Unknown Lathes Home Page

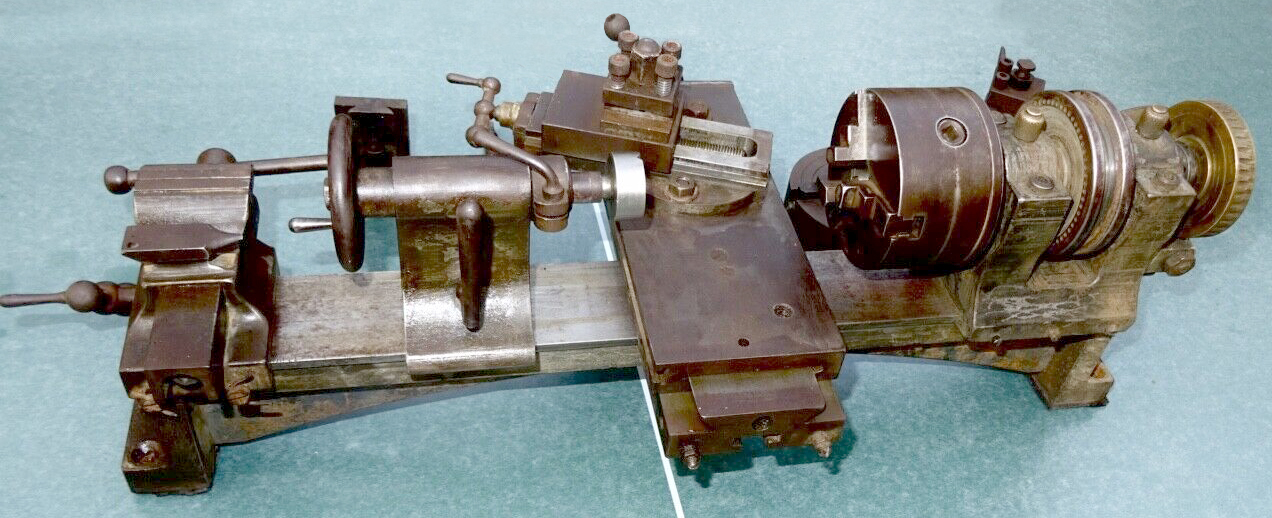

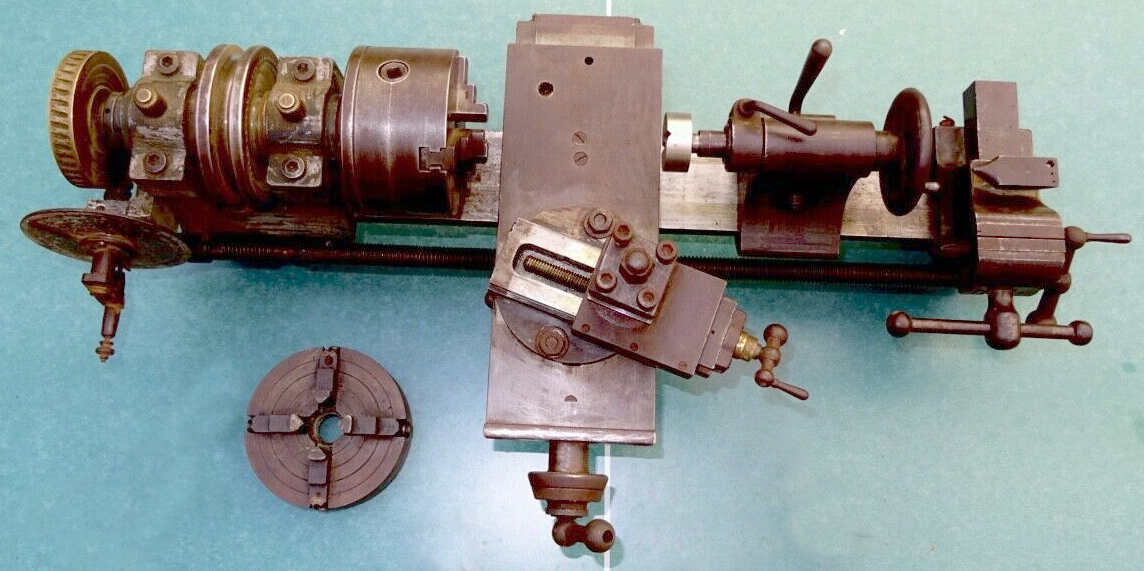

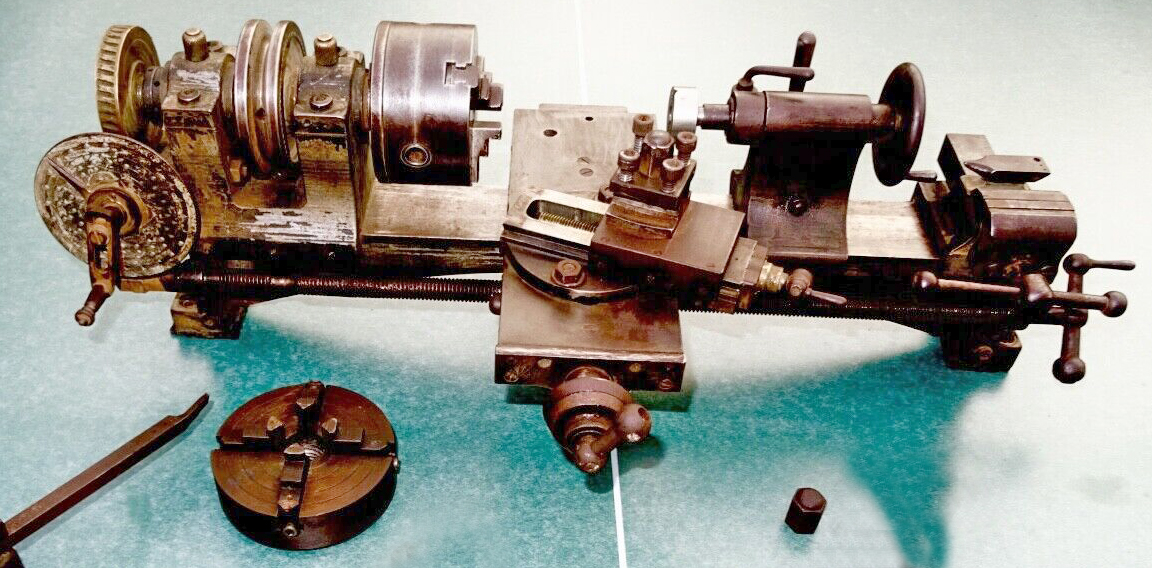

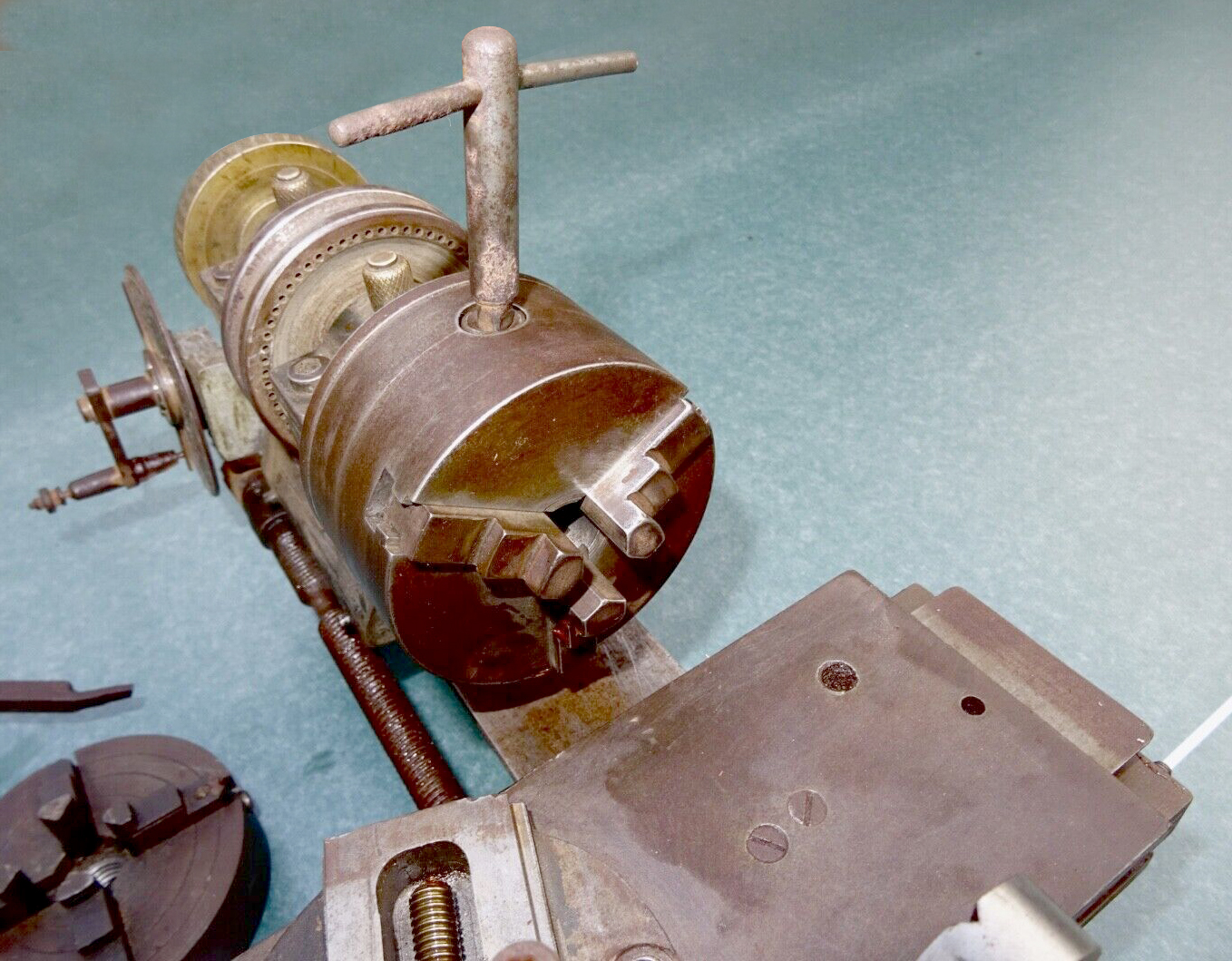

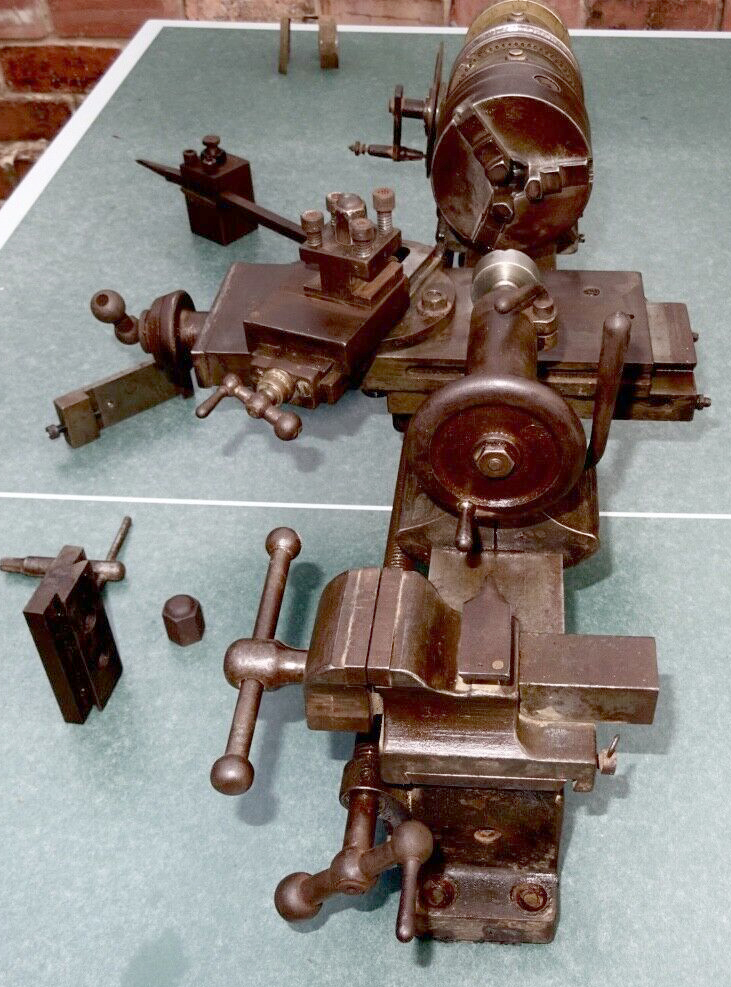

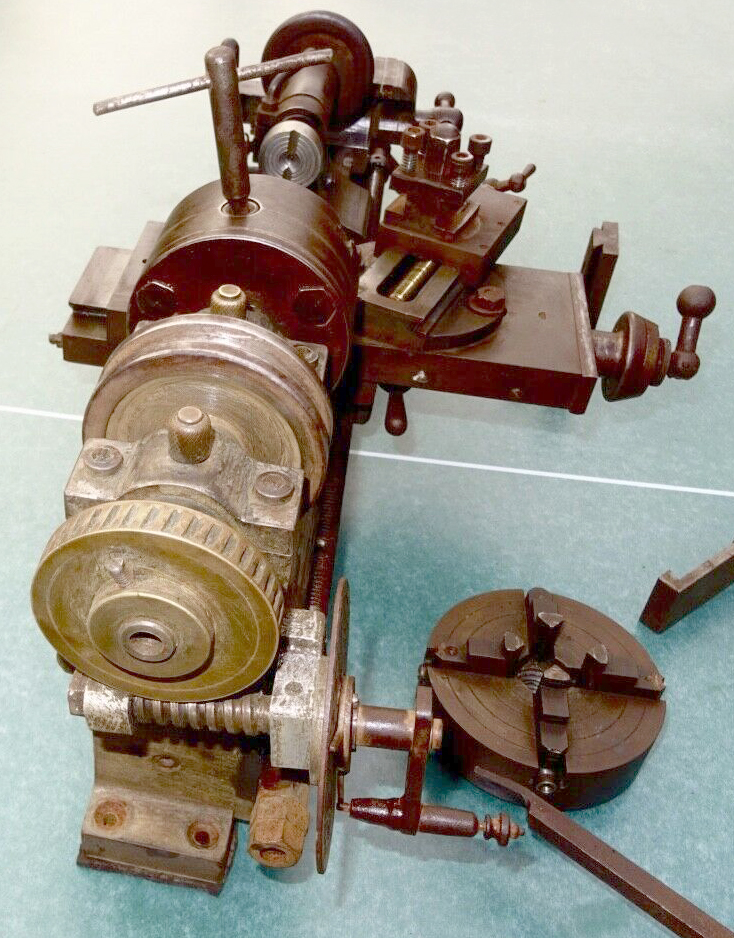

