Based in High Holborn, London, England George Adams (sometimes calling themselves "The Pittler Company") were machine-tool dealers, manufacturers and assemblers who also commissioned various makers, in the UK and Europe, to make machine on their behalf - with some being copies, not originals, of existing designs by Lorch, G.Boley, Wolf Jahn and Portass. The company sold a very wide variety of lathes (and associated tooling) and were best known for their small machines aimed at watch, clock and instrument makers. However, Adams had strong connections with Germany and was, for many years, the UK representative for the Pittler Company and also sold larger lathes almost certainly manufactured by Oscar Ehrlich - a well known and long-established lathe maker with premises in Chemnitz. One highly unusual George Adams lathe was a round-bed model, first offered in 1902 after he had parted company with Pittler. Based on Pittler lines the lathe incorporated some of that maker's features and examples are known to survive (should any reader have one, the writer would be interested to know). George Adams died in 1935, with a "closing-down" sale held during the early 1930s and the remains of the enterprise incorporated into Tyzack & Son - well known in the 1930s for their extensive mail-order tool and machinery catalogues.

A close examination of Adam's products shows that the quality was highly variable: some machines were entirely acceptable, others less so, while elements of the various designs were often, to be kind, rather unusual.

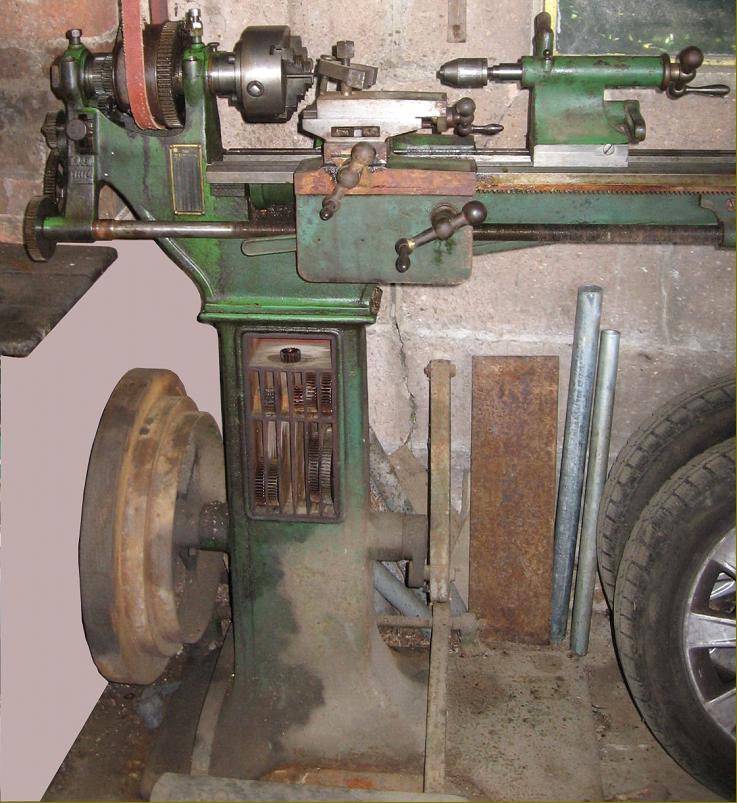

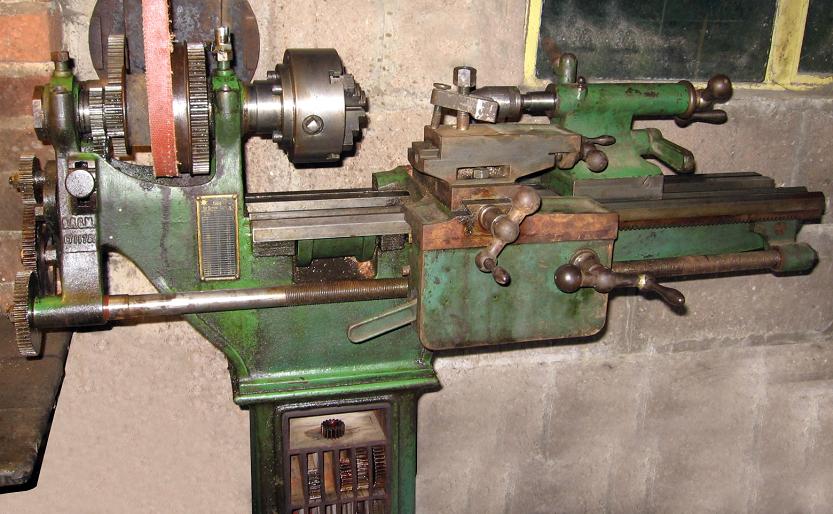

Shown immediately below is a typical larger George Adams lathe, a 4.75" x 20" pedestal mounted machine looking very much like an early Ehrlich (a well-known German exporter of machine tools to the retail trade) that shows, in the context of its era, evidence of thoughtful design and attention to detail. Also found in Europe and Australia (where is was badged as the Aster), it had a heavy, cast-iron pedestal that doubled as the support for very heavy flywheel and treadle assembly - the latter having a most unusual arrangement of crank rods to transmit the drive from foot bar to flywheel shaft. As on many lathes of that era, the pedestal also provided a handy storage compartment for the screwcutting changewheels, these being held, individually, in narrow wooden shelves.

