|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

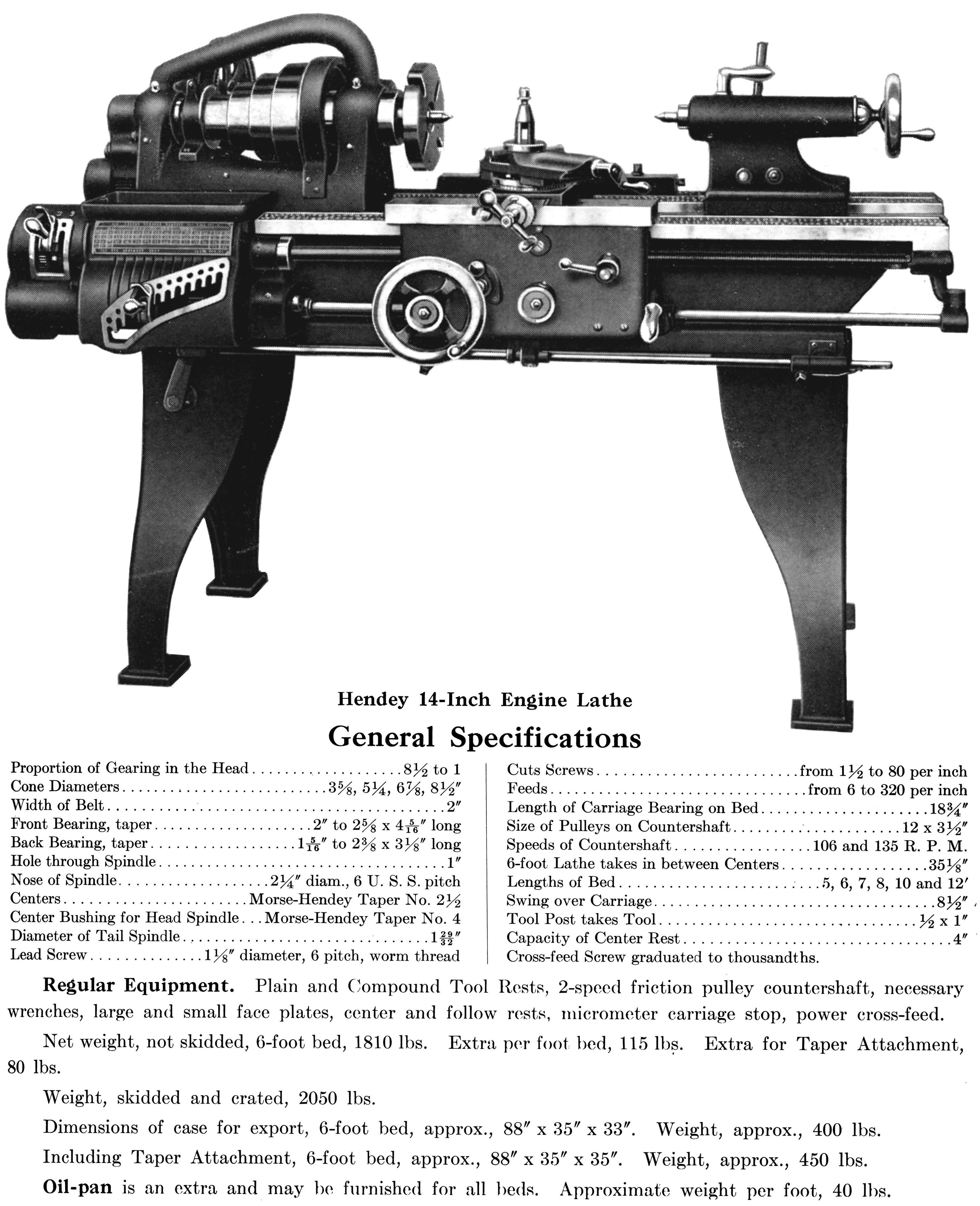

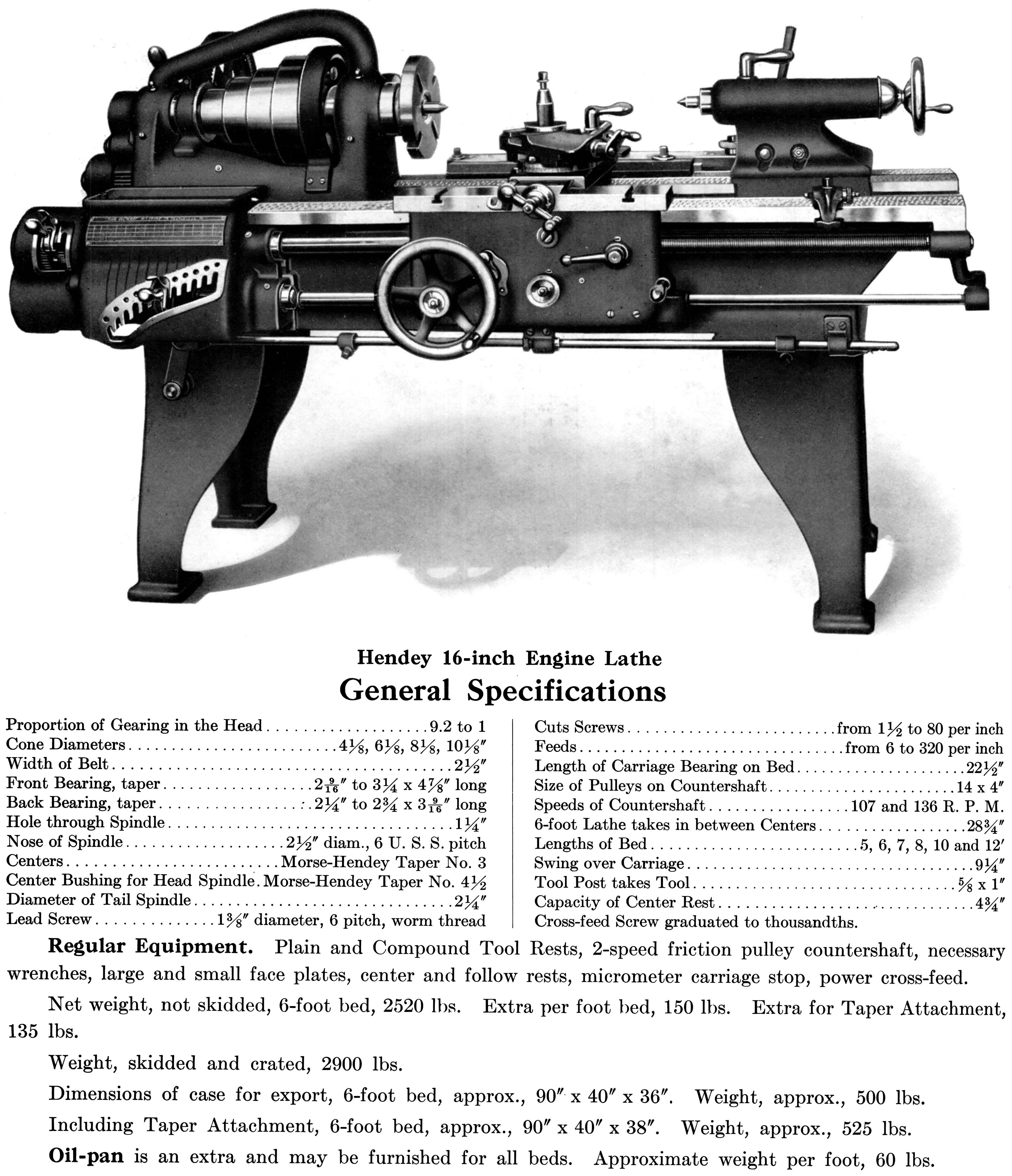