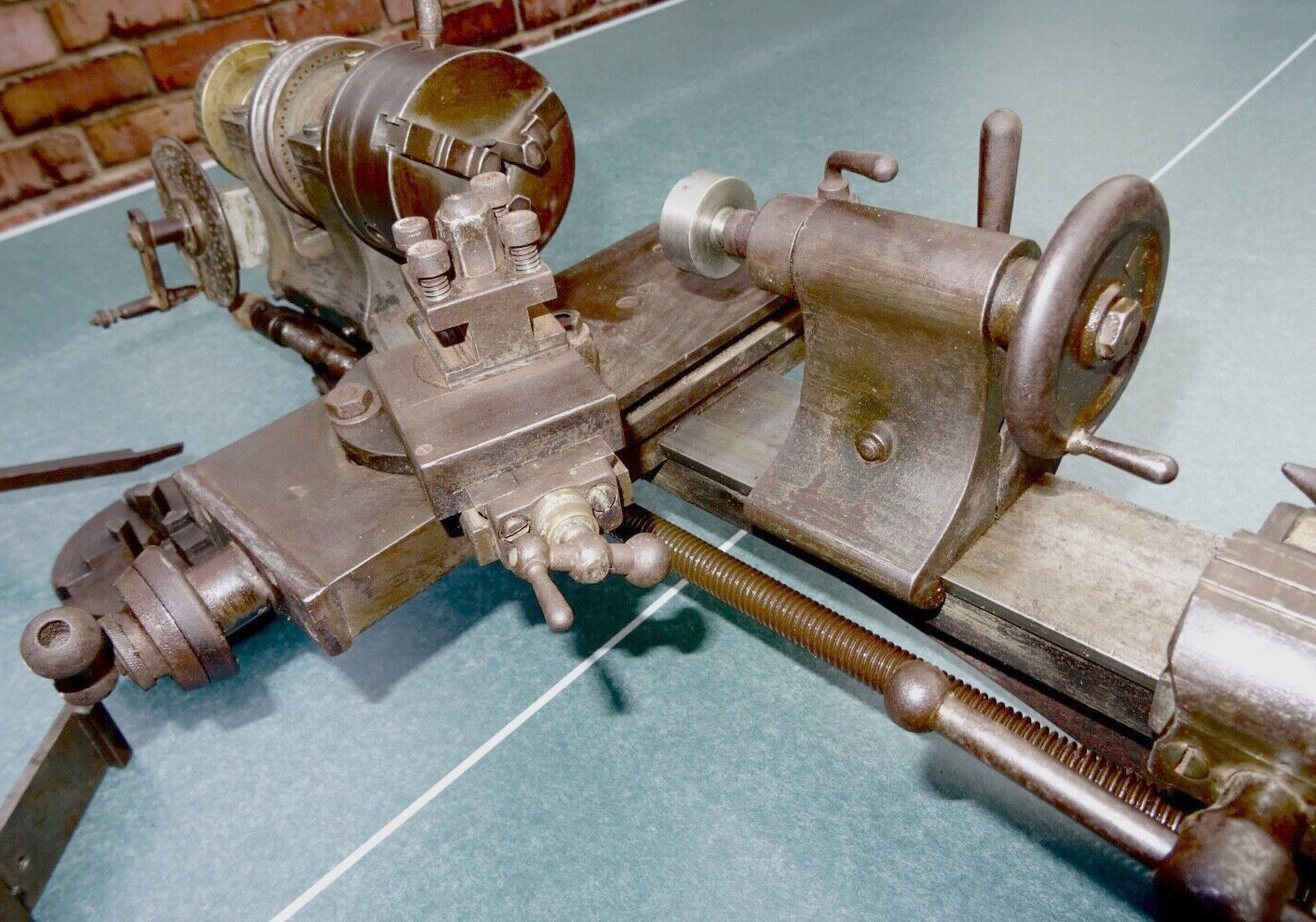

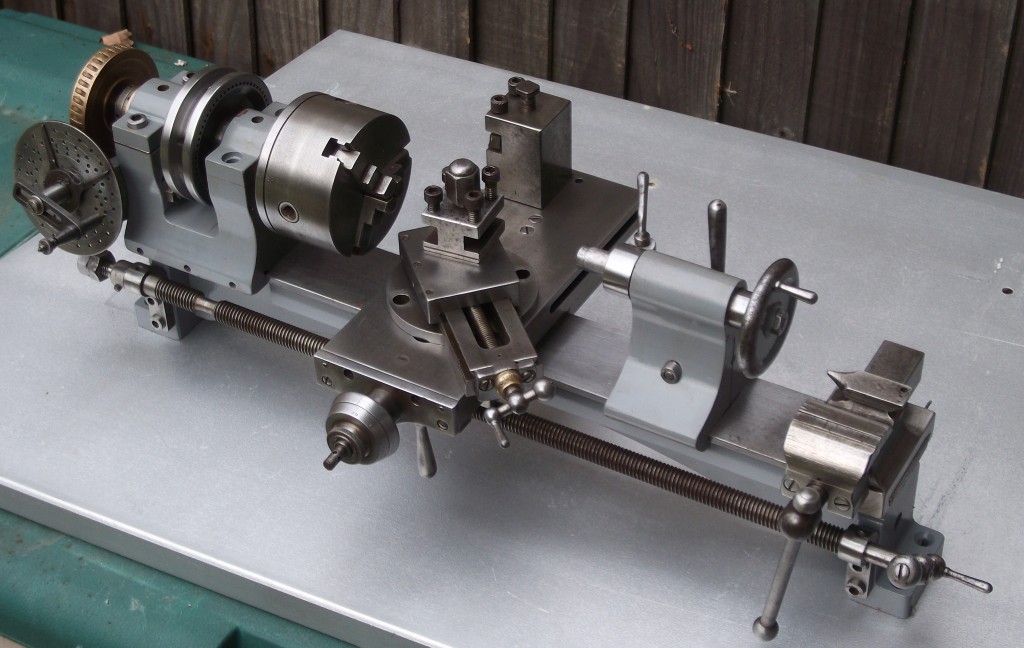

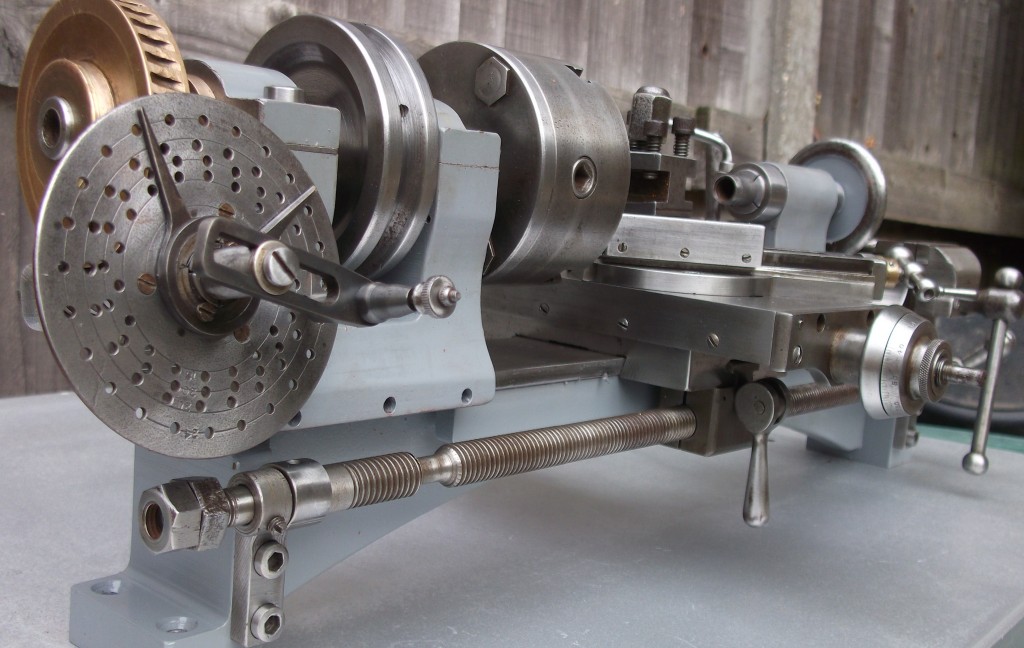

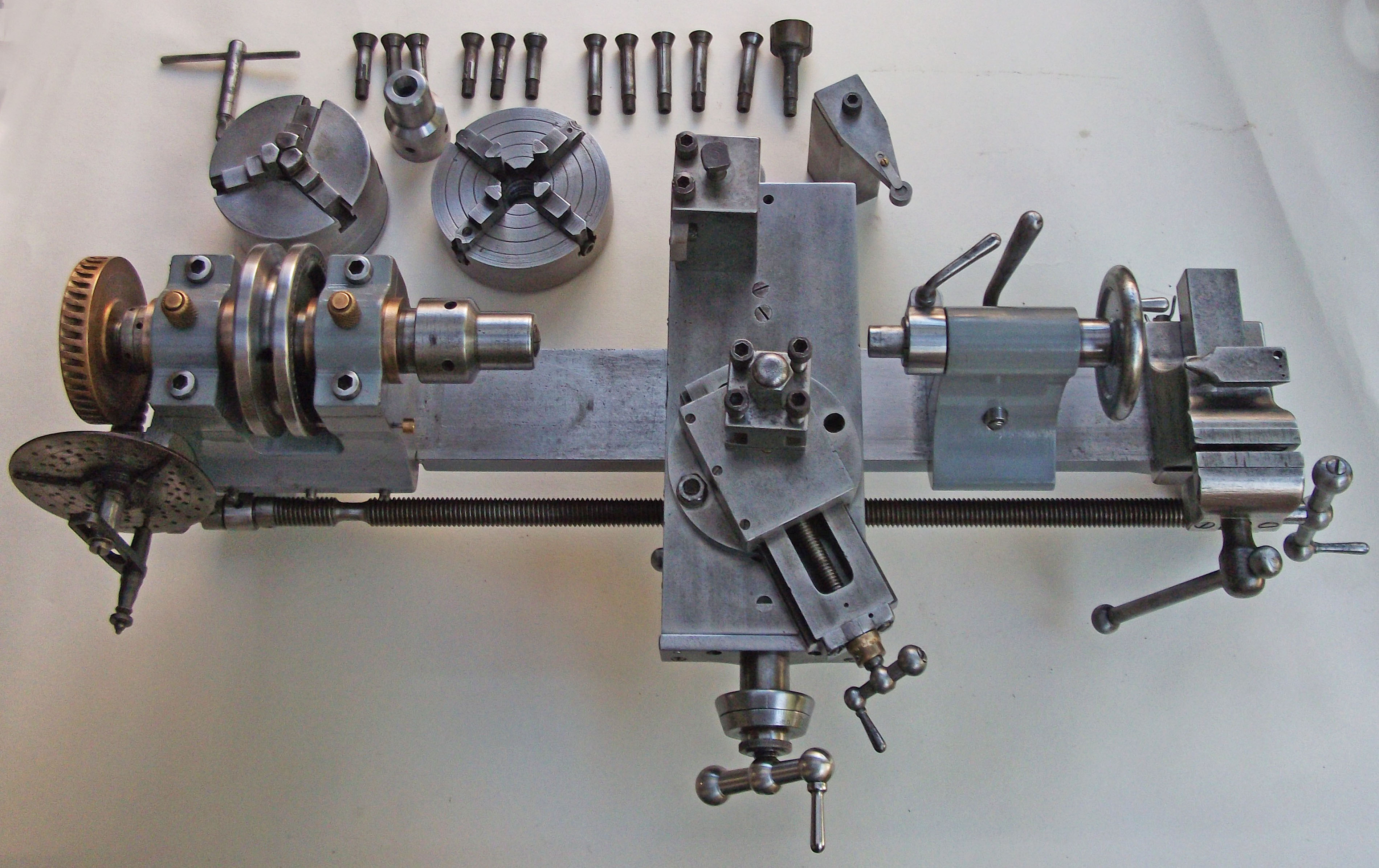

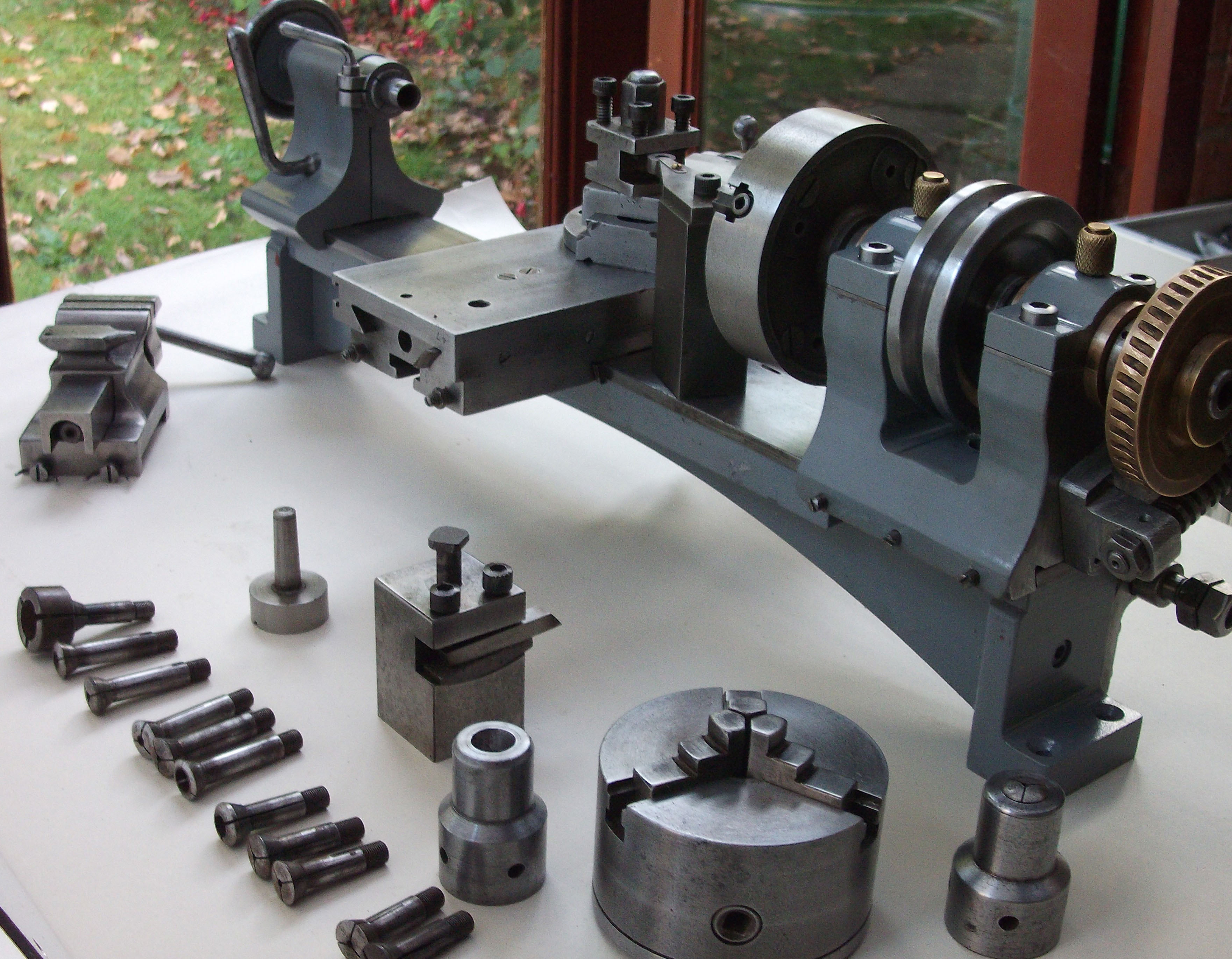

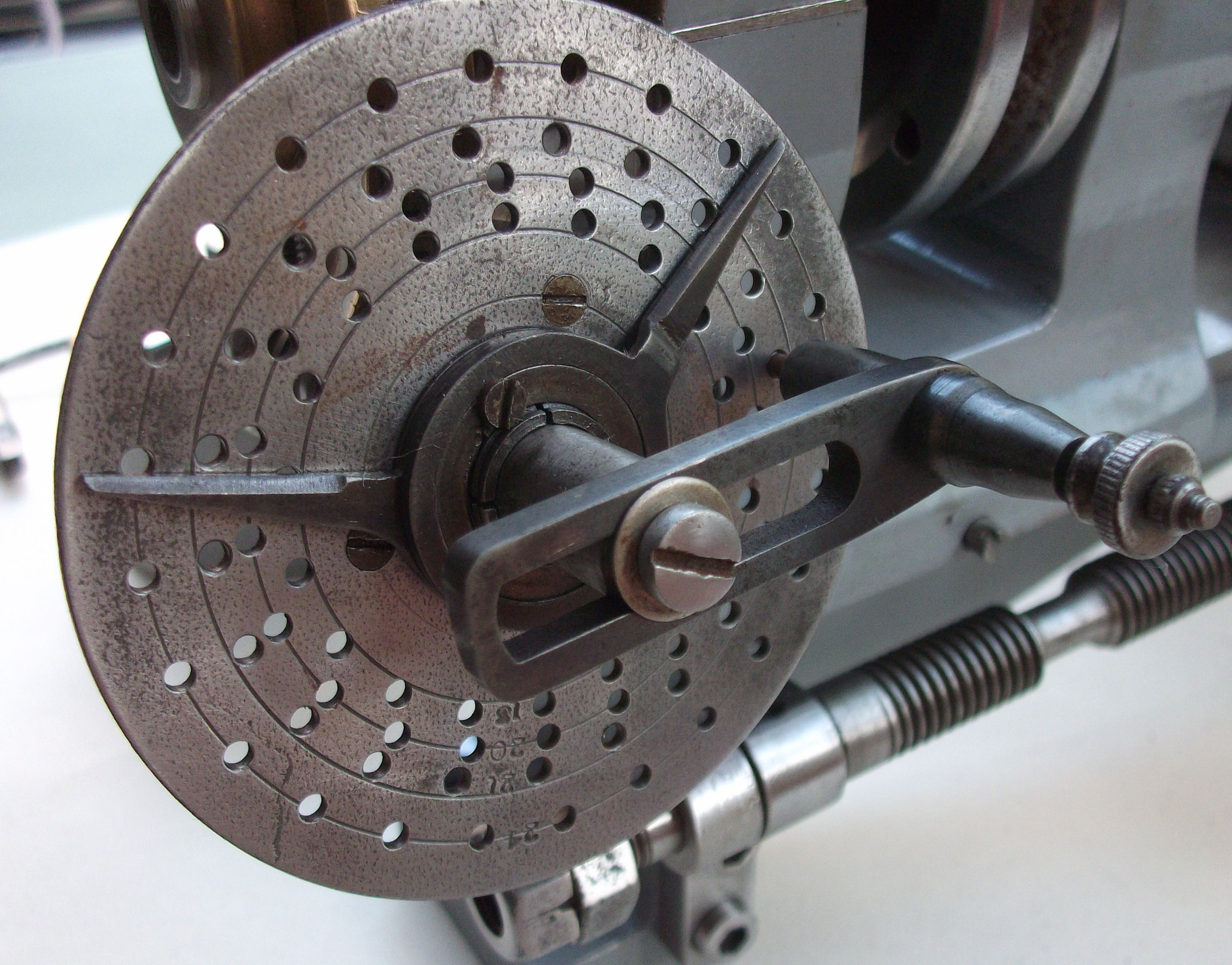

