|

Machine Tool Manuals Machine Tool Catalogues Belts Books Walker-Turner Wood Lathes Walker Turner Page 2 Walker Turner "Driver Add-A-Tool" variable-speed drive is available |

||

|

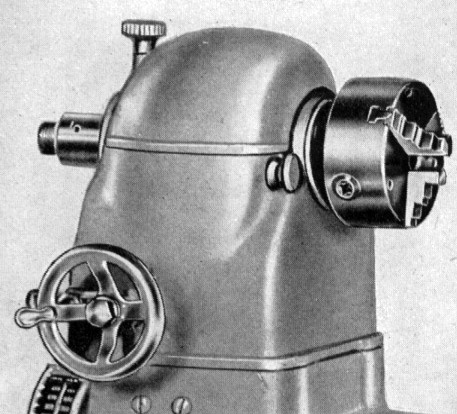

Walker-Turner were based, originally, in Plainfield, N.J. USA and made a wide range of metal and woodworking equipment including a combination wood and light-duty metal-turning bench lathe (of the plain, non-screwcutting type), and the most unusual "Driver-Add-A-Tool"; the latter, a universal wood and metal-turning machine, is shown in detail on this page. However, their most popular lathe was a variable-speed drive wood-turning model first advertised in the early 1940s that was to continue in, in various modified forms, until at least the early 1970s. This machine was also available in a simpler form, which appeared to use largely the same main components, but with a cheaper drive system that used ordinary V-belts - with the guard cover on the headstock left open to allow easy accesses to the pulleys. |

|

|

|

|

|

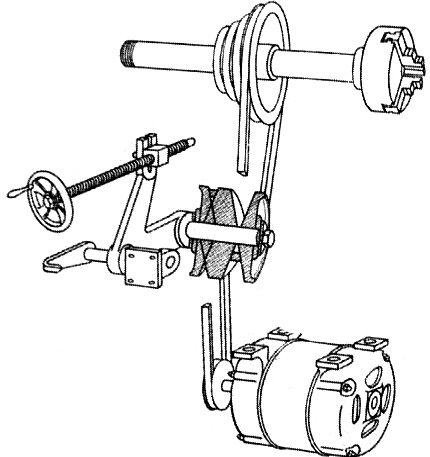

The variable speed drive system was simple but effective and used two V belts running through expanding and contracting pulleys mounted on a common shaft. This system was also used on certain of the company's band saws. |

||

|

|

|

|

||

|

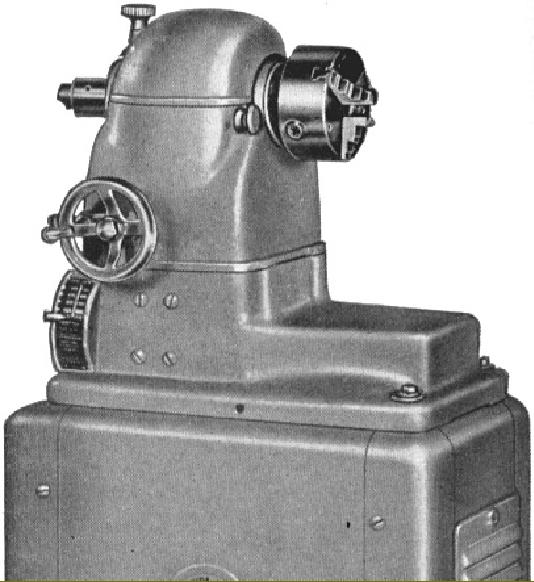

A "Polishing" or "Speed" lathe which used the complete headstock, variable speed drive unit and cabinet leg of the wood-turning model. |

||

|

variable-speed drive is available Machine Tool Manuals Machine Tool Catalogues Belts Books Sought - a copy of the "Driver Add a Tool" operating |

||