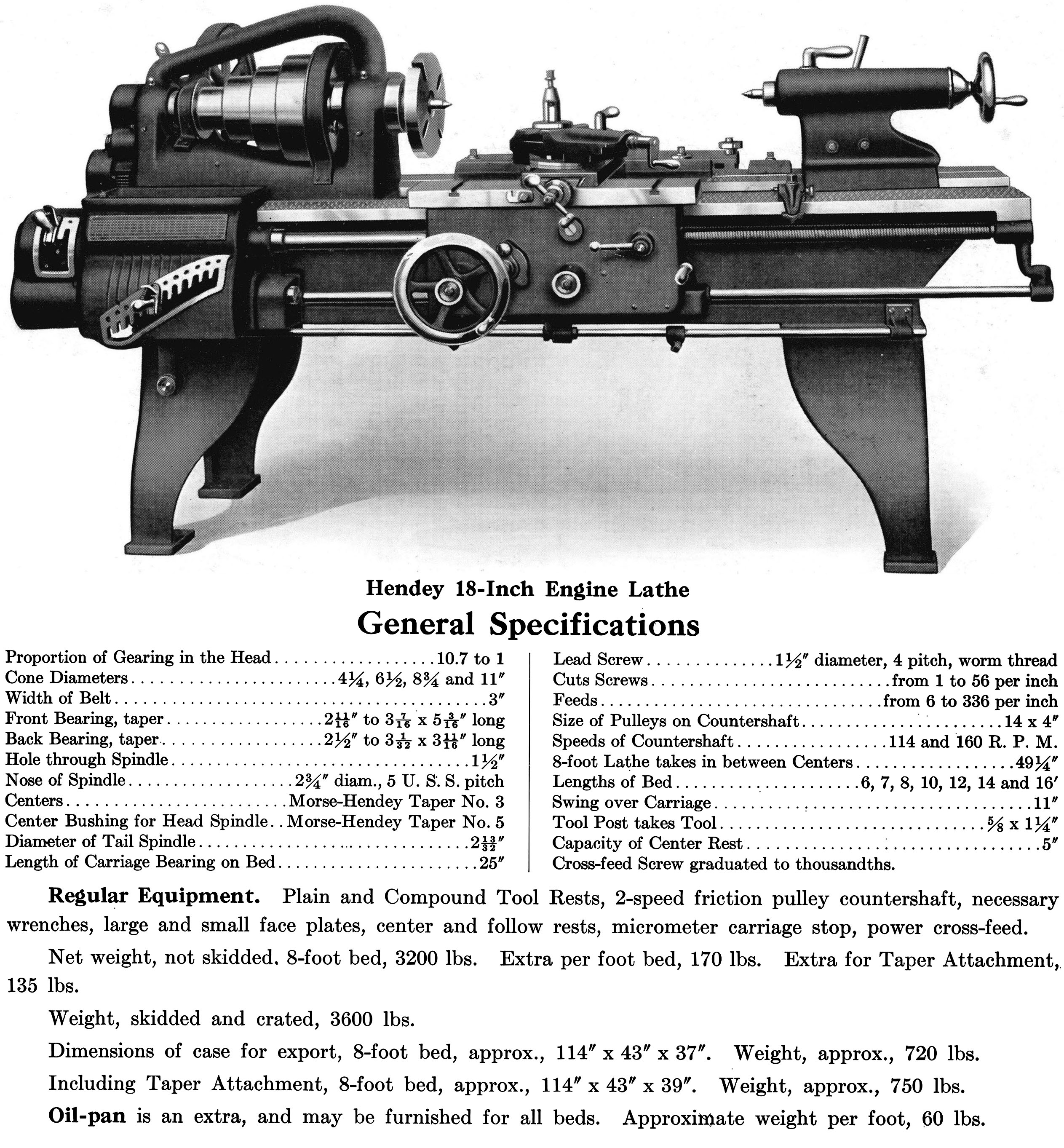

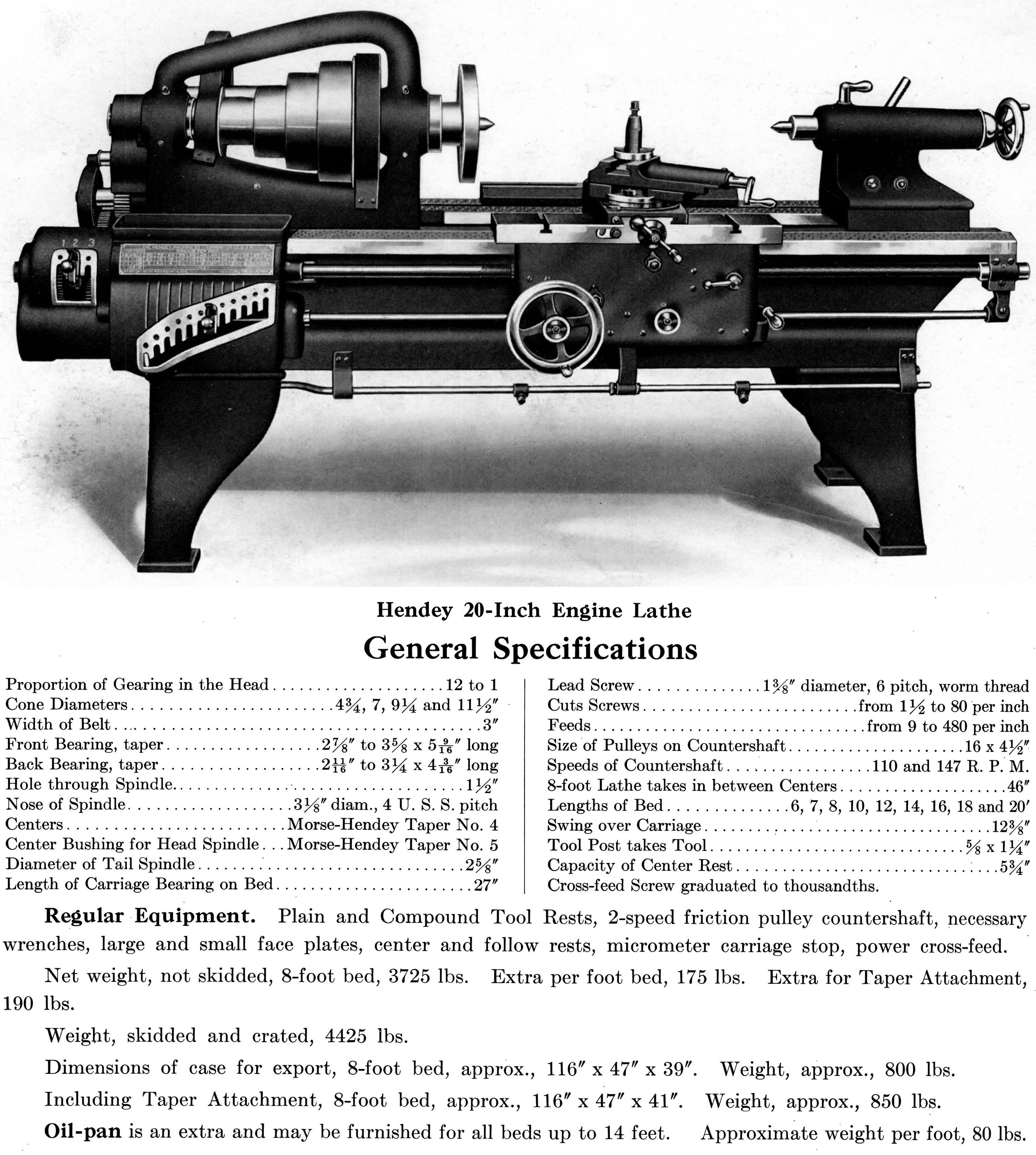

Hendey Lathes 1920s Catalog