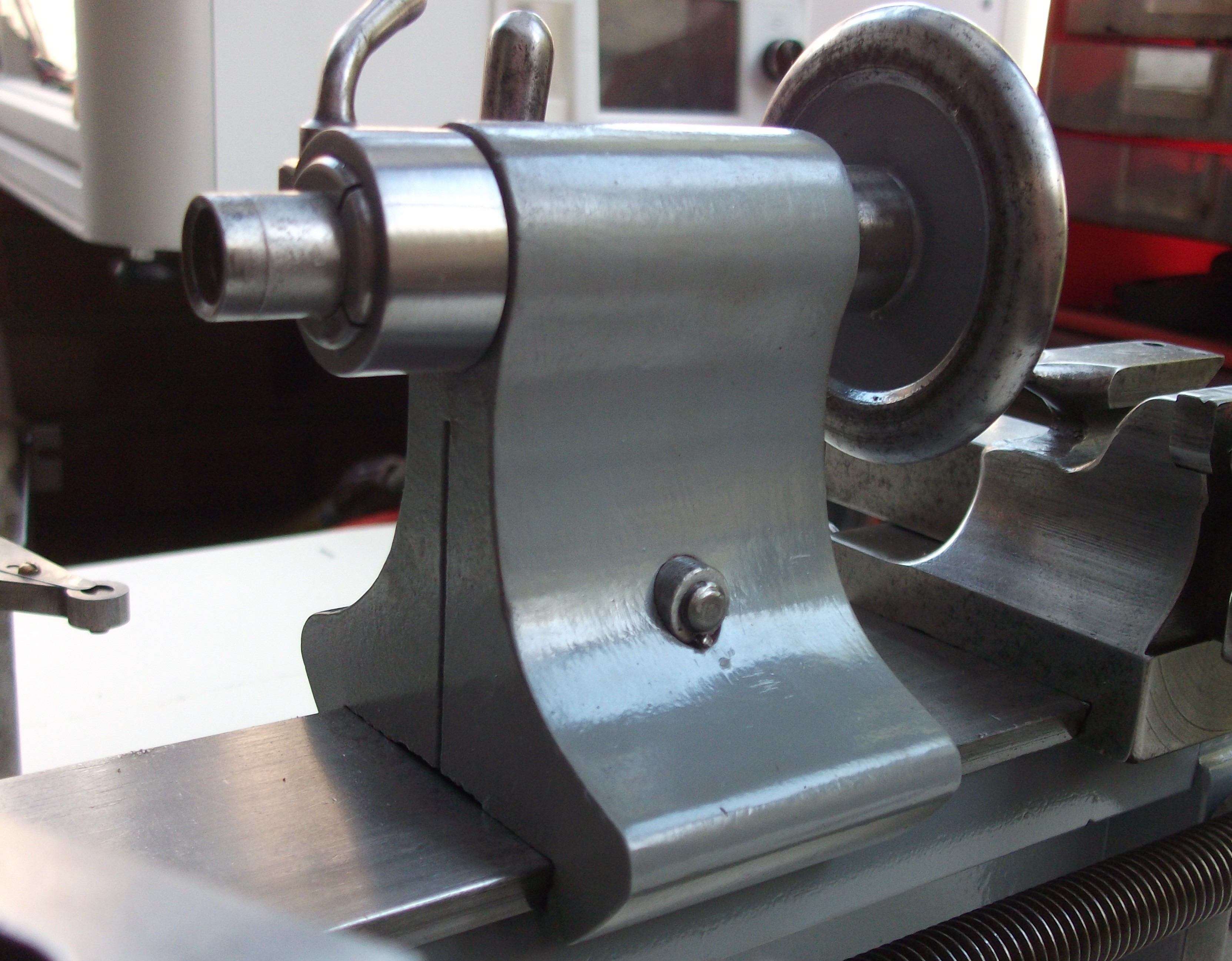

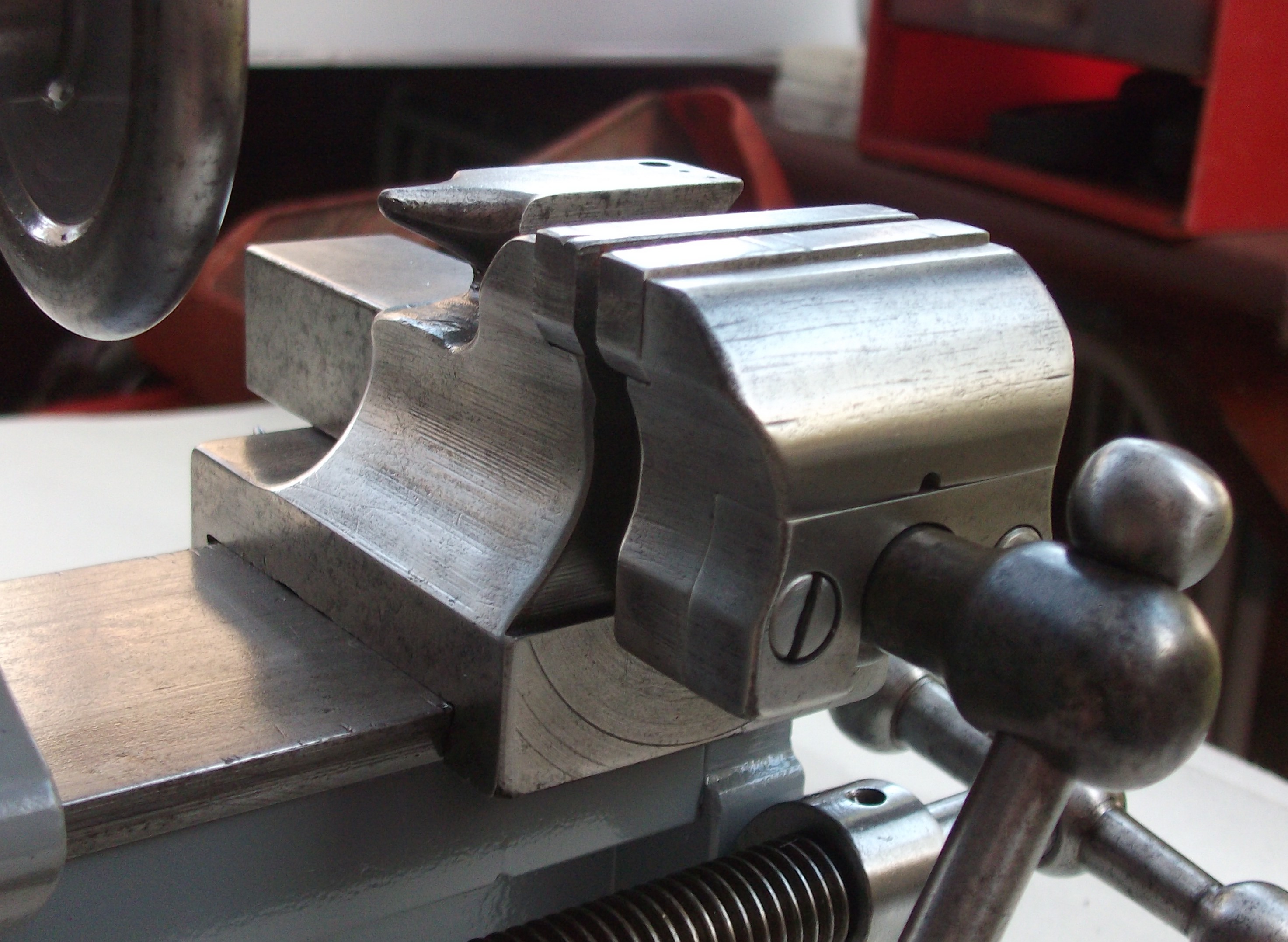

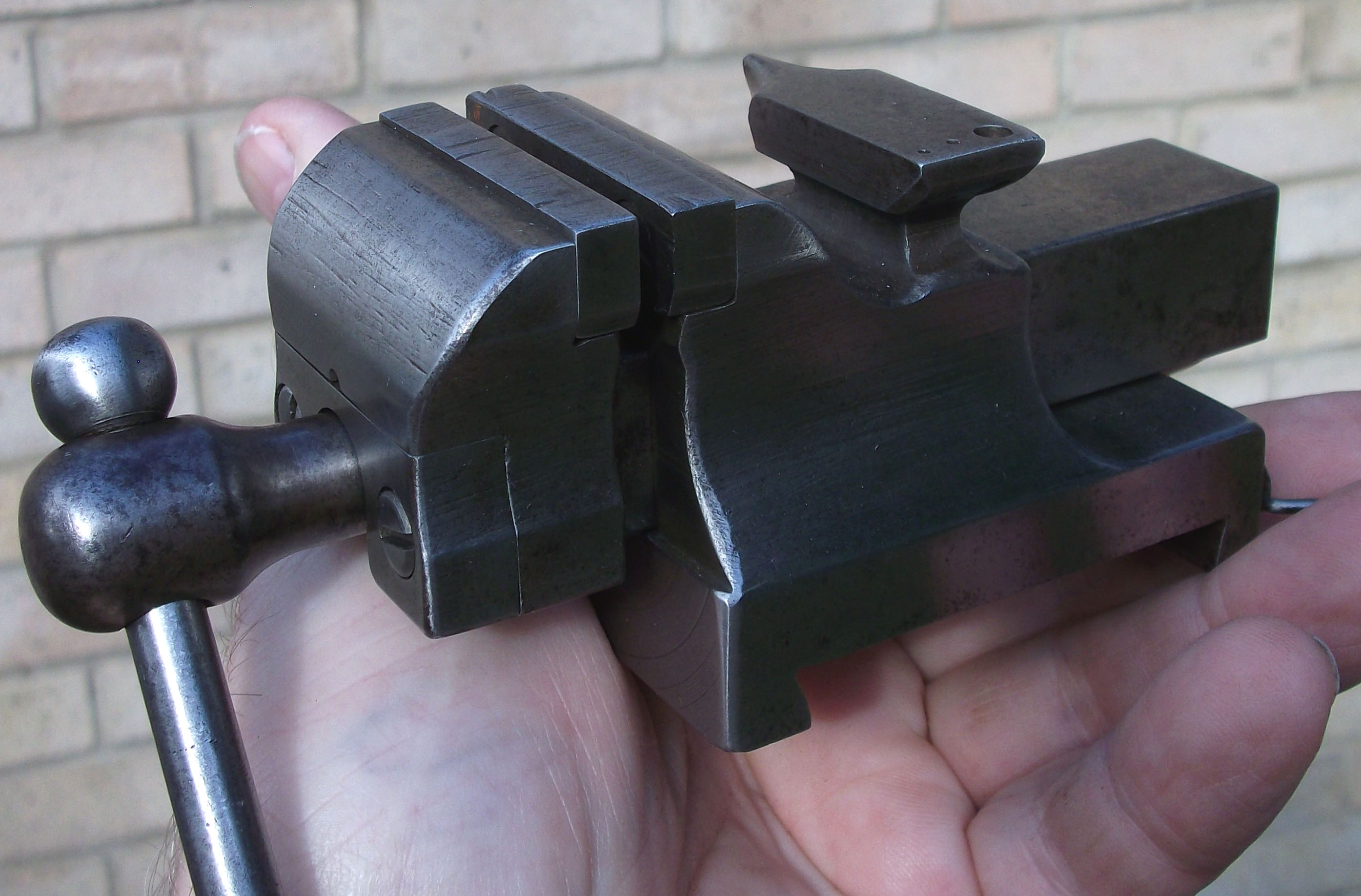

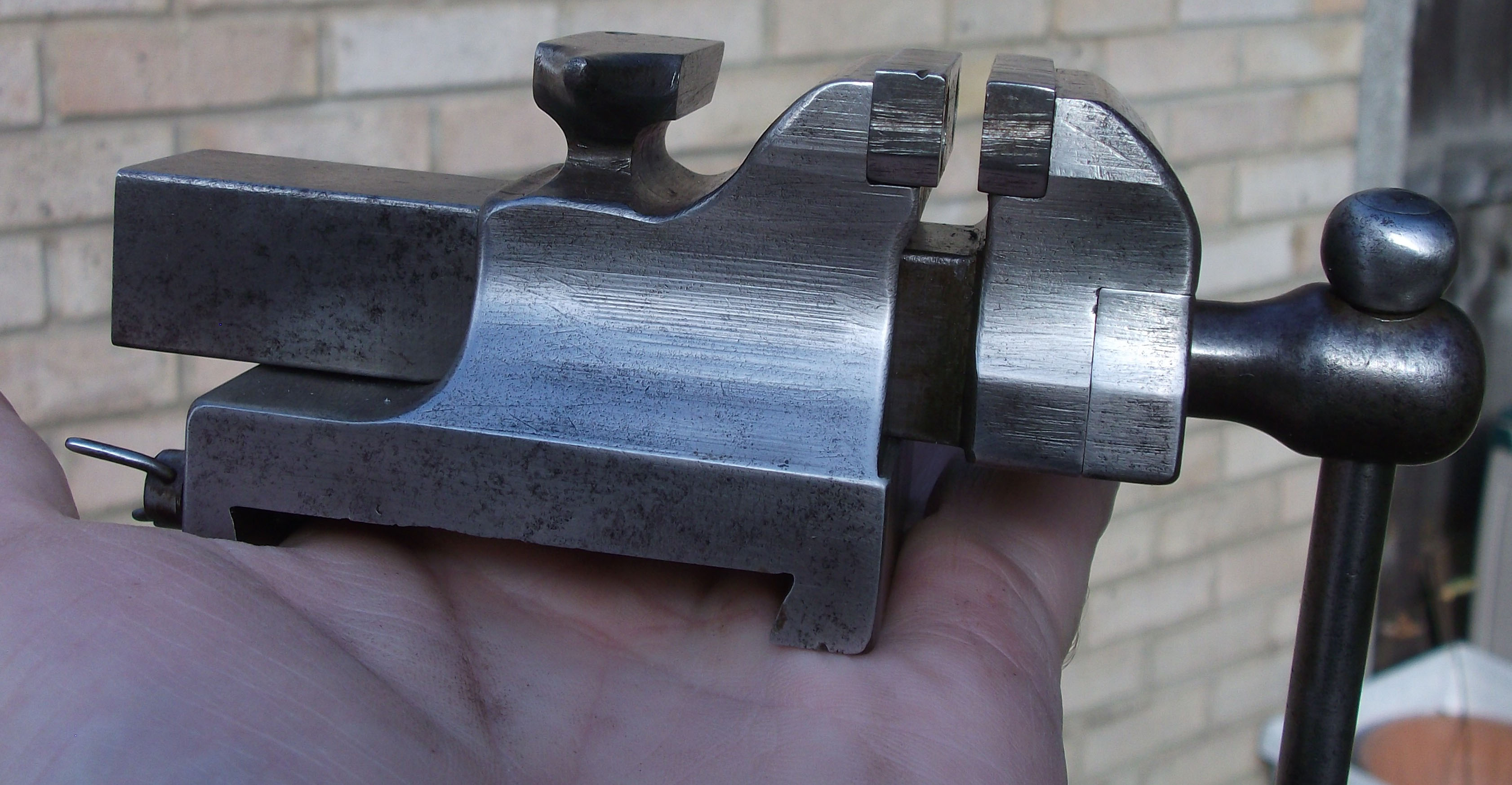

Yet another traditional "bench precision" lathe of unknown origin - this having a centre height