|

Home Machine Tool Archive Machine-tools Sale & Wanted Hjorth Precision Lathes - USA High-quality reprints of the comprehensive Hjorth brochures are available |

|

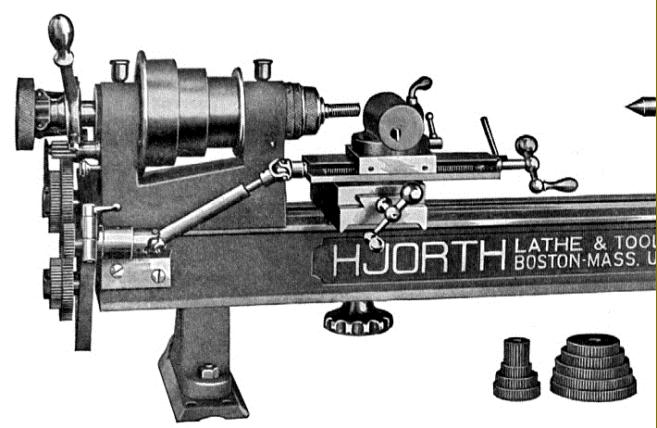

Mr. Henrick J. Hjorth had his Hjorth Lathe & Tool Company works at Woburn, Massachusetts in the USA (with the registered office at 27 School Street, Boston) and produced a range of what were known, in their day, as "Bench Lathes". However, today we have to add the word "Precision" to that description, if we are to understand the meaning of the phrase as understood in the late part of the nineteenth and early part of the twentieth centuries. |

|

Although the Hjorth would normally have been supplied as a plain-turning lathe, with a simple tip-up tool rest, this comprehensive screwcutting attachment was produced to drive the top slide of the optional compound slide assembly. |

||

|

Universal Milling Attachment. |

||

|

Component parts of the Milling Attachment. |

||

|

The Standard Vertical Milling Attachment, carrying a pawl-operated indexing unit and shown here combined with the Universal Milling Attachment. |

||

|

Hjorth Universal Grinding Attachment with screw-action cross feed and lever-action longitudinal feed. The centre bracket could be removed and replaced with the Internal Grinding Attachment shown below. |

||

|

Hjorth Internal 32,000 rpm Grinding Attachment. There were at least two different versions produced, one for use on lathes and another, almost identical, for use on plain or universal grinders. The variety illustrated had its own speed-increasing countershaft built on to the mounting bracket with the bearings supplied with oil from wick-feed lubricators. |

||

|

An unusual patented combination tailstock with screw and lever feeds. The dividing head fastened to the barrel was designed to hold rings that could be indexed round and bored through their edges by a drill held in the headstock chuck. Another use was to sharpen small saw blades by replacing the drill with a grinding wheel. The collet capacity was 5/8" with step chucks available to hold up to 21/2" in diameter. |

||

|

|

||

|

Lever-action tailstock with cross-feed slide. |

||

|

|

|

|

||

|

|

||

|

Hjorth Headstock Spindle. |

||

|

|

||

|

|

||

|

Home Machine Tool Archive Machine-tools Sale & Wanted Hjorth Precision Lathes - USA High-quality reprints of the comprehensive Hjorth brochures are available |