Continued on Page 2, Page 3, Page 4

Hendey Machine Tools Home Page Hendey Factory Tour

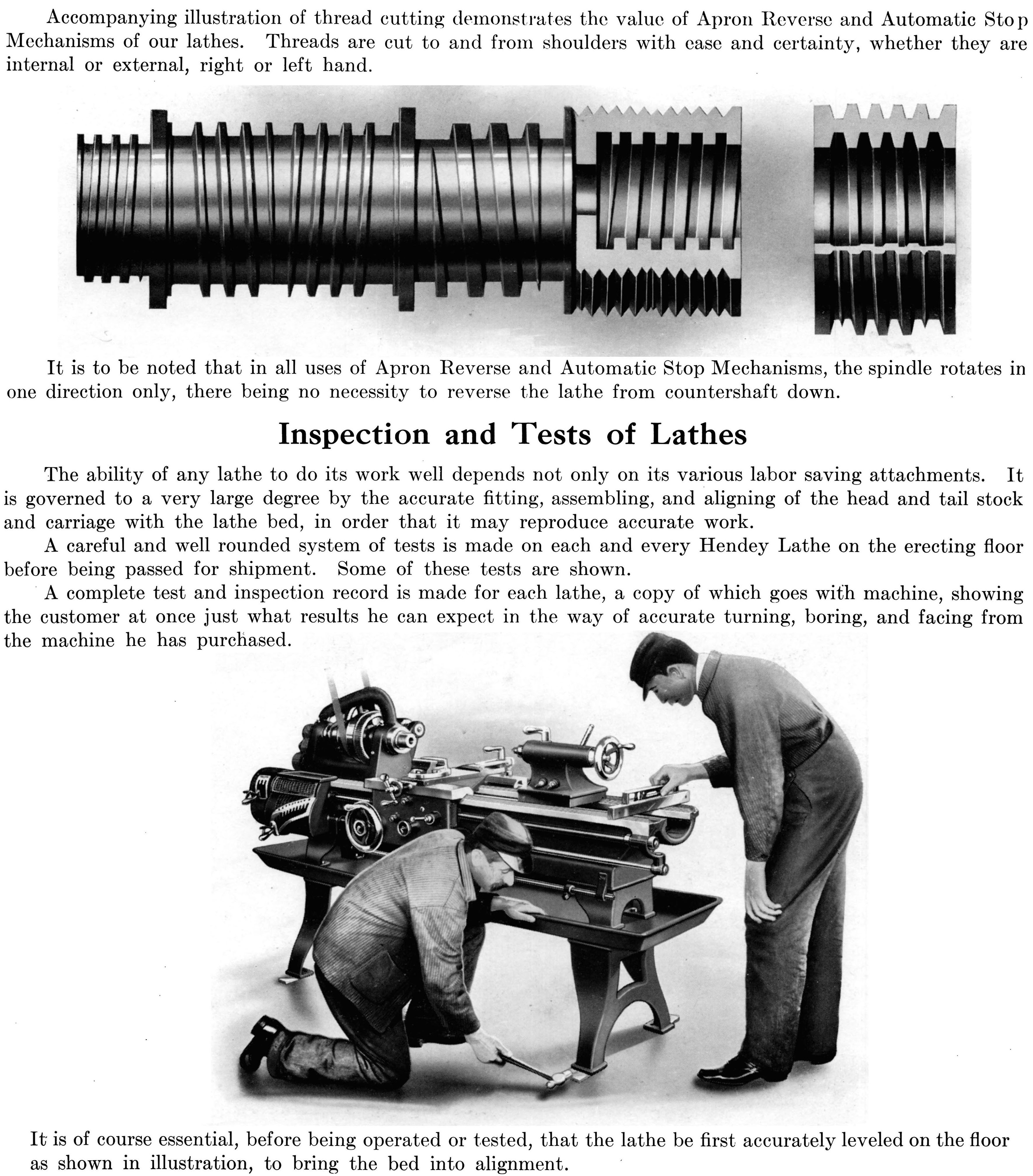

Hendey lathes had a considerable reputation and were regarded as one of the very best-made lathes it was possible to buy. The company were also in the forefront of development, their lathes always up-to-date in design and execution>