of 2.5" and taking around 8" between centres. Of an interesting design,, the lathe is of high-quality, heavily built and fitted with a full compound screw-feed slide rest. An unusual fitting - also found on the American UND lathe - is a worm-and-wheel driven headstock spindle indexing attachment complete with an indexing plate. Also original to the lathe is a small vice - complete with a small "anvil" section - that clamps to the tailstock end of the bed.

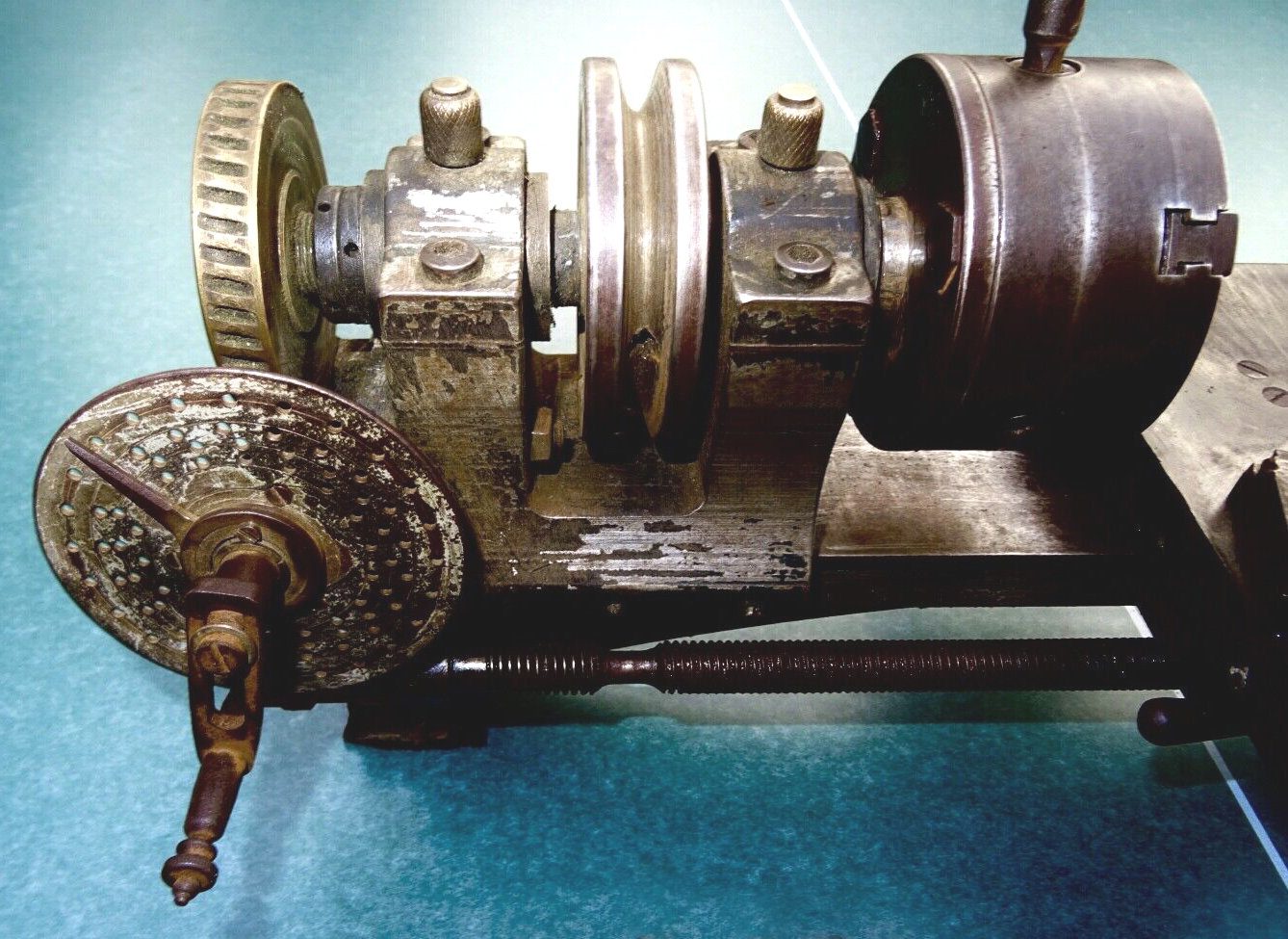

As the single-groove headstock pulley (complete with a circle of 60 indexing holes) is original, the lathe must have had, when new, a multi-speed countershaft unit - this being lost. Shown in the first set of photographs in as-found condition, lower down the page it can be seen as restored.

