Instruction Books & Drive belts are available

for the ML210, ML360 & ML1

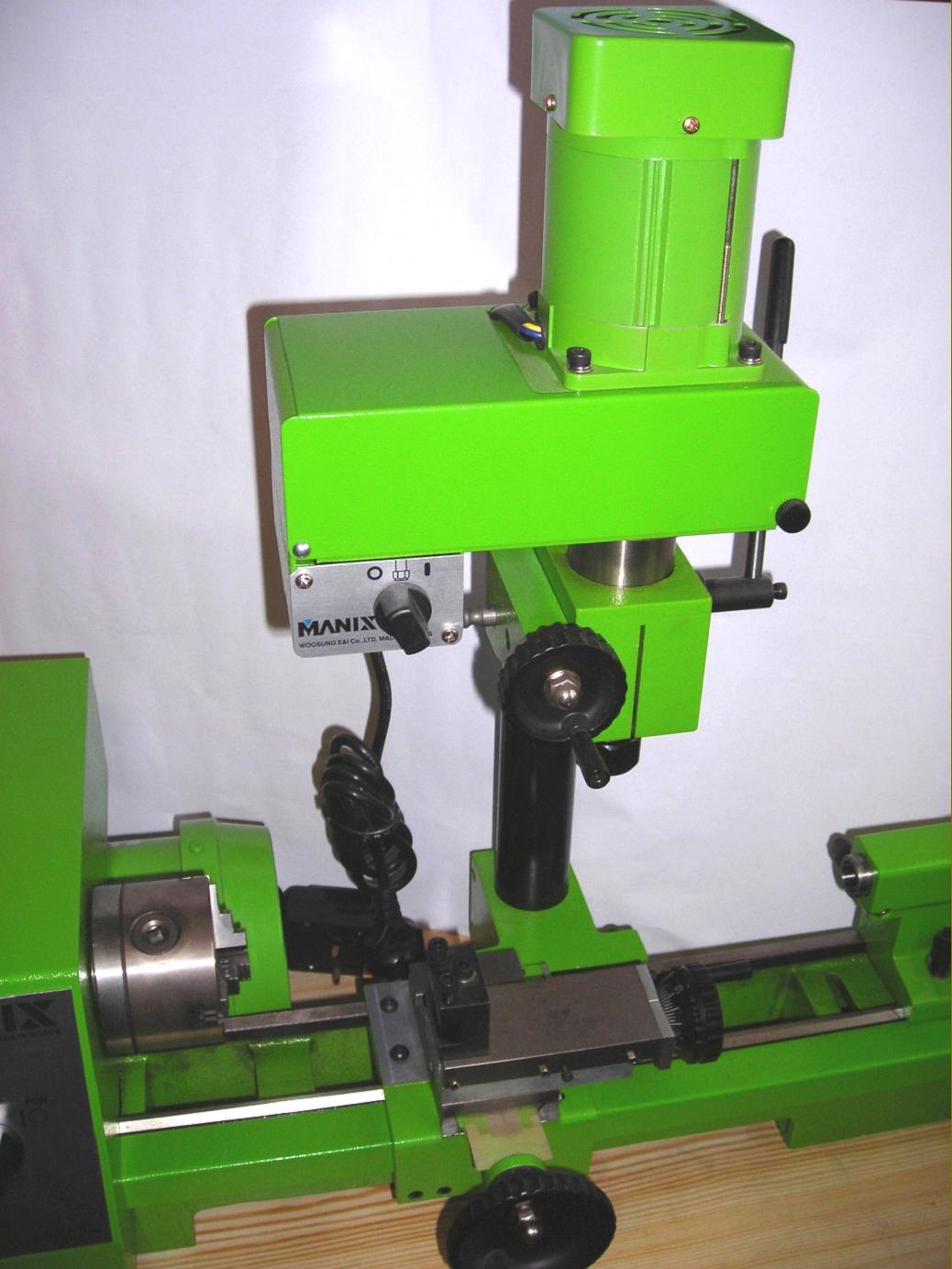

ML210 Milling Head Toyo ML1 Lathe Toyo ML2 Lathe

Branded initially as the "Toyo", the first lathe known to have been manufactured and sold by the Japanese Sakai Special Camera Mfg. Co. Ltd. was the delightful and cleverly-engineered precision ML1 together with a most unusual (for its size) facing version, the ML2. This lathe was designed and developed by Mr. Sakai during the early 1950s and, originally, intended for sale but to help with production of his large-format box cameras. However, so successful did the lathe prove that it found a ready home market (few machine tools of the type were available in Japan at the time) followed by strong overseas sales where the competitive price undercut similar machines from Germany (Lorch and Boley Leinen) and America (Levin and Derbyshire).

