Home Machine Tool Archive Machine-tools Sale & Wanted

|

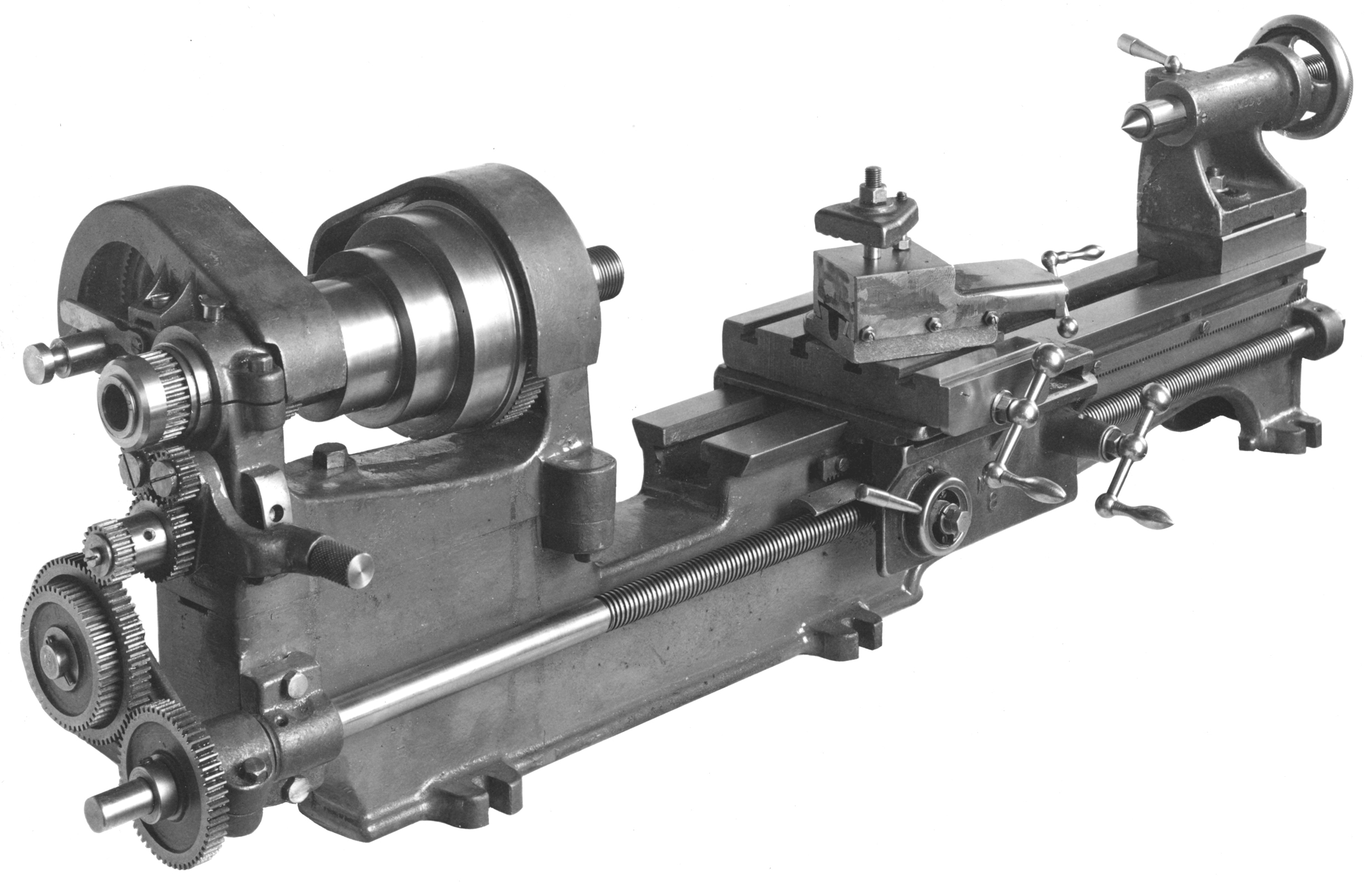

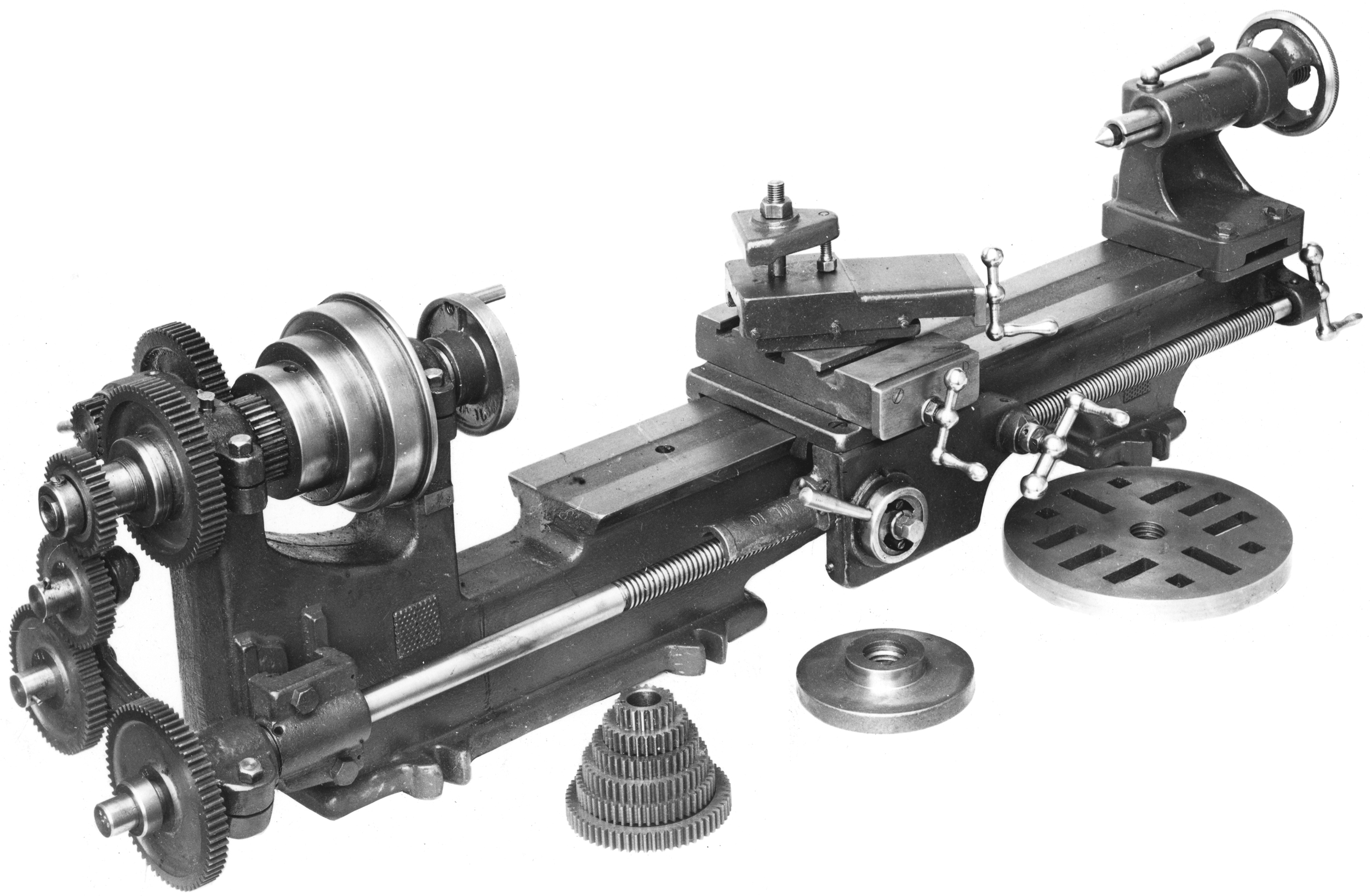

A Grayson as manufactured during the late 1920s to early 1930s. This maker's publicity photograph was discovered in the first bound volume of Archive material from the Myford Company (circa 1932/3) when, it is suspected, they were also selling ones made by Randa (badged as the B.S.W.) and also Portass, this version being sold as the "Lincoln". The lathe shown above appears to have an increased centre height, possibly to 4 inches - note the thicker base to the tailstock and the much deeper "built-up" top slide that also lacks the T-slots of the later models |

