|

Home Machine Tool Archive Machine-tools Sale & Wanted Original Versions of the "Workshop" 9-inch Lathe an interesting catalog is available and other South Bend Literature |

|

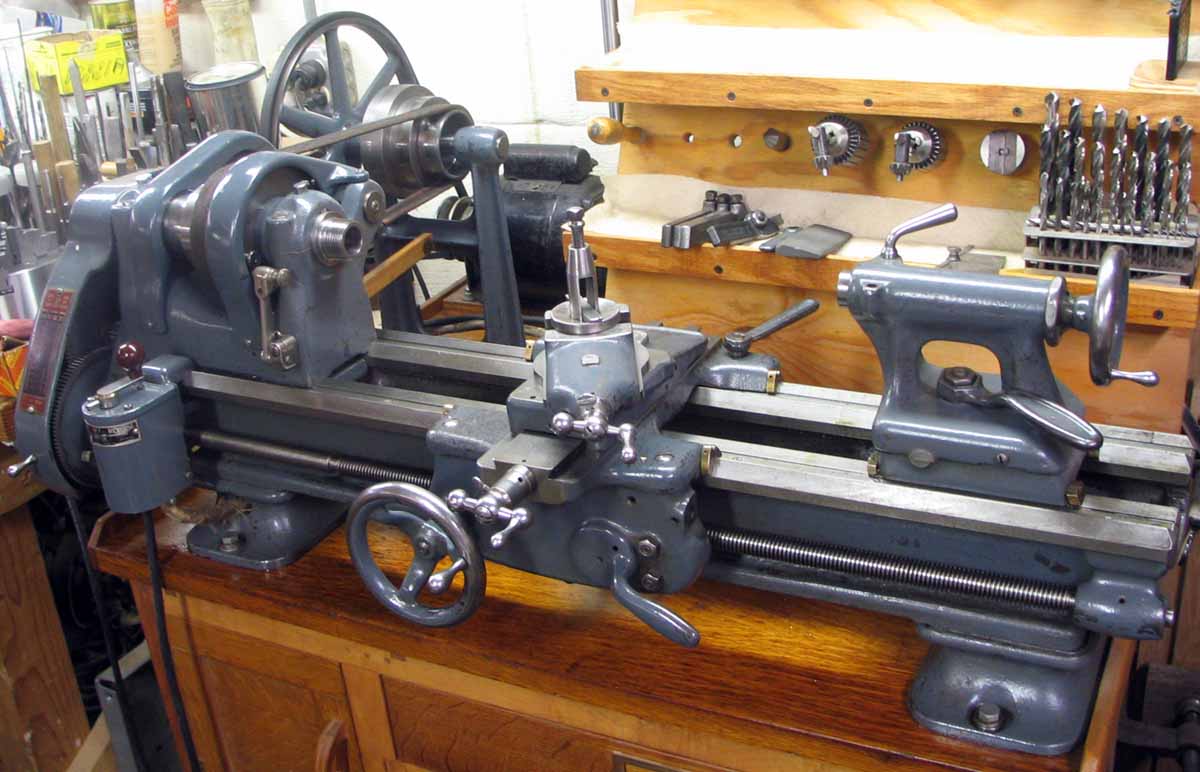

This beautifully kept 405 has been maintained by its owner, John Crombe, for over 35 years. Its ID tags carry the following inscriptions: 405-Y, 9" x 3' serial number o56447, Type- Work.B. Hor.Plain,MDr., Overall Length of Spindle 11-13/16". It was shipped from the factory on December 15th, 1934. A few minor modifications have been made to enhance the machine's usability, these including bed wipers on the saddle and tailstock, thumb-screw locks on the compound slide rest feed dials and a very neatly arranged a bull-wheel indexing attachment. |