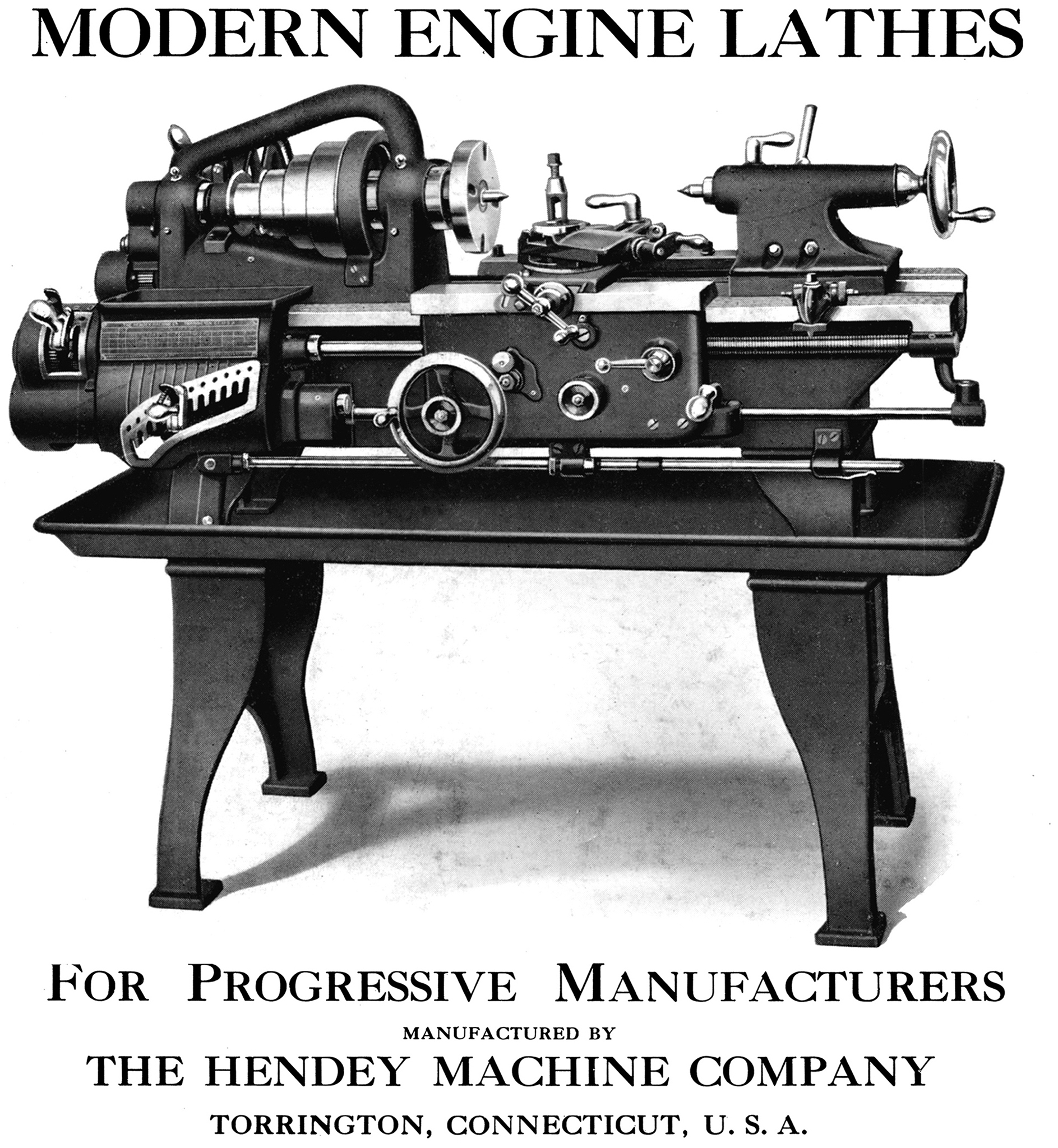

The 1920s saw a continuation of the gradual revolution in the way that lathes were offered. While the basic mechanical layout remained the same, more and more machines were specified with all-geared headstocks replacing "cone-head" open flat belt drive. In this respect, the Hendey catalog below shows this process in some detail with both "cone head" and "geared" lathes listed - the latter with either a wide flat pulley to take drive from existing overhead line shafting, or an electric motor carried on the headstock. The latter, of course, met with some initial resistance - for why spend a considerable extra sum on a motor when a complete drive system was already installed in one's factory? However, those industrialists looking to the future realised that, like one of the pioneers of the system, the American Mr Baldwin, line shafting had problems. If only a few machines were in use, or even just one, there was no need to run a huge steam engine or giant electric motor; it limited where machines could be placed; it was noisy and needed constant lubrication and maintenance; belts, clips and bearings needed constant replacement; oil dripped onto the machines and floor below and the flapping belts were not only unsafe but inefficient. A flat belt could never provided the metal-removal ability of an all-geared machine. Stripping out the installation opened the factory floor to more natural light and the chance to move machines around to provide the most efficient way for a production run to be completed. Switch-controlled automatic and manual safety controls could be fitted to guard the machine, the operator and the workpieces and, as a further advantage, small individual motors could be applied to separate parts of a machine to automate or power what had previously been manual operations.

However, such conversions were expensive, and it took some time for the whole industry to convert - though in the years leading up to World War 1 they did become increasing popular. By the 1920s, individual machine tools were commonly supplied with their own motors and by the end of that decade, according to published sources, some 90 percent were so fitted. Even so, many makers' catalogues into the mid 1940s still listed machines for drive by line shafting - and the writer, as a little boy. clearly remembers a factory in Sheffield were the system survived into the early 1950s.

Initially there was much messing about with motor installations - as with the Hendey lathes shown below - where motors were mounted, for example, on top of a lathe's headstock making the machine very top heavy. But, as time passed and all-geared headstocks on engine lathes became a standard feature, motors began to be positioned behind, beneath or inside machines with just short belts driving to the gearbox input pulley. At this point a new "modern age" had arrived; drop the machine off, manoeuvre it into place, plug it in - and start production.