|

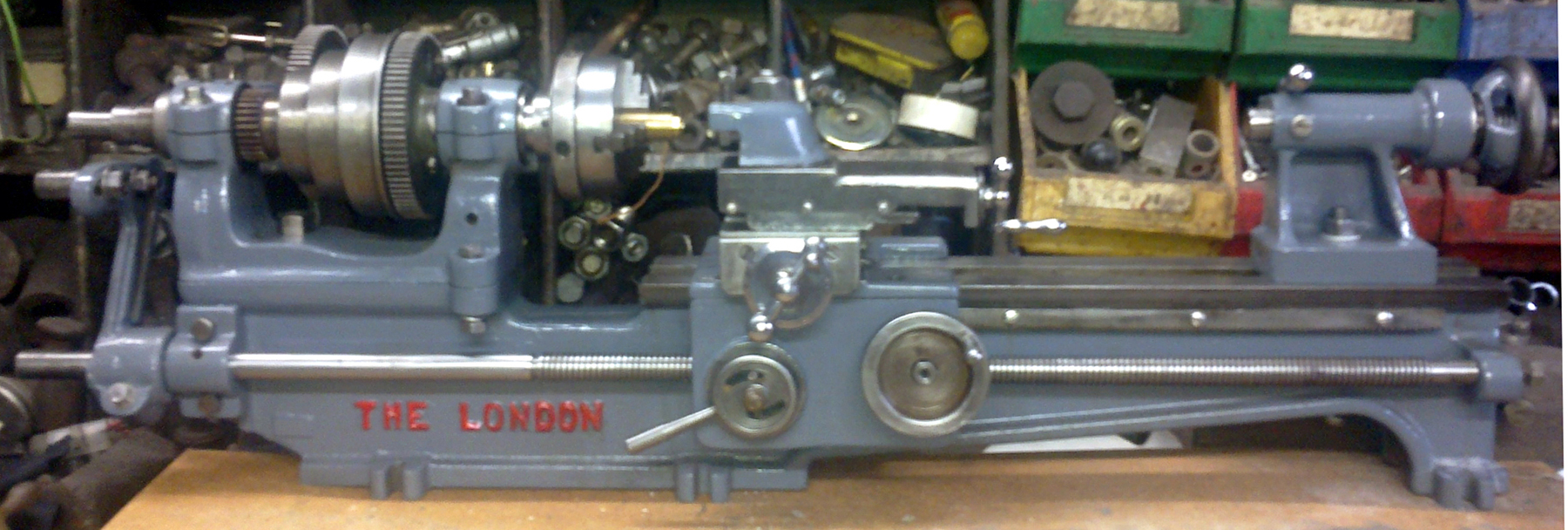

An English lathe, made from the late 1920s until the early 1950s, the Grayson was manufactured by E.Gray & Son of 18-20 Clerkenwell Road, London, E.C.1. - a company established in 1822. The firm marketed at least two models and sizes of lathe: a rather light and now rare 3-inch centre-height machine and the much more robust and common 3.5" x 18" model illustrated above. As usual with English machines of this type, there was a degree of cross-fertilisation between makers: the smaller of the two lathes being a re-badged Randa (also made in London) while the larger model (with all-V-belt drive and other small improvements) was adopted during the early 1950s by the Granville company as their Type CSL2 - and also badged as a Warwick for sale by the Victa Company and as the "London" for an unknown distributor. |

|

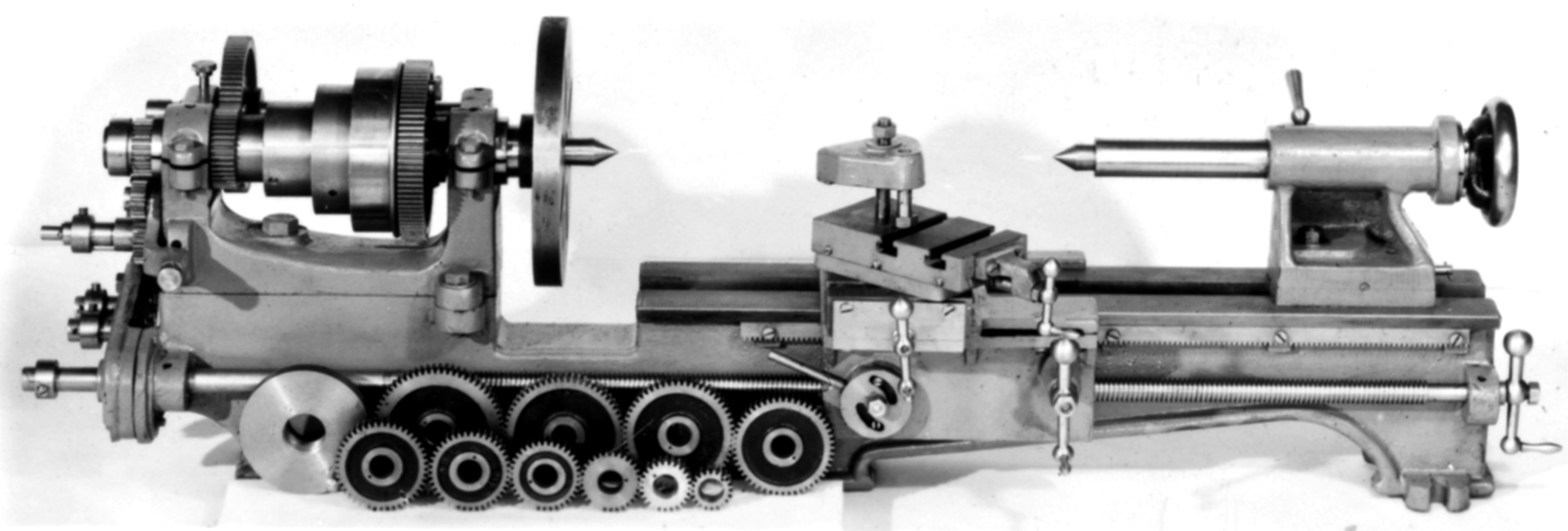

A Grayson lathe as badged during the early 1950s for the Corbett Company of Sutton-in-Ashfield, Nottinghamshire, as a "Granville" Model CSL2. This version was fitted with all-V-belt drive and other minor refinements. |