|

|

|

|

|

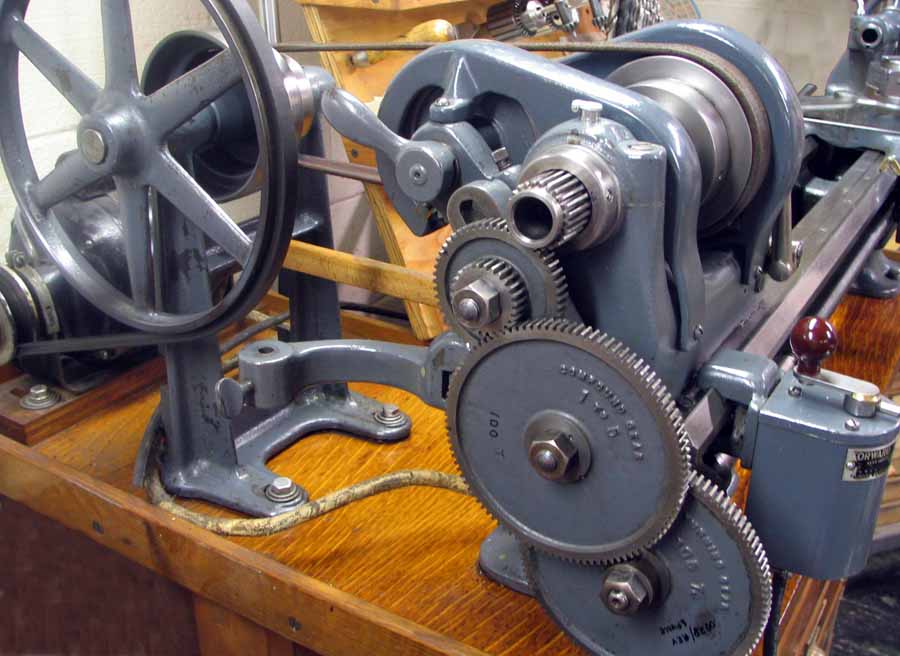

View showing the long, single-slot "banjo" used to carry the changewheels. At the 8 o'clock position, relative to the end of the spindle, can be seen the hole used to mount a simple 5/8"-diameter by 21/2"-long "reversing stud" that allowed a 32-tooth flanged changewheel to be incorporated into the gear train to allow the generation of left-hand threads. The stud was retained by a "blued" square-headed bolt (of the same size as those used to lock both saddle and top slide) threaded into the casting near the backgear handle and bearing directly against a dimple in the shaft. |

