Larger Barker Ram-head Milling Machine

Although the particularly rigid and heavily built little Barker horizontal milling machines began in the 1940s, demand for this high-quality machine continues even today with the Leyland-Gifford machine-tool organisation now being responsible for production. However, these may not be American-made machines - for it is known that the Hong Da Machinery Company Ltd. of Taipei, Taiwan built what appears to have been an identical copy of a late version- this being marked as the Type HMH. A surviving example (found in the USA) has a table around 12 inches long with a travel of approximately 3", carries the serial number 7072 and is dated July, 1976.

The Barker Company, in their original guise. were always a small organisation, who for many years appear to have offered just three Models: a rather unusual floor-standing ram-head vertical together with a little bench-mounting type, the stub-milling "PM" and the "AM", the former with the motor mounted on a pivoting plate set low on the column and the latter with it positioned near the top and with the top of the head enlarged to accommodate a round overarm. In later years, the range was extended with several variations on the theme offered including the original models (now with the option of hand or power-feed tables), the "PMO" with the head casting also able fit a round steel bar over-arm arbor support and the dual-head Type "AMD", a machine that could be equipped with automatic air-hydraulic feeds for production work.

Though tiny (width 22.25", length 24" and standing 18.5" high) the PM was no toy and intended for proper, professional work. Weighing around 175 lbs, it was very robustly constructed and so ideally suited to a wide variety of workshop tasks, including spline and key-seat cutting. The main spindle was hardened and ground, ran in pre-loaded taper-roller bearings and held its cutters in relatively tiny draw-tube retained 3C collets (as used in 9-inch South Bend and Boxford lathes) with a capacity from 1/16" to 1/2" diameter. However, although limited in its cutter-carrying ability, users report that, if kept within its (restricted) work envelope, it was stable and accurate. Early models had a simple, bolt-on outboard support for its stub arbor while later models were more highly developed with the option of a traditional (round) overarm that carried, on its outer end, a drop-bracket supporting the far end of the arbor.

Because the table was fixed (to aid stiffness) the head was arranged to move up and down the main column with, on the other side, the electric motor. In order to maintain tension in the V-belt (which ran over 5-step pulleys) the motor was carried on a bar that fitted into two downward-pointing slots - so allowing it to rotate slightly as the head rose and fell.

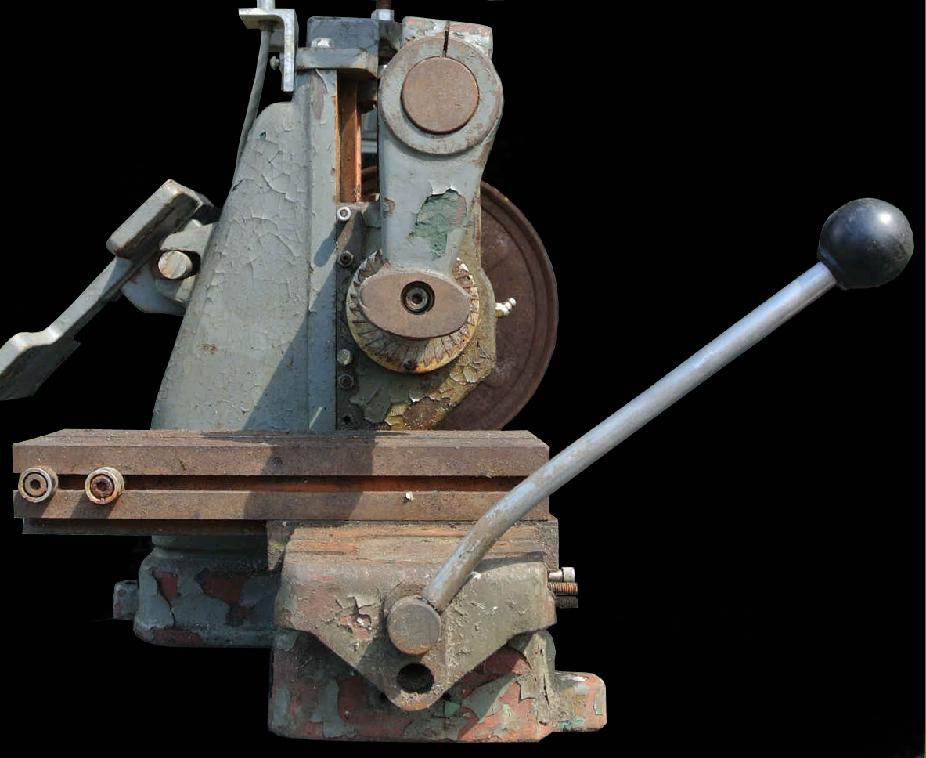

Shown below are two models: the first, a Type PM, was made in Cincinnati in about 1956 with a simple stub-milling arbor without overarm support. On this model (intended for production work) the 12" x 4" table (with 5 inches of longitudinal feed and 3 inches across) had both with quick-action lever feeds - though a screw-feed with zeroing micrometer dials on all axes was an option - and, of course, the better choice for precision toolroom jobs. The example illustrated has it main column raised by one of the two thicknesses of the cast iron height-extension block listed by the makers - though a caution was (sensibly) issued that no more than two should be used and, when so equipped, the mares wrote: We advise the use of lighter cuts. The second machine, a rather fine and original example, is the more robust Type PMO, this having a proper overarm support for the arbor and all-lever control of table and head.

If you have a Barker milling machine of any type, the writer would be interested to hear about it - or your experience of using it..

The maker's Serial numbers are listed at the bottom of the page..