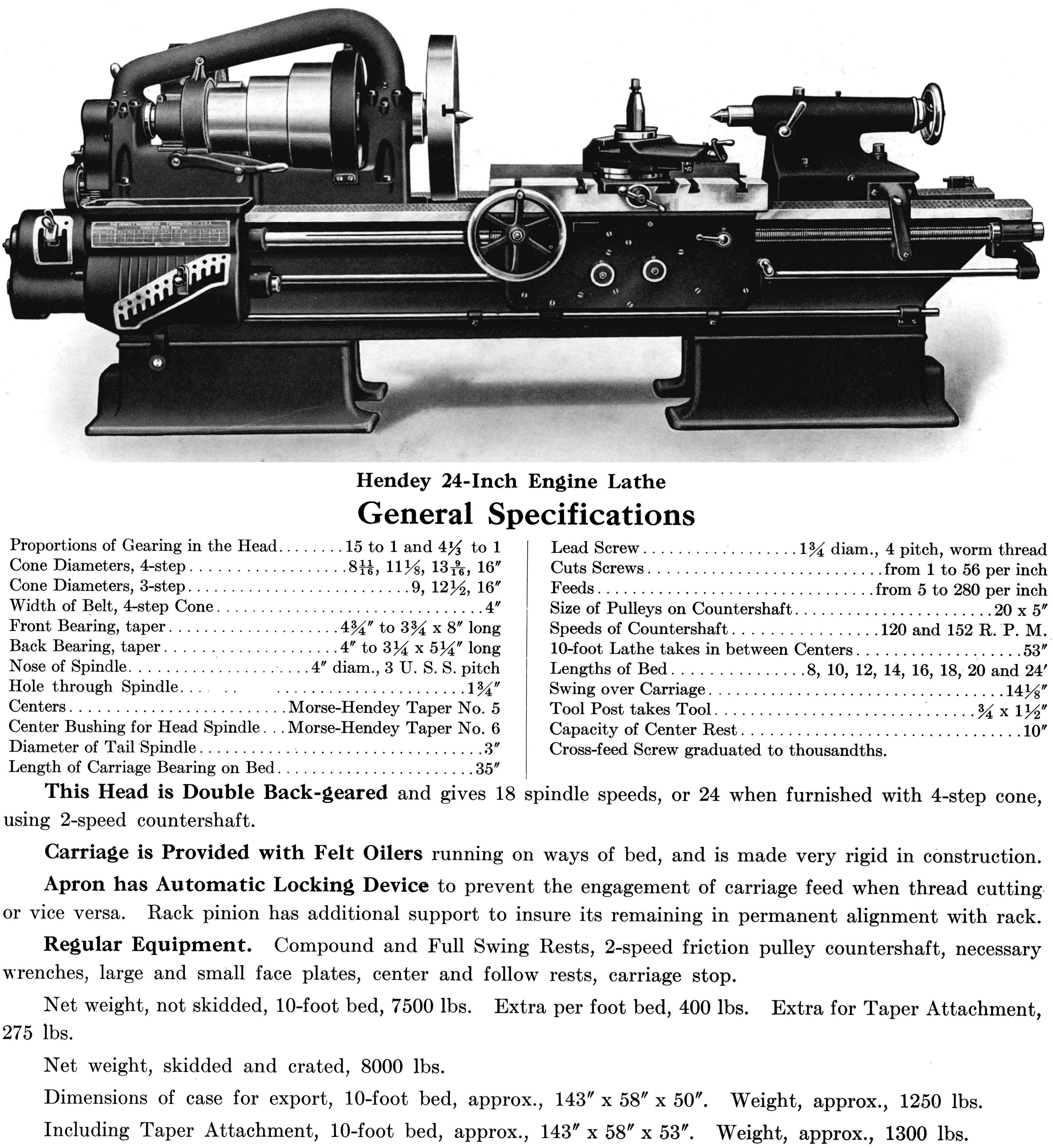

Lathes covered in the publication below include the cone head 14-inch, 16-inch, 18-inch and 24-inch; geared-head 12-inch, 14-inch, 18-inch, 20-inch, 24-inch, metric-specification lathes; lathes equipped for toolroom and production use and accessories.

|

|

|

|