The owner writes:

I've found very little so far about the history of the lathe. The previous owner got it from S.Davall's & Sons (later Vinten Aerospace) ,when he left the firm in the 1986 . Davall's made clocks (https://www.britishpathe.com/video/making-coronation-clocks/query/coronations) and later, flight data recorders . The previous owner had several patents in his name related to wire handling mechanisms for such data recorders , but I don't think he had anything to do with the lathe's initial construction.

I thought it might be an apprentice project, but it seems to have had too much use to be a long term project and, again, one would expect apprentices to finish parts - so perhaps best guess would be a special project for in-house work at a time when availability of small lathes was tight. The are no markings except a small F on front of the headstock and matching 0 & 1 marks on the bearing caps.

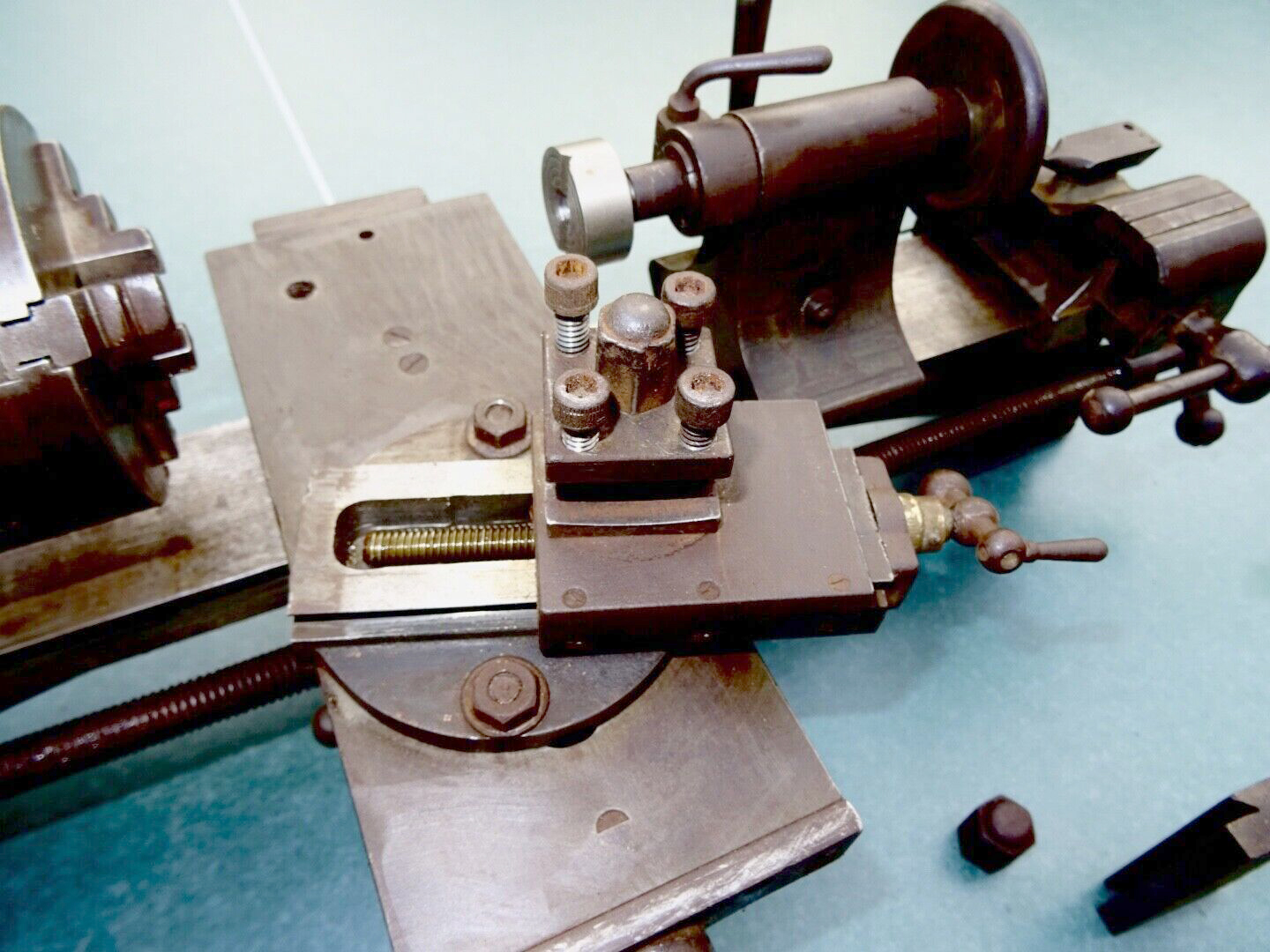

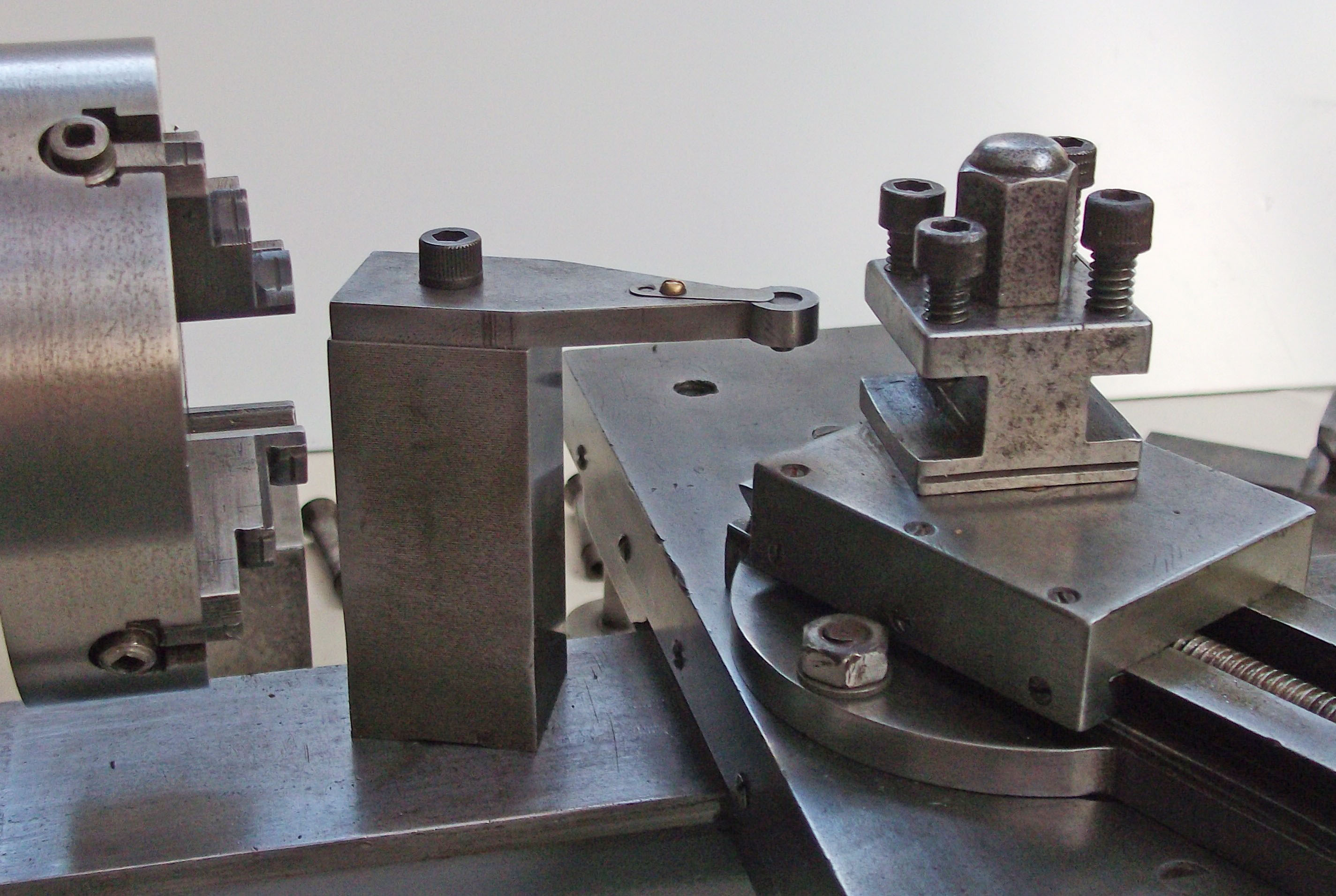

It is a real enigma: it is well made but not well finished. Everything that needs to be good is good, but it's as though they didn't have the time to add the finishing touches. If it weren't for the allen screws I would think this is 'war finish ' - the cross slide appears to be a Hardinge Cataract of pre 1920 design (or more likely a copy - there are a couple of odd differences - it is marked '47' on the back edge).

There is a consistent design aesthetic as the handle tapers, etc, all match. The tri-ball handles are locked with a screw from the end (Hardinge style) rather than pinned.

