|

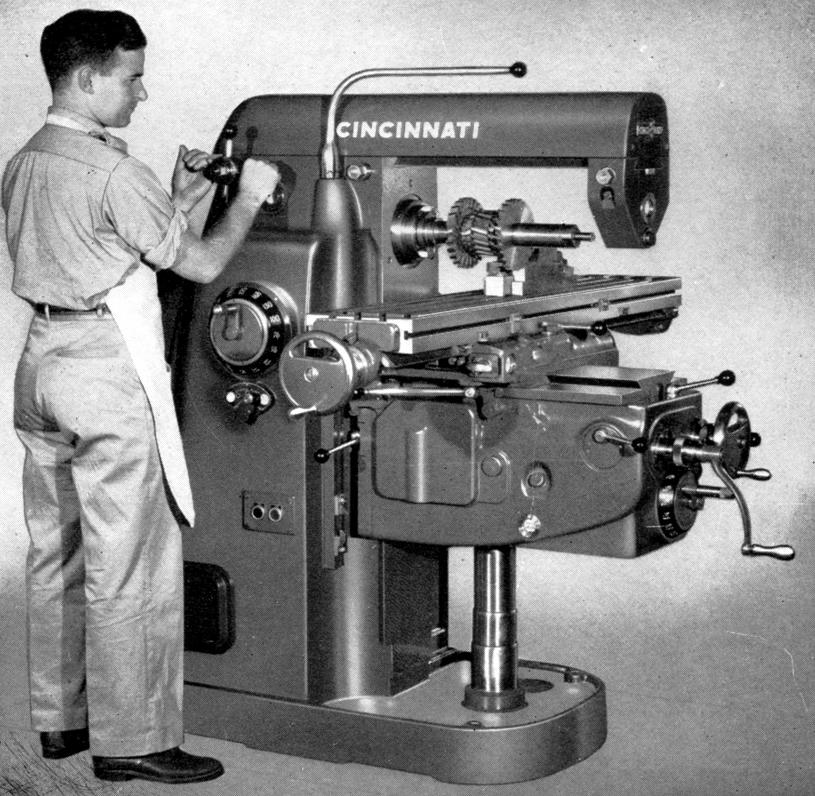

Home Machine Tool Archive Machine-tools for Sale & Wanted and 203/205/307/410 MI & ML Milling Machines Page 3 for the Cincinnati No. 2 MI and 205 M1 machines. Operating the Dial Type Accessories Factory Cincinnati Cinedo Cincinnati 8" x 18" Tool & Die Miller Cincinnati Contourmaster |

||

|

|

|

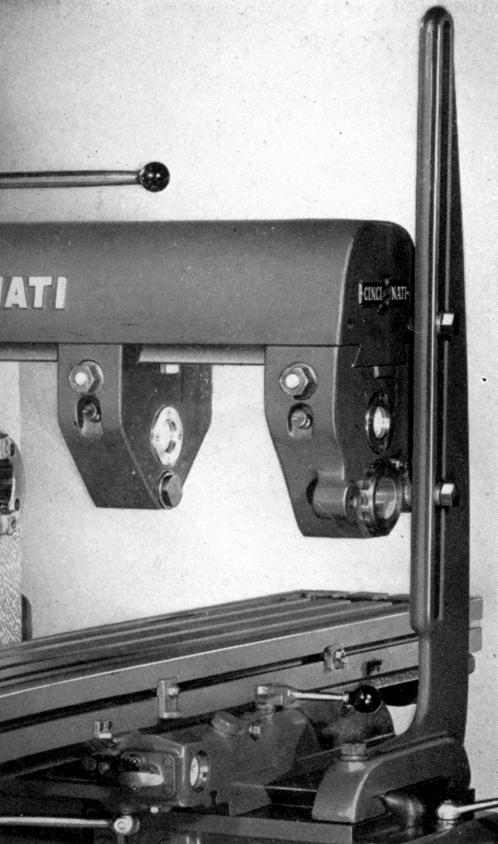

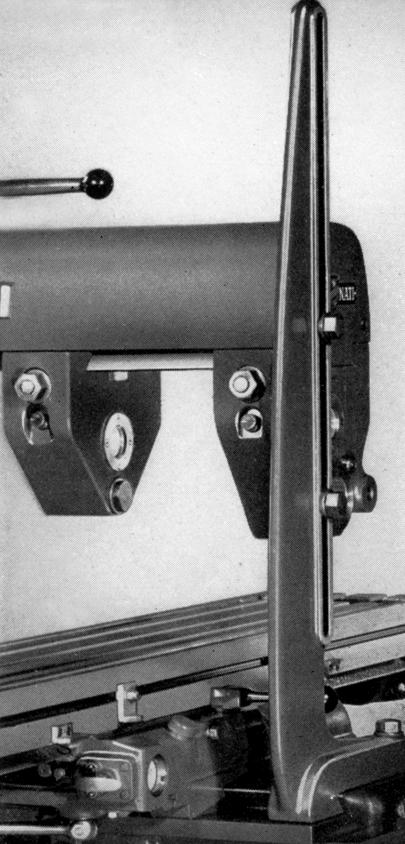

Two arbor supports (drop brackets) were supplied with each machine: both were made of aluminium and complete with an oil reservoir large enough to last for several days' use. Type A was intended for arbors with a plain end and the other, Type B, for those fitted with bearing collars - the latter also having provision to clamp on the overarm-to-knee bracing bar . |

|

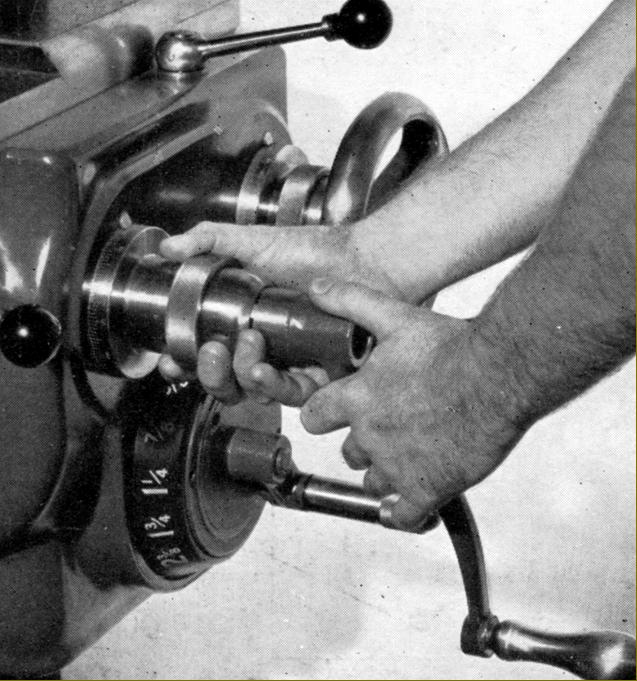

Relatively small but beautifully engraved, the micrometer dials used a pull-and-turn mechanism (against light spring pressure), to zero them - an arrangement that eliminated possible setting errors as a locking knob or ring was loosened or tightened. |

|

|

|

|

|

hand-pump drawing oil from a sight-glass-equipped reservoir built into the front of the saddle. |

|

for the Cincinnati No. 2 MI and 205 M1 machines. Operating the Dial Type Accessories Factory Cincinnati Cinedo Cincinnati 8" x 18" Tool & Die Miller Cincinnati Contourmaster and 203/205/307/410 MI & ML Milling Machines Page 3 Home Machine Tool Archive Machine-tools for Sale & Wanted |

||