||

|

|

|

|

||

|

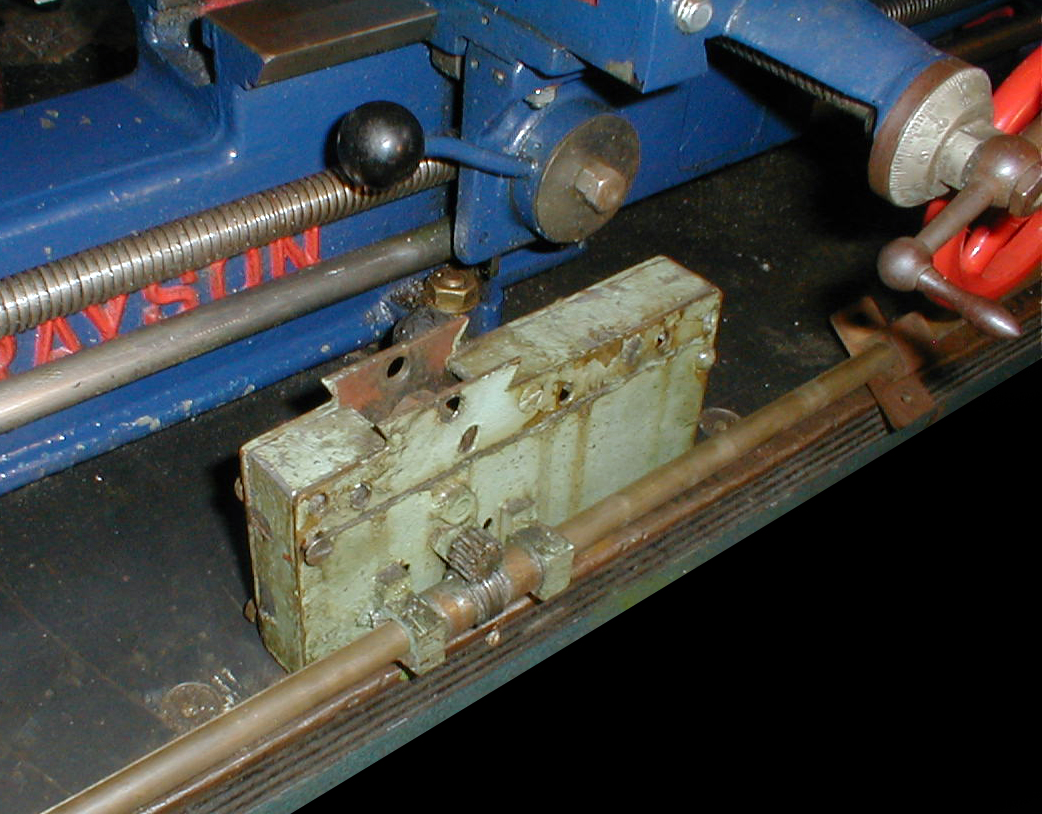

Grayson from a 1930s catalogue. The model illustrated has a direct drive from carriage handwheel to the bed-mounted rack. |

||

|

The top slide carried an end bracket arranged to allow the slide to pass over it and so increase its travel to a useful 3.5-inches. Unfortunately the rather short cross slide, with exactly the same travel, did not benefit (other than on very late machines) from the same type of fitting but had to make do instead with a flat end plate that deprived the user of those two extra inches that would have been so useful when employing a vertical milling slide. |

