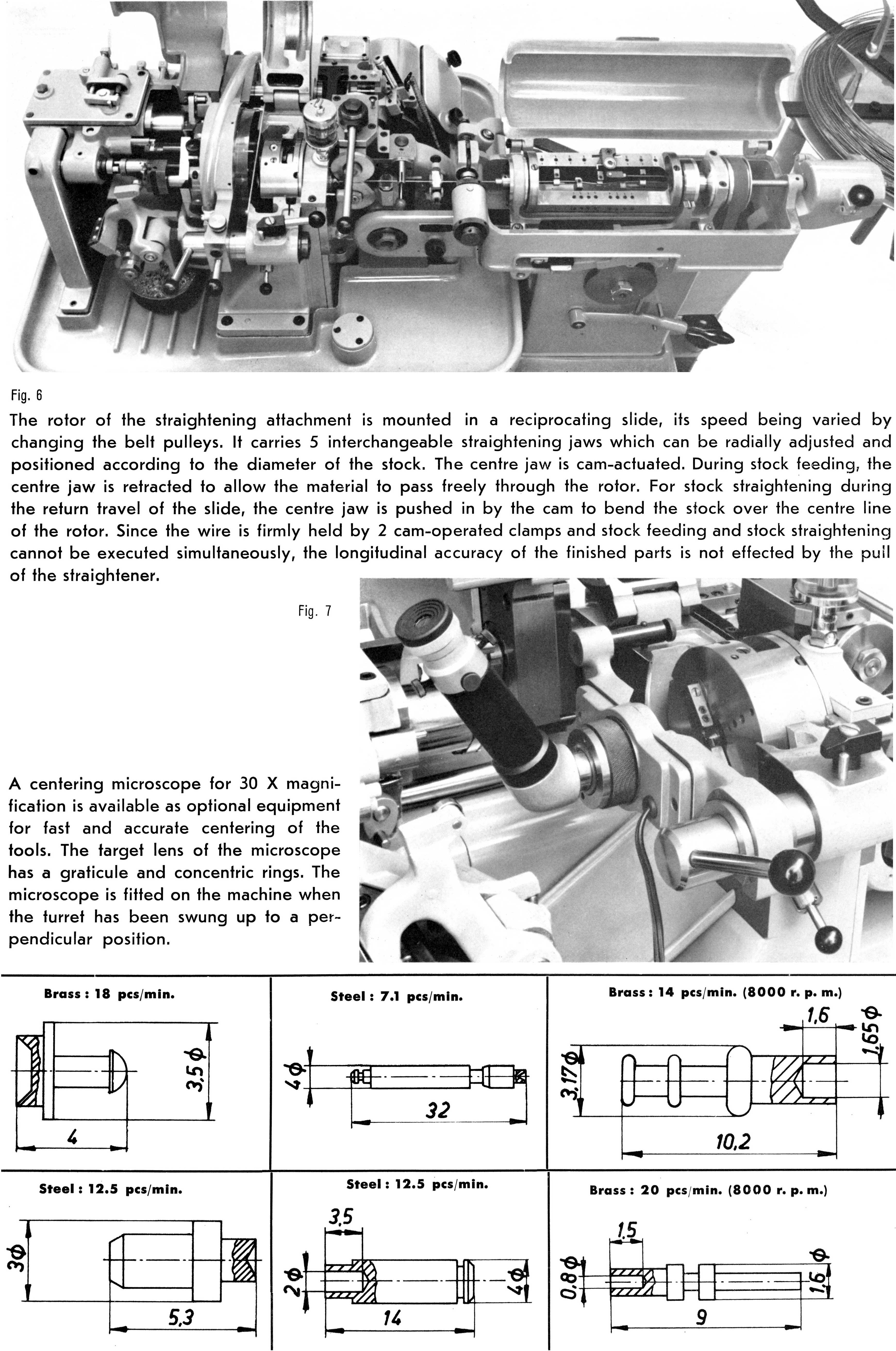

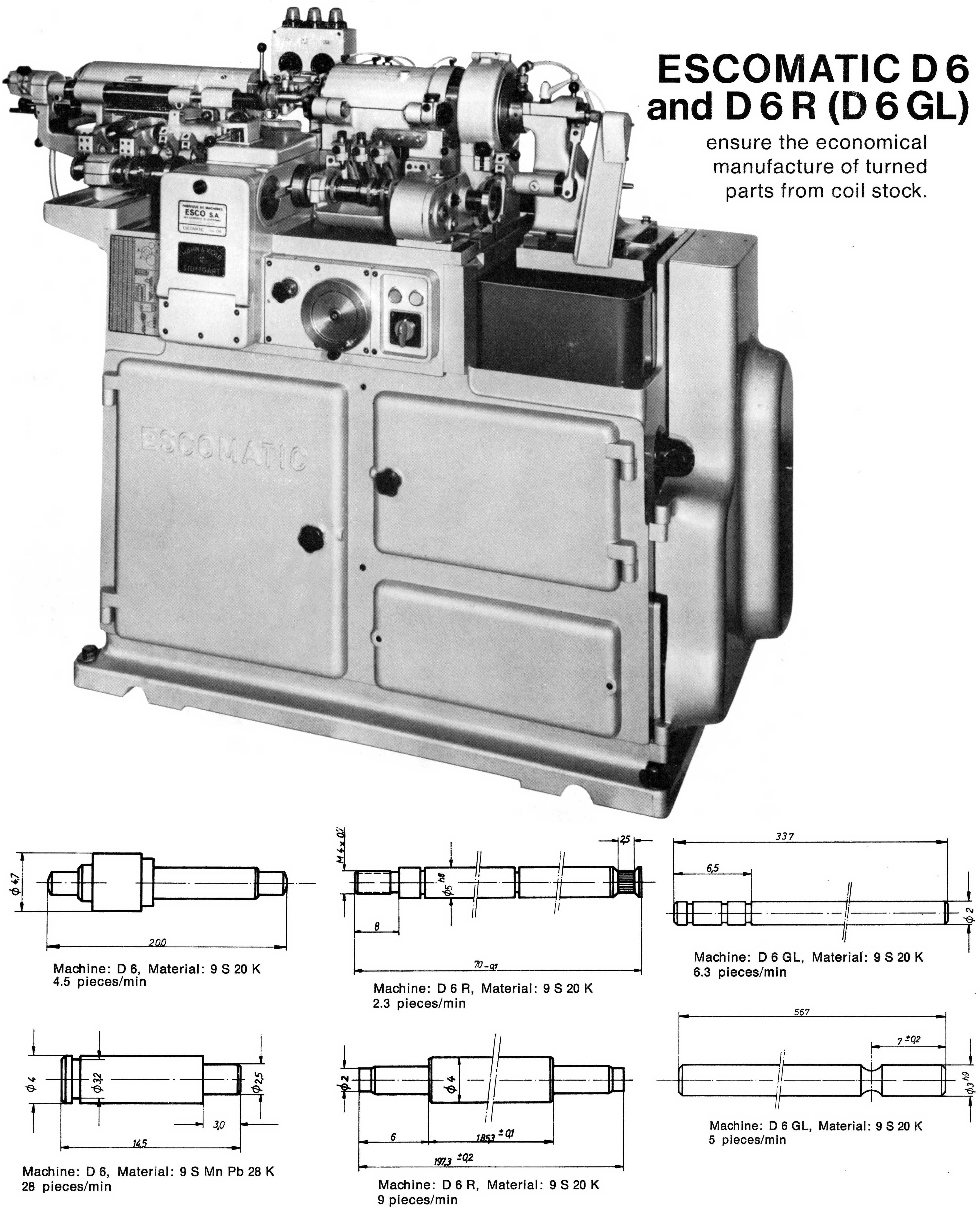

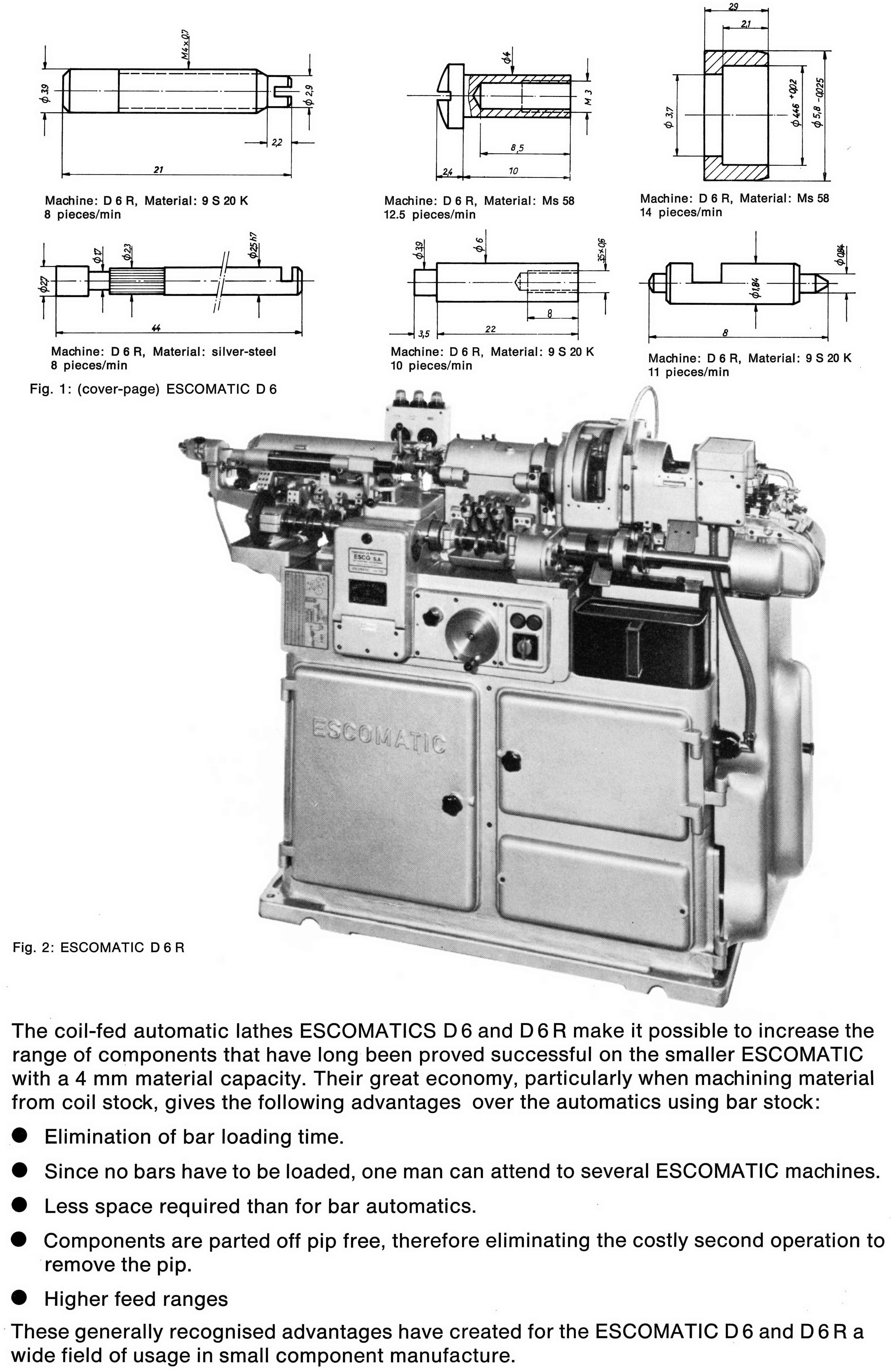

Still in production today in Switzerland by Ecso and equipped with the latest CNC control systems, Escomatic lathes were originally designed in the 1950s to offer high-speed production of parts for the watch-making industry. It quickly became apparent that they could also be employed for the automatic, high-speed production of many other tiny components and development of them continued to develop this facility. |

|

Home Machine Tool Archive Machine-tools Sale & Wanted |