|

|

|

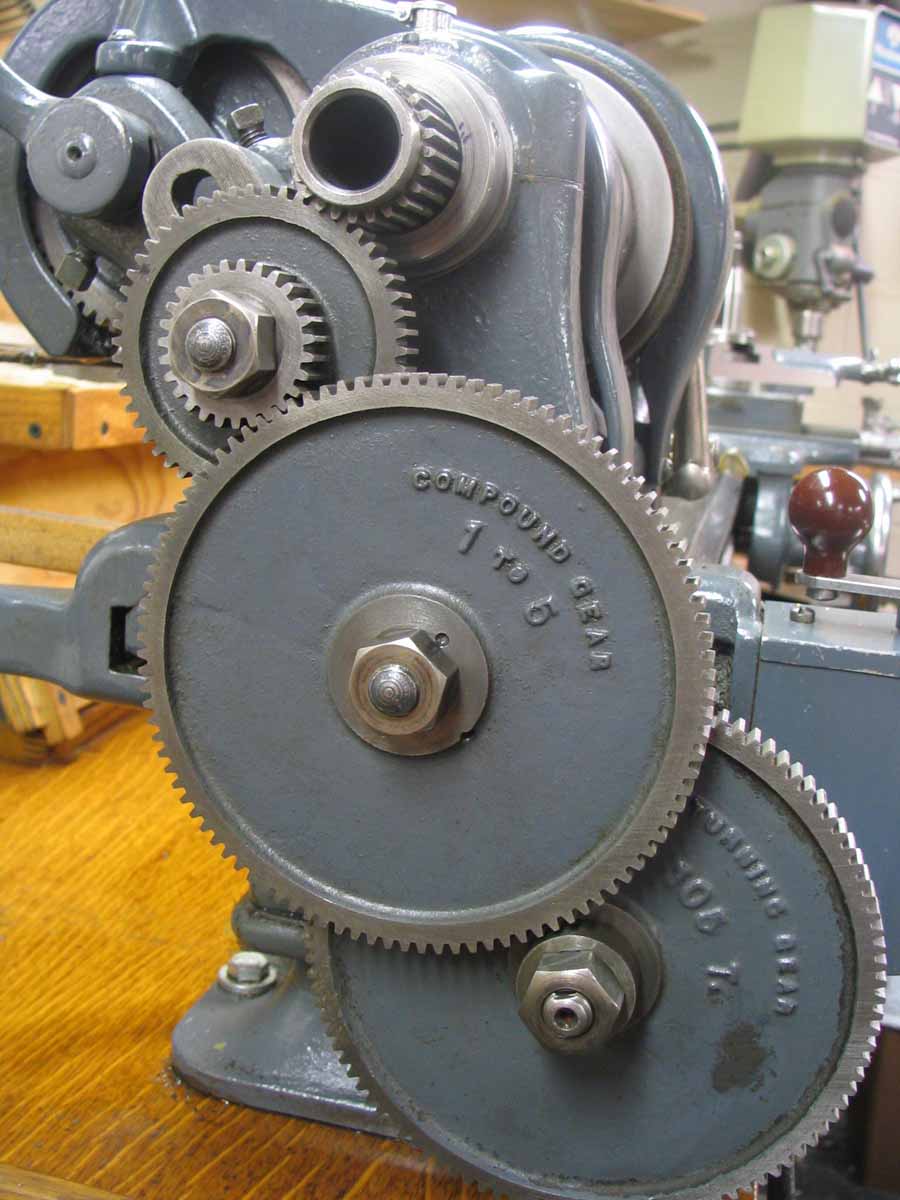

To help beginners identify the fine-feed gears the pair on the banjo arm were clearly marked: compound gear 1 to 5 (with 110/20T) and, on the leadscrew, a single gear marked turning gear 105t. With these and others gears in place the finest feed was set at 0.0028" per revolution of the spindle. |