||

|

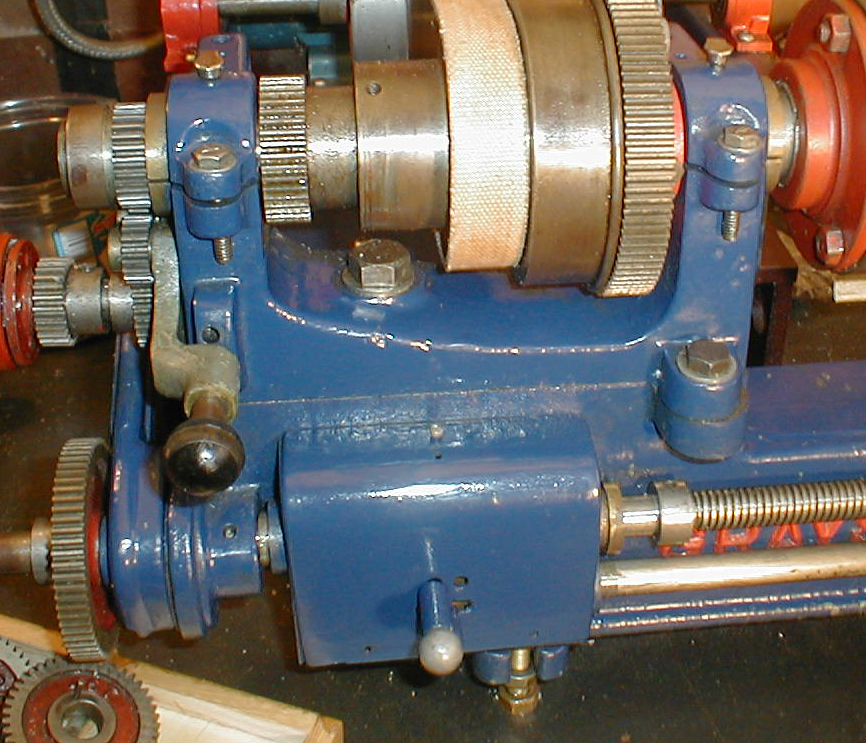

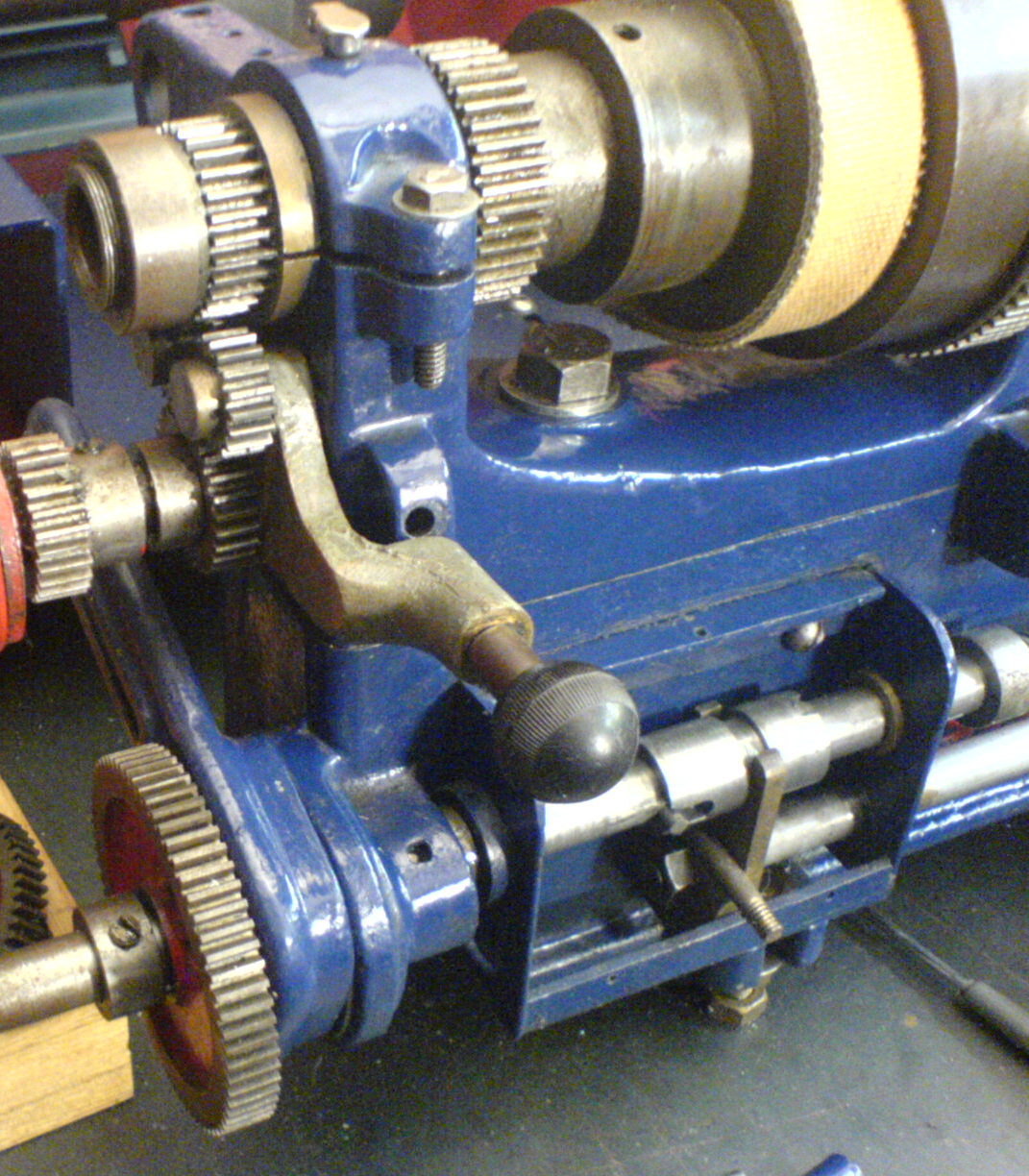

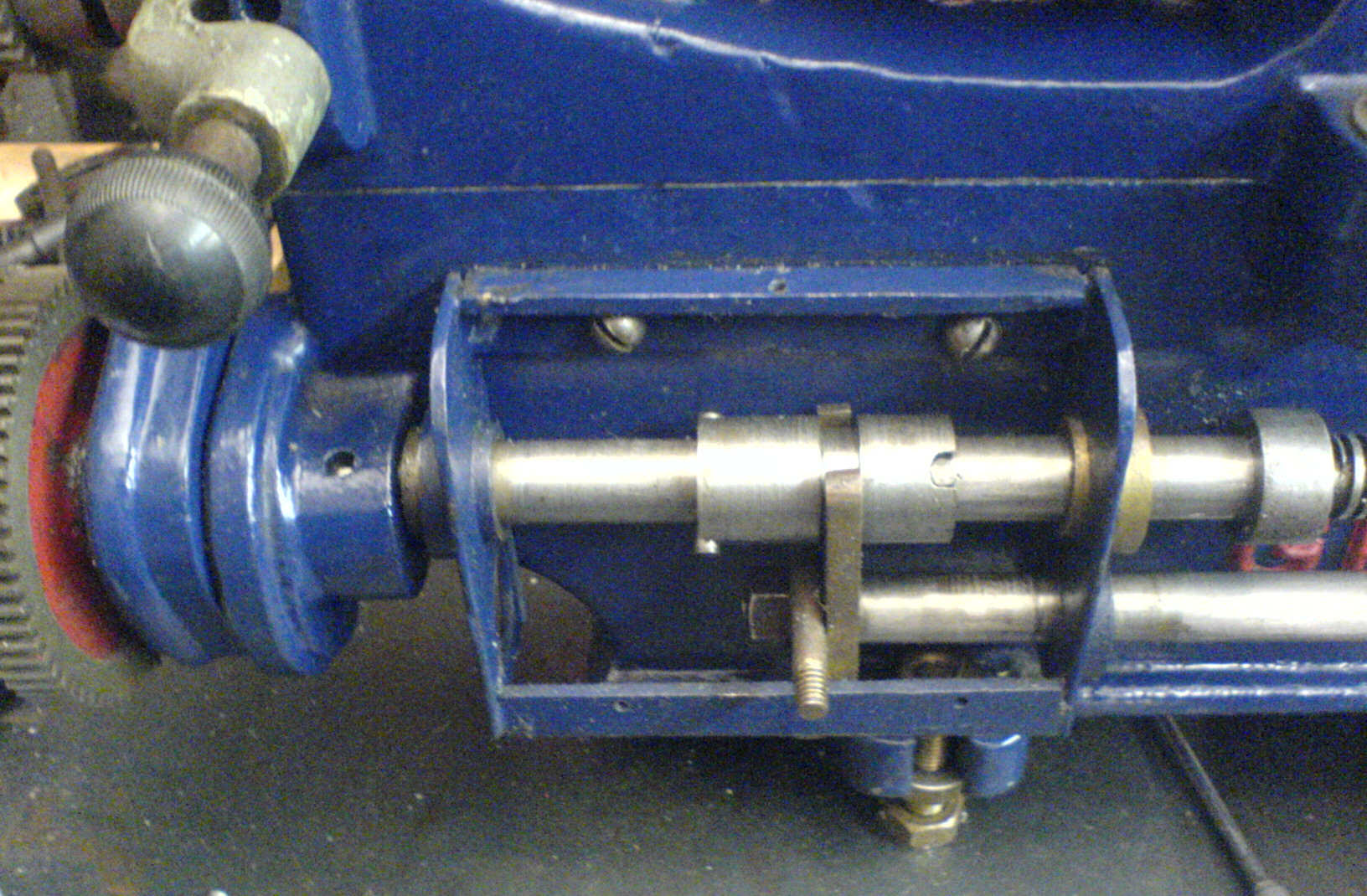

Tumble reverse was fitted from the start of production; at first the mechanism (as above) was locked into its setting by a bolt but later models were fitted with a much-quicker-to-operate spring-plunger arrangement with the operating arm being cast in either iron or bronze. Note the twin parallel slots in the changewheel banjo. |

