|

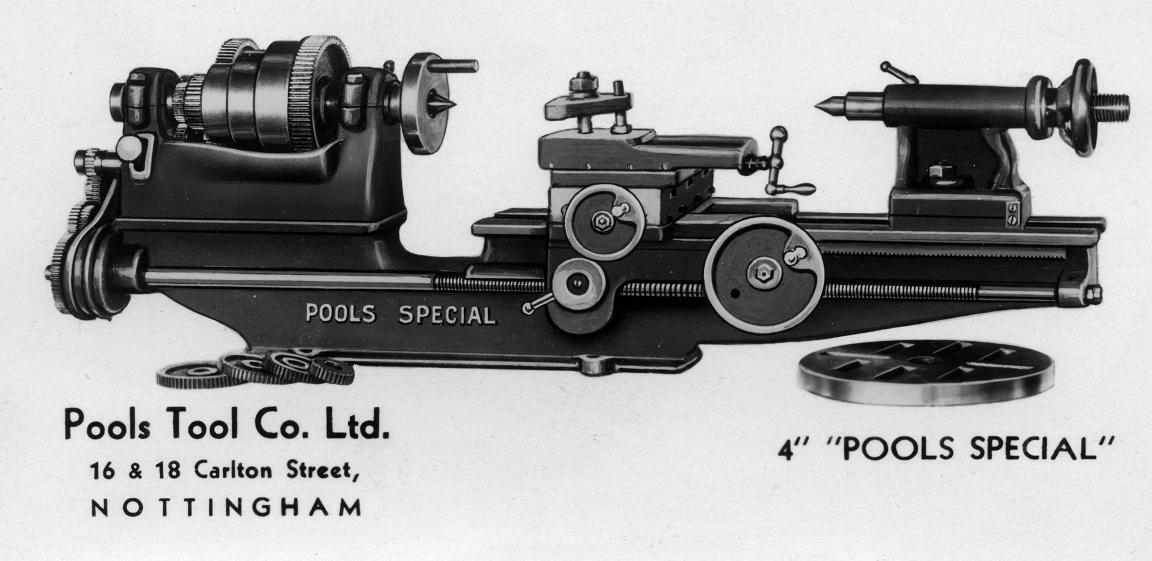

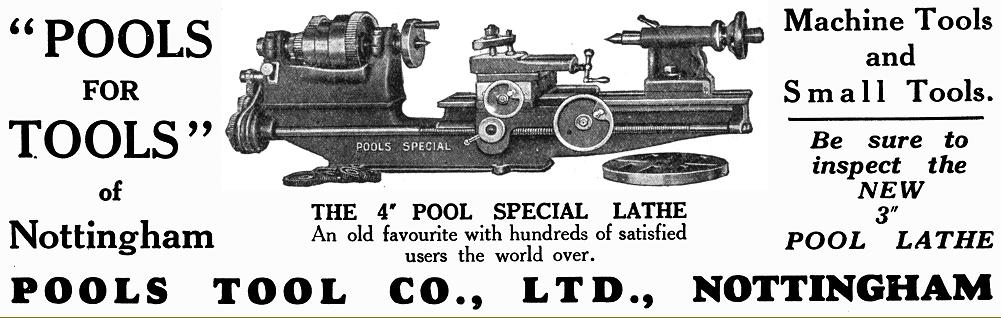

Machine Tool Manuals Machine Tool Catalogues Belts Accessories Books Pool 4-inch Major Lathe Pool Milling Machine Pool 3-inch Special Lathe |

|

Based in Carlton Street, Nottingham, the Pool Tool Company appear to have sourced their lathes from several sources including Slack and Parr of Kegworth (a company still trading) and Ross and Alexander of London - whose lathes were also sold under the Randa label. They are also known to have assembled machines themselves - presumably from bought-in components - with a fitter, Ron Barry, recalling time spent on the top floor of the shop building up lathes and complaining about the difficulty of setting up and aligning the spindle in its split bearings. Pools lathes were frequently mentioned and advertised in the amateur-engineering press before World War 2 - but failed to reappear afterwards. Interestingly, some models were marked Pool and others Pools - and always with the possessive apostrophe missing…. |

|

|

|

A standard bed-length Pools 4" x 17" of the early 1930s on the maker's treadle stand. Between the legs of the lathe sits the standard fast-and-loose countershaft supplied for wall or ceiling mounting. Later machines were offered with the further option of a neatly-built-on - but very expensive - all-V-belt drive countershaft . The long-bed version of the lathe retained the four bolts in the region of the gap but added a foot at the tailstock end. Some of the later cast-iron chip trays were provided with a deep stiffening rib which ran along the full length of their underside. |

||

|

|

||

|

Pools 4-inch Special. The well-braced 4-speed (8 with backgear) headstock had its tumble reverse gears mounted on the inside of the casting. |

||

|

Pools 4-inch Special. The tumble reverse lever was not spring-loaded, but had to be unscrewed before it could be repositioned. |

||

|

The No. 2 Morse taper tailstock used a hollow barrel with the thrust from its square-section thread taken by a large "split washer". The tailstock was located on ways between the two halves of the bed - a far more satisfactory arrangement than sharing the potentially worn outer dovetails with the carriage. |

||

|

The apron was reduced to the elements of simplicity - with just sufficient metal to support the bronze clasp nuts and the carriage traverse handwheel. |

||

|

Substantial, cast-iron handwheels with well-shaped finger grips. The swivelling action of the top slide was locked by screws at each side of its base. |

|

Above and below: T slots in both cross and top slides (the latter an optional extra) and the built-in threading indicator with its dial showing through the right-hand front wing of the apron. |

|

By 1939 Pool were offering a heavily-built, 4-speed countershaft unit (obviously inspired by the American Atlas lathe) that could be bolted to the maker's stand or onto an ordinary bench. The bearings were supported in exactly the same (ingenious) Atlas way between adjustable studs and even the large drive pulley exhibited the same "wavy-spoke" appearance as the American machine. |

|

As was common on many small English lathes of the era, no changewheel, backgear or belt guards were fitted - although most small lathes from America had been so equipped for some time. |

||

|

The belt-tensioning lever on early versions was a lovely, heavy casting ( later slimmed down to incorporate a short bar) but there was no screw adjustment incorporated in its "cam action" which meant a limited range over which to tension the belt - which, consequently, had to be exactly the right length. |

||

|

|

||

|

Machine Tool Manuals Machine Tool Catalogues Belts Accessories Books |