Although sales of the original ML1 were limited (if you have one, or any sales or service literature, the writer would be interested to hear from you) the later and far more common ML210 and ML360 model-engineering types are around in considerable numbers and, being eventually manufactured in low-cost Korea, were distributed worldwide by Sakai under a variety of names: Record and Toyo in the British Isles, Sakai in the USA and Proxxon in Germany and other European countries. Today the same two lathes, almost unaltered save for minor improvements, are sold under the "MANIX" brand and also still appear - though modified and improved - as "Proxxon" (at one time marketed by "Sell-it-Easy", a large German-based tool distributor - check their web site for details).

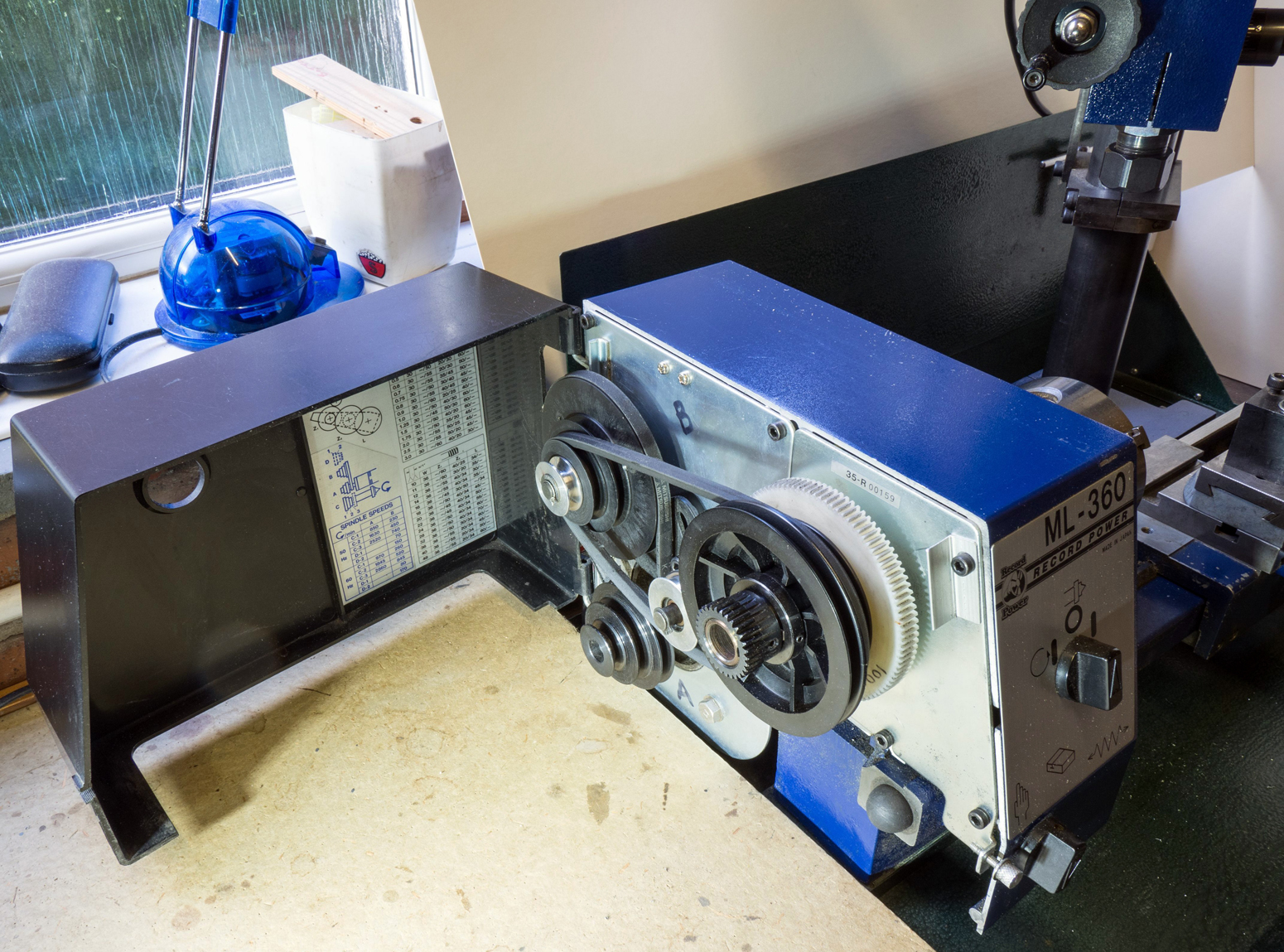

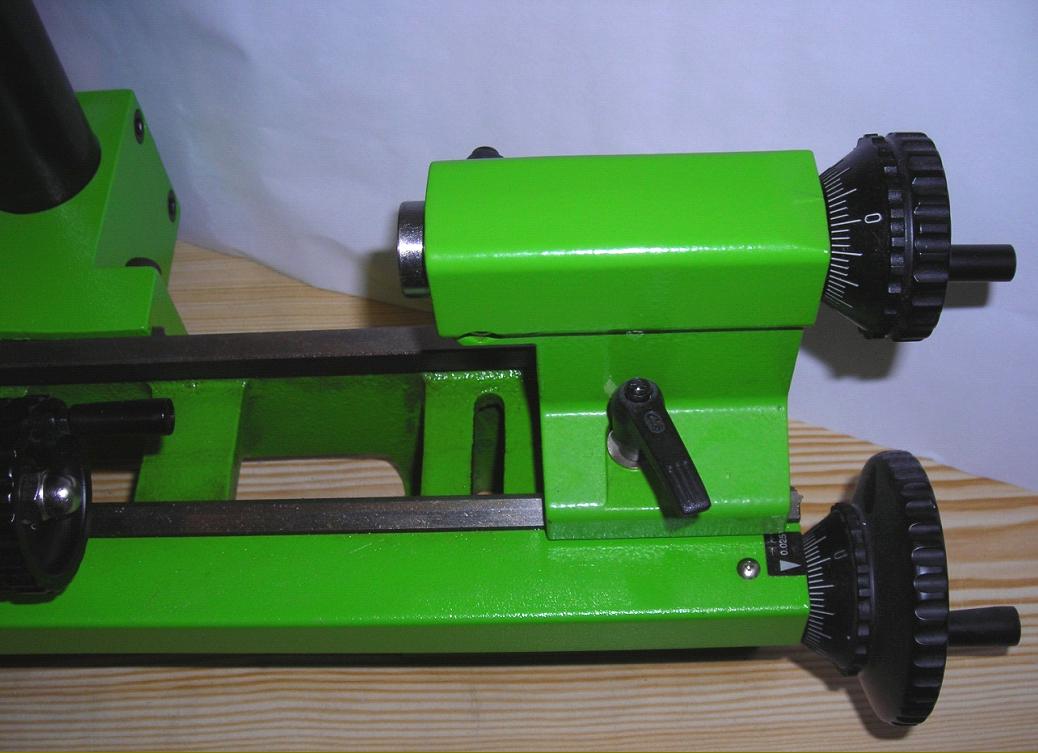

With a centre height of 75 mm and a capacity between centres of 300 mm (3" x 12"), the ML360 was a compact, well-built and genuinely useful little lathe. It even had a No. 2 Morse taper centre in the tailstock and a 16 mm capacity through the roller-bearing headstock spindle - the later larger than that on a Series 7 Myford. However, although the Toyo bed was hardened and ground - and the circular dividing head, machine vice, indexing unit and other accessories superbly made - the leadscrew-handwheel zero mark was just a plastic sticker and both the changewheels and feed-screw micrometer dials also of plastic - with the latter carrying inadequate, coarse markings (as a substitute, Sherline make a superb pair of metal micrometer dials that are easily adapted and well worth acquiring). Another failing, at least in some eyes, is the spindle nose fitting - a simple flange to take bolt-on fittings. This arrangement, whilst giving absolutely precision and security when run in reverse, can be horribly frustrating and time-wasting when a change of chuck or faceplate is needed.