Because the bed was of cantilever form, it should have been free from distortion when clamped to its base support. The lathe was fitted with a 16" capacity gap, a 0.9" hole through the headstock spindle, tumble reverse, backgear, split clasp nuts on the apron, a set-over tailstock with a proper barrel clamp (rather than the "split" casting then so common) - and, one final clue to the lathe's quality, an oil reservoir and dipper rod fitted to the tailstock - so there was no excuse for not lubricating (usually with poisonous white lead, not oil) the "back centre" as it was then known. The artist (or engraver) of the picture seems to have limited the top slide to a rather meagre length of travel, in reality it was rather longer than illustrated.

Should you have a George Adams lathe or other machine tool of any description, the writer would be interested to hear from you..

|

George Adams lathe, a 4.75" x 20" pedestal mounted machine probably by Ehrlich and also found in Europe and Australia - in the latter country being badged as the Aster |

|

|

|

George Adams TE6 2.25" x 8" precision lathe - a heavy-duty watch and clockmaker's lathe based on the American WW type. Typical of the many different small precision lathes "manufactured" and factored by the George Adams Company before WW2, this example is probably a German Lorch |

||

|

A Portass Mk. 5 badged as a George Adams - this example lacks the top slide |

|

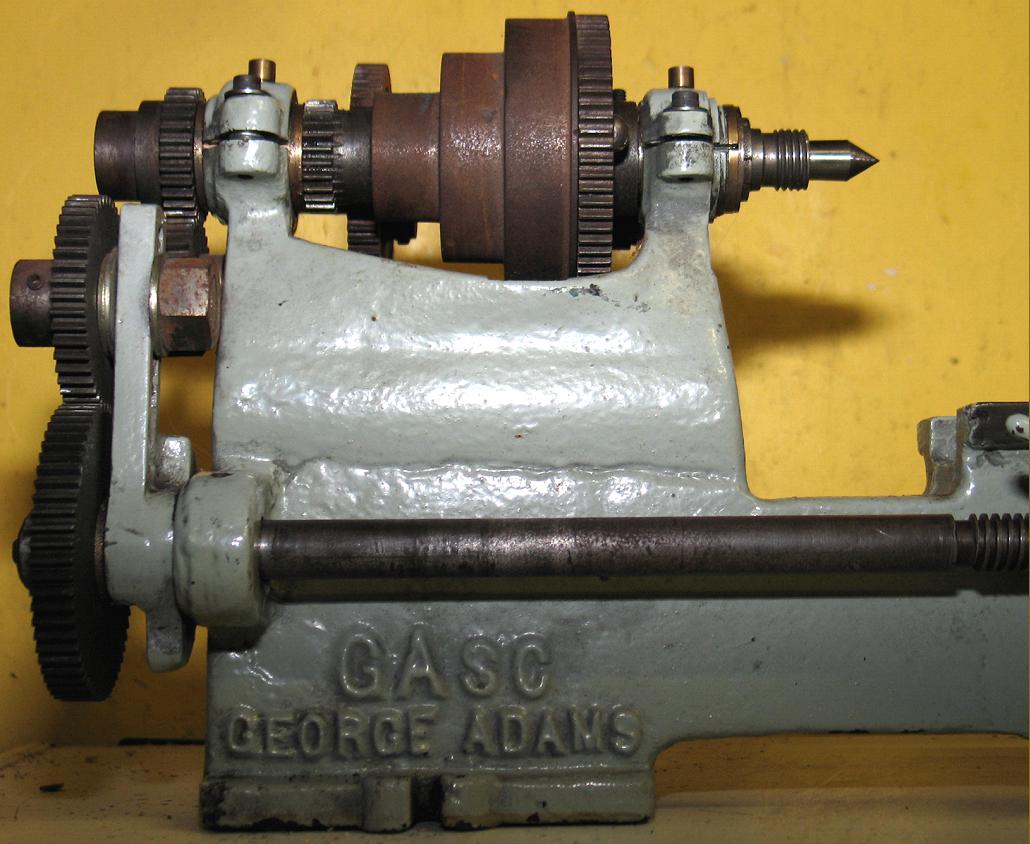

A very unusual - and early - treadle-powered lathe branded for George Adams but probably made by Ehrlich in Germany. Although the lathe was of the simple plain-turning type - and so bereft of screwcutting and even a slow-speed backgear - it was fitted with worm-and-wheel indexing gearing on the headstock spindle. |