|

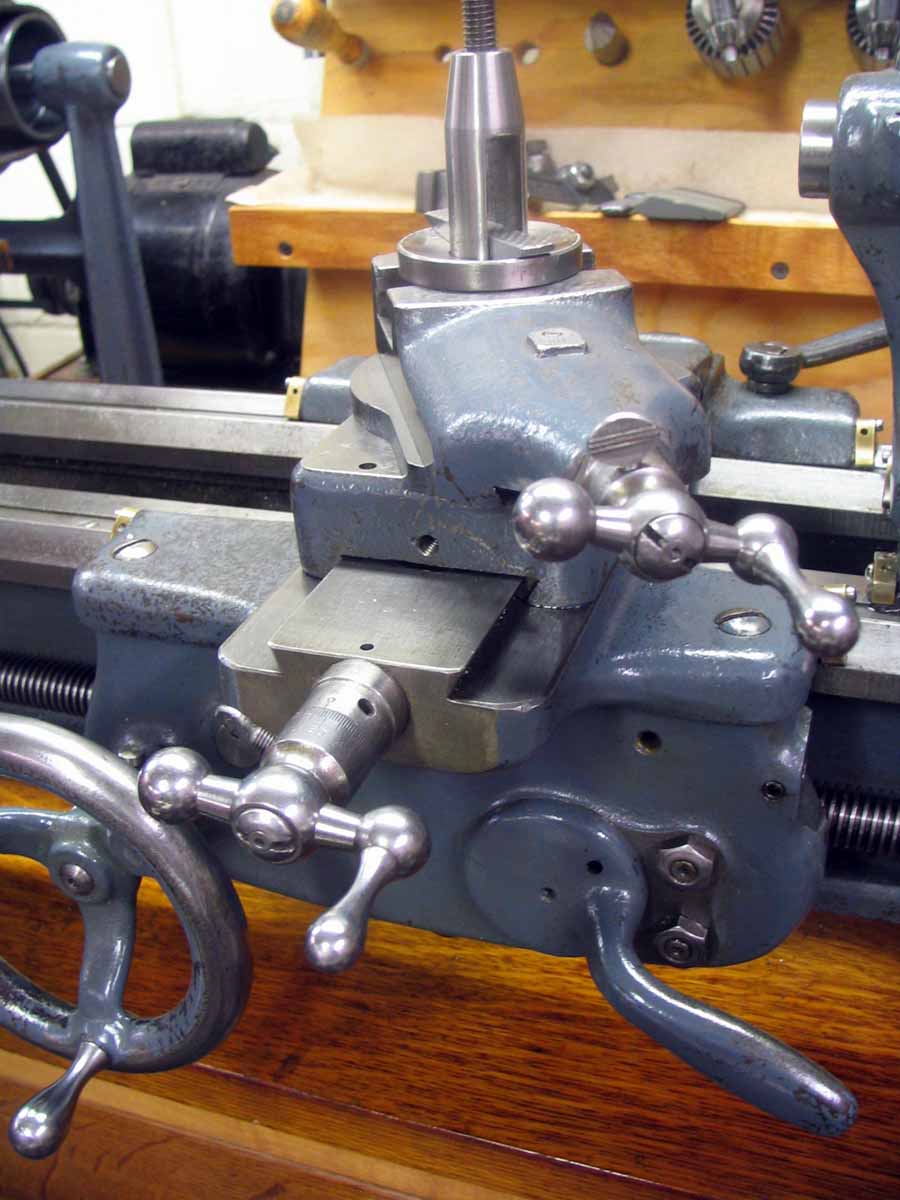

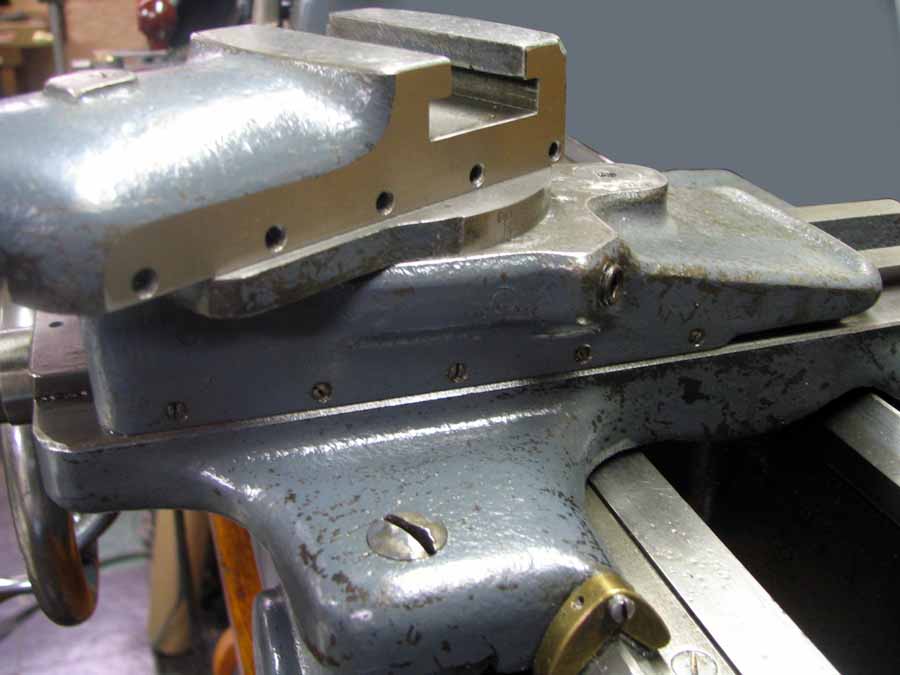

Above and below: the very short cross slide of the Model 5 (that left the rear end of the feed screw exposed), the single topslide retaining screw (it should be a square-headed bolt not a hexagon socket screw) - and the shorter, tailstock-end curved-edged saddle wings - all are clearly evident in theses views. |

|

|

|

|

|

face of the changewheel cover |

|

|

|

an interesting catalog is available and other South Bend Literature Original Versions of the "Workshop" 9-inch Lathe Home Machine Tool Archive Machine-tools Sale & Wanted |