Six (reversing) spindle speeds were provided as standard: 230, 450, 740, 850, 1630 and 2520 rpm; however, when fitted with the optional slow-speed (belt-drive) kit these were extended to include a six-speed range from 70 to 150 rpm that made both screwcutting and very-fine feeds a possibility - though a proper gear-driven backgear (that was able to give a bottom speed of 30 rpm or so) would have been preferable, if awkward to engineer. The electrical system was neatly built-in and a reversing switch supplied as standard.

Bolted to the back of the lathe's V and flat-way bed the self-powered milling and drilling attachment had five speeds: 210, 420, 630, 960 and 1880 rpm. As supplied, the unit had only a quick-action drill feed, the essential fine-down-feed attachment had to be bought as an expensive extra. The milling-column to spindle distance was 101 mm, the clearance between the spindle face and toolpost 200 mm and the main spindle travel 30 mm - with a 12 mm-chucking capacity.

Unusually for a small lathe, the handbook (email for details) was a paragon of clarity and sensible advice - and included comprehensive instructions about the mounting and use of the extensive accessory range.

Because the lathe was often marketed shorn of all accessories - not even a power feed along the bed or a top slide - before buying a used example it is essential to know the exact specification on offer; a basic version is useful, but a well-equipped example should be greatly preferred - even if considerable more expensive. Ideally, the lathe should be equipped with: a top slide, power feed and screwcutting (often combined in one accessory pack, sometimes two), a slow-speed attachment and a fine down-feed unit on the milling head.

Occupying a space of 756 mm x 377 mm x 245 mm (29.7" x 14.8" x 9.6") the ML360 weighed, in standard form without any accessories, 30 kg (66 lbs)..