||

|

The Randa 3-inch badged as a Grayson. This model is the long-bed Type B fitted with the less expensive single-sided leadscrew clasp nut engaged by a snap-in-and-out lever |

||

|

A works publicity photograph of the Randa Type B as sold by Grayson and also, in the early 1930s, by Myford badged as the B.S.W. This version of the lathe has double clasp nuts to the leadscrew opened and closed by a lever-operated snail cam. Constructed as cheaply as possible, and making an interesting comparison with its larger, far better-engineered brother, the smaller of the two Grayson lathes was just a re-badged Randa lathe. It was available in both short and long-bed versions which offered 12.5 and 20 inches between centres respectively; the shorter lathe had a "cantilever" bed, with the four fastening bolts at the headstock end, whilst the long-bed model had an additional foot cast under its tailstock end. |

|

|

|

"Foot motor" for mounting under the owner's own bench. In the mid 1930s this cost £2 : 9s : 0d |

||

|

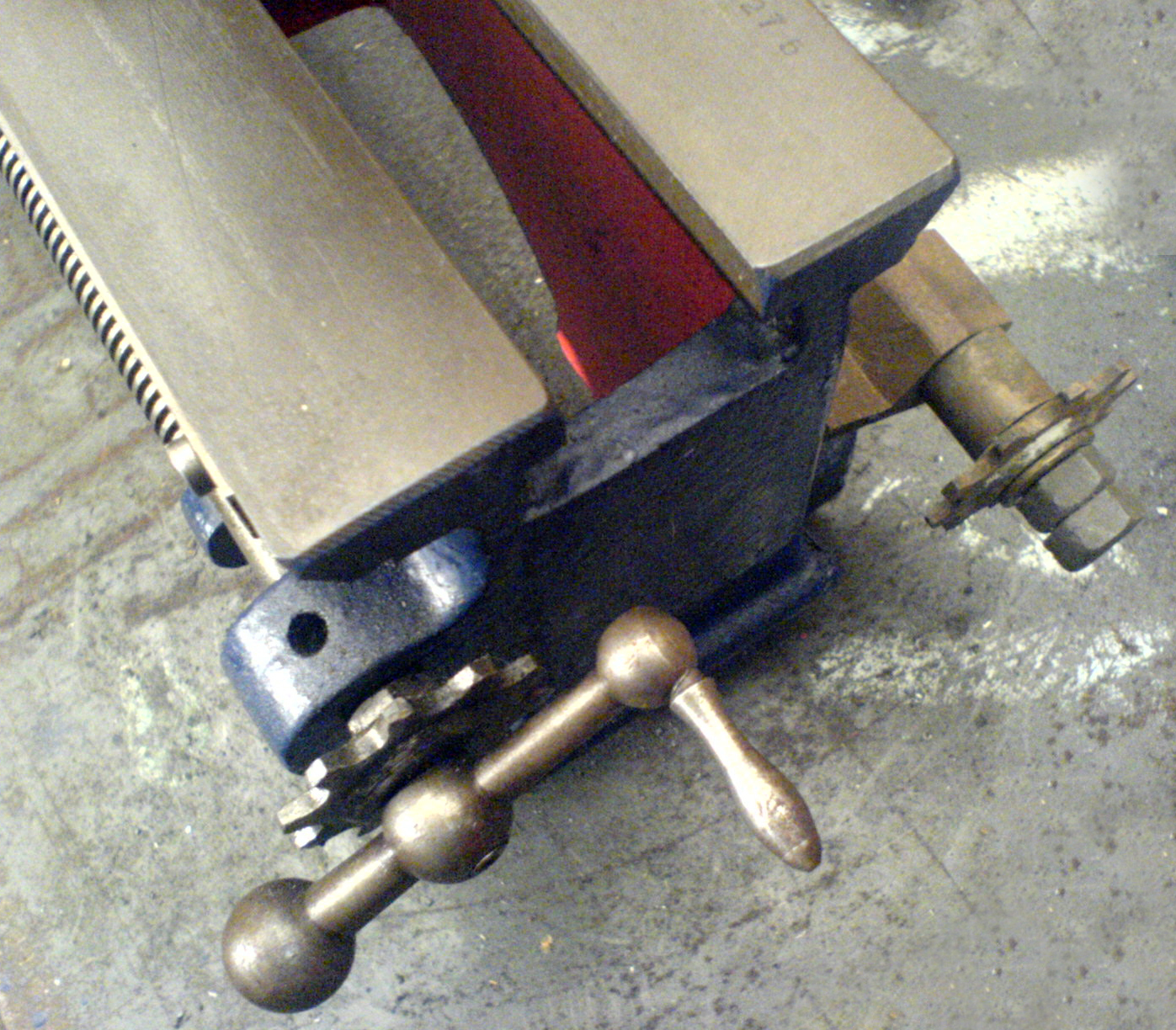

The stand, at £5 : 5s : 0d, had cast iron legs and a pressed-steel drip tray with "welded corners" and a counterbalanced flywheel. |