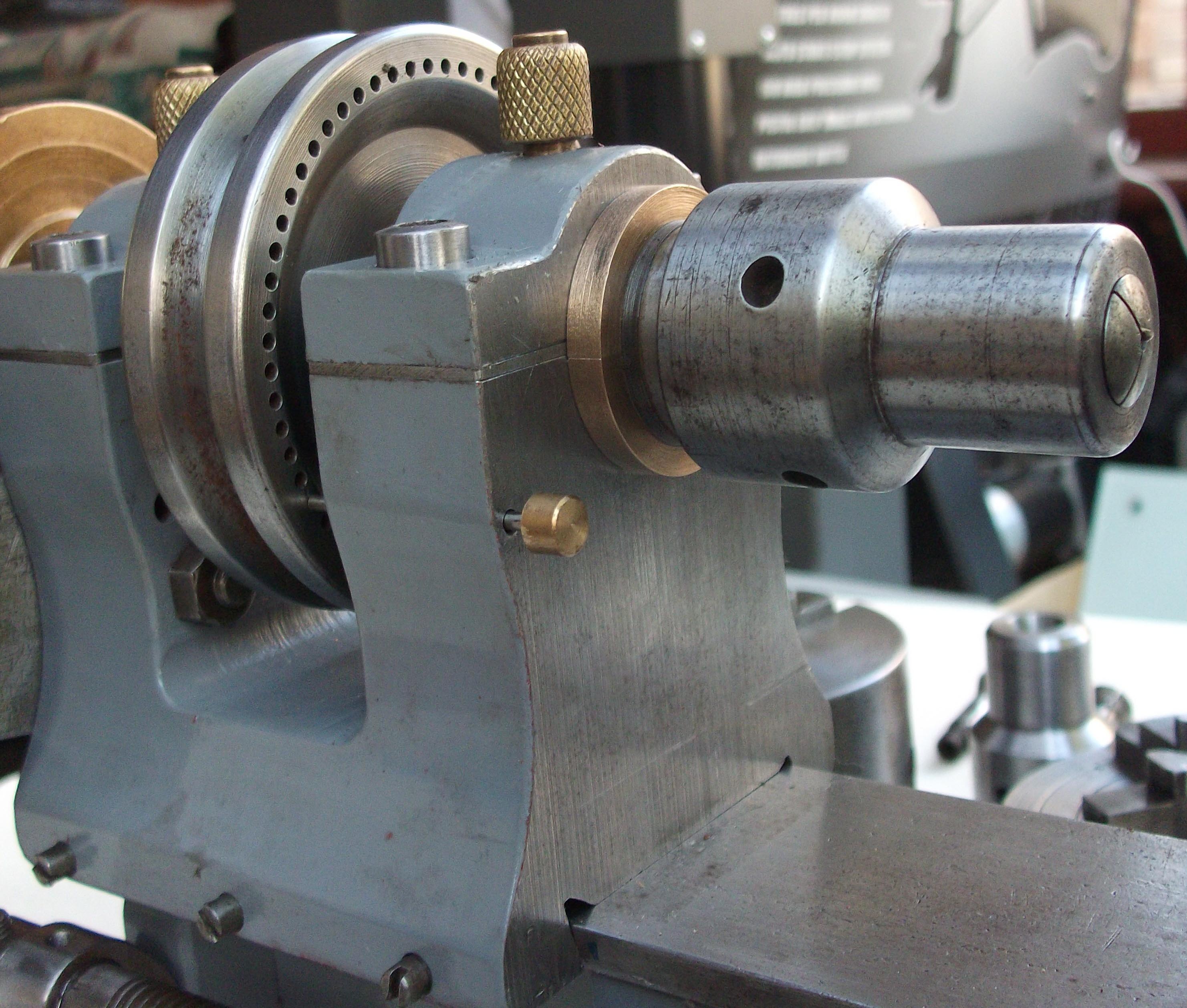

Both the headstock and tailstock have been carved from stock with a shaper and the then dovetails ground to fit. The tailstock spindle lock is a neat design, clamping onto a split steel tubular section that carries the quill, rather than squeezing a split casting closed - but I had the draw file and polish it to improve the finish. Beautifully carved as part of the main body, the tiny anvil on the vice did not have the shaper marks removed before hardening - and I have left it unpainted to show this..

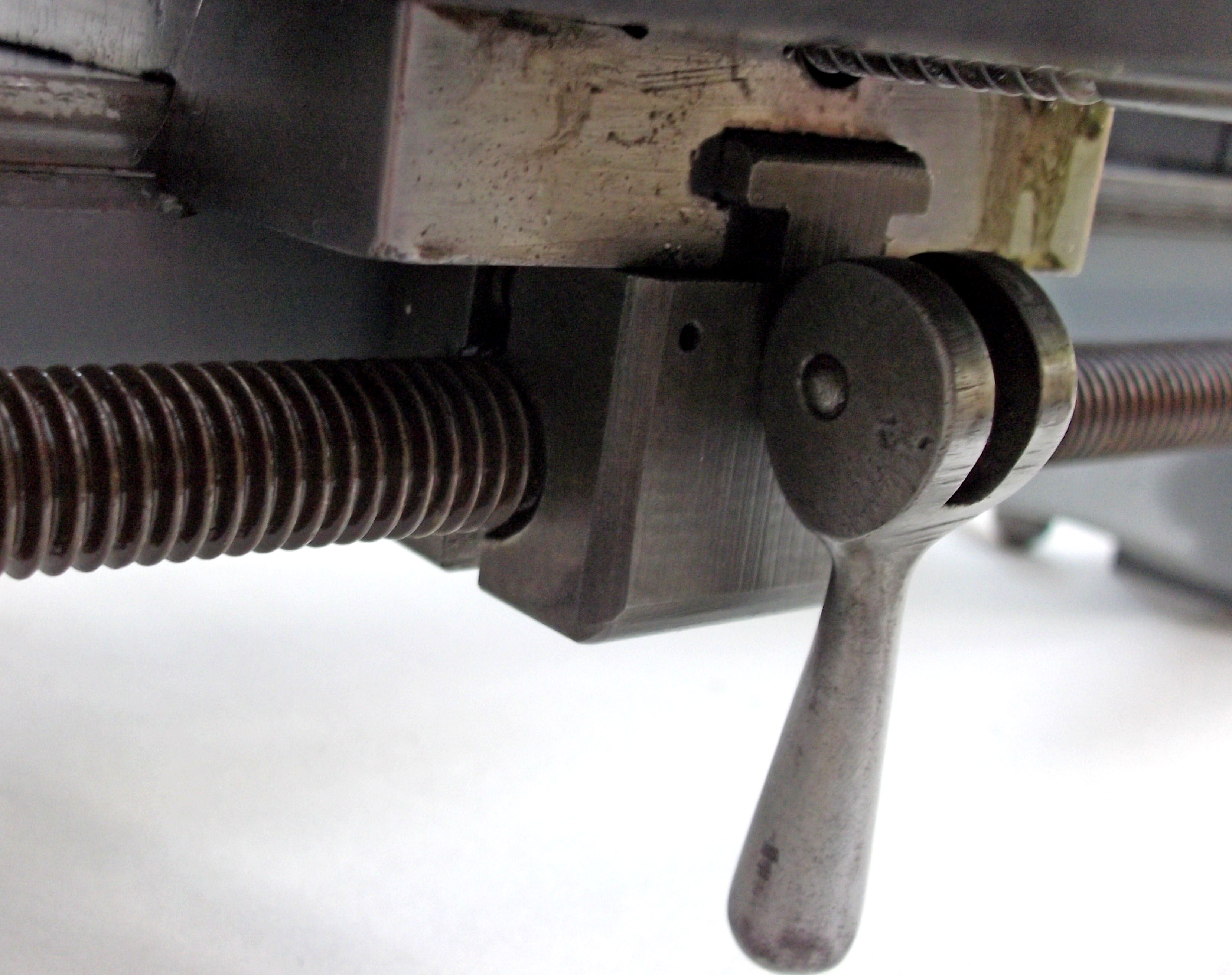

The 12 t.p.i. leadscrew is clamped to the cross-slide with a cam-locked pair of half-nuts running in the cross-slide's bottom T slot. It, and the tailstock screw, have right-hand threads giving what used to be known as a "cack-handed" action where turning the handle clockwise results in the unit moving backwards instead of forwards. All very well if it's the only lathe that you use, but potentially disastrous if other lathes are in the workshop.

Of an early design, the topslide seems to have be adapted for use on the cross-slide , rather than being made for purpose. I have search your site for a similar one without success.

Of fabricated construction the bed has with a dovetail section bolted to a nicely curved central brace with two additional supports each side. The two L shaped feet book-ending it into a solid and heavy bed.

With its square-form worm screw, the indexing assembly engages with the 40T pinion with near zero backlash. The worm runs in a U shaped casting that attaches it to the headstock and the index fingers have a leaf spring friction pad. The index pin is sprung loaded

The lathe came with a handful of Boley-Leinen 8mm collets and two collet noses, though unfortunately, I'll have to make a new draw-tube. The three and four jaw chucks have no makers marks .

The tool height gauge ,made with shaper and surface grinder, is interesting having a spring-loaded plunger as an indicator..