|

Home Machine Tool Archive Machine-tools Sale & Wanted |

|

|

|

|

|

Some versions of the lathe were fitted with a spindle-direction control shaft below and parallel to the leadscrew with an operating handle (A) fastened to the right-hand face of the apron. |

||

|

|

||

|

A 3-speed, 1 hp motor with its 4-step V pulley was mounted inside the cabinet stand on a height-adjustable plate pivoted on a bracket fastened to the substantial cast-iron door; opening the door automatically relaxed the belt tension, allowing the speed to be changed |

||

|

|

||

|

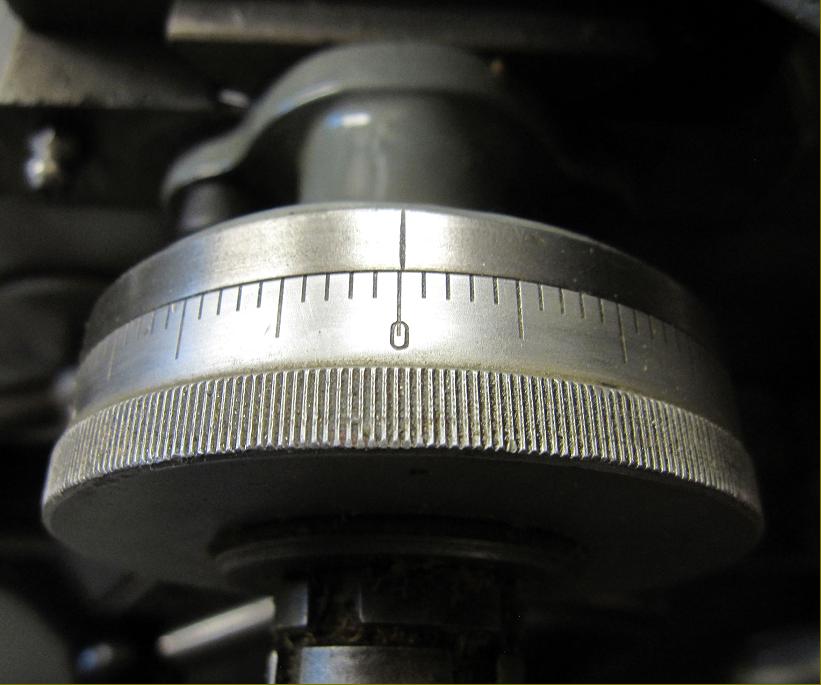

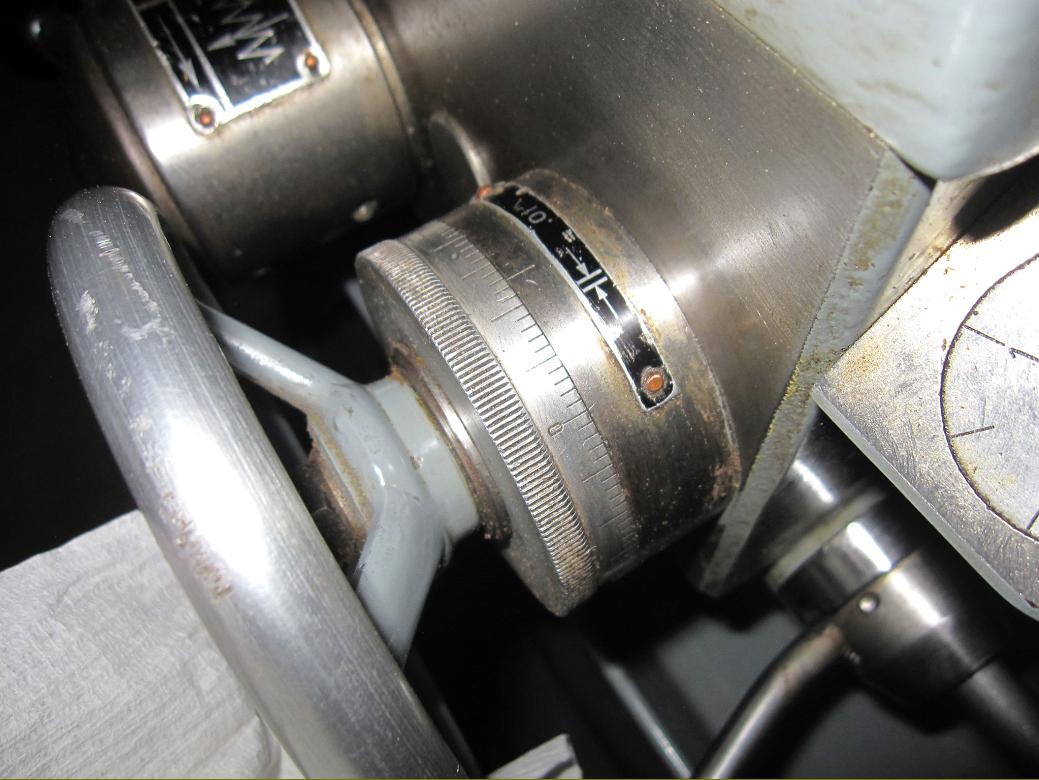

The compound slide rest was beautifully constructed; both grip strips were of the taper type and the feed screws were provided with miniature ball-bearing thrust washers to improve the feel against both inward and outward movements. |

||

|

|

||

|

|

||

|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||