||

|

|

||

|

|

||

|

|

|

|

||

|

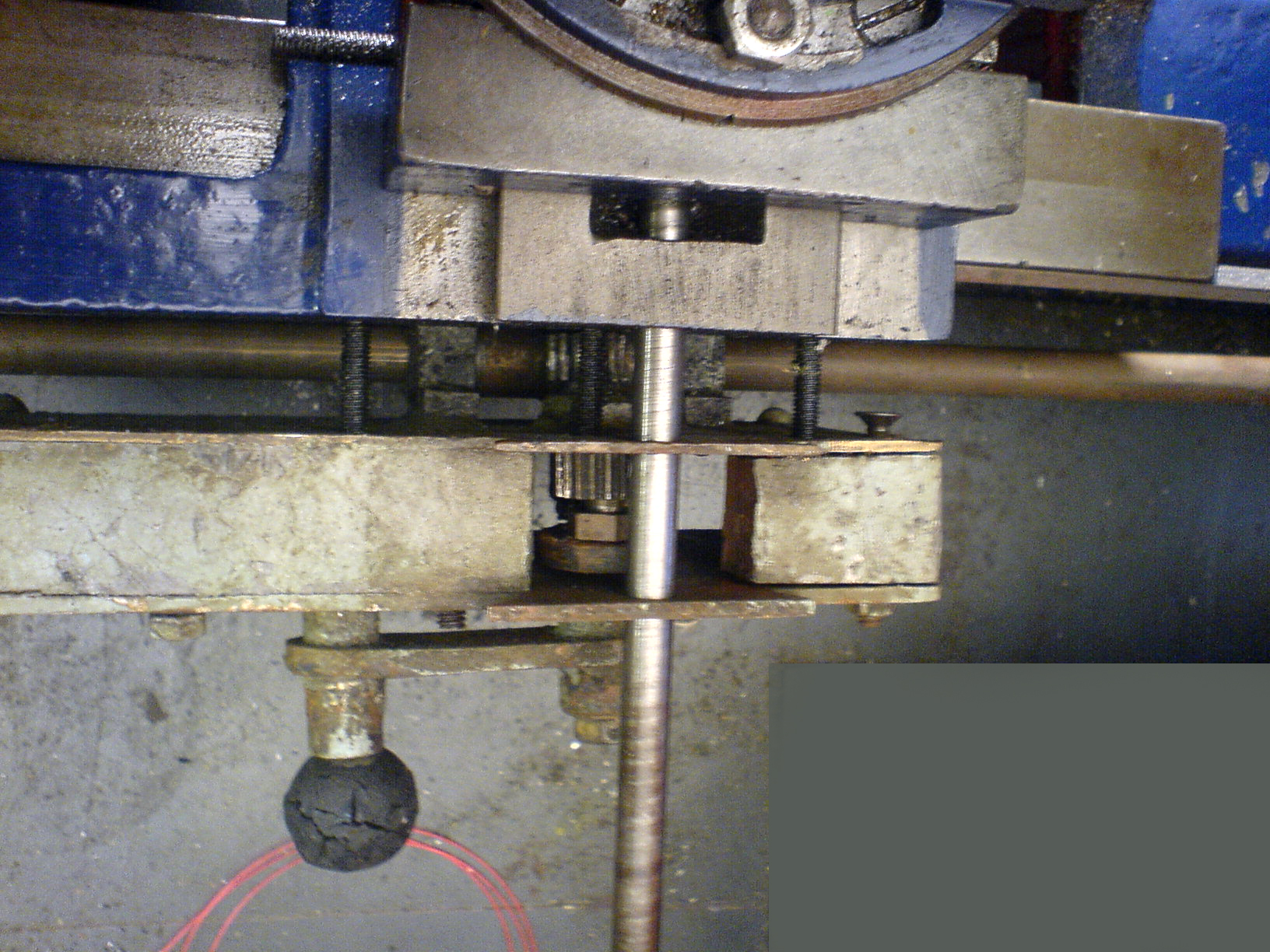

rear face and the short worm gear on the power shaft |

No longer the site of a small factory, the former corner-site home of Gray & Son at 18 Clerkenwell Road, London, is now an anonymous block of shops and apartments. However, the area, once heavily involved in watch and clock making, is still associated with the trade.

Gray & Son London

Home Machine Tool Archive Machine-tools Sale & Wanted