|

Manufactured by Compagnie Europeéne de Fonderie, a French firm specialising in die castings, the Minilor TR1 was simple, non-backgeared but screwcutting lathe with a 65 mm (2.5") centre height that could take 350 mm (14") between centres. A built-on 0.5 h.p. motor provided eight speeds from 90 to 5250 rpm driving either directly to the spindle via a toothed-belt drive for high speeds, or through an intermediate pulley for a slow-speed range. Although 90 r.p.m was just a little too fast for screwcutting by a beginner, the very high top speed was welcomed by those needing to turn very small parts.

For a small lathe the headstock spindle carried a nose thread of an enormous diameter and was bored through 17 mm - this arrangement also allowing standard (and inexpensive) ER25 collets to be fitted, these being of the nose-closing, double-split type (on the front and back surfaces) compressed by an external ring. The whole arrangement was well designed and had a better inherent accuracy than the usual sort of external collet holder normally required on tiny lathes. Because the spindle nose was adapted to carry collets, a special large centre was supplied with the lathe - and is something to look for when buying a used example.

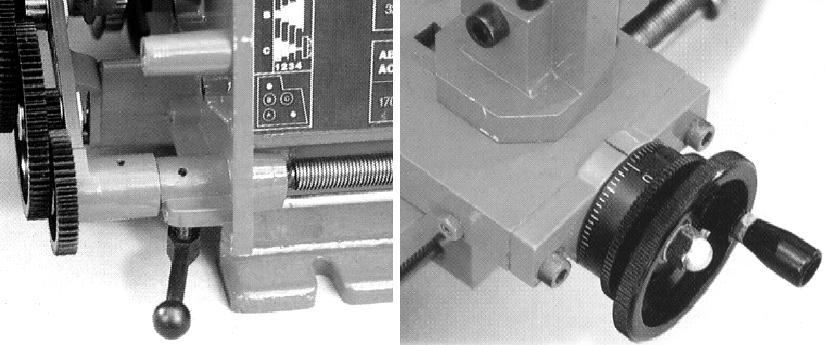

For each setting of the plastic changewheels, three auto-feed speeds were available, selected by a lever beneath the end-guard cover. A very useful automatic disengage was fitted to the leadscrew drive - ideal if you wished to leave a long, gentle cut running under power whilst attending to some other job. A very useful fitting, supplied as standard , was a graduated handwheel on the leadscrew end.

Unfortunately only a cross-slide was fitted, there being no option of a swivelling top slide. However, it is reported that, with a little work, the slide from an Emco Compact 5 can be fitted - a worthwhile modification.

Fitted with a rather too-short, No. 1 Morse barrel (though very unusually for this class of machine, it was fitted with a very large micrometer dial) the tailstock could be set over for taper turning and had,

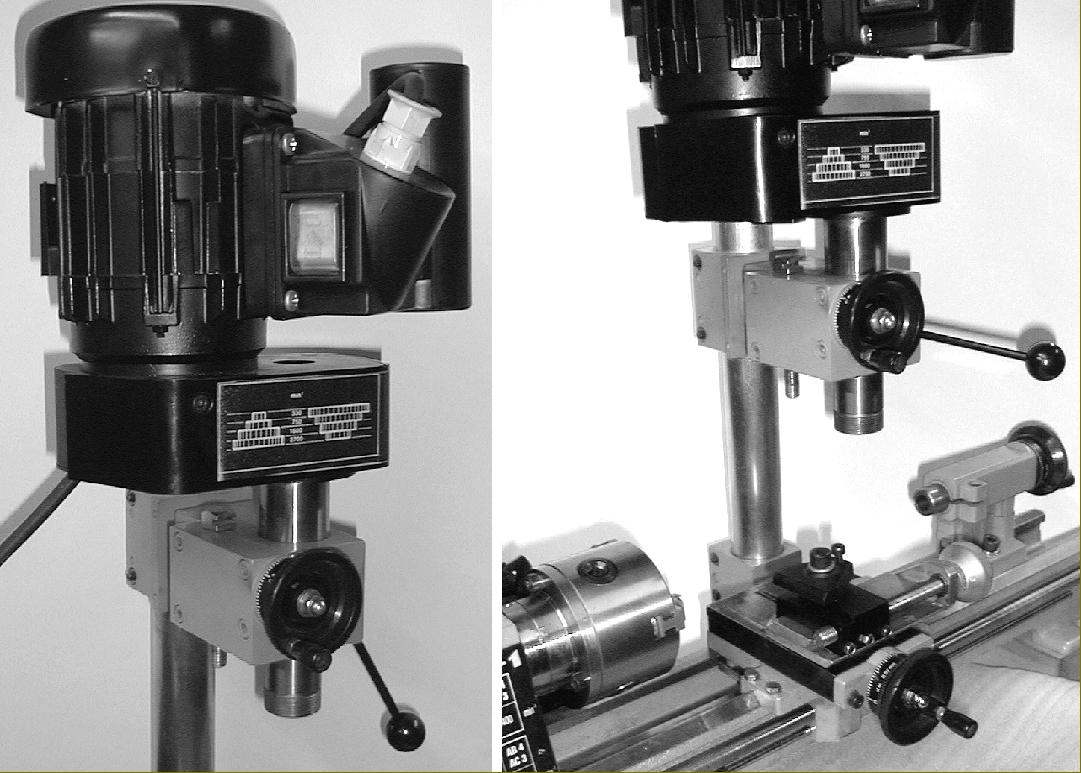

One very useful attachment was a neat, 4-speed (330, 750, 1600 and 2700 r.p.m) No. 1 Morse taper milling and drilling head with both fine and drilling feeds that bolted to the back of the bed - unfortunately, the controls for moving the quill were relatively crude, and lacked feel. A T-slotted table and vice were available to replace the cross slide when using the milling head.

In some countries the lathe was known as the "Vario-lux 130" and was also imported into the UK badged as a "Proxxon." In Germany the name "Robbe" was used with the a type designation "Romat-Vario 300".

A good range of accessories, 3 and 4-jaw chucks, fixed and travelling steadies, quick-change toolposts, tailstock chucks and rotating centres, etc., was offered..

The Minilor was not designed to tackle very heavy turning, nor can it be considered at the top of its class for rigidity of construction; however, owners report that not only is its specification very complete, but it will happily cut steel and is an ideal lathe for the modeller who needs a light, easily-handled lathe with a particularly wide speed range.

Two other models branded Minilor has been discovered, the Multipro Minilor TR-11 and the Minilor TR-20, both taking inspiration from the Emco Compact 8 (and possibly also from the well-established Taiwanese "918" type, a lathe also based on the Compact 8 . The TR-20 was labeled as being manufactured by the European Foundry Company of 88120 Vagney, France (Compagnie Européenne de Fonderie CEF) and is believed to have been sold from the 1980s into the late 1990s. The centre height was 105 mm, the capacity between centres 450 mm, it had overall dimensions of 930 mm long, 470 mm wide and 345 mm high and weighed 85 kg. Pictures and further details of the